1. Introduction

The abundance of biomass and the qualitative variability of the raw wood material are largely affected by the conditions of forest areas. The technical parameters of wood vary depending on the tree species, age, and habitat, as well as various ancillary factors. Specific types of raw material bases are significantly influenced by a set of climatic and soil factors, which are important parameters affecting both the health of trees and the quality of wood obtained from them. The quality of tree resources is also influenced by species-specific and habitat-specific factors, which indicate their usefulness, growth rate, and abundance [

1,

2].

The analysis of the influence of regionalisation on the structure of wood resources makes it possible to predict how the wood material will be used according to its expected quality. The type of forest may translate into changes in the abundance of wood. For conifers, it is the ratio of timber to low-quality secondary assortments or the share of by-products. Therefore, the type of the forest habitat and its abundance may determine the level of wood harvested for specific purposes [

3,

4].

In order to correctly define the quantity of wood biomass products, it is necessary to determine the detailed conditions of forest abundance, which translate into the abundance of the mass of forest by-products and the quality of raw wood. Regionalisation and the type of forest are classification units referring to forest areas of similar abundance. All these characteristics significantly affect the wood productivity and the ability to generate a forest biomass. The choice of the right wood harvesting method for a specific type of forest depends on the forest species composition, and it involves the eco-friendly selection of trees and shaping of their abundance. Such a selection is justified due to the potential economic values resulting from the management of wood materials with a specific volume increment and the shaping of the quality of trees in a particular habitat. The type of forest land is strictly specified and reflects the fertility of the soil on which trees grow. It determines the future species composition of the forest, its growth, and qualitative development [

5,

6]. The right selection of tree species based on the knowledge of their ecological conditions ensures better land use [

6,

7].

The variability of the habitat conditions directly translates into the tree growth structure and wood quality. The share of mature wood with dimensions adapted to the cross-sections of products has the greatest influence on its mechanical processing, because it reflects its use in defined branches of the wood industry. Although the variability of the habitat significantly affects only the volume of wood in older forests of age class V, separate habitat types are essential in all age classes of timber in trees aged over 60 years [

3,

8]. The average wood density in fresh mixed coniferous forests is about 20 kg/m

3 greater than in coniferous forests. Trees growing on post-agricultural lands tend to form denser structures with the qualitative variability of trees similar to that of forest lands [

9,

10,

11].

At the same time, due to the increasing intensity of industrial development, the share of wood by-products is growing. The increased use of biomass is influenced by the greater demand for renewable energy, which generates the demand for environment-friendly products. In many countries around the world, there is a growing demand for natural resources, including biomass, in the power industry. The results of scientific research and the recent directives of the Paris Agreement [

12] cause the need to implement radical changes in this area. These changes are implemented on the basis of new legal regulations [

13], as well as the decisions and actions taken by manufacturers, who follow the circular economy model, as they try to maximise the use of available raw materials in the production process [

14,

15]. Many wood-processing institutions and entities follow the trend of the maximised use of renewable resources [

16,

17]. The wood industry also makes the maximum use of raw materials in the production process. It also applies the solutions aimed at the complete use of the by-products as biomass. Due to the nature of wood production, waste and by-products originating from a particular enterprise can be used as biomass in this entity or in other branches of the industry [

18]. The efficient use of resources such as wood harvesting materials and remains extends the total availability of biomass in the wood industry. In practice, this means that not only forest biomass but also wood biomass are reusable by-products [

19,

20,

21]. In consequence, round wood can be used more rationally [

22,

23]. In the circular economy model, which is used in wood enterprises, a large part of the biomass is marketed (sold to other wood enterprises) or used to supply energy [

24,

25,

26]. In-house biomass management translates directly into the production of briquettes and pellets or direct combustion, which has economic and environmental effects. Therefore, it is important to determine the share of by-products with the lowest possible environmental effect at all stages of the processing, finishing, and preparation of the wooden elements. The sawmill industry has the greatest potential in this area. Elemental wood processing involves the processing of raw material into finished products, as well as by-products, which can be used to supply energy due to their considerable comminution. Sawmills need to apply the wood-processing solutions that enable the use of raw material while minimising the generation of by-products in the form of processed biomass. The aim of these activities is to continuously optimise the production process and flexibly adapt to the current needs of the market economy. In most cases, enterprises only provide biomass for the production of boards, as well as bio-fuels or thermal energy for technological purposes (drying timber, heating production rooms, etc.). When the enterprise has satisfied its demand for energy, it can sell the surplus of biomass to local recipients. These solutions enable the local community to directly use the heat or energy generated from renewable fuels, and thus, the negative influence on the environment is reduced. Biomass produced in sawmills is becoming an increasingly important source of heat and electricity in European countries. The widespread implementation of the use of biomass in sawmills improves the socioeconomic and environmental aspects [

27,

28].

The implementation of the solutions of biomass resource regionalisation reduces the cost of transport and energy consumption. Thanks to these activities, it is possible to achieve the desired environmental indicators on a global scale. These solutions are necessary due to the increasing demand for renewable energy in the EU member states. It is one of the requirements included in the EU Climate and Energy Package 2030, which was adopted by the European Parliament. The package indicates the most important goals are to be achieved between 2021 and 2030, which include the abandonment of fossil fuels and the use of biomass to supply energy.

The contemporary energy policy of the European Union, including Poland, sets a framework for the development of the power industry based on biomass. However, due to the use of local resources, this energy sector is not developing as expected. Due to the availability of biomass, as well as the development of technology enabling its conversion into energy, it is necessary to acquire adequate knowledge in this field. In the context of legal regulations and product quality, the problems of a comprehensive approach to biomass management are a combination of the effectiveness of processes and the optimal selection of the biomass quality parameters. A comprehensive assessment of the current biomass availability and management is of key importance to the Polish power industry.

These goals clearly show the directions to be followed by the economy of Poland and the EU member states and, consequently, by production enterprises [

29]. As there is no detailed information on the material potential of biomass in Poland, nor is the issue in the form of wood biomass discussed in scientific publications, it is justified to conduct scientific research to investigate these problems. The main aim of this study was to determine the directions of harvesting woody biomass for energy purposes within the forest and wood industry in Poland. It is important to indicate the potential sources of woody biomass for both energy purposes and, alternatively, the need for further processing. The availability of woody biomass for energy purposes is of particular importance in times of an energy crisis.

2. Materials and Methods

The methodology of this study took into account the harvesting level of the selected wood biomass assortments based on data from the State Forests and the Central Statistical Office (GUS). At the same time, the potential wood processing companies, which process more valuable wood raw material, were indicated as suppliers of biomass as a by-product. The study of the influence of regionalisation on the level of forest biomass generated was based on data obtained from the areas managed by the General Directorate of State Forests in Poland. As of 1 January 2020, the area of forests was 9,258,800 ha, including 9,462,900 ha of forest land (Report on the State of Forests in Poland 2020 [

29]). This study was conducted on an area with various forms of nature conservation, including national parks and Natura 2000 sites.

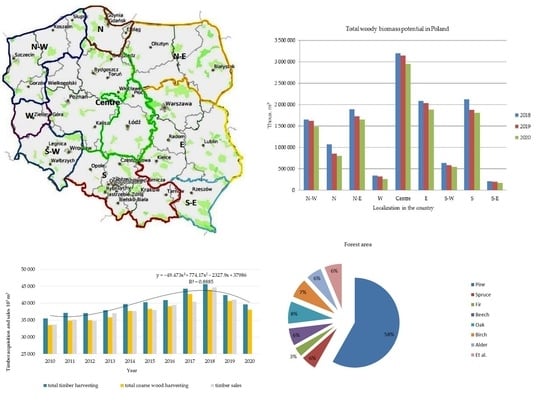

Figure 1 shows the percentage of individual types of the forest habitat.

The dominant species in the research area was Scots pine (

Pinus sylvestris L.)—60.9% of the raw material resources. Other tree species were: Norway spruce—5.8%, fir—4.4%, common beech—6.8%, common oak—6.6%, alder—5.3%, birch—4.7%, and others. The percentage of the area occupied by individual tree species was proportional to the volume share, i.e., Scots pine—58.0%, Norway spruce—5.7%, common oak—7.9%, common beech—6.1%, black alder—5.6%, and warty birch—7.1%. The total share of other species amounted to 1.0% of the total forest area under study (Statistical Yearbooks of Forestry 2021 [

30]).

In the habitat structure of forests, deciduous forest habitats slightly predominate, occurring in 50.2% of the forest area; coniferous habitats occupy 49.8%. In both groups, there are also upland habitats, covering a total of 6.7% of the forest area, and mountain habitats, occurring on 8.5% of the area. Coniferous species predominate in 68.4% of Poland’s forest area (

Figure 2). They are also the main source of forest biomass. The share and form of biomass materials depends on the maturity and quality of the raw wood harvested.

In 2020, 39,674,000 m

3 of round wood was harvested in Poland (

Table 1), including a net large round wood volume of 38,069,000 m

3 (2,569,000 m

3 less than in 2019) and a small round wood volume of 1,605,000 m

3. The volume of large round wood harvested in private forests amounted to 1,032,000 m

3 (275,000 m

3 less than in 2019), whereas, in national parks, it was 155,000 m

3. The largest round wood was harvested in the following voivodeships: West Pomeranian Voivodeship (4,350,000 m

3), Warmian-Masurian Voivodeship (3,619,000 m

3), and Greater Poland Voivodeship (3,334,000 m

3). The smallest round wood was harvested in the following voivodeships: Lesser Poland Voivodeship (1,180,000 m

3), Opole Voivodeship (1,323,000 m

3), Świętokrzyskie Voivodeship (1,337,000 m

3), and Łódź Voivodeship (1,353,000 m

3).

Sawmills, which are the first link in the processing of round wood in Poland (

Figure 3), were selected for the analysis of the potential of post-production biomass. The sawmills were classified according to the amount of wood biomass they produced. The types and amount of by-products generated by the sawmills were specified, and the trends in these groups of wood-processing enterprises were indicated. The production in these enterprises was analysed in terms of the flow of material and the management of wood by-products. The researchers indicated the possibilities of the implementation of these solutions in other enterprises of the wood industry.

The manner in which raw wood moves depends on the efficient operation of the logistic chain and the effective function of the organisational subsystems [

33,

34,

35]. The displacements shown in

Figure 3 refer to the generation of post-industrial wood biomass.

The technological solutions introduced by sawmill companies result in a specific wood-processing capacity (

Table 1). At the same time, sawmill production is optimised, whereas the consumption of electricity and heat is reduced [

13].

The amount of by-products generated by the sawmill industry in Poland is important because of the growing significance of biomass management for the national economy. The sawmill industry is a dominant branch generating wood biomass (about 75% of the total amount of biomass produced) for further processing, as well as for energy-supplying purposes [

36,

37]. The amount of generated by-products depends on the wood-processing directions and their advancement in the technological process.

The starting point for the analysis of the biomass generation potential is a comparison of the amount of wood harvested. The full comparison covers the period from 2010 to 2020 (

Figure 4).

Between 2010 and 2018, the amount of wood harvested tended to increase (

Figure 4), which resulted in an increasing share of wood biomass in this period. The amount of wood harvested between 2017 and 2019 was affected by the damage ‘the hurricane of the century’ caused to large forest areas in 2017. An additional volume of 8.5 million m

3 of wood was harvested (Report on the State of Forests 2019 [

38]). As results from the data in

Figure 4, the largest amount of wood was harvested in Poland in 2018. After that year, the amount of wood harvested tended to decrease gradually. This period can be assumed as the starting point for the verification of wood biomass resources. The directions of wood biomass production largely depend on the regionalisation in Poland. As the supply of biomass is limited by the costs of transport, it is economically justified to process a biomass as close to the place of its acquisition as possible. Regionalisation based on the division of Poland according to geographical directions was adopted in the research methodology. The administrative division of the Regional Directorate of State Forests was taken into account (

Figure 5).

The following values were determined in the research: the amount of wood harvested and processed as a source of biomass in Poland, including the amount of large timber; the amount of wood by-products produced in primary wood-processing plants and their intended use; the approximate demand of sawmills and their energy biomass production capacity; and the potential capacity of sawmills to supply excess biomass for energy or to enterprises manufacturing wood-based products.

3. Results

In order to assess the possibilities of obtaining wood biomass from forest areas, the amount of wood assortments intended for chipping or processing into biofuels was determined. The data of the Regional Directorates of State Forests in Poland were taken into account.

Between 2018 and 2020, the total volume of wood biomass acquired by the State Forests and private suppliers amounted to over 28 million m

3. The biomass could be industrially processed (wood quality and dimension classes M1 and S3A) or used for energy-supplying purposes (mostly the wood quality and dimension classes M2E and S4 and fatwood). In 2019 and 2020, the amount of wood harvested for chipping decreased (

Table 2). The resources of this biomass decreased from 4,570,000 m

3 in 2018 to 4,022,000 m

3 in 2020.

High-quality wood is referred to as a ‘small pole’. It is a full-value raw material with high-utility values for industrial purposes. As shown in

Table 2, the amount of M1 assortment obtained in individual years decreased gradually. In 2019, it was 12.3% lower than in 2018, whereas, in 2020, it was 36.7% lower than in 2019. Due to the lack of acceptable biological degradation, this assortment is also materials of high energetic value. The highest shares of wood biomass were noted in the following regions: Central Poland (30–36%), the west—W (38%; it dropped to 27% in 2020), and northwest N-W (24–27%)—

Figure 6.

Class S3A wood (

Figure 7), which can be mainly industrially processed and can also be the basis for energy biomass, has a similar role. The total amount of this wood harvested annually does not exceed 83,000 m

3. It is not dominant in the forest biomass market. The distribution of the amount of the S3A biomass harvested from individual regions in Poland is similar to that of the M1 biomass.

Class M2E wood (wood remains left after machine processing) constitutes a significant group of forest biomass intended for chipping or to be used for energy-supplying purposes (

Figure 8). Between 2018 and 2020, the share of this wood on the market increased by almost 90%—from 427,000 m

3 in 2018 to 808,000 m

3 in 2020. This means that the use of this wood for biomass processing increased. Low-quality materials left after machine processing are better used. The most M2E wood was harvested in Central Poland (42–45%) and in the north (N-E 20–26%, N-W 11–14%).

S4 firewood is the most important group of wood resources. In 2019, more than 3,740,000 m

3 was harvested, whereas, in 2020, this volume dropped to 2,996,000 m

3. The largest amounts were harvested in Central Poland (about 23%), whereas the share of the west (W) and southeast (S-E) was minimal, i.e., about 2 to 3% (

Figure 9). The resources of this firewood amounted to over 74% of the biomass produced in Poland, including energy biomass. During the period under analysis, the potential of these resources was gradually decreased due to the decreasing amount of post-disaster wood harvested.

Stump wood is the last item on the list of energy biomass harvested (

Figure 10). According to the Polish State Forests Holding, in 2020, about 4400 m

3 of stump wood was harvested in Poland. There is a significant but unused potential of logging areas. It is estimated that stump wood in the form of unused biomass for further processing may constitute about 6% of the annual amount of timber harvested (out of the total volume of about 40 million m

3) [

38,

39]. Such a low amount is harvested, because it is necessary to maintain the biological balance of the soil. At the same time, there are no confirmed data on the amount of stump wood harvested in private areas and the areas managed by other public entities. From a climatic point of view, the production of bioenergy from fatwood is much better than the production of non-renewable energy. Fatwood is a valuable biomass raw material, but its harvesting has a negative influence on the environment. Stump woods left to decay are food for numerous wildlife species. Thus, the overharvesting of fatwoods may pose a risk to their populations. Stump woods located next to watercourses, conservation areas, diverse biogroups, etc. should be left. It is also advisable to leave stump woods that have an impact on the ground reinforcement of slopes and escarpments. Stump woods left after logging form a significant part of the dead wood in forests [

40].

The analysis of the total resources of the wood biomass (

Table 3) that could be used for energy purposes revealed a significant potential of Central Poland, where this amount exceeded 1,128,000 m

3 of biomass in 2020 (28% of the resources). The lowest biomass resources were found in the southeast of Poland, i.e., only 90,000 m

3 in 2019 and 70,000 m

3 in 2020.

Sawmill by-products are another group of wood biomass with potential energy significance.

In order to assess the possibilities of using by-products generated at the initial stage of wood processing, the amount of wood processed in sawmills in Poland was determined (

Table 4). It ranged from 21 to 24 million m

3. This value indicates the level of wood processing and translates into a share of the main materials released on the market as products and processed biomass (

Table 5).

Between 2019 and 2020, the share of wood biomass decreased from 8,661,000 m

3 to 7,554,000 m

3, which resulted from the limitation of the amount of wood processed in sawmills. Sawmills processing more than 10,000 m

3 of wood a year generate the most biomass and have the greatest production potential. There is a significant share of wood biomass generated due to high-efficiency production technologies. The average share of by-products (sawdust and woodchips) is about 40%. Sawmills processing smaller amounts of wood decide to increase their outlays to maximise the volume of round wood processed at the expense of higher labour input [

13]. The total balance of sawmill biomass is twice as high as the amount of biomass generated directly in forests.

The analysis of the locations of sawmills in Poland shows that their processing capacity is significantly affected by the local raw material resources and distribution channels [

41]. The most sawmill biomass (

Table 6) is generated in Central Poland (24%), but the biomass resources generated by sawmills in the northeast and northwest (about 13%) are also very important. Large amounts of wood are processed in Eastern Poland (17%) due to the availability of the raw material. Low industrialisation in South-eastern Poland significantly affects the amount of sawmill biomass generated in this region, where its share is the lowest, i.e., about 1%. The share of sawmill biomass generated in the narrow zone in the west of Poland is also low. Despite the high afforestation in that area, there are not many sawmills there. By contrast, for logistic reasons, there are large numbers of sawmills in the north and south of Poland.

The summary of wood biomass resources in Poland (

Figure 11) includes both the forest biomass generated in the form of potential assortments for energy purposes (groups M1, M2E, S3A, and S4), as well as the potential of sawmills, which produce about 75% of the industrial biomass. In 2020, the total amount of biomass generated amounted to 11.5 million m

3, which was a significant processing potential. However, the volume of production of this form of wood biomass decreased by about 6% (from 13.2 million m

3), which may have been caused by the rational management of lower-quality wood for mechanical processing. The most biomass is generated in Central Poland, where its volume amounted to about 3 million m

3, i.e., 25% of the biomass.

4. Discussion

Forest biomass mainly consists of wood waste generated during forest works, damaged dead wood, wood from fallen trees, and fatwood. Renewable energy is mostly produced from the raw material, which is usually useless for the wood industry. At the same time, it is the wood industry that provides a significant amount of biomass, which can be used both for energy purposes and to complement the stock of raw materials for the manufacturing of wood products.

Between 2018 and 2020, the average volume of wood assortments harvested annually in Polish forests for comminution and used indirectly for the production of wood materials and energy amounted to 12 million m3, which was about 25% of the total volume of wood harvested annually. About 8 million m3 of wood assortments used for the production of wood materials and energy biomass was annually produced in Polish sawmills, which was about 20% of the total production of this raw material.

The potential of wood biomass is all the more important, because, since 2013, more than 50% of energy wood biomass has been imported to Poland from Belarus. In 2020, the import of this biomass amounted to about 79.6%. The raw material came mainly from Belarus. Additionally, about 8.3% of energy wood was imported from the Ukraine and Russia. Between 2010 and 2020, the import of wood materials from these countries for energy-supplying purposes increased by 1255%. However, recently, this trend stopped due to geopolitical changes. As a result, the availability of biofuels has been significantly reduced while there is a strong pressure on the abandonment of fossil fuels.

The export of wood biomass from Poland increased from 0.51 Mt in 2010 to 1.14 Mt in 2020. Almost all of the wood energy biomass in the form of pellets and briquettes (99%) is exported from Poland to Western Europe (about 50% to Germany). The shortage of biomass combined with the high demand causes a price rise risk and partial market insecurity. As a result, the available wood biomass resources that have not been used so far may be used, including the potential of fatwood [

42,

43,

44].

There may be a preference for the policy of plantation. It will involve intensification of the clearing cycle to obtain the raw material of lower age classes and plant new trees in cleared areas. Now that environment protection and the implementation of ecological trends are so important, it is necessary to stress the fact that the plantation of new trees will increase the absorption of carbon dioxide. When old trees are gradually dying, the carbon contained in them is released back into the environment. The combustion of forest biomass generates net CO

2 emissions. This is criticised by ecologists, who show that the total greenhouse gas emissions exceed the capacity of the world forest resources to absorb carbon dioxide. The use of wood biomass reduces the amount of CO

2 bound by forests, but it generates space for afforestation and increases environmental regeneration [

44].

The bioenergy sector is developing dynamically in Poland. By 2020 it reached a power capacity of about 1512 MW. Wood biomass is the main fuel in the Polish bioenergy sector (in 2019, it was about 65%). Throughout the period under analysis, i.e., from 2018 to 2020, the share of bioenergy in the consumption of primary energy from renewable resources gradually decreased. In 2019, it dropped to 81% due to the greater use of solar and wind energy. Currently, in Poland, there are 21 renewable energy installations with a capacity greater than 5 MW, which are powered by combusted wood biomass. However, between 2018 and 2020, the greatest amount of wood biomass was consumed by households. Their consumption was estimated at 10–12 million m

3 [

42,

43].

When considering the market of wood biomass for energy-supplying purposes and the possibilities of its development, the following key assumption should be taken into account—wood must be burnt only after it has been used as a material and recycled multiple times (the idea of cascade consumption). The efficiency of wood processing into products, especially those with high added values, is much greater than its conversion into energy, even if it is green energy [

45]. The development of renewable energy sources, including the market of wood biomass for energy-supplying purposes, is largely conditioned by the economic aspects, as well as active support, with legal and financial instruments enabling the competition of renewable technologies on the energy market [

46,

47]. In fact, renewable energy is relatively more expensive than energy generated from conventional sources, whereas the potential of its resources is considerably dispersed and technologically diversified [

48].

The economic downturn, which has already begun in Poland, the European Union, and around the world, creates great opportunities to calm down various market segments, including the market of wood biomass for energy-supplying purposes [

49,

50]. This may facilitate the development of rules concerning the harvesting and distribution of biomass within the forest and wood sector [

40]. Currently, the demand for individual energy results in a higher demand for briquettes and pellets made from wood (forest biomass) and agricultural biomass [

51,

52]. The economic calculation shows that this procedure is reasonable, especially if pellets and briquettes are used for household energy, together with solar and wind energy [

53].

The optimal use of various types of wood biomass resources in economic practice is a significant problem in the development of the market of wood biomass used for energy-supplying purposes [

54]. This particularly concerns wood from other sources than forest (post-consumer wood and wood processing by-products). Poland does not have infrastructural systems of using post-consumer wood as a source of renewable energy. The use of pure (chemically unmodified) by-products for energy does not pose a threat to the environment. However, it is necessary to ensure the further development of the technology so that the combustion products emitted into the atmosphere are completely oxidised so that they have minimal influence on the environment. The production of a valuable fuel from wood biomass usually involves additional costs, as it is necessary to comminute wood and dry it so that it can be easily burnt and/or transported, e.g., as pellets. Therefore, the use of biomass for energy is determined by its availability and the cost-effectiveness of the entire process, ranging from the obtaining of biomass and through the supply chain from suppliers to recipients [

55,

56].

5. Conclusions

The development of forest management and the increasing level of wood-processing technology has caused changes in the use of by-products, which are a valuable source of energy biomass.

Between 2018 and 2020, Polish forests annually generated over 4 million m3 of forest biomass, which could be used to supply energy. The volume of post-production biomass from sawmills decreased from about 8.7 million m3 in 2018 to about 7.6 million m3 in 2020, which was about 190% of the obtained forest biomass.

Softwood, whose share in the wood resources amounts to over 68%, significantly influences the production of biomass. The availability of this raw material is significantly influenced by the share of forest habitats and mixed forests with the largest number of coniferous species.

The decrease in the share of forest biomass for energy-supplying purposes was influenced by the 10–12% decrease in the amount of S4 fuel assortments produced.

Between 2018 and 2020, the supply of forest biomass was gradually decreasing by 8% a year. This trend may increase the demand for biomass imported from abroad and cause the need to search for other sources of biomass (agriculture).

The amount of post-production biomass generated by sawmills is gradually decreasing by about 8% a year due to the lower supply of sawmill wood and the higher material efficiency of wood-processing enterprises.

Due to the gradual decrease in the supply of wood biomass in Poland by about 7%, and due to individual and industrial recipients’ growing interest in renewable energy, it is necessary to search for new sources of biomass (agriculture and the recycling of wood products).

The use of stump wood may play a crucial role and be a partial alternative solution to biomass shortages. At present, only a low amount of fatwood is harvested, i.e., 4000–11,000 m3, whereas its potential is estimated at 2 million m3.