Application of Electrically Conducting Nanocomposite Material Polythiophene@NiO/Frt/GOx as Anode for Enzymatic Biofuel Cells

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of NiO

2.2. Synthesis of Polythiophene (Pth)

2.3. Preparation of Composite Dispersion

2.4. Preparation of the Electrode

3. Results and Discussion

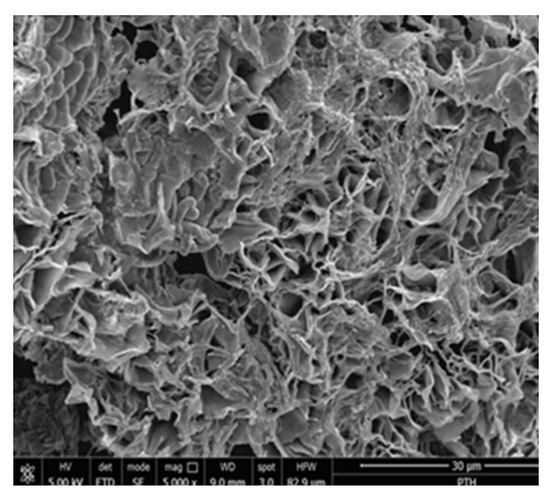

3.1. SEM and EDX Analyses

3.2. Electrochemical Analyses

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alanne, K.; Cao, S. An overview of the concept and technology of ubiquitous energy. Appl. Energy 2019, 238, 284–302. [Google Scholar] [CrossRef]

- Cosnier, S.; Gross, A.J.; Giroud, F.; Holzinger, M. Beyond the hype surrounding biofuel cells: What’s the future of enzymatic fuel cells? Curr. Opin. Electrochem. 2018, 12, 148–155. [Google Scholar] [CrossRef]

- Perveen, R.; Nasar, A.; Inamuddin; Asiri, A.M.; Mishra, A.K. Optimization of MnO2-graphene/polythioaniline (MnO2-G/PTA) hybrid nanocomposite for the application of biofuel cell bioanode. Int. J. Hydrogen Energy 2018, 43, 15144–15154. [Google Scholar] [CrossRef]

- Kuwahara, T.; Kameda, M.; Isozaki, K.; Toriyama, K.; Kondo, M.; Shimomura, M. Bioelectrocatalytic fructose oxidation with fructose dehydrogenase-bearing conducting polymer films for biofuel cell application. React. Funct. Polym. 2017, 116, 87–91. [Google Scholar] [CrossRef]

- Neto, S.A.; Zimbardi, A.L.; Cardoso, F.P.; Crepaldi, L.B.; Minteer, S.D.; Jorge, J.A.; Furriel, R.P.; De Andrade, A.R. Potential application of laccase from Pycnoporus sanguineus in methanol/O2 biofuel cells. J. Electroanal. Chem. 2016, 765, 2–7. [Google Scholar] [CrossRef]

- Perveen, R.; Inamuddin; Nasar, A.; Beenish; Asiri, A.M. Synthesis and characterization of a novel electron conducting biocomposite as biofuel cell anode. Int. J. Biol. Macromol. 2018, 106, 755–762. [Google Scholar] [CrossRef]

- Ramanavicius, A.; Kausaite, A.; Ramanaviciene, A. Enzymatic biofuel cell based on anode and cathode powered by ethanol. Biosens. Bioelectron. 2008, 24, 761–766. [Google Scholar] [CrossRef]

- Bullen, R.A.; Arnot, T.C.; Lakeman, J.B.; Walsh, F.C. Biofuel cells and their development. Biosens. Bioelectron. 2006, 21, 2015–2045. [Google Scholar] [CrossRef] [Green Version]

- Perveen, R.; Haque, S.; Nasar, A.; Asiri, A.M.; Ashraf, G.M. Electrocatalytic performance of chemically synthesized PIn-Au-SGO composite toward mediated biofuel cell anode. Sci. Rep. 2017, 7, 13353. [Google Scholar] [CrossRef] [Green Version]

- Kalathil, S.; Pant, D. Nanotechnology to rescue bacterial bidirectional extracellular electron transfer in bioelectrochemical systems. RSC Adv. 2016, 6, 30582–30597. [Google Scholar] [CrossRef] [Green Version]

- Zebda, A.; Alcaraz, J.P.; Vadgama, P.; Shleev, S.; Minteer, S.D.; Boucher, F.; Cinquin, P.; Martin, D.K. Challenges for successful implantation of biofuel cells. Bioelectrochemistry 2018, 124, 57–72. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Zhang, L.; Zhang, Z.; Guo, S.; Shang, H.; Li, Y.; Liu, J. Wearable biofuel cells based on the classification of enzyme for high power outputs and lifetimes. Biosens. Bioelectron. 2019, 125, 40–52. [Google Scholar] [CrossRef]

- Navaee, A.; Salimi, A. FAD-based glucose dehydrogenase immobilized on thionine/AuNPs frameworks grafted on amino-CNTs: Development of high power glucose biofuel cell and biosensor. J. Electroanal. Chem. 2018, 815, 105–113. [Google Scholar] [CrossRef]

- Ocasio-Vega, C.; Delgado, R.; Abad-Guamán, R.; Carabaño, R.; Carro, M.D.; García, J. Effect of cellobiose supplementation on growth performance and health in rabbits. Livest. Sci. 2019, 221, 163–171. [Google Scholar] [CrossRef]

- Arrocha, A.A.; Cano-Castillo, U.; Aguila, S.A.; Vazquez-Duhalt, R. Enzyme orientation for direct electron transfer in an enzymatic fuel cell with alcohol oxidase and laccase electrodes. Biosens. Bioelectron. 2014, 61, 569–574. [Google Scholar] [CrossRef]

- Campbell, A.S.; Murata, H.; Carmali, S.; Matyjaszewski, K.; Islam, M.F.; Russell, A.J. Polymer-based protein engineering grown ferrocene-containing redox polymers improve current generation in an enzymatic biofuel cell. Biosens. Bioelectron. 2016, 86, 446–453. [Google Scholar] [CrossRef] [Green Version]

- Khoshnejad, M.; Parhiz, H.; Shuvaev, V.V.; Dmochowski, I.J.; Muzykantov, V.R. Ferritin-based drug delivery systems: Hybrid nanocarriers for vascular immunotargeting. J. Control. Release 2018, 282, 13–24. [Google Scholar] [CrossRef]

- Beenish; Inamuddin; Ahamed, M.I.; Asiri, A.M.; AlAmry, K.A. Biocompatible mediated bioanode prepared by using poly(3,4-ethylene dioxythiophene) poly(styrene sulfonate) (PEDOT:PSS) and sulfonated graphene oxide integrated enzyme for biofuel cells applications. Mater. Sci. Energy Technol. 2018, 1, 63–69. [Google Scholar]

- Kumar, A.; Sharma, S.; Pandey, L.M.; Chandra, P. Nanoengineered material based biosensing electrodes for enzymatic biofuel cells applications. Mater. Sci. Energy Technol. 2018, 1, 38–48. [Google Scholar] [CrossRef]

- Pugazhendhi, A.; Shobana, S.; Nguyen, D.D.; Banu, J.R.; Sivagurunathan, P.; Chang, S.W.; Ponnusamy, V.K.; Kumar, G. Application of nanotechnology (nanoparticles) in dark fermentative hydrogen production. Int. J. Hydrogen Energy 2019, 44, 1431–1440. [Google Scholar] [CrossRef]

- Xu, J.; Wang, L. Carbon Nanomaterials. In Nano-Inspired Biosensors for Protein Assay with Clinical Applications 3–38; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Zhao, Y.; Fan, L.; Zhang, Y.; Que, Q.; Hong, B. Three-dimensional PtxNi1−x nanoclusters supported on multiwalled carbon nanotubes in enzyme-free glucose biofuel cells. J. Power Sources 2015, 296, 30–39. [Google Scholar] [CrossRef]

- Wang, S.C.; Yang, F.; Silva, M.; Zarow, A.; Wang, Y.; Iqbal, Z. Membrane-less and mediator-free enzymatic biofuel cell using carbon nanotube/porous silicon electrodes. Electrochem. Commun. 2009, 11, 34–37. [Google Scholar] [CrossRef]

- Korani, A.; Salimi, A.; Hadadzadeh, H. Nickel-phendione complex covalently attached onto carbon nanotube/cross linked glucose dehydrogenase as bioanode for glucose/oxygen compartment-less biofuel cell. J. Power Sources 2015, 282, 586–595. [Google Scholar] [CrossRef]

- Kananizadeh, N.; Lee, J.; Mousavi, E.S.; Rodenhausen, K.B.; Sekora, D.; Schubert, M.; Bartelt-Hunt, S.; Schubert, E.; Zhang, J.; Li, Y. Deposition of titanium dioxide nanoparticles onto engineered rough surfaces with controlled heights and properties. Colloids Surf. A Physicochem. Eng. Asp. 2019, 571, 125–133. [Google Scholar] [CrossRef]

- Kumar, S.; Umar, M.; Saifi, A.; Kumar, S.; Augustine, S.; Srivastava, S.; Malhotra, B.D. Electrochemical paper based cancer biosensor using iron oxide nanoparticles decorated PEDOT:PSS. Anal. Chim. Acta 2019, 1056, 135–145. [Google Scholar] [CrossRef] [PubMed]

- Bunga, Y.; Kataky, R. Silver nanoparticle impacts on gold electrode surfaces in flow-injection configuration. Sens. Actuators B Chem. 2019, 290, 140–146. [Google Scholar] [CrossRef]

- Bollella, P.; Fusco, G.; Stevar, D.; Gorton, L.; Ludwig, R.; Ma, S.; Boer, H.; Koivula, A.; Tortolini, C.; Favero, G.; et al. A Glucose/oxygen enzymatic fuel cell based on gold nanoparticles modified graphene screen-printed electrode. Proof-of-concept in human saliva. Sens. Actuators B Chem. 2018, 256, 921–930. [Google Scholar] [CrossRef]

- Waclawik, E.R.; Chang, J.; Ponzoni, A.; Concina, I.; Zappa, D.; Comini, E.; Motta, N.; Faglia, G.; Sberveglieri, G. Functionalised zinc oxide nanowire gas sensors: Enhanced NO2 gas sensor response by chemical modification of nanowire surfaces. Beilstein J. Nanotechnol. 2012, 3, 368–377. [Google Scholar] [CrossRef] [Green Version]

- Safaei-Ghomi, J.; Ghasemzadeh, M.A. Zinc oxide nanoparticles: A highly efficient and readily recyclable catalyst for the synthesis of xanthenes. Chin. Chem. Lett. 2012, 23, 1225–1229. [Google Scholar] [CrossRef]

- Lu, P.-J.; Huang, S.-C.; Chen, Y.-P.; Chiueh, L.-C.; Shih, D.Y.-C. Analysis of titanium dioxide and zinc oxide nanoparticles in cosmetics. J. Food Drug Anal. 2015, 23, 587–594. [Google Scholar] [CrossRef] [Green Version]

- Samah, M.; Merabet, S.; Bouguerra, M.; Bouhelassa, M.; Ouhenia, S.; Bouzaza, A. Photo-oxidation process of indole in aqueous solution with ZnO Catalyst: Study and optimization. Kinet. Catal. 2011, 52, 34–39. [Google Scholar] [CrossRef]

- Paganini, M.C.; Giorgini, A.; Gonçalves, N.P.; Gionco, C.; Prevot, A.B.; Calza, P. New insight into zinc oxide doped with iron and its exploitation to pollutants abatement. Catal. Today 2019, 328, 230–234. [Google Scholar] [CrossRef]

- El-Kemary, M.; Nagy, N.; El-Mehasseb, I. Nickel oxide nanoparticles: Synthesis and spectral studies of interactions with glucose. Mater. Sci. Semicond. Process. 2013, 16, 1747–1752. [Google Scholar] [CrossRef]

- Eluri, R.; Paul, B. Synthesis of nickel nanoparticles by hydrazine reduction: Mechanistic study and continuous flow synthesis. J. Nanoparticle Res. 2012, 14, 800. [Google Scholar] [CrossRef]

- Pascariu, P.; Vernardou, D.; Suchea, M.P.; Airinei, A.; Ursu, L.; Bucur, S.; Tudose, I.V.; Ionescu, O.N.; Koudoumas, E. Tuning electrical properties of polythiophene/nickel nanocomposites via fabrication. Mater. Des. 2019, 182, 108027. [Google Scholar] [CrossRef]

- Ruscello, M.; Sarkar, T.; Levitsky, A.; Matrone, G.M.; Droseros, N.; Schlisske, S.; Sachs, E.; Reiser, P.; Mankel, E.; Kowalsky, W.; et al. Nanocomposite of nickel oxide nanoparticles and polyethylene oxide as printable hole transport layer for organic solar cells. Sustain. Energy Fuels 2019, 3, 1418–1426. [Google Scholar] [CrossRef] [Green Version]

- Haque, S.; Inamuddin; Nasar, A.; Asiri, A.M. Fabrication and characterization of electrochemically prepared bioanode (polyaniline/ferritin/glucose oxidase) for biofuel cell application. Chem. Phys. Lett. 2018, 692, 277–284. [Google Scholar] [CrossRef]

- Haque, S.; Inamuddin; Nasar, A.; Rajender, B.; Khan, A.; Asiri, A.M.; Ashraf, G.M. Optimization of glucose powered biofuel cell anode developed by polyaniline-silver as electron transfer enhancer and ferritin as biocompatible redox mediator. Sci. Rep. 2017, 7, 12703. [Google Scholar] [CrossRef] [Green Version]

- Zeng, G.; Li, W.; Ci, S.; Jia, J.; Wen, Z. Highly dispersed NiO nanoparticles decorating graphene nanosheets for non-enzymatic glucose sensor and biofuel cell. Sci. Rep. 2016, 6, 36454. [Google Scholar] [CrossRef] [Green Version]

- Inamuddin; Kashmery, H.A. Ternary graphene@polyaniline-TiO2 composite for glucose biofuel cell anode application. Int. J. Hydrogen Energy 2019, 44, 22173–22180. [Google Scholar]

- Laviron, E. General expression of the linear potential sweep voltammogram in the case of diffusionless electrochemical systems. J. Electroanal. Chem. Interfacial Electrochem. 1979, 101, 19–28. [Google Scholar] [CrossRef]

- Nicholson, R.S. Theory and application of cyclic voltammetry for measurement of electrode reaction kinetics. Anal. Chem. 1965, 37, 1351–1355. [Google Scholar] [CrossRef]

- Haque, S.; Nasar, A.; Inamuddin; Asiri, A.M. Preparation and characterization of a bioanode (GC/MnO2/PSS/Gph/Frt/GOx) for biofuel cell application. Int. J. Hydrogen Energy 2019, 44, 7308–7319. [Google Scholar] [CrossRef]

- Shim, J.; Woo, J.-J.; Moon, S.-H.; Kim, G.-Y. A preparation of a single-layered enzyme-membrane using asymmetric pBPPO base film for development of pesticide detecting biosensor. J. Memb. Sci. 2009, 330, 341–348. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Inamuddin; Alamry, K.A. Application of Electrically Conducting Nanocomposite Material Polythiophene@NiO/Frt/GOx as Anode for Enzymatic Biofuel Cells. Materials 2020, 13, 1823. https://0-doi-org.brum.beds.ac.uk/10.3390/ma13081823

Inamuddin, Alamry KA. Application of Electrically Conducting Nanocomposite Material Polythiophene@NiO/Frt/GOx as Anode for Enzymatic Biofuel Cells. Materials. 2020; 13(8):1823. https://0-doi-org.brum.beds.ac.uk/10.3390/ma13081823

Chicago/Turabian StyleInamuddin, and Khalid A. Alamry. 2020. "Application of Electrically Conducting Nanocomposite Material Polythiophene@NiO/Frt/GOx as Anode for Enzymatic Biofuel Cells" Materials 13, no. 8: 1823. https://0-doi-org.brum.beds.ac.uk/10.3390/ma13081823