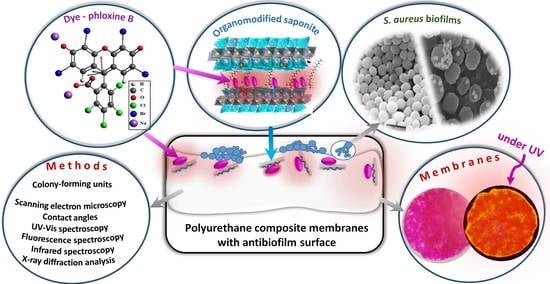

Surface Characterization and Anti-Biofilm Effectiveness of Hybrid Films of Polyurethane Functionalized with Saponite and Phloxine B

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Bacterial Strains

2.3. Synthesis of Modified and Functionalized Organoclay Films

2.4. Preparation of PU Membranes with Functionalized Surfaces

2.5. Preliminary Tests

2.6. Interaction of Polyurethane Composite with the Medium Used in Biological Experiments

2.7. Physico-Chemical Characterization of Polyurethane Membranes

2.8. Anti-Biofilm Assay by Photodynamic Inactivation

2.9. Scanning Electron Microscopy of Biofilms

2.10. Mathematical, Statistical, and Chemometric Methods

3. Results and Discussion

3.1. Selection of Optimal Polyurethane Composite Membranes

3.2. Phloxine B Release from Polymer Composite Membranes

3.3. Physico-Chemical Characterization of the Membranes

3.3.1. X-ray Diffraction

3.3.2. Infrared Spectroscopy

3.3.3. Phloxine Spectral Properties in the Visible Range

3.3.4. Surface Properties

3.4. Biological Experiments

3.4.1. Anti-Biofilm Assays by Photodynamic Inactivation

3.4.2. Scanning Electron Microscopy

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Murugesan, S.; Scheibel, T. Copolymer/Clay Nanocomposites for Biomedical Applications. Adv. Funct. Mater. 2020, 30, 1908101. [Google Scholar] [CrossRef] [Green Version]

- Buruga, K.; Song, H.; Shang, J.; Bolan, N.; Jagannathan, T.K.; Kim, K.H. A review on functional polymer-clay based nanocomposite membranes for treatment of water. J. Hazard. Mater. 2019, 379, 120584. [Google Scholar] [CrossRef] [PubMed]

- Dawson, J.I.; Oreffo, R.O.C. Clay: New opportunities for tissue regeneration and biomaterial design. Adv. Mater. 2013, 25, 4069–4086. [Google Scholar] [CrossRef] [PubMed]

- Jayrajsinh, S.; Shankar, G.; Agrawal, Y.K.; Bakre, L. Montmorillonite nanoclay as a multifaceted drug-delivery carrier: A review. J. Drug Deliv. Sci. Technol. 2017, 39, 200–209. [Google Scholar] [CrossRef]

- Gmoshinski, I.V.; Bagryantseva, O.V.; Arnautov, O.V.; Khotimchenko, S.A. Nanoclays in food products: Benefits and possible risks (literature review). Health Risk Anal. 2020, 2020, 142–164. [Google Scholar] [CrossRef]

- Maisanaba, S.; Pichardo, S.; Puerto, M.; Gutiérrez-Praena, D.; Cameán, A.M.; Jos, A. Toxicological evaluation of clay minerals and derived nanocomposites: A review. Environ. Res. 2015, 138, 233–254. [Google Scholar] [CrossRef] [PubMed]

- Brzeska, J.; Tercjak, A.; Sikorska, W.; Mendrek, B.; Kowalczuk, M.; Rutkowska, M. Degradability of polyurethanes and their blends with polylactide, chitosan and starch. Polymers 2021, 13, 1202. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Dong, Q.; Xiao, Y.; Du, Q.; Huselsteind, C.; Zhang, T.; He, X.; Tian, W.; Chen, Y. A biodegradable soy protein isolate-based waterborne polyurethane composite sponge for implantable tissue engineering. J. Mater. Sci. Mater. Med. 2020, 31, 120. [Google Scholar] [CrossRef]

- Kim, I.K.; Yeum, J.H. Electrospinning fabrication and characterization of polyvinyl alcohol/waterborne polyurethane/montmorillonite nanocomposite nanofibers. Polymer 2011, 35, 553–557. [Google Scholar] [CrossRef]

- Liu, H.; Shukla, S.; Vera-González, N.; Tharmalingam, N.; Mylonakis, E.; Fuchs, B.B.; Shukla, A. Auranofin Releasing Antibacterial and Antibiofilm Polyurethane Intravascular Catheter Coatings. Front. Cell. Infect. Microbiol. 2019, 9, 37. [Google Scholar] [CrossRef] [Green Version]

- Vishwakarma, A.; Dang, F.; Ferrell, A.; Barton, H.A.; Joy, A. Peptidomimetic Polyurethanes Inhibit Bacterial Biofilm Formation and Disrupt Surface Established Biofilms. J. Am. Chem. Soc. 2021, 143, 9440–9449. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.; Kim, D.; Kim, J.; Oh, J.K.; Castaneda, H.; Kim, J.H. Antimicrobial Activities of Thermoplastic Polyurethane/Clay Nanocomposites against Pathogenic Bacteria. ACS Appl. Biol. Mater. 2020, 3, 6672–6679. [Google Scholar] [CrossRef]

- Tseng, H.J.; Lin, J.J.; Ho, T.T.; Tseng, S.M.; Hsu, S.H. The biocompatibility and antimicrobial activity of nanocomposites from polyurethane and nano silicate platelets. J. Biomed. Mater. Res.—Part A 2011, 99A, 192–202. [Google Scholar] [CrossRef]

- Bujdáková, H.; Bujdáková, V.; Májeková-Koščová, H.; Gaálová, B.; Bizovská, V.; Boháč, P.; Bujdák, J. Antimicrobial activity of organoclays based on quaternary alkylammonium and alkylphosphonium surfactants and montmorillonite. Appl. Clay Sci. 2018, 158, 21–28. [Google Scholar] [CrossRef]

- Melinte, V.; Buruianə, T.; Buruianə, E.C. Effect of organomodified montmorillonite on the properties of some piperazinium polyurethanes. Rev. Roum. Chim. 2015, 60, 769–775. [Google Scholar]

- Kurt, P.; Wood, L.; Ohman, D.E.; Wynne, K.J. Highly effective contact antimicrobial surfaces via polymer surface modifiers. Langmuir 2007, 23, 4719–4723. [Google Scholar] [CrossRef] [PubMed]

- Nigmatullin, R.; Gao, F. Onium-functionalised polymers in the design of non-leaching antimicrobial surfaces. Macromol. Mater. Eng. 2012, 297, 1038–1074. [Google Scholar] [CrossRef]

- Samrot, A.V.; Mohamed, A.A.; Faradjeva, E.; Jie, L.S.; Sze, C.H.; Arif, A.; Sean, T.C.; Michael, E.N.; Mun, C.Y.; Qi, N.X.; et al. Mechanisms and impact of biofilms and targeting of biofilms using bioactive compounds—A review. Medicina 2021, 57, 839. [Google Scholar] [CrossRef]

- Karygianni, L.; Ren, Z.; Koo, H.; Thurnheer, T. Biofilm Matrixome: Extracellular Components in Structured Microbial Communities. Trends Microbiol. 2020, 28, 668–681. [Google Scholar] [CrossRef]

- Fletcher, M. The Physiological Activity of Bacteria Attached to Solid Surfaces. Adv. Microb. Physiol. 1991, 32, 53–85. [Google Scholar] [CrossRef]

- Saha, K.; Dutta, K.; Basu, A.; Adhikari, A.; Chattopadhyay, D.; Sarkar, P. Controlled delivery of tetracycline hydrochloride intercalated into smectite clay using polyurethane nanofibrous membrane for wound healing application. Nano-Struct. Nano-Objects 2020, 21, 100418. [Google Scholar] [CrossRef]

- Dadi, N.C.t.; Dohál, M.; Medvecká, V.; Bujdák, J.; Koči, K.; Zahoranová, A.; Bujdáková, H. Physico-Chemical Characterization and Antimicrobial Properties of Hybrid Film Based on Saponite and Phloxine B. Molecules 2021, 26, 325. [Google Scholar] [CrossRef] [PubMed]

- Kureková, V.B.; Belušáková, S.; Boháč, P.; Bujdák, J. Resonance energy transfer in the systems of smectite modified with a fluorescent cationic polymer and a photosensitizer. Appl. Clay Sci. 2019, 183, 105326. [Google Scholar] [CrossRef]

- Furka, S.; Furka, D.; Dadi, N.C.T.C.T.; Palacka, P.; Hromníková, D.; Dueñas Santana, J.A.; Pineda, J.D.; Casas, S.D.; Bujdák, J. Novel antimicrobial materials designed for the 3D printing of medical devices used during the COVID-19 crisis. Rapid Prototyp. J. 2021, 27, 890–904. [Google Scholar] [CrossRef]

- Przybyłek, M.; Biakowska, A.; Bakar, M.; Kosikowska, U.; Szymborski, T. Effect of aging conditions on the mechanical properties and antimicrobial activity of elastomer nanocomposites. J. Polym. Eng. 2019, 39, 316–325. [Google Scholar] [CrossRef]

- Patel, D.K.; Biswas, A.; Maiti, P. Nanoparticle-Induced Phenomena in Polyurethanes. In Advances in Polyurethane Biomaterials; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 171–194. [Google Scholar]

- Rudawska, A.; Jacniacka, E. Analysis for determining surface free energy uncertainty by the Owen–Wendt method. Int. J. Adhes. Adhes. 2009, 29, 451–457. [Google Scholar] [CrossRef]

- Rasooly, R. Expanding the bactericidal action of the food color additive phloxine B to gram-negative bacteria. FEMS Immunol. Med. Microbiol. 2005, 45, 239–244. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shiotsu-Ogura, Y.; Yoshida, A.; Kan, P.; Sasaki, H.; Toyama, T.; Izukuri, K.; Hamada, N.; Yoshino, F. Antimicrobial photodynamic therapy using a plaque disclosing solution on Streptococcus mutans. Photodiagn. Photodyn. Ther. 2019, 26, 252–257. [Google Scholar] [CrossRef]

- Ishiyama, K.; Nakamura, K.; Ikai, H.; Kanno, T.; Kohno, M.; Sasaki, K.; Niwano, Y. Bactericidal Action of Photogenerated Singlet Oxygen from Photosensitizers Used in Plaque Disclosing Agents. PLoS ONE 2012, 7, e37871. [Google Scholar] [CrossRef]

- Litman, Y.E.; Rodríguez, H.B.; Braslavsky, S.E.; San Román, E. Photophysics of Xanthene Dyes at High Concentrations in Solid Environments: Charge Transfer Assisted Triplet Formation. Photochem. Photobiol. 2018, 94, 865–874. [Google Scholar] [CrossRef] [PubMed]

- Naheed, S.; Zuber, M.; Salman, M.; Rasool, N.; Siddique, Z.; Shaik, M.R.; Sharaf, M.A.F.; Abdelgawad, A.; Sekou, D.; Awwad, E.M. Impact of Macrodiols on the Morphological Behavior of H12MDI/HDO-Based Polyurethane Elastomer. Polymers 2021, 13, 2060. [Google Scholar] [CrossRef] [PubMed]

- Pistor, V.; De Conto, D.; Ornaghi, F.G.; Zattera, A.J. Microstructure and crystallization kinetics of polyurethane thermoplastics containing trisilanol isobutyl POSS. J. Nanomater. 2012, 2012, 283031. [Google Scholar] [CrossRef] [Green Version]

- Madejová, J.; Gates, W.P.; Petit, S. IR spectra of clay minerals. In Infrared and Raman Spectroscopies of Clay Minerals; Elsevier: Amsterdam, The Netherlands, 2017; pp. 107–149. [Google Scholar]

- Litman, Y.; Rodríguez, H.B.; San Román, E. Tuning the concentration of dye loaded polymer films for maximum photosensitization efficiency: Phloxine B in poly(2-hydroxyethyl methacrylate). Photochem. Photobiol. Sci. 2016, 15, 80–85. [Google Scholar] [CrossRef] [PubMed]

- Kuang, P.; Lee, J.H.; Kim, C.H.; Ho, K.M.; Constant, K. Improved surface wettability of polyurethane films by ultraviolet ozone treatment. J. Appl. Polym. Sci. 2010, 118, 3024–3033. [Google Scholar] [CrossRef]

- Pergal, M.V.; Stefanović, I.S.; Poręba, R.; Steinhart, M.; Jovančić, P.; Ostojić, S.; Špírková, M. Influence of the Organoclay Content on the Structure, Morphology, and Surface Related Properties of Novel Poly(dimethylsiloxane)-Based Polyurethane/Organoclay Nanocomposites. Ind. Eng. Chem. Res. 2017, 56, 4970–4983. [Google Scholar] [CrossRef] [Green Version]

- Taghaddosi, S.; Akbari, A.; Yegani, R. Preparation, characterization and anti-fouling properties of nanoclays embedded polypropylene mixed matrix membranes. Chem. Eng. Res. Des. 2017, 125, 35–45. [Google Scholar] [CrossRef]

- Muppalla, R.; Jewrajka, S.K. Properties and Applications of Poly(dimethylsiloxane) Containing Poly(meth)acrylate-Based Thermoplastic Elastomer/Clay Nanocomposites. Ind. Eng. Chem. Res. 2012, 51, 15942–15952. [Google Scholar] [CrossRef]

- Turri, S.; Valsecchi, R.; Viganò, M.; Levi, M. Hydrophilic–oleophobic behaviour in thin films from fluoromodified nanoclays and polystyrene. Polym. Bull. 2009, 63, 235–243. [Google Scholar] [CrossRef]

- Sellami, F.; Kebiche-Senhadji, O.; Marais, S.; Lanel, C.; Fatyeyeva, K. Novel Poly(Vinylidene Fluoride)/Montmorillonite Polymer Inclusion Membrane: Application to Cr(VI) Extraction from Polluted Water. Membranes 2021, 11, 682. [Google Scholar] [CrossRef]

- Efimova, S.S.; Zakharova, A.A.; Ismagilov, A.A.; Schagina, L.V.; Malev, V.V.; Bashkirov, P.V.; Ostroumova, O.S. Lipid-mediated regulation of pore-forming activity of syringomycin E by thyroid hormones and xanthene dyes. Biochim. Biophys. Acta Biomembr. 2018, 1860, 691–699. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Koffi, P.F.; English, O.F.; Lee, J.C. Staphylococcus aureus Extracellular Vesicles: A Story of Toxicity and the Stress of 2020. Toxins 2021, 13, 75. [Google Scholar] [CrossRef] [PubMed]

| Sample | cSap | nODTMA/mSap | nPhB/mSap |

|---|---|---|---|

| g L−1 | mmol g−1 | mmol g−1 | |

| M1 | 0.1 | 1.6 | 0.1 |

| M2 | 0.1 | 3.2 | 0.2 |

| M3 | 0.1 | 3.2 | 0.1 |

| M4 | 0.1 | 0.8 | 0.1 |

| Membrane | cPhB0 | cPhB,supern | xPhB,% |

|---|---|---|---|

| (mmol/L) | (mmol/L) | (%) | |

| M1 (a) | 0.05 | 4.0 × 10−5 | 99.9 |

| M1 (b) | 0.05 | 4.5 × 10−5 | 99.9 |

| M2 (a) | 0.1 | 0.0271 | 72.8 |

| M2 (b) | 0.1 | 0.0262 | 73.8 |

| M3 (a) | 0.05 | 0.0360 | 28.1 |

| M3 (b) | 0.05 | 0.0381 | 23.7 |

| M4 (a) | 0.05 | 6.77 × 10−4 | 98.6 |

| M4 (b) | 0.05 | 6.96 × 10−4 | 98.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dadi, N.C.T.; Bujdák, J.; Medvecká, V.; Pálková, H.; Barlog, M.; Bujdáková, H. Surface Characterization and Anti-Biofilm Effectiveness of Hybrid Films of Polyurethane Functionalized with Saponite and Phloxine B. Materials 2021, 14, 7583. https://0-doi-org.brum.beds.ac.uk/10.3390/ma14247583

Dadi NCT, Bujdák J, Medvecká V, Pálková H, Barlog M, Bujdáková H. Surface Characterization and Anti-Biofilm Effectiveness of Hybrid Films of Polyurethane Functionalized with Saponite and Phloxine B. Materials. 2021; 14(24):7583. https://0-doi-org.brum.beds.ac.uk/10.3390/ma14247583

Chicago/Turabian StyleDadi, Nitin Chandra Teja, Juraj Bujdák, Veronika Medvecká, Helena Pálková, Martin Barlog, and Helena Bujdáková. 2021. "Surface Characterization and Anti-Biofilm Effectiveness of Hybrid Films of Polyurethane Functionalized with Saponite and Phloxine B" Materials 14, no. 24: 7583. https://0-doi-org.brum.beds.ac.uk/10.3390/ma14247583