From 2-D to 0-D Boron Nitride Materials, The Next Challenge

Abstract

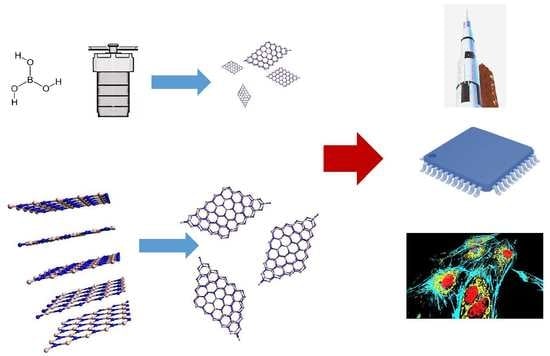

:1. Introduction

2. Understanding BN Materials by Theoretical Calculations

3. Making of 2D BN Materials

3.1. Top-Down Synthesis Routes

3.2. Bottom-Up Synthesis Routes

3.3. Synthesis Route for BNQD

4. Summary

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| h-, c-, r-, w- | hexagonal, cubic, rhombohedral, wurzite |

| BCNO | C, N-doped h-BNQDs |

| BOND | boron-oxynitride |

| BN | boron nitride |

| BNQD | boron nitride quantum dots |

| CNT | carbon nanotubes |

| CVD | chemical vapor deposition |

| DFT | density functional theory |

| DMF | dimethylformamide |

| DMSO | dimethyl sulfoxide |

| DUV | deep ultraviolet |

| EELS | electron energy loss spectroscopy |

| HOMO | highest occupied molecular orbital |

| LEED | low-energy electron diffraction |

| LUMO | lowest occupied molecular orbital |

| MBE | molecular beam epitaxy |

| NMP | N-Methyl-2-pyrrolidone |

| NT | nanotubes |

| PL | photoluminescence |

| PLD | pulsed laser deposition |

| PLE | photoluminescence excitation |

| QD | quantum dot |

| QY | quantum yield |

| SAED | selected area electron diffraction |

| TEM | Transmission electron microscopy |

References

- Mishra, N.S.; Saravanan, P. A Review on the Synergistic Features of Hexagonal Boron Nitride (White Graphene) as Adsorbent-Photo Active Nanomaterial. ChemistrySelect 2018, 3, 8023–8034. [Google Scholar] [CrossRef]

- Yu, S.; Wang, X.; Pang, H.; Zhang, R.; Song, W.; Fu, D.; Hayat, T.; Wang, X. Boron nitride based materials for the removal of pollutants from aqueous solutions: A review. Chem. Eng. J. 2017, 333, 343–360. [Google Scholar] [CrossRef]

- Liu, X.; Chen, X.; Ma, H.A.; Jia, X.; Wu, J.; Yu, T.; Wang, Y.; Guo, J.; Petitgirard, S.; Bina, C.R.; et al. Ultrahard stitching of nanotwinned diamond and cubic boron nitride in C2-BN composite. Sci. Rep. 2016, 6, 30518. [Google Scholar] [CrossRef] [PubMed]

- Chubarov, M.; Pedersen, H.; Hogberg, H.; Jensen, J.; Henry, A. Growth of High Quality Epitaxial Rhombohedral Boron Nitride. Cryst. Growth Des. 2012, 12, 3215–3220. [Google Scholar] [CrossRef]

- Liu, Y.; Zhan, G.D.; Wang, Q.; He, D.; Zhang, J.; Liang, A.; Moellendick, T.E.; Zhao, L.; Li, X. Hardness of Polycrystalline Wurtzite boron nitride(wBN) compacts. Sci. Rep. 2019, 9, 10215. [Google Scholar] [CrossRef]

- Pan, Z.; Sun, H.; Zhang, Y.; Chen, C. Harder than Diamond: Superior Indentation Strength of Wurtzite BN and Lonsdaleite. PRL 2009, 102, 055503. [Google Scholar] [CrossRef]

- Lin, Y.; Connell, J.W. Advances in 2D boron nitride nanostructures: Nanosheets, nanoribbons, nanomeshes, and hybrids with graphene. Nanoscale 2012, 4, 6908–6939. [Google Scholar] [CrossRef]

- Pakdel, A.; Bando, Y.; Golberg, D. Nano boron nitride flatland. Chem. Soc. Rev. 2014, 43, 934–959. [Google Scholar] [CrossRef]

- Kostoglou, N.; Polychronopoulou, K.; Rebholz, C. Thermal and chemical stability of hexagonal boron nitride (h-BN) nanoplates. Vacuum 2015, 112, 42–45. [Google Scholar] [CrossRef]

- Li, L.H.; Cervenka, J.; Watanabe, K.; Taniuguchi, T.; Chen, Y. Strong oxidation resistance of atomically thin atomically thin boron nitride nanosheets. ACS Nano 2014, 8, 1457–1462. [Google Scholar] [CrossRef]

- Cai, Q.; Scullion, D.; Gan, W.; Falin, A.; Zhang, S.; Watanabe, K.; Taniguchi, T.; Chen, Y.; Santos, E.J.G.; Li, L.H. High thermal conductivity of high-quality monolayer boron nitride and its thermal expansion. Sci. Adv. 2019, 5, eaav0129. [Google Scholar] [CrossRef] [PubMed]

- Cassabois, G.; Valvin, P.; Gil, B. Hexagonal boron nitride is an indirect bandgap semiconductor. Nat. Photon. 2016, 10, 262. [Google Scholar] [CrossRef]

- Wickramaratne, D.; Weston, L.; Van de Walle, C.G. Monolayer to Bulk Properties of Hexagonal Boron Nitride. J. Phys. Chem. C 2018, 122, 25524–25529. [Google Scholar] [CrossRef]

- Elias, C.; Valvin, P.; Pelini, T.; Summerfield, A.; Mellor, C.J.; Eaves, L.; Foxon, C.T.; Beton, P.H.; Novikov, S.V.; Gil, B.; et al. Direct band-gap crossover in epitaxial monolayer boron nitride. Nat. Commun. 2019, 10, 2639. [Google Scholar] [CrossRef] [PubMed]

- Corso, M.; Auwarter, W.; Muntwiler, M.; Tamai, A.; Greber, T.; Osterwalder, J. Boron nitride nanomesh. Science 2004, 303, 217–220. [Google Scholar] [CrossRef] [PubMed]

- Berner, S.; Corso, M.; Widmer, R.; Groening, O.; Laskowski, R.; Blaha, P.; Schwarz, K.; Goriachko, A.; Over, H.; Gsell, S.; et al. Boron Nitride, NAnomesh: Funcionality from a Corrugated Monolayer. Angew. Chem. Int. Ed. 2007, 46, 5115–5119. [Google Scholar] [CrossRef]

- Goriachko, A.; He, Y.; Knapp, M.; Over, H.; Corso, M.; Brugger, T.; Berner, S.; Osterwalder, J.; Greber, T. Self-Assembly of a Hexagonal Boron Nitride Nanomesh on Ru (0001). Langmuir 2007, 23, 2928–2931. [Google Scholar] [CrossRef]

- Cun, H.; Seitsonen, A.P.; Roth, S.; Decurtins, S.; Liu, S.X.; Osterwalder, J.; Greber, T. An electron acceptor molecule in a nanomesh: F4TCNQ on h-BN/Rh (111). Surf. Sci. 2018, 678, 183–188. [Google Scholar] [CrossRef]

- Jiang, H.X.; Lin, J.Y. Hexagonal boron nitride for deep ultraviolet photonic devices. Semicond. Sci. Technol. 2014, 29, 084003. [Google Scholar] [CrossRef]

- Song, Y.; Sun, Y.; Shin, D.H.; Yun, K.N.; Song, Y.H.; Milne, W.I.; Lee, C.J. Excellent oxidation endurance of boron nitride nanotube field electron emitters. Appl. Phys. Lett. 2014, 104, 163102. [Google Scholar] [CrossRef]

- Maity, A.; Grenadiar, S.J.; Li, J.; Lin, J.Y. Jiang Toward achieving flexible and high sensitivity hexagonal boron nitride neutron detectors. Appl. Phys. Lett. 2017, 111, 033507. [Google Scholar] [CrossRef]

- Maity, A.; Grenadiar, S.J.; Li, J.; Lin, J.Y.; Jiang, H.X. Hexagonal boron nitride neutron detectors with high detection efficiencies. J. Appl. Phys. 2018, 123, 044501. [Google Scholar] [CrossRef]

- Shankar, R.; Sachs, M.; Francas, L.; Lubert-Perquel, D.; Kerherve, G.; Regoutz, A.; Petit, C. Porous Boron Nitride for Combined CO2 Capture and Photoreduction. J. Mater. Chem. A 2019, 7, 23931–23940. [Google Scholar] [CrossRef]

- Wang, N.; Yang, G.; Wang, H.; Sun, R.; Wong, C.P. Visible Light-Responsive Photocatalytic Activity of Boron Nitride Inorporated Composites. Front. Chem. 2018, 6, 440. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Lai, C.; Zeng, G.; Huang, D.; Cheng, M.; Hu, L.; Xiong, W.; Chen, M.; Wang, J.; Yang, Y.; et al. Semiconductor/boron nitride composites: Synthesis, properties, and photocatalysis applications. Appl. Catal. B Environ. 2018, 15, 6–18. [Google Scholar] [CrossRef]

- Fredrickson, J.E.; Redanz, W.H. Boron nitride for aerospace applications. Mater. Sci. Res. 1965, 2, 245–260. [Google Scholar]

- Chen, X.; Dmuchowki, C.M.; Park, C.; Fay, C.; Ke, C. Quantitative characterization of structural and mechanical properties of boron nitride nanotubes in high temperature environments. Sci. Rep. 2017, 7, 11388. [Google Scholar] [CrossRef]

- Du, A. In silico engineering of grapheme-based van der Waals heterostructured nanohybrids for electronics and energy applications. Comput. Mol. Sci. 2016, 6, 551–570. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Yamijala, S.S.R.K.C.; Pati, S.K. Tuning the electronic and optical properties of grapheme and botron-nitride quantum dots by molecular charge-transfer interactions: A theoretical study. Phys. Chem. Chem. Phys. 2013, 15, 13881–13887. [Google Scholar] [CrossRef]

- Berseneva, N.; Gulas, A.; Krasheninnikov, A.V.; Nieminen, R.M. Electronic structure of boron nitride sheets doped with carbon from first-principles calculations. Phys. Rev. B 2013, 87, 035404. [Google Scholar] [CrossRef]

- Zhao, Y.X.X.; Wang, A.; Wang, X.; Bu, H.; Zhao, M. Tuning the electronic and magnetic properties of triangular boron nitride quantum dots via carbon doping. Physica E 2013, 49, 52–60. [Google Scholar]

- Huang, C.; Chen, C.; Zhang, M.; Lin, L.; Ye, X.; Lin, S.; Antonietti, M.; Wang, X. Carbon-doped BN nanosheets for metal-free photoredox catalysis. Nat. Com. 2015, 6, 7698. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Adachi, M.; Lyalin, A.; Taketsugu, T. Long range functionalization of h-BN monolayer by carbon doping. J. Phys. Chem. C 2016, 120, 15993–16001. [Google Scholar] [CrossRef]

- Krepel, D.; Kalikhman-Razvozov, L.; Hod, O. Edge chemistry effects on the structural, electronic and electric response properties od boron nitride quantum dots. J. Phys. Chem. C 2014, 118, 21110–21118. [Google Scholar] [CrossRef] [Green Version]

- Shayeganfar, F.; Tabar, M.R.R.; Simchi, A.; Beheshtian, J. Effects of functionalization and side defects on single-photon emission in boron nitride quantum dots. Phys. Rev. B 2017, 96, 165307. [Google Scholar] [CrossRef]

- Tran, T.T.; Bray, K.; Ford, M.J.; Toth, M.; Aharonovich, I. Quantum emission form hexagonl boron nitride monolayers. Nat. Nanotechnol. 2016, 11, 37–41. [Google Scholar] [CrossRef]

- Tran, T.T.; Elbadawi, C.; Totonjian, D.; Lobo, C.; Grosso, G.; Moon, H.; Englund, D.R.; Ford, M.J.; Aharonovich, I.; Torh, M. Robust multicolor single photon emission from pint defects in hexagonal boron nitride. ACS Nano 2016, 10, 7331–7338. [Google Scholar] [CrossRef]

- Attaccalite, C.; Bockstedte, M.; Marini, A.; Rubio, A.; Wirtz, L. Coupling of excitons and defect states in boron-nitride nanostructures. Phys. Rev. B 2011, 88, 144115. [Google Scholar] [CrossRef] [Green Version]

- Cheng, G.D.; Zhang, Y.G.; Yan, L.; Huang, H.F.; Huang, Q.; Song, Y.X.; Chen, Y.; Tang, Z. A parametric neutral CBVN center in hexagonal boron nitride monolayer for spin qubit application. Comp. Mater. Sci. 2017, 129, 247–251. [Google Scholar] [CrossRef] [Green Version]

- Sajid, A.; Reimers, J.R.; Ford, M.J. Defect states in hexagonal boron nitride: Assignments of observed properties and prediction of properties relevant to quantum computation. Phys. Rev. B 2018, 97, 064101. [Google Scholar] [CrossRef] [Green Version]

- Korona, T.; Chojecki, M. Exploring point defects in hexagonal boron-nitrogen monolayers. Int. J. Quantum Chem. 2019, 119, e25925. [Google Scholar] [CrossRef]

- Weston, L.; Wickramaratne, D.; Mackoit, M.; Alkauskas, A.; Van de Walle, C.G. Native point defect and impurities in hexagonal boron nitride. Phys. Rev. B 2018, 97, 214104. [Google Scholar] [CrossRef] [Green Version]

- Ranjian, P.; Agrawal, S.; Sinha, A.; Rao, T.R.; Balakrishnan, J.; Thakur, A.D. A low-cost non-explosive synthesis of graphene oxide for scalable applications. Sci. Rep. 2018, 8, 12007. [Google Scholar] [CrossRef] [PubMed]

- Zhong, J.; Sun, W.; Wei, Q.; Qian, X.; Cheng, H.M.; Ren, W. Efficient and scalable synthesis of highly aligned and compact two-dimensional nanosheet films with record performances. Sci. Rep. 2018, 9, 3484. [Google Scholar] [CrossRef] [PubMed]

- Bhimanapati, G.R.; Glavin, N.R.; Robinson, J.A. Semiconductors and Semimetals; Iacopi, F., Boeckl, J.J., Jagadish, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 95, p. 101. [Google Scholar]

- Arole, V.M.; Munde, S.V. Fabrication of Nanomaterials by Top-Down and Bottom-Up approaches—An Overview. J. Mater. Sci. 2014, 1, 89–93. [Google Scholar]

- Liu, B.; Yan, S.; Song, Z.; Liu, M.; Ji, X.; Yang, W.; Liu, J. One-step synthesis of boron nitride quantum dots: Simple chemistry meets delicate nanotechnology. Chem. Eur. J. 2016, 22, 18899–18907. [Google Scholar] [CrossRef]

- Lian, G.; Zhang, X.; Si, H.; Wang, J.; Cui, D.; Wang, Q. Boron Nitride Ultrathin Fibrous Nanonets: One-Step Synthesis and Applications for Ultrafast Adsorption for Water Treatment and Selective Filtration of Nanoparticles. ACS Appl. Mater. Interfaces 2013, 5, 12773–12778. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Das, D.; Samanta, A.; de los Reyes, C.A.; Deng, L.; Alemany, L.B.; Weldeghiorghis, T.K.; Khabashesku, V.N.; Kochat, V.; Jin, Z.; et al. Fluorinated h-BN as a magnetic semiconductor. Sci. Adv. 2017, 3, e1700842. [Google Scholar] [CrossRef] [Green Version]

- Tian, Z.; Chen, K.; Sun, S.; Zhang, J.; Cui, W.; Xie, Z.; Liu, G. Crystalline boron nitride nanosheets by sonication-assisted hydrothermal exfoliation. J. Adv. Ceram. 2019, 8, 72–78. [Google Scholar] [CrossRef] [Green Version]

- Lei, Z.; Xu, S.; Wan, J.; Wu, P. Facile preparation and multifunctional applications of boron nitride quantum dots. Nanoscale 2015, 7, 18902–18907. [Google Scholar] [CrossRef] [Green Version]

- Thangasamy, P.; Santhanam, M.; Sathish, M. Supercritical fluid facilitated disintegration of hexagonal boron nitride nanosheets to quantum dots and its application in cells imaging. ACS Appl. Mater. Interfaces 2016, 8, 18647–18651. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in Atomically thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, Y.; Sutter, E.; Shi, N.N.; Zheng, J.; Tang, T.; Englund, D.; Gao, H.J.; Sutter, P. Reliable Exfoliation of Large-Area high-quality flakes of Graphene and other two-Dimensional materials. ACS Nano 2015, 9, 10612–10620. [Google Scholar] [CrossRef] [PubMed]

- Tang, D.M.; Kvashnin, D.G.; Najmaei, S.; Bando, Y.; Kimoto, K.; Koskinen, P.; Ajayan, P.M.; Yakobson, B.I.; Sorokin, P.B.; Lou, J.; et al. Nanomechanical cleavage of molybdenum disulfide atomic layers. Nat. Commun. 2014, 5, 3631. [Google Scholar] [CrossRef]

- Namba, S.; Takagaki, A.; Jimura, K.; Hayashi, S.; Kikuchi, R.; Oyama, S.T. Effects of ball-milling treatment on physicochemical properties and solid base activity of hexagonal boron nitrides. Catal. Sci. Technol. 2019, 9, 302–309. [Google Scholar] [CrossRef]

- Deepika, A.; Li, L.H.; Glushenkov, A.M.; Hait, S.K.; Hodgson, P.; Chen, Y. High-Efficient Production of Boron Nitride Nanosheets via an Optimized Ball Milling Process for Lubrication in Oil. Sci. Rep. 2014, 4, 7288. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.; Lee, B.; Park, K.H.; Ryu, H.J.; Jeon, S.; Hong, S.H. Scalable Exfoliation process for highly soluble boron nitride nanoplatelets by hydroxide-assisted ball milling. Nanoletters 2015, 15, 1238–1244. [Google Scholar] [CrossRef]

- Li, L.H.; Chen, Y.; Behan, G.; Zhang, H.; Petravic, M.; Glushenkova, A.M. Large-scale mechanical peeling of boron nitride nanosheets by low-energy ball milling. J. Mater. Chem. 2011, 21, 11862–11866. [Google Scholar] [CrossRef]

- Yurdakul, H.; Goncu, Y.; Durukan, O.; Akay, A.; Seyhan, A.T.; Ay, N.; Turan, S. Nanoscopic characterization of two-dimensional (2D) boron nitride nanosheets (BNNSs) produced by microfluidization. Ceram. Int. 2012, 38, 2187–2193. [Google Scholar] [CrossRef]

- Chen, X.; Dobson, J.F.; Raston, C.L. Vortex fluidic exfoliation of graphite and boron nitride. Chem. Commun. 2012, 48, 3703–3705. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Zhao, Y.; Xie, Y.; Ma, X.; Zhang, X. Recent progress in synthesis of two-dimensional hexagonal boron nitride. J. Semic. 2017, 38, 031003. [Google Scholar] [CrossRef]

- Zhang, K.; Feng, Y.; Wang, F.; Yanga, Z.; Wang, J. Two dimensional hexagonal boron nitride (2D-hBN): Synthesis, properties and applications. J. Mater. Chem. C 2017, 5, 11992–12022. [Google Scholar] [CrossRef]

- Kim, J.; Kwon, S.; Cho, D.H.; Kang, B.; Kwon, H.; Kim, Y.; Park, S.O.; Jung, G.Y.; Shin, E.; Kim, W.G.; et al. Direct exfoliation and dispersion of two-dimensional materials in pure water via temperature control. Nat. Commun. 2015, 6, 8294. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Cao, H.; Xue, Y.; Li, B.; Cai, W. Liquid-Phase Exfoliation of Graphene: An Overview on Exfoliation Media, Techniques, and Challenges. Nanomaterials 2018, 8, 942. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Flint, E.B.; Suslick, K.S. The temperature of cavitation. Science 1991, 253, 1397–1399. [Google Scholar] [CrossRef] [PubMed]

- Han, W.; Wu, L.; Zhu, Y.; Watanabe, K.; Taniguchi, T. Structure of chemically derived mono- and few-atomic-layer boron nitride sheets. Appl. Phys. Lett. 2008, 93, 223103. [Google Scholar] [CrossRef]

- Coleman, J.N.; Lotya, M.; O’neill, A.; Bergin, S.D.; King, P.J.; Khan, U.; Young, K.; Gaucher, A.; De, S.; Smith, R.J.; et al. Two-Dimensional NAnosheets Produced by Liquid Exfoliaiton of Layered Materials. Science 2011, 331, 568–571. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; He, Y.; Wu, J.; Gao, C.; Keyshar, K.; Zhang, X.; Yang, Y.; Ye, M.; Vajtai, R.; Lou, J.; et al. Liquid phase exfoliation of two-Dimansional Materials by Directly Probilng and Maching Surface Tension Components. Nano Lett. 2015, 15, 5449–5454. [Google Scholar] [CrossRef]

- Stengl, V.; Henych, J.; Slusna, M.; Echorchard, P. Ultrasound exfoliation of inorganic analogues graphene. Nanoscale Res. Lett. 2014, 9, 167. [Google Scholar] [CrossRef]

- Rafiei-Sarmazdeh, Z.; Jafari, S.H.; Ahmadi, S.J.; Zahedi-Dizaj, S.M. Large-scale exfoliation of hexagonal boron nitride with combined fast quenching and liquid exfoliation strategies. J. Mater. Sci. 2016, 51, 3162–3169. [Google Scholar] [CrossRef]

- Kim, D.; Nakajima, S.; Sawada, T.; Iwasaki, M.; Kawauchi, S.; Zhi, C.; Bando, Y.; Golberg, D.; Serizawa, T. Sonication-assisted alcoholysis of boron nitride nanotubes for their sidewalls chemical peeling. Chem. Commun. 2015, 51, 7104–7107. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ortiz, D.G.; Pochat-Bohatier, C.; Cambedouzou, J.; Bechelany, M.; Miele, P. Exfoliation of Hexagonal Boron Nitride (h-BN) in Liquide Phase by Ion Intercalation. Nanomaterials 2018, 8, 716. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, L.; Emami, S.; Lafdi, K. Large-scale exfoliation of hexagonal boron nitride nanosheets in liquid phase. Mater. Express 2014, 4, 165–171. [Google Scholar] [CrossRef]

- Lin, Y.; Williams, T.V.; Xu, T.B.; Cao, W.; Elsayed-Ali, H.E.; Connell, J.W. Aqueous Dispersions of Few-Layered and Monolayered Hexagonal Boron Nitride Nanosheets from Sonication-Assisted Hydrolysis: Critical Role of Water. J. Phys. Chem. C 2011, 115, 2679–2685. [Google Scholar] [CrossRef]

- Bhimanapati, G.R.; Kozuch, D.; Robinson, J.A. Large-scale synthesis and functionalization of hexagonal boron nitride nanosheets. Nanoscale 2014, 6, 11671–11675. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, Z.; Yin, J. Boron nitride nanosheets: Large-scale exfoliation in methanesulfonic acid and their composites with polybenzimidazole. J. Mater. Chem. 2011, 21, 11371–11377. [Google Scholar] [CrossRef]

- Paffett, M.T.; Simonson, R.J.; Papin, P.; Paine, R.T. Borazine adsorption and decomposition at Pt (111) and Ru (001) surfaces. Surf. Sci. 1990, 232, 286–296. [Google Scholar] [CrossRef]

- Nagashima, A.; Teijima, N.; Gamou, Y.; Kawai, T.; Oshima, C. Electronic dispersion relations of monolayer hexagonal boron nitride formed on the Ni (111) surface. Phys. Rev. B 1995, 51, 4606–4613. [Google Scholar] [CrossRef]

- Muller, F.; Stowe, K.; Sachdev, H. Symmetry versus Commensurability: Epitaxial Growth of Hexagonal Boron Nitride on Pt (111) From B-Trichloroborazine (ClBNH)3. Chem. Mater. 2005, 17, 3464–3467. [Google Scholar] [CrossRef]

- Chatterjee, S.; Luo, Z.; Acerce, M.; Yates, D.M.; Johnson, A.C.; Sneddon, L.G. Chemical Vapor Deposition of Boron Nitride Nanosheets on metallic Substrates via Decaborane/Ammonia Reactions. Chem. Mater. 2011, 23, 4414–4416. [Google Scholar] [CrossRef]

- Jeong, H.; Kim, D.Y.; Kim, J.; Moon, S.; Han, N.; Lee, S.H.; Okello, O.F.N.; Song, K.; Choi, S.; Kim, J.K. Wafer-Scale and selective-area growth of high-quality hexagonal boron nitride on Ni (111) by metal-organic chemical vapor deposition. Sci. Rep. 2019, 9, 5736. [Google Scholar] [CrossRef] [Green Version]

- Acacia, N.; Fazio, E.; Neri, F.; Ossi, P.M.; Trusso, S.; Santo, N. Pulsed laser deposition of boron nitride thin films. Radiat. Eff. Defects Solids 2008, 163, 293–298. [Google Scholar] [CrossRef]

- Velazquez, D.; Seibert, R.; Man, H.; Spentouris, L.; Terry, J. Pulsed laser deposition of single layer, hexagonal boron nitride (white graphene, h-BN) on fiber-oriented Ag (111)/SrTiO3 (001). J. Appl. Phys. 2016, 119, 095306. [Google Scholar] [CrossRef] [Green Version]

- Glavin, N.R.; Jespersen, M.L.; Check, M.H.; Hu, J.; Hilton, A.M.; Fisher, T.S.; Voevodin, A.A. Synthesis of few-layer, large area hexagonal-boron nitride by pulsed laser deposition. Thin Solid Films 2014, 572, 245–250. [Google Scholar] [CrossRef]

- Zagho, M.; Dawoud, H.D.; Bensalah, N.; Altahtamouni, T.M. A brief overview of RF sputtering deposition of boron carbon nitride (CBN) thin films. Emergent Mater. 2019, 2, 79–93. [Google Scholar] [CrossRef] [Green Version]

- Lopes, J.M.J.; Vignaud, D. Molecular Beam Epitaxy; Henini, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; Chapter 21; pp. 487–513. [Google Scholar]

- Tsai, C.L.; Kobayashi, Y.; Akasaka, T.; Kasu, M. Molecular beam epitaxial growth of hexagonal boron nitride on Ni (111). J. Cryst. Growth 2009, 311, 3054–3057. [Google Scholar] [CrossRef]

- Nakhaie, S.; Wofford, J.M.; Schumann, T.; Jahn, U.; Ramsteiner, M.; Hanke, M.; Lopes, J.M.; Riechert, H. Synthesis of atomically thin hexagonal boron nitride films on nickel foils by molecula beam epitaxy. Appl. Phys. Lett. 2015, 106, 213108. [Google Scholar] [CrossRef] [Green Version]

- Tonkikh, A.A.; Voloshina, E.N.; Werner, P.; Blumtritt, H.; Senkovskiy, B.; Guntherodt, G.; Parkin, S.S.P.; Dedkov, Y.S. Structural and electronic properties of epitaxial multilayer h-BN on Ni (111) for spintronics applications. Sci. Rep. 2016, 6, 23547. [Google Scholar] [CrossRef] [Green Version]

- Merlo, A.; Mokkapati, V.R.S.S.; Pandit, S.; Mijakovic, I. Boron nitride nanomaterials: Biocampatibility and bio-applications. Biomater. Sci. 2018, 6, 2298–2311. [Google Scholar] [CrossRef] [Green Version]

- Lin, L.; Xu, Y.; Zhang, S.; Ross, I.M.; Ong, A.C.; Allwood, D.N. Fabrication and Luminescence of Monolayered Boron Nitride Quantum dots. Small 2014, 10, 60–65. [Google Scholar] [CrossRef]

- Stengl, V.; Henych, J.; Kormunda, M. Self-Assembled BN and BCN Quantum dots obtained from high intensity ultrasound exfoliated nanosheets. Sci. Adv. Mater. 2014, 6, 1106–1116. [Google Scholar] [CrossRef]

- Li, H.; Tay, R.Y.; Tsang, S.H.; Zhen, X.; Teo, E.H.T. Controllable Synthesis of highly luminescent boron nitride quantum dots. Small 2015, 11, 6491–6499. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.H.; Kotal, M.; Jang, M.H.; Lee, J.; Cho, Y.H.; Kim, W.J.; Oh, I.K. Defect engineering route to boron nitride quantum dots and edge-hydroxylated functionalization for bio-imaging. RSC Adv. 2016, 6, 73939–73946. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.K.; Yadav, S.K.; Savu, R. Mechanical pressure induced chemical cutting of boron nitride sheets into boron nitride quantum dots and optical properties. J. All. Comp. 2016, 683, 38–45. [Google Scholar] [CrossRef]

- Liu, M.; Xu, Y.; Wand, Y.; Chen, X.; Ji, X.; Niu, F.; Song, Z.; Liu, J. Boron nitride quantum dots with solvent-regulated blue/green photoluminescence and electrochemiluminescent behavior for versatile applications. Adv. Opt. Mater. 2017, 5, 1600661. [Google Scholar] [CrossRef]

- Huo, B.; Liu, B.; Chen, T.; Cui, L.; Xu, G.; Liu, M.; Liu, J. One-step synthesis of fluorescent boron nitride quantum dots via hydrothermal strategy using melamine as nitrogen source for the detection of ferric ions. Langmuir 2017, 40, 10673–10678. [Google Scholar] [CrossRef]

- Fan, L.; Zhou, Y.; He, M.; Tong, Y.; Zhong, X.; Fang, J.; Bu, X. Facile approach to controllable boron nitride quantum dots. J. Mater. Sci. 2017, 52, 13522–13532. [Google Scholar] [CrossRef]

- Dehghani, A.; Ardekani, S.M.; Lesani, P.; Hassan, M.; Gomes, V.G. Two-photon active boron nitride quantum dots for multiplexed imaging, intercellular ferric ion biosensing, and pH Tracking in living cells. ACS Appl. Bio Mater. 2018, 1, 975–984. [Google Scholar] [CrossRef]

- Ren, J.; Malfatti, L.; Enzo, S.; Carbonaro, C.M.; Calvillo, L.; Granozzi, G.; Innocenzi, P. Boron oxynitride two-colour fluorescent dots and their incorporation in a hybrid organic-inorganic film. J. Colloid Interface Sci. 2019. [Google Scholar] [CrossRef]

- Watanabe, K.; Taniguchi, T.; Kanda, H. Direct-bandgap properties and evidence for ultraviolet lasing of hexagonal boron nitride single crystal. Nat. Mater. 2003, 3, 404. [Google Scholar] [CrossRef]

- Lei, W.; Portehault, L.; Dimova, R.; Antonietti, M. Boron Carbon Nitride Nanostructures from Salt Melts: Tunable Water-Soluble Phosphors. J. Am. Chem. Soc. 2011, 133, 7121–7127. [Google Scholar] [CrossRef]

- Rong, M.; Yang, X.; Huang, L.; Chi, S.; Zhou, Y.; Shen, Y.; Chen, B.; Deng, X.; Liu, Z.Q. Hydrogen Peroxide-Assisted Ultrasonic Synthesis of BCNO QDs for Anthrax Biomarker Detection. ACS Appl. Mater. Interfaces 2019, 11, 2336–2343. [Google Scholar] [CrossRef]

- Mura, S.; Ludmerczki, R.; Carbonaro, C.M.; Ricci, P.C.; Casula, F.; Malfatti, L.; Innocenzi, P. Integrating sol-gel and carbon dots chemistry for the fabrication of fluorescent hybrid organic-inorganic films. Sci. Rep. 2019. submitted. [Google Scholar]

- Liu, X.; Ye, S.; Qiao, Y.; Dong, G.; Zhang, Q. Facile synthetic strategy for efficient and multi-color fluorescent BCNO nanocrystals. Chem. Commun. 2009, 4073–4075. [Google Scholar] [CrossRef]

- Iwasaki, H.; Ogi, T.; Iskandar, F.; Aishima, K.; Okuyama, K. Microwave synthesis of homogeneous and highly luminescent BCNO nanoparticles for the light emitting polymer materials. J. Lumin. 2015, 166, 148–155. [Google Scholar] [CrossRef]

- Kang, Y.; Yuan, B.; Zhang, D.; Ma, T.; Huang, X.; Chu, Z.; Lai, K. Green synthetic strategy of BCNO nanostructure and phosphor-based light emitting diodes. J. Lumin. 2016, 179, 501–510. [Google Scholar] [CrossRef]

- Xue, Q.; Zhang, H.; Zhu, M.; Wang, Z.; Pei, Z.; Huang, Y.; Huang, Y.; Song, X.; Zeng, H.; Zhi, C. Hydrothermal synthesis of blue-fluorescent monolayer BN and BCNO quantum dots for bio bioimaging probes. RSC Adv. 2016, 6, 79090–79094. [Google Scholar] [CrossRef]

- Ogi, T.; Kaihatsu, Y.; Iskandar, F.; Wang, W.N.; Okuyama, K. Facile Synthesis of New Full-Color-Emitting BCNO Phosphors with High Quantum Efficiency. Adv. Mater. 2008, 20, 3235–3238. [Google Scholar] [CrossRef]

| Precursors | Growth Conditions | Structure/Quantum Yield | Ref |

|---|---|---|---|

| (a) NaBH4 (b) CO(NH2)2 (c) CH5N3, HCl | Ball milling in a eutectic mixture of LiCl/KCl and then treated at 700 °C for 2 h | C, N-doped h-BNQDs (BCNO) nanoparticles with tunable luminescence from blue to green. a/b/c = 1/10/0, 1/0/1, 1/0/15, 1/0/10, 1/0/15 QY of 23%, 16%, 26%, 11%, and 5.6% | [103] |

| (a) B(OH)3 (b) CO(NH2)2 (c) PEG | Calcination at 750 °C for 1 h and ultrasonic treatment at 40 kHz for 3 h | BCNO QDs with a mean size of 10.1 nm. Broad luminescence with two components at 400 nm and 500 nm. QY = 19.9% | [104] |

| (a) H3BO3 (b) CO(NH2)2 (c) PEG MW = 20000) | Calcination of the raw materials mixture at 800 °C for 30 min | BCNO with tunable luminescence from blue to red with atomic ratio B/N = 0.2, 0.3, 0.4, 0.5; B/C = 0.5. QY = 9.3%, 20%, 17%, 5.2% | [106] |

| (a) H3BO3 (b) CO(NH2)2 (c) C6H8O7 | Microwave treatment at 800 W for 40 s after solvent evaporation | BCNO dots with tunable luminescence from blue to red. Molar ratio a/b/c = 1/1/2, 1/1/1, 1/2/1, 1/2/2, 1/1/0.5, 1/0.5/1, 1/0/1. QY = 50.9%, 40.0%, 7.5%, 19.9%, 23.2%, 41.2%, 3.5% | [107] |

| (a) B(OH)3 (b) CO(NH2)2 (c) C6H12O6 | Microwave treatment at 800 W for 10 min | BCNO particles of 2 nm in size Blue emission peaked at 450 nm with QY = 27.1% | [108] |

| B(OH)3 | Annealing at 800 °C for 5 h and hydrothermal treatment with NH3 (pH = 10) at 100 °C for 6 h and sonication for 2 h | BCNO nanoparticles with average size of 4.0 nm. PL emission at 410 nm with QY = 5% | [109] |

| (a) B(OH)3 (b) CO(NH2)2 (c) PEG (MW = 20000) | Calcination at 700−900 °C for 30−60 min | BCNO (t-BN) nanoparticles of 5 nm in size. Tunable luminescence in correspondence of different c/a ratios. External QY = 79% (λem = 469 nm); 76% (λem = 520 nm); 53% (λem = 542 nm); 10% (λem = 571 nm) | [110] |

| BN powder | Sonication of BN powder in DMF for 8 h and solvothermal treatment at 200 °C for 8 h | BCN nanoparticles lower than 4 nm PL emission peaked at 396 nm, tunable down to 450 nm. QY = 19.5% (λex = 330 nm) | [94] |

| BN powder | Sonication of BN powder in DMSO or DMF for 8 h | BNO nanoparticles of 2.5 nm. Blue PL emission peaked at 442 nm. QY = 8.6% (λex = 360 nm) | [51] |

| BN powder | Sonication of BN powder in EtOH, DMF, NMP for 3 h and solvothermal treatment at 180 °C for 10 h | BNCO dots. Blue-green emission EtOH: 4 nm; QY = 12.6% DMF: 2.8 nm; QY = 16.4% NMP: 2 nm QY = 21.3% | [97] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stagi, L.; Ren, J.; Innocenzi, P. From 2-D to 0-D Boron Nitride Materials, The Next Challenge. Materials 2019, 12, 3905. https://0-doi-org.brum.beds.ac.uk/10.3390/ma12233905

Stagi L, Ren J, Innocenzi P. From 2-D to 0-D Boron Nitride Materials, The Next Challenge. Materials. 2019; 12(23):3905. https://0-doi-org.brum.beds.ac.uk/10.3390/ma12233905

Chicago/Turabian StyleStagi, Luigi, Junkai Ren, and Plinio Innocenzi. 2019. "From 2-D to 0-D Boron Nitride Materials, The Next Challenge" Materials 12, no. 23: 3905. https://0-doi-org.brum.beds.ac.uk/10.3390/ma12233905