The Effect of Polarity and Hydrostatic Pressure on Operational Characteristics of Rutile Electrode in Underwater Welding

Abstract

:1. Introduction and Theoretical Approach

2. Materials and Methods

2.1. Equipment and Materials

2.2. Methodology

2.2.1. Welding Test

2.2.2. Data Processing

2.2.3. Electrode Tip Analysis

3. Results and Discussion

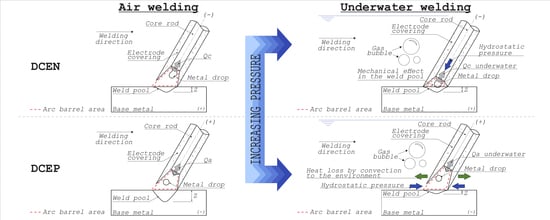

3.1. Polarity and Pressure Effect on Arc Phenomena

3.1.1. Voltage Welding and Characteristic Arc Length

3.1.2. Metal Transfer, Melting Rate of Electrode, and Voltage Drop in the Anodic and Cathodic Region (Ua+c)

3.2. Effect of the Pressure and Polarity on the Weld Bead Morphology of UWW

3.3. Closure

4. Conclusions

- For the reverse polarity configuration (DCEP), an increase in hydrostatic pressure generates an increase in the operating voltage and in the arc length, consequently leading to radial heat losses in the plasma column as a result of the greater surface area, as compared to that under air conditions. This behavior generates a decrease in the cross section of the weld bead, as reflected in lower reinforcement, width, and penetration values.

- In contrast, for the configuration of the electrode on the negative pole (DCEN), the hydrostatic pressure affects the generation of energy in the arc–electrode connection. This decreases the fusion efficiency, and therefore causes a drop in the average welding voltage with an increase in depth, together with a shorter arc length and an evident increase in the number of short-circuit events.

- For DCEN, a shorter arc length minimizes radial heat losses in the plasma column, and thus more heat is transferred to the surface of the workpiece, developing a thermal effect on the weld bead geometry. At the same time, the occurrence of short circuits develops a mechanical effect on the melt pool, possibly guaranteeing that the weld bead geometry remains unchanged as the operating depth increases.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rowe, M.D.; Liu, S. Recent developments in underwater wet welding. Sci. Technol. Weld. Join. 2001, 6, 387–396. [Google Scholar] [CrossRef]

- Shi, Y.; Zheng, Z.; Huang, J. Sensitivity model for prediction of bead geometry in underwater wet flux cored arc welding. Trans. Nonferrous Met. Soc. China 2013, 23, 1977–1984. [Google Scholar] [CrossRef]

- Ando, S.; Asahina, T. A Study on the Metallurgical Properties of Steel Welds with Underwater Gravity Welding. In Proceedings of the Underwater Welding. International Institute of Welding, Trondheim, Norway, 27–28 June 1983; Pergamon Press: Oxford, UK, 1983; pp. 255–261. [Google Scholar]

- Pope, A.M.; Teixeira, J.C.G.; Dos Santos, V.R.; Paes, M.T.P.; Liu, S. The effect of nickel on the mechanical properties of high-oxygen underwater wet welds. J. Offshore Mech. Arct. Eng. 1996, 118, 165–168. [Google Scholar] [CrossRef]

- Suga, Y.; Hasui, A. The Effect of Pressure on Welding Results and Welding Phenomena in Gravity Arc Welding. Jpn. Weld. Soc. Trans. 1990, 21, 78–84. [Google Scholar]

- Tomków, J.; Fydrych, D.; Wilk, K. Effect of Electrode Waterproof Coating on Quality of Underwater Wet Welded Joints. Materials 2020, 13, 2947. [Google Scholar] [CrossRef]

- Klett, J.; Hecht-Linowitzki, V.; Grünzel, O.; Schmidt, E.; Maier, H.J.; Hassel, T. Effect of the water depth on the hydrogen content in SMAW wet welded joints. SN Appl. Sci. 2020, 2, 1–14. [Google Scholar] [CrossRef]

- Chen, H.; Guo, N.; Liu, C.; Zhang, X.; Xu, C.; Wang, G. Insight into hydrostatic pressure effects on diffusible hydrogen content in wet welding joints using in-situ X-ray imaging method. Int. J. Hydrog. Energy 2020, 45, 10219–10226. [Google Scholar] [CrossRef]

- DuPont, J.N.; Babu, S.; Liu, S. Welding of Materials for Energy Applications. Met. Mater. Trans. A 2013, 44, 3385–3410. [Google Scholar] [CrossRef]

- Pessoa, E.C.P. Estudo da Variação da Porosidade ao Longo do Cordão em Soldas Subaquáticas Molhadas. Ph.D. Thesis, Universidade Federal de Minas Gerais, Belo Horizonte–MG, Brazil, 2007. (In Portuguese). [Google Scholar]

- Szelagowski, P.; Ibarra, S.; Ohliger, A.; dos Santos, J.F. In-Situ Post-Weld Heat Treatment of Wet Welds. Offshore Technol. Conf. 1992. [Google Scholar] [CrossRef]

- Grubbs, C.E.; Bertelmann, A.E.; Ibarra, S.; Liu, S.; Marshall, D.J.; Olson, D.L. Welding Handbook-Materials and Applications, Part 1. AWS 1996, 3, 446–500. [Google Scholar]

- Mazzaferro, J.A.E. Estudo da Estabilidade do Arco Elétrico na Soldagem Subaquática com Eletrodos Revestidos. Ph.D. Thesis, Universidade Federal do Rio Grande do Sul, Porto Alegre–RS, Brazil, 1998. (In Portuguese). [Google Scholar]

- Tsai, C.L.; Masubuchi, K. Interpretive Report on Underwater Welding. Weld. Res. Counc. Bull. 1977, 224, 1–37. [Google Scholar]

- Giedt, W.H.; Tallerico, L.N.; Fuerschbach, P.W. GTA welding efficiency: Calorimetric and temperature field measurements. Weld. J. 1989, 68, 28. [Google Scholar]

- Essers, W.G.; Walter, R. Heat transfer and penetration mechanisms with GMA and plasma-GMA welding. Weld. J. 1981, 60, 37–42. [Google Scholar]

- Cirino, L.M.; Dutra, J.C. The influence of positive polarity time on GTAW AC of aluminium. Weld. Int. 2010, 24, 825–833. [Google Scholar] [CrossRef]

- Waszink, J.H.; Piena, M.J. Thermal Processes in Covered Electrodes. Weld. Res. Suppl. 1985, 64, 37–48. [Google Scholar]

- Allum, C.J. The Characteristics and Structure of High Pressure (1-42 bars) Gas Tungsten Arcs. Ph.D. Thesis, Cranfield Institute of Technology, Bedford, UK, 1982. [Google Scholar]

- Fuerschbach, P.W. Cathodic cleaning and heat input in variable polarity plasma arc welding of aluminum. Weld. J. 1998, 77, 76s–85s. [Google Scholar]

- Scotti, A.; Reis, R.P.; Liskevych, O. Modelo descritivo do fluxo de calor em soldagem a arco visando o conceito de calor imposto efetivo. Soldag Inspeção 2012, 17, 166–172. (In Portuguese) [Google Scholar] [CrossRef]

- Wainer, E.; Brandi, S.D.; de Mello, F.D.H. Soldagem: Processos e Metalurgia; Editora Blucher: São Paulo, Brazil, 1992. (In Portuguese) [Google Scholar]

- Quites, A.M.; Dutra, J.C. Tecnologia da Soldagem a Arco Voltaico; Edeme: Florianópolis, Brazil, 1979. (In Portuguese) [Google Scholar]

- Marques, P.V.; Modenesi, P.J. Algumas equações úteis em soldagem. Soldag Inspeção 2014, 19, 91–101. (In Portuguese) [Google Scholar] [CrossRef]

- Lesnewich, A. Control of melting rate and metal transfer in gas-shielded metal-arc welding—Part I—Control of electrode melting rate. Weld. J. 1958, 37, 343–353. [Google Scholar]

- Nunes, J.L. Metal Transfer Investigations with a Synergic Power Supply. MSc Thesis, Cranfield Institute of Technology, Bedford, UK, 1982. [Google Scholar]

- Lancaster, J. The physics of welding. Phys. Technol. 1984, 15, 73–79. [Google Scholar] [CrossRef]

- Scotti, A.; Ponomarev, V. Soldagem MIG/MAG: Melhor Entendimento, Melhor Desempenho; Artliber: São Paulo, Brazil, 2008. (In Portuguese) [Google Scholar]

- Modenesi, P.J. Introdução à Física do Arco Elétrico. 2012. Available online: https://demet.eng.ufmg.br/wp-content/uploads/2012/10/fundamentosfisicos1.pdf (accessed on 15 August 2020).

- Arias, A.R.; Bracarense, A.Q. Fatigue crack growth rate in underwater wet welds: Out of water evaluation. Weld. Int. 2017, 31, 348–353. [Google Scholar] [CrossRef]

- Brown, A.J.; Brown, R.T.; Tsai, C.L.; Masubuchi, K. Report on Fundamental Research on Underwater Welding. MIT Sea Gran Report 1974. Available online: https://repository.library.noaa.gov/view/noaa/9979/noaa_9979_DS1.pdf (accessed on 15 August 2020).

- Uribe, A.M.M.; Bracarense, A.Q.; Pessoa, E.C.P.; dos Santos, V.R. Influência da Polaridade Sobre a Estabilidade do Processo de Soldagem Subaquática Molhada com Eletrodo Revestido. Soldag Inspeção 2017, 22, 429–441. (In Portuguese) [Google Scholar] [CrossRef]

- Pessoa, E.C.P.; Ribeiro, L.F.; Bracarense, A.Q.; Dias, W.C.; Andrade, L.G.D.; Liu, S. Arc stability indexes evaluation on underwater wet welding. In Proceedings of the 29th International Conference on Ocean, Offshore and Arctic Engineering (OMAE 2010), Shanghai, China, 6–11 July 2010; pp. 1–7. [Google Scholar]

- Modenesi, P.J.; de S Costa, M.C.M.; Santana, I.J.; Berganholi, J.P.P. Estudo de alguns parâmetros básicos da soldagem GMAW com transferência por curto-circuito. Soldag Inspeção 2011, 16, 12–21. (In Portuguese) [Google Scholar] [CrossRef]

- De Santana, I.J.; Modenesi, P.J. Modelagem matemática do processo de soldagem GMAW: Transferência por vôo livre. Soldag Inspeção 2011, 16, 213–222. (In Portuguese) [Google Scholar] [CrossRef]

- Modenesi, P.J.; De Avelar, R.C. The influence of small variations of wire characteristics on gas metal arc welding process stability. J. Mater. Process. Technol. 1999, 86, 226–232. [Google Scholar] [CrossRef]

- Omajene, J.E.; Martikainen, J.; Kah, P.; Pirinen, M. Fundamental Difficulties Associated with Underwater Wet Welding. Int. J. Eng. Res. Appl. 2014, 4, 26–31. [Google Scholar]

- De Mello Liberato, F.; Modenesi, P.J.; Bracarense, A.Q. Aspectos Operacionais da Soldagem Subaquática Molhada com Eletrodos Revestidos Inoxidável Austenítico. Soldag Inspeção 2018, 23, 277–291. (In Portuguese) [Google Scholar] [CrossRef]

- Scotti, A.; Ponomarev, V.; da Costa, A.V. A methodology for voltage drop determination in GMA welding: Arcs with short-circuiting metal transfer. Eur. Phys. J. Appl. Phys. 2006, 34, 231–236. [Google Scholar] [CrossRef]

- Richardson, I.; Nixon, J.H. Open arc pulsed current GMAW: Application to hyperbaric welding operations. In Proceedings of the ASM International Welding Conference, Toronto, ON, Canada, 15–17 October 1985; pp. 153–163. [Google Scholar]

- Menezes, P.H.R.; Pessoa, E.C.P.; Bracarense, A.Q. Comparison of underwater wet welding performed with silicate and polymer agglomerated electrodes. J. Mater. Process. Technol. 2019, 266, 63–72. [Google Scholar] [CrossRef]

- Scotti, A.; Ponomarev, V.; Lucas, W. A scientific application oriented classification for metal transfer modes in GMA welding. J. Mater. Process. Technol. 2012, 212, 1406–1413. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno-Uribe, A.M.; Bracarense, A.Q.; Pessoa, E.C.P. The Effect of Polarity and Hydrostatic Pressure on Operational Characteristics of Rutile Electrode in Underwater Welding. Materials 2020, 13, 5001. https://0-doi-org.brum.beds.ac.uk/10.3390/ma13215001

Moreno-Uribe AM, Bracarense AQ, Pessoa ECP. The Effect of Polarity and Hydrostatic Pressure on Operational Characteristics of Rutile Electrode in Underwater Welding. Materials. 2020; 13(21):5001. https://0-doi-org.brum.beds.ac.uk/10.3390/ma13215001

Chicago/Turabian StyleMoreno-Uribe, Andrés M., Alexandre Q. Bracarense, and Ezequiel C. P. Pessoa. 2020. "The Effect of Polarity and Hydrostatic Pressure on Operational Characteristics of Rutile Electrode in Underwater Welding" Materials 13, no. 21: 5001. https://0-doi-org.brum.beds.ac.uk/10.3390/ma13215001