1. Introduction

Most households living in rural developing countries meet their cooking energy demand in open fire stoves with firewood collected from common forests. Common forests are public resources without restriction to which everybody can have free access. The availability of these free resources depends on the extent to which these resources are being exploited. These resources are declining very fast in densely populated areas where people have no access to alternative modern energy sources for cooking. The rate of decline can be high when people continue to use inefficient stoves. The resulting scarcity would impose additional time for traveling and collection of firewood. Spending much time on firewood collection affects the time for other activities, especially in rural areas where women are traditionally in charge of several household chores. This is shown in the survey made in rural Sub-Saharan Africa where over 50% of the women are reported as time-poor [

1,

2]. The time women spend on walking and carrying firewood is a big concern due to increasing deforestation that will cause the distance to the resource source to become larger, requiring extra time. As a consequence, they look for closer resources (crop residues and cow dung) as alternatives to solve the time problem. Use of their own biomass depends on availability of land and livestock resources holdings, which are also very scarce [

3]. In addition, crop residues and dung are an integral part of the agricultural system providing feed and fertilizers. So, direct combustion of these resources to meet the cooking energy needs has a significant impact on crop yield [

4,

5,

6]. Hence, direct use of both firewood and dung for cooking is limited by scarcity and loss of essential soil nutrients.

Biogas energy is an alternative to reduce the environmental and socio-economic consequences related to the traditional use of biomass energy. Adoption and installation of biogas facilities requires sufficient financial resources mobilization. Hence, several countries in the developing world have developed biogas program initiatives in partnership with donor organizations [

7]. However, little success has been reported on their installation and functionality particularly in Sub-Saharan Africa despite provision of financial support [

7,

8]. Even in Asian countries where the technologies are mature and governments are dedicated to their implementation, the success rate of biogas digesters is close to 50% [

8,

9]. Several studies have been conducted to determine the constraints related to their low adoption rate and operations. Lack of installation funds, technical competencies, socio-cultural factors, and insufficiency of feedstock and water have been identified as the main factors [

7,

8,

9,

10]. These factors are related to the financial capacity of the people, the technical capacity to maintain the system, and socio-cultural barriers preventing people from using the digesters. Even though biogas is often suggested as a solution based on its clean energy and slurry for fertilizer, up until now no attention was paid to its labor requirements. However, time shortage could be the main reason for not using the biogas digester. Hence, it is vital to have an indication of how much time is needed for running a biogas system in a household since operation of biogas digesters requires daily collection of water, feedstock, and removal of its slurry. The time spent on these activities depends on the availability of resources. Therefore, if the time spent on biogas production exceeds the time for wood collection, the installation and operation of biogas digester is not a realistic option.

This study, therefore, aims to determine the labor requirements of biogas production involving varying resource availability. The analysis was made using a simple model made of different biogas digestions and resources extraction options and compared to a traditional energy system using common forest firewood and dry dung. The rest of the paper is organized as follows. The second section discusses the methodology used for the study. In this section we first describe the system and then make assumptions. We present the results in

Section 3 and discuss them in

Section 4. Concluding remarks are presented in

Section 5. Findings from the study can help to create insight in the technical factors attributed to implementation of biogas from the perspective of labor for their operations.

2. Methodology

2.1. System Description

People need energy for cooking. Meeting the energy demand requires collection and transportation of resources to the site of conversion and use. This is mostly done with human power. Women and young girls are traditionally in charge of collecting biomass for energy use. The labor for these activities relies on the conversion technologies and the volume of resources and the distance to them. Different technologies are available to convert the energy in biomass into useful energy used for cooking. In this paper, we study the labor spent on a biogas energy system compared to a traditional system involving firewood and dry dung collection. In the comparison, a clear distinction is made between the time spent on collecting versus transporting resources. All collection and transportation activities are performed by human labor and the corresponding labor time is presented annually in hours (h).

Resources that supply the energy to meet the demand are obtained from common or private resources. Common resources are public resources with unlimited access. Unlimited access leads to over-exploitation. When resources are over-exploited their availability declines. Resources are already scarce in areas with a dense population which have no access to modern energy alternatives. When resources are scarce, additional time is needed for traveling long distances to where sufficient resources are available. Otherwise, private resources are used as substitutes. Cow dung and crop residues are mostly used for this purpose. They are also part of an agricultural system to provide soil amendment needs. Using them as alternative energy sources in traditional stoves have a significant influence on soil fertility. Conversion of cow dung and crop residues to biogas can be an advantage to provide clean energy and to curb the loss of soil nutrients.

The use of resources for energy requires technologies to convert them into useful energy. The amount of useful energy obtained per technology varies with the efficiencies of the conversion processes. During the processes, some of the energy dissipates into the environment or is left unconverted. However, the amount of useful energy required to make food ready for consumption usually remains the same. Over-or under-cooking is not desirable for the quality of food. The amount of resources needed to meet the cooking demand thus depends on the conversion processes. Inefficient systems require large amounts of resources to compensate the energy lost during the conversion processes. Energy technologies like biogas digesters require additional resources to assist the process of conversion. When biomass resources are processed and converted into useful energy, wastes are produced as byproducts. The type and amount of byproducts (wastes) vary with the conversion technologies. These byproducts are not worthless resources. Byproducts containing high nutritional values can be used as fertilizers. For instance, slurry from a biogas system can be directly used or processed into compost for fertilizer. The schematic diagram showing a household energy supply system is presented in

Figure 1. The system shows resource conversion into useful energy and wastes. We study the labor requirements of various biogas systems and compare them with an open fire system involving firewood and dry dung.

Up to now, firewood dominates the rural households’ cooking energy consumption. Firewood is mostly collected from common forests. Its collection involves cutting, collection, chopping, and sizing activities. Moreover, most common forests are located in mountain areas outside the village, requiring hilly road walking. Hence, the collection activities and transport situations are vital to determine the labor needed to meet the cooking demands.

Agricultural residues and dung can substitute firewood in time of scarcity. These resources are an integral part of the agricultural system used for feeding and fertilizing. In addition, crop residues are limited to the crop harvesting season. We study dry dung as an alternative to firewood taking into account its continuous supply. Availability of dung can be affected by the type of feeding. Grass-fed cattle produce more dung in the field than stall-fed cattle. Dung contains low calorific values. Thus, meeting the cooking demand requires a large quantity of dung. Hence, additional dung must be transported from the field when dung produced in a pen is not sufficient. Collection and transportation of dung may not consume much time since cattle are mostly kept in nearby fields. However, direct burning of dung leads to indoor air emissions and soil nutrient losses. The schematic diagram involving firewood and dung used in traditional stoves is presented in

Figure 2.

Instead, conversion of residues and dung to biogas can curtail the problems related to traditional energy use. The biogas energy system involves two levels of conversion processes. The first process deals with the production of biogas. This process involves feedstock collection, transportation, preparation, digestion, and removal of slurry. Feedstock preparation requires additional water supply which is determined by the quantity and moisture contents of the feedstock. Feedstock quantity is determined by the yield of gas produced by the system. The system produces sufficient biogas when the feedstock nutrient composition is at its optimum and its solid content is adjusted with water. In the process of digestion, slurry will be produced. In the second process the produced biogas will be converted into useful energy in a biogas burner. The efficiency of the burner determines the amount of useful energy obtained for cooking. Hence, the efficiency of both digestion and combustion processes determine the quantity of feedstock and related water. The biogas production activities involving resource collection and removal of slurry are performed on a daily basis. Scarce resources require additional labor for transportation. The advantage of a biogas system is that essential soil nutrients like nitrogen and phosphorus are kept in the system without losses. The slurry containing these nutrients can be applied directly to farmlands or converted into compost. Both biogas production and removal of slurry involve collection and transportation activities.

Figure 3 shows the biogas energy production system and use.

2.2. Quantifying System Assumptions

The labor requirements of a households’ cooking energy production depend on the quantity of resources and their availability at certain distances. Specific assumptions on the quantity of resources and the time for extraction were made in the following sections. We present the results on the time spent on meeting the cooking demand in hours, although the term time can be interchangeably used with labor.

2.2.1. Quantifying Biomass Demand in a Traditional System

A household with an average number of family members of six requires about 6 GJ of useful energy annually for cooking [

3]. The amount of biomass resources required to meet this demand relies on the efficiencies of conversion technologies. The conversion efficiency of biomass burning stoves varies from 10%–20% [

11,

12]. One kilogram (kg) of air dried biomass typically provides about 15 MJ of gross energy [

13]. The traditional stoves (open fires) most commonly used in rural areas convert about 10% of the gross energy into useful energy during cooking. One kg of air dried firewood provides about 1.5 MJ of useful energy in this stove. Meeting the 6 GJ of useful cooking energy requires about four tons of firewood. This is in line with the survey results from developing countries with varying accessibility to firewood sources. Therefore, households with access to nearby common forests at short distances collect more firewood than those living at a distance. However, several studies conducted in Ethiopia reported an annual consumption of 3.0–5.0 tons per household [

4,

5,

14]. Households without access to firewood use dung cake for cooking instead. A kg of dry dung with a calorific value of about 11 MJ [

15] combusted in traditional stoves provides 1.1 MJ of useful energy. Meeting the 6 GJ of useful cooking energy requires about 5.4 tons of dry dung. During combustion, about 2% of the firewood and dung can be produced as ash [

16,

17]. This provides a daily ash yield of about 0.2 kg from firewood and 0.3 kg from dry dung combustion. The amount of ash produced in a day is so small that it does not require separate collection. This means that it can be easily removed during house cleaning.

2.2.2. Quantifying the Resources Demand of Biogas

Anaerobic Digestion Processes

Any organic waste containing high volatile organic matter can be digested to produce biogas which contains methane as the main energy carrier. The digestion process consists of four phases with different species of bacteria operating in different specific anoxic environmental conditions [

18]. The level of performance at each phase and ultimate biogas yield relies on feedstock composition and process operation involving complex biochemical reactions [

19]. Digester temperature, feedstock feeding ratio, organic loading rate, and mixing frequency are some of the crucial factors. Most biogas digesters in developing countries operate at ambient temperature without continuous mixing, thus, temperature adjustment may not be needed. Feedstock feeding ratio contributes to carbon and nitrogen balances. A high or low carbon/nitrogen (C/N) ratio is not desirable for the microbial digestion processes. Feedstock with high nitrogen content (i.e., low C/N ratio) facilitates production of ammonia which is toxic to methane producing microbes. Excessive carbon content (high C/N ratio) is also not suitable as it leads to the enhancement of hydrolysis processes and drops in the pH of the system. The optimum C/N ratio for effective performance of anaerobic digestion (AD) and biogas yield is 20–30:1 [

20]. Nutritional composition, feedstock feeding ratio, and organic loading rate correspond to the processes of substrate adjustments. Adjustments are made by the addition of different waste streams and water. For instance, cow dung contains a relatively low C/N ratio while crop residues contain a high C/N ratio [

20,

21]. Therefore, addition of plant materials with high carbon content to cow dung inhibits production of ammonia and causes a drop in pH. This is the advantage of co-digestion when compared to mono-digestion where nutritional adjustment cannot be made. Only the organic loading rate can be adjusted by the addition of more water in mono-digestion. Hence, adjustments in nutritional and operational conditions are crucial to determine the proportion of methane and other gases. Co-digestion favors better biogas yield containing better methane content.

Theoretically, biogas is a mixture of 60%–75% CH

4 and 25%–40% CO

2 with a calorific value of about 20–25 MJ/m

3 [

13,

22]. Its energy value depends on the methane content. This is crucial when the gas is converted into different forms of energy like heat and electricity. Several technologies are available to convert biogas into a different energy form at varying conversion efficiencies. Up to now, the most advanced technology to convert biogas directly into heat on the household scale is a biogas burner (stove). A biogas stove is technically advanced in that it is able to adapt and modify its design to make it suitable to cook local foods [

23]. Its thermal efficiency varies from about 50%–68% with a biogas consumption rate of 0.220–0.450 m

3/h [

24,

25]. Biogas can also be appropriate to provide lighting energy in rural areas despite its low conversion efficiency [

23]. In this study, biogas for cooking energy is considered taking into account the cooking energy issues in developing countries.

The Demand for Feedstock

The amount of feedstock required to meet the 6 GJ of useful cooking energy relies on its biogas yield and the stove’s conversion efficiencies [

14,

25]. The yield of biogas varies with the types of feedstock and specific operational processes. The biogas yield from cow dung varies from 150 m

3 to over 450 m

3 per ton of volatile solid (tVS) due to varying types of animals and feeding [

10]. Volatile solids (VS) are mostly used to characterize the organic matter contents of manure. The main components of VS are lipids, proteins, and carbohydrates including lignin and trace amounts of volatile fatty acids [

26]. It is the fraction of the dry matter contents of the biomass accessible to biological digestions. The yields of biogas and its methane contents are thus determined by the amount of VS destroyed during digestion [

26,

27]. We considered a biogas yield of 200 m

3/tVS of dung based on References [

8,

10,

19,

28]. The amount of useful energy obtained from a certain volume of biogas is determined by the conversion efficiency of the stoves. A typical biogas burner most commonly used in developing countries hourly consumes about 0.4 m

3 of biogas and converts about 60% of its energy into useful energy [

23,

24]. One cubic metre (m

3) of biogas provides about 21 MJ of energy [

8,

28] or 12.6 MJ of useful energy when combusted in biogas stoves. Accordingly, meeting the annual useful cooking energy demand (i.e., 6 GJ) requires about 475 m

3 of biogas. Production of 475 m

3 of biogas with 200 m

3/tVS requires about 2.3 tVS. Fresh dung contains about 25% solid contents out of which 85% is VS [

10]. One ton of fresh dung thus provides about 0.213 tVS. Provision of 2.3 tVS requires about 11 tons of fresh dung (about 30 kg/day). This corresponds to 20–40 kg of fresh dung reported in literature for the daily cooking demand of the family [

10,

29].

Use of co-digestion can increase the yield of biogas due to improvement of nutrient composition of the feedstock [

19,

30]. Co-digestion of cow dung and crop residues provides better nutrient compositions. Cow dung contains a low C/N ratio compared to crop residues. Several studies reported an increase in biogas yield ranging from 40% to over 100% from the co-digestion of cow dung and crop residues [

19,

30,

31]. In this study, we assume a 50% increment from digesting dung alone, which is equivalent to 250 m

3/tVS of co-digested dung and residues. With the same calorific value of 21 MJ/m

3, meeting the household’s useful cooking energy requires 475 m

3 of biogas. Production of 475 m

3 with the biogas yields of 250 m

3/tVS needs about 1.9 tVS. The ratio of dung to residue is vital in the yield increment. The dung to residues ratio is determined at 3:1 based on the results from different co-digestion studies [

19,

30]. Residues contain about 85% solid contents and 80% VS. We assumed average values of the two feedstock’s solid and volatile content taking into account their proportions. Thus, we assumed 30% total solids with 82% VS for co-digestion containing a dung to residues ratio of 3:1. One ton of co-digested fresh dung and residues provides about 0.255 tVS. Hence, provision of 1.9 tVS requires about 7.5 tons of fresh dung and residues (about 5.5 tons of fresh dung and 2.0 tons of residues). On average, on a daily basis, about 20 kg of co-feedstock is needed to meet the typical household cooking energy demand. This is about two-thirds of the amount considered in mono-digestions.

Quantifying Digester’s Water Demand

Meeting the useful cooking energy demand with mono-digestion biogas requires about 11 tons of fresh dung. Production of the same useful energy with co-digestion of dung and residues requires about 7.5 tons. Preparations of feedstock to achieve optimum biogas digester performance require sufficient amounts of water [

10,

32]. The water demand of the digester depends on the moisture content of the feedstock and its organic loading rates. Most studies recommend a 1:1 ratio of water to fresh dung to maintain performance consistency of the system. These ratios can be increased to 1:2 based on the moisture contents of the feedstock and optimum organic loading rates [

32,

33]. An organic loading rate of 4–8 kg VS per m

3 of digesters can be achieved with the 1:1 ratio for the digesters using mixers [

10,

32,

34]. However, most biogas digesters in developing countries do not have preinstalled mixers. The optimum performance of a digester without mixer should be adjusted to a solid content of 6%–10% with an organic loading rate of 2 kg VS per m

3 [

10,

32,

35]. Thus, sufficient amounts of water have to be added until the desired substrate dilution is achieved. Over-dilution or under-dilution affects the yields of biogas. Over-dilution makes the solid contents settle down into the digester and under-dilution can make the solid contents impede the flow of the gas formed at the lower part of the digester, but also contributes to scum formation on top. Hence, adjusting the solid contents of the mono-digestion containing 25% solid contents to the optimum range requires about 1:1.5 dung to water ratios. This means that the preparation of 11 tons of fresh dung requires about 16 m

3 of water (assuming that 1 ton = 1 m

3). Similarly, preparation of the co-digestion feedstock containing 30% solid contents needs to be adjusted with a 1:2 ratio of feedstock to water. Preparation of 7.5 tons of co-feedstock requires about 15 m

3 of water (about 40 L/day). The quantity of water considered in both mono and co-digestions more or less corresponds to the values reported (about 60–100 L) in relevant literature [

10,

36]. The variation in our assumption and in literature is attributed to varying quantities of feedstock. Increasing the quantity of feedstock and its solid content most likely increases the demand for additional water.

Quantifying the Slurry

In the process of AD, the carbon content of the feedstock is converted into methane and CO

2, while the nitrogen and phosphorus content remain unaltered [

37]. About 20% of the carbon can be lost in the AD processes [

37]. Production of sufficient biogas for the annual cooking energy demand requires about 27 tons and 22 tons of substrate (feedstock and water) for mono- and co-digestion, respectively. The volatile organic matter in both mono and co-digestion accounts for about 2.3 tons and 1.9 tons, respectively. Assuming a total destruction of VS and a 20% reduction in the volume of water, about 23 tons and 19 tons of slurry can be obtained from mono and co-digestions, respectively (

Table 1).

2.2.3. Quantifying the Time (Labor) Demand

The time spent on collection and transportation of biomass and water is determined by the number of their annual loads. The number of loads relies on the weight of the resources required to meet the demand. Collection and transportation activities are performed by women, since they are traditionally in charge of household chores [

2]. Women use head-loading and back-loading for transportation of resources [

38]. Therefore, the weight of the load managed per trip relies on the type of resources, size of person, and carrying experience [

38,

39]. In this section we estimate the load per trip of collection and transportation and their corresponding time based on reported literature.

Quantifying Loads

The weight of the load an adult person can handle per trip of collection varies from 20–30 kg due to carrying ability and size of the person [

5,

39,

40]. In this study, we assume an average load of 25 kg of firewood or dung per trip of collection taking into account physiological and health aspects related to load carrying [

38,

41]. Transportation of water is made by means of plastic containers of about 20 L. A clay pot with an approximate volume of 15–20 L is also used in remote rural areas. Therefore, on average, one load of feedstock corresponds to about 25 kg and one load of water is about 20 L. Transportation of slurry is mostly performed in barrels on hand-pulled carts [

42], due to factors related to hygiene and difficulties of using capped containers. Thus, we assume about 40 kg of load per trip. The number of loads required to meet the annual energy demand of the household is presented in

Table 2.

Quantifying Time for Collection of Loads

The time spent on each load collection depends on the processes and availability of the resources. For instance, collection of firewood involves cutting, collecting, and chopping activities. However, allocation of specific collection time is difficult due to the varying availability of resources and methods of collection. We used reported relevant literature to estimate the time for firewood collection. Accordingly, a survey from Lupeta, Tanzania reported 104 min for collection and 71 min for traveling a roundtrip of 3.86 km [

40]. Similar studies from different places in India reported about 3 h per trip of firewood collection over a distance of 2–3 km [

43,

44]. A comparative study between two rural Sub-Saharan African villages reported 2–4 h per trip of collection covering about 2 km [

39]. Hence, we estimated 90 min per load (min/load) of firewood collection in this study based on the information reported in the literature. The time for collection of dung and water is not reported in the literature; we made reasonable assumptions taking into account collection processes. Collection of dung and water does not require as much processing as firewood collection. We estimated 25 min/load of dung and 10 min/load of water collection. Collection of water requires significantly less time than firewood and dung. However, in densely populated areas the time for queuing for water can be up to an hour [

45]. However, this may not be an issue for the rural households relying on river water if the river crosses through the village.

Quantifying Time for Transportation of Loads

The time spent on transportation depends on the speed of walking the distances. The speed for walking is affected by age, sex, health, terrain, and load. Normal walking speeds equivalent to 10–12 min per kilometer (min/km) for men and 12–18 min for women were reported [

46,

47]. Other studies made on women walking distances with varying loads show an equivalent of about 20–30 min/km [

38,

48]. Transporting loads involves slow walking and resting in between due to physiological discomforts related to body position [

39,

40,

41]. This depends on the length of transport distances. Transport distances can vary from about 2–3 km to up to 10 km of walking distances [

49]. Accessibility to water sources also varies from place to place [

29,

50]. However, transporting any of the loads require almost the same time per transport distance. We estimated 20 min/km of walking distance per load of biomass, water, and slurry (40 min/km per round trip) based on [

38,

40,

48]. The speed in a round trip with and without loads may vary, but is unlikely to affect the overall results. The time spent on transportation of dung depends on the type of livestock farming. We assumed 50% of the dung load to be transported from the field.

There is variation in what individual woman can carry and how fast they walk, but based on the physical properties of female bodies, carrying 20–30 kg at a speed of 3 km an hour is considered typical based on the literature in the Sub-Saharan region. The time required is dependent on the amount of resources they have to collect and on the distance from the source of the resource. Hence, comparisons of the annual time (in hours) spent on collection and transportation of resources between the systems are made at 1, 2 and 5 km. Comparison at a 1 km distance shows the transport time intensity of the resources and that of 2 km and 5 km is to track the time saving of biogas production at varying distances.

3. Results

Assumptions on the energy resources for the cooking demands with various traditional and biogas system were made in

Section 2.2.2. The quantity of biomass, water, and byproducts produced annually in the conversion processes are presented in

Table 1. So, meeting the annual 6 GJ of useful cooking energy demand in traditional stoves requires about 4.0 tons of firewood or 5.4 tons of dry dung. Alternatively, mono-digestion biogas requires about 11 tons of fresh dung and 16 m

3 of water, and it produces about 23 tons of slurry. That of co-digestion requires about 7.5 tons of feedstock and 15 m

3 of water, and produces about 19 tons of slurry.

The time spent annually on the extraction of resources was determined by the collection activities and the transportation distances. Assumptions on specific weights of load and corresponding collection and transportation time are made in

Section 2.2.3. The quantities of energy resources required to meet the demand are presented in

Table 1. Accordingly, meeting the cooking energy demand requires about 160 loads of firewood and 220 loads of dry dung. Similarly, satisfying the demand with mono-digestion biogas requires about 440 loads of fresh dung, 820 loads of water, and removal of 575 loads of slurry. Production in co-digestion requires about 295 loads of feedstock, 730 loads of water, and removal of 465 loads of slurry. The annual number of loads of biomass, water and slurry required to meet the demand are presented in

Table 2.

The time spent annually on individual energy resources and systems were calculated based on the annual number of loads presented in

Table 2. Accordingly, collection of 160 loads of firewood requires 240 h and 110 h/km of transportation. Similarly, collection of 220 loads of dry dung requires 90 h. Transporting half of the dung quantity requires 75 h/km of transportation distance. Collection of fresh dung, water, and slurry in mono-digestion requires 185, 140 and 90 h, respectively. Annually, every km distance of transportation of feedstock, water, and slurry requires 150, 550 and 365 h, respectively. Similarly, collection of the feedstock and water in co-digestion and removal of its slurry requires 110, 120 and 75 h, respectively. Covering every km distance of transporting feedstock, water, and slurry requires 50, 490 and 290 h, respectively. The results are presented in

Table 3.

The results on the time spent annually on collection and transportation of resources for traditional and biogas energy systems are shown in

Table 4. The time spent on collection and transportation of firewood and dry dung for the open fire system remains the same with the individual results presented in

Table 3. However, biogas production requires the sum of the time individually spent on collection and transportation of resources. Accordingly, production of biogas in mono-digestion and removal of slurry corresponds to 1835 loads. Collection of the substrates and removal of slurry requires 410 h and every km of transportation requires 1060 h. Likewise, production of biogas in co-digestion and removal of its slurry corresponds to 1490 loads. Both substrates and slurry collection require 305 h and every km of transportation corresponds to 830 h. The difference in the amount of time between mono and co-digestion system is related to the quantity of resources used in both systems (

Table 1).

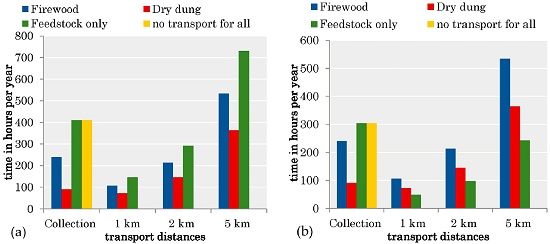

The results presented in

Table 3 show huge time consumption for water and slurry transportation. As shown in

Table 4, a biogas system involving transportation of resources consumes a disproportionally large amount of time compared to the traditional system. The results for a biogas system without water and slurry transportation are presented in

Figure 4. Exclusions are made based on the assumption that water is available nearby and slurry is directly applied to nearby farmland or converted into compost. Only the time spent on their collection is considered. Nevertheless, their collection time remains the same with the results presented in

Table 4, since modification is made only on transportation. The results with both mono and co-digestion systems are thus indicative of the time saved compared to firewood at varying distances. Mono-digestion biogas systems involving dung transportation over a distance of 2 km consumes less time than firewood collected over a 5 km distance. Collection and transportation of firewood over a 5 km distance requires about 775 h and biogas production with dung transport over 2 km requires 705 h. The time saving can be achieved at 2 km distances of firewood collection when biogas production does not involve any resource transportation (

Figure 4a). More time saving can be achieved with a co-digestion at the distance of 1 km of firewood collection (

Figure 4b). Collection of resources in co-digestion requires about 305 h while about 350 h are spent on firewood collection and transportation over one km. Therefore, increasing biogas efficiency through co-digestion and avoiding transportation of resources favor biogas to be produced at lower labor costs than traditional energy systems.

4. Discussion

We made an evaluation of the labor requirements of biogas production based on the time spent on collection and transportation of resources and compared that to the open fire systems. These activities are vital for the adoption and installation of the biogas system. The analyses in both traditional and biogas systems are based on the reported relevant literature from Sub-Saharan African countries and reasonable realistic assumptions. Most of the rural households living in these countries depend on common forests for their cooking energy and experience similar water resource scarcities. However, women in rural areas in developing counties do not differ that much in how much they can carry. The amount of useful energy required for cooking also remains constant. The energy content of a kg of dry wood varies between 15–18 MJ [

13] and nutritional content of waste streams (feedstock) also varies, however, the difference between categories remains stable. In this study, a model was used for the situation in Ethiopia for available biomass (with their typical energy values) using distances typical for this region of the world. Hence, the model can be applied everywhere in the world having similar energy and resource situations.

Moreover, most of the load related specific assumptions are common for both systems. For instance, we used an average value of 25 kg per load of firewood and feedstock and 20 min per km distance of transport for all resources (

Table 2). Changing these values does not have an effect on the labor differences between the biogas and traditional systems. Some changes can occur if the volume of resources and related time per load of collections are changed. For instance, collection of firewood involves several processes like cutting, collecting and chopping activities. As a result, the time spent on firewood collection is about twice the time individually spent on other resources. However, it is less compared to the per load collection time reported from the survey made in Tanzania [

40]. The specific time per load of firewood collection is about nine times the specific time per load of water and four times of the specific time per load of dung collection. However, biogas production requires the sum of the individual time spent daily on resource (i.e., substrates and slurry) collection. In addition, firewood collection is not made on a daily basis. Hence, more time is spent on the collection of resources for both mono and co-digestion than on that of firewood (

Table 4). The annual loads of resources in both biogas production options are about 9–11 times larger than the annual loads of firewood. Their transportation also increases with the same order of magnitude. Additionally, increasing the biogas efficiency through co-digestion does not help to achieve time savings. Biogas can help to achieve time savings when resources are available nearby and firewood collection is from a distance of at least 2 km. Collection and transportation of firewood over a distance of 2 km requires about 455 h compared to a collection time of 410 h in mono and 305 h in co-digestion biogas (

Table 4).

As shown in the results, transporting water accounts for the largest share of biogas production processes. In addition, an adult person requires about 20 L of water daily for basic consumption [

51]. As indicated in the analysis, the digester’s water demand is related to the feedstock’s moisture content and its volume. The feedstock (fresh dung) considered in mono-digestion in this study contains high moisture. However, additional water is needed to maintain the substrate organic loading rate and optimum performance of the system [

10,

32]. In this study, we adjusted the ratio of dung to water at 1:1.5. Reducing this ratio to 1:1 does not lead to a significant change in the biogas system time demands. It achieves only 17% reduction in overall biogas time demands (a reduction from 410 h to 350 h). In addition, a ratio of 1:1 cannot achieve the desired solid content in digesters without mixers. By using co-digestion, it is possible to reduce the volume of the feedstock from 11 tons to 7.5 tons. The significant reduction in the feedstock quantity attributed to an increased yield of biogas and a substitution of 5.5 tons of fresh dung by about 2 tons of residues. However, the system requires higher water to feed ratio because of the high solid content of residues. Due to this, the use of co-digestion only contributes to 11% (a reduction from 140 h to 120 h) reduction in the overall water demand of the system. Therefore, use of high moisture content or reduction in volume of feedstock does not bring about significant change in the time spent on water collection. The insignificant reduction in time due to system modification is related to the volume of water. The annual loads of water are about five times that of firewood. This gap increases to about seven times if the yield of biogas in mono-digestion (200 m

3/tVS) decreases to about 150 m

3/tVS (yield reported from cows in Sudan [

52]). The water demand estimated with this study is less than the quantity reported in the literature [

10,

32]. Therefore, meeting the digester’s water demand will remain a challenge if distant river water sources are considered.

As shown in the results, a lot of time is spent on biogas production involving resource transportation at least from the distance of 1–2 km. About 4–7 h is spent daily on mono-digestion and 3–5 h on co-digestion. However, daily only about 2 h is needed for collection of firewood over 5 km. One of the advantages of the adoption and installation of a biogas digester is to recycle the essential nutrients available in feedstock [

7,

9]. However, collection and transportation of slurry at every km distance requires about 1.2 h daily compared to less than one hour required for firewood. Increasing the transportation distance by 1 km almost doubles (2.2 h) the corresponding time in slurry. Therefore, slurry transportation is another challenge of biogas production with huge labor time. Since the model can also be applied to other locations, it can be used as a tool to understand why biogas systems are successful in some locations and why they fail in others. The examples where slurry is dumped in the nearby river or in the sewage system become clear; getting rid of slurry is a time problem. This is shown with the comparative study made in Vietnam among biogas users and non-biogas users [

42]. Accordingly, most biogas users directly release the slurry to the environment compared to non-biogas users. This was also shown with the urban biogas users releasing the slurry to a nearby river or a sewerage line [

32]. Releasing directly to the environment can be worse than the burning of dung in traditional stoves. Converting slurry into compost with other organic wastes can be an option to reduce the labor time and to recycle the nutrients. Otherwise, installing biogas without proper slurry management will be a waste of resources. In that case direct burning of dung can be better for the labor and environment.

It is also important to look at the labor required for biogas production from the real life perspective of rural households. In rural areas, each member of the family, including children, has certain tasks. The labor for farming, household chores, caring for children and elders, and other social activities are performed by the members of the families. Therefore, the actual time daily spent on biogas production might be more important than the other benefits of biogas. Moreover, spending additional time on biogas production can pose significant problems, especially for rural women who are already strapped for time (i.e., below time poverty line) [

1,

2,

53]. Ignoring the importance of time for its operation and focusing on the general benefits, namely on reduction of indoor air pollution, deforestation, and its slurry use alone, may not help in the adoption and use of the technology. The labor for biogas production can have significant impacts on its adoption and use. Lack of ability to separate individual interest from public interest was indicated as one of the major constraints of success in most of the failed energy projects [

54]. Therefore, the results from this study can be robust enough to indicate labor-related constraints of different biogas energy production options.

Although biogas systems have the potential of providing energy and saving the fertility of the soils, the labor requirements are such that this system does not fit in the rural household’s labor availability. However, the model also provides insights in options to improve this challenging situation. The large volume of the slurry is a problem and so is the water. Locating the digester near the water source may help. In addition, composting of the slurry before carrying it to the fields also reduces the labor burden. It is also necessary to suggest additional, better production options with lower labor requirements. Low labor biogas production can be achieved through a biogas system design based on system integration at the community level. System integration provides a lot of advantages from resource and implementation perspectives. When systems are integrated, resource scarcities are avoided and use efficiencies are increased which in turn reduces the labor for its implementation. For instance, integration of a biogas digester with livestock farming and toilets can improve the efficiency of biogas production while contributing to increased availability of resources (urine and feedstock) at short distances. When livestock farming is integrated with a biogas system, biogas production does not require additional labor but is part of the farming system. This means that cleaning water along with the dung can be fed directly to the digester. The examples of successful implementation of biogas in China and other places in Asia all concern integrated systems where all resources needed for the digesters are at hand [

55]. The biogas system integration can be easier to arrange at the community level than at the household level. Arranging at the community level helps to run the digester with little permanent labor where households are not physically expected to be present for its operation. Problems related to water for the digester also can be easier to solve at the community level with lower costs than at the individual household level. Hence, households can share the resulting biogas energy without being physically present for its production.

5. Conclusions

The present biomass energy use in developing countries involves many aspects related to long distance traveling, indoor air pollution, soil nutrient losses, and deforestation. These factors are severe in Sub-Saharan Africa where the majority of rural households depend on common forests for the cooking energy in a traditional setting. Biogas energy can be an alternative option to provide clean energy, save time, and provide slurry enriched with soil nutrients. However, the extent to which a biogas system can save time and reduce labor also depends on the time spent on its resources collection and transportation. A biogas system involving dung, water, and slurry transportation cannot save time at all in a traditional setting. Generally, water transportation is the most time consuming activity followed by slurry transportation time. Water transportation requires about five times the amount of time spent on firewood transportation in a traditional system. This gap can be increased to about ten times when transportation of feedstock and slurry is included. Biogas energy can save the time spent on firewood when all the biogas resources are available nearby and slurries are converted to compost or applied on nearby lands. Otherwise, biogas production involving river water and slurry transportation can be a waste of time and money due to the associated high labor costs. In such cases a household’s biogas system cannot be considered as an acceptable option. However, a community biogas system involving resource system integration can be an option to provide clean energy with acceptable labor requirements of production. In general, the outcome of the model is only a first indication to provide an insight on the time requirement of biogas production. Specific application requires a detailed analysis on the spot since individual village resource availabilities can be different from the averages used here.