Influence Mechanism of Foamed Concrete Coating Thickness on the Blast Resistance of RC Walls

Abstract

:1. Introduction

2. Microstructure and Mechanical Properties of Foamed Concrete

3. Methods

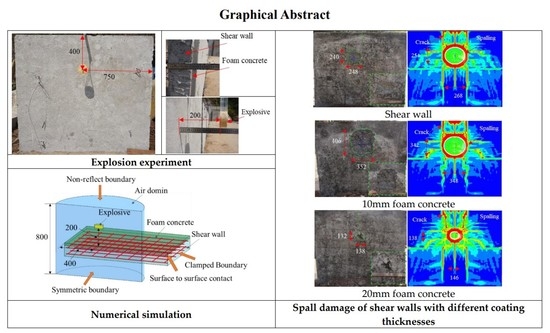

3.1. Blast Experiment

3.1.1. Construction of Experimental Walls

3.1.2. Experimental Design and Layout

3.2. Numerical Simulation

3.2.1. Finite Element Model

3.2.2. Material Models and Parameters

3.2.3. Mesh Convergence Verification

4. Experimental and Simulation Results

5. Discussion

5.1. Blast Resistance of Foamed Concrete-Coated RC Walls

5.2. Attenuation of the Blast Wave in Foamed Concrete

5.3. Incident Stress and Energy on the Front Side of RC Walls

5.4. Damage of Foamed Concrete-Coated RC Walls

6. Conclusions

- (1)

- The influences of foamed concrete coating on the blast resistance of RC walls include: Due to the impedance of foamed concrete is low, the initial stress of the structure is reduced; after high-speed compression, foamed concrete enters the compacted state, and the stress on the surface of RC wall increases significantly when the coating thickness is insufficient; and the fragmentation process of foamed concrete absorbs the energy of stress wave, and the transmitted stress gradually attenuates.

- (2)

- Coating thickness is one of the important factors that affect the attenuation of the blast wave in foamed concrete. The attenuation of stress is exponential with the increase of coating thickness. The attenuation index increases with the increase of load intensity.

- (3)

- Foamed concrete coated RC wall has a lower critical coating thickness. When the thickness of foamed concrete is less than that value, the blast resistance of the RC wall decreases; when it is greater than that value, the blast resistance of the RC wall is gradually improved as the coating thickness increases. The lower critical coating thickness can be predicted by monitoring the explosive stress and energy incident to the RC wall.

- (4)

- For the given 120 mm RC wall, the lower critical thickness of the foamed concrete coating to enhance the blast resistance is 15 mm. In the blast resistance design, the coating thickness of foamed concrete should not be less than the lower critical thickness, and the optimum coating thickness can be determined by comprehensively considering the blast resistance, economy, and space.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, W.; Chen, Y.; Peng, F. The yield estimation of the explosion at the Xiangshui, Jiangsu chemical plant in March 2019. Chin. J. Geophys. 2020, 63, 541–550. [Google Scholar]

- Rigby, S.; Lodge, T.; Alotaibi, S. Preliminary yield estimation of the 2020 Beirut explosion using video footage from social media. Shock Waves 2020, 30, 671–675. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Chen, L. Anti-collapsing Performance of POZD Coated Reinforced Concrete Slab. ACTA Armamentarii 2021, 42, 133–140. [Google Scholar]

- Ramamurthy, K.; Kunhanandan, N.; Indu, S. A classification of studies on properties of foamed concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Amran, Y.; Farzadnia, N.; Abang, A. Properties and applications of foamed concrete: A review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Edward, F.; Shen, W.; Hamlin, M. Development of Frangible Concrete to Reduce Blast-Related Casualties. ACI Mater. J. 2012, 109, 31–40. [Google Scholar]

- Kolluru, V.; Yiannis, A. Blast Response of Cellular Cement Foams: An Experimental Evaluation. In Proceedings of the Fifth Biot Conference on Poromechanics, Vienna, Austria, 10–12 July 2013. [Google Scholar]

- Nian, W.; Subramaniam, K.; Andreopoulos, Y. Experimental investigation on blast response of cellular concrete. Int. J. Impact Eng. 2016, 96, 105–115. [Google Scholar] [CrossRef] [Green Version]

- Monir, M.; Moncef, L.; Ahmed, M.; Maged, A. Critical overview of blast resistance of different concrete types. Mag. Concr. Res. 2014, 66, 72–81. [Google Scholar]

- Shang, W.; Zu, X.; Huang, Z. Experimental study on the energy dissipation of foam concrete plate fragmentation under explosion loading. Lat. Am. J. Solids Struct. 2022, 19, e452. [Google Scholar] [CrossRef]

- Tian, X.; Li, Q.; Lu, Z. Experimental study of blast mitigation by foamed concrete. Int. J. Prot. Struct. 2016, 7, 179–192. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, D.; Lu, F. Experimental study and numerical simulation of the damage mode of a square reinforced concrete slab under close-in explosion. Eng. Fail. Anal. 2013, 27, 41–51. [Google Scholar] [CrossRef]

- Zhao, H.; Yu, H.; Yuan, Y.; Zhu, H. Blast mitigation effect of the foamed cement base sacrificial cladding for tunnel structures. Constr. Build. Mater. 2015, 94, 710–718. [Google Scholar] [CrossRef]

- Yu, H.; Wang, Z.; Yuan, Y.; Li, W. Numerical analysis of internal blast effects on underground tunnel in soils. Struct. Infrastruct. Eng. 2015, 12, 1090–1105. [Google Scholar] [CrossRef]

- Li, L.; Xie, Q.; Tang, L. Influence Factors of Impact Reduction Performance of Foamed Concrete Backfill Layer. Blasting 2015, 32, 166–171. [Google Scholar]

- Zhou, H.; Li, Y.; Wang, X. Flexible Protection of Underground Structures with Foam Concrete Subjected to Ground Shocks. J. Beijing Univ. Technol. 2020, 46, 533–539. [Google Scholar]

- GB 11969-2020; Test Methods of Autoclaved Concrete. Standardization Administration of China, China Architecture & Building Press: Beijing, China, 2020.

- JGJ/T 341-2014; Technical Specification for Application of Foamed Concrete. Ministry of Housing and Urban-Rural Development, China Architecture & Building Press: Beijing, China, 2014.

- McVay, M. Spall Damage of Concrete Structures; Department of the Army: Hattiesburg, MS, USA, 1988. [Google Scholar]

- Zhao, C.; Lu, X.; Wang, Q. Experimental and numerical investigation of steel-concrete (SC) slabs under contact blast loading. Eng. Struct. 2019, 196, 109337. [Google Scholar] [CrossRef]

- Yang, C.; Jia, X.; Huang, Z.; Zhao, L.; Shang, W. Damage of full-scale reinforced concrete beams under contact explosion. Int. J. Impact Eng. 2022, 163, 104180. [Google Scholar] [CrossRef]

- Shang, W.; Huang, Z.; Zu, X.; Xiao, Q.; Jia, X. Energy Evolution Mechanism of Air Shock Wave Propagation and Attenuation Based on VMD–HT Energy Spectrum. J. Appl. Fluid Mech. 2022, 15, 1049–1059. [Google Scholar]

- Thomas, B. The RHT Concrete Model in LS-DYNA. In Proceedings of the Conference: 8th European LS-DYNA Conference, Strasbourg, France, 5–7 October 2011. [Google Scholar]

- Leppänen, J. Concrete subjected to projectile and fragment impacts: Modelling of crack softening and strain rate dependency in tension. Int. J. Impact Eng. 2006, 32, 1828–1841. [Google Scholar] [CrossRef]

- Hallquist, J. LS-DYNA Keyword User’s Manual; Livermore Software Technology Corporation: Livermore, CA, USA, 2007. [Google Scholar]

- Zhao, C.; Chen, J.; Wang, Y. Damage mechanism and response of reinforced concrete containment structure under internal blast loading. Theor. Appl. Fract. Mech. 2012, 61, 12–20. [Google Scholar] [CrossRef]

- Su, B.; Zhou, Z.; Li, Z.; Wang, Z.; Shu, X. Experimental investigation on the mechanical behavior of foamed concrete under uniaxial and triaxial loading. Constr. Build. Mater. 2019, 209, 41–51. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, J.; Cui, J. Experimental studies on fragments of reinforced concrete slabs under close-in explosions. Int. J. Impact Eng. 2020, 144, 103630. [Google Scholar] [CrossRef]

- Ekström, J.; Rempling, R.; Plos, M. Spalling in concrete subjected to shock wave blast. Eng. Struct. 2016, 122, 72–82. [Google Scholar] [CrossRef]

- Ma, W. Behavior of Aged Reinforced Concrete Columns under High Sustained Concentric and Eccentric Loads. Ph.D. Thesis, University of Nevada, Las Vegas, NV, USA, 2021. [Google Scholar]

- Ma, W. Simulate Initiation and Formation of Cracks and Potholes. Master’s Thesis, Northeastern University, Evanston, IL, USA, 2016. [Google Scholar]

- Meyers, M. Dynamic Behavior of Materials; John Wiley & Sons, Inc.: New York, NY, USA, 1994. [Google Scholar]

- Yadav, H.; Nath, T.; Sundaram, S.; Kamath, P.; Kulkarni, M. Shock Initiation of Sheet Explosive. Propellants Explos. Pyrotech. 1994, 19, 26–31. [Google Scholar] [CrossRef]

- Gencel, O.; Nodehi, M.; Yavuz, B. Basalt fiber-reinforced foam concrete containing silica fume: An experimental study. Constr. Build. Mater. 2022, 326, 126861. [Google Scholar] [CrossRef]

- Gencel, O.; Kazmi, S.; Munir, M. Influence of bottom ash and polypropylene fibers on the physico-mechanical, durability and thermal performance of foam concrete: An experimental investigation. Constr. Build. Mater. 2021, 306, 124887. [Google Scholar] [CrossRef]

- Dey, V.; Bonakdar, A.; Mobasher, B. Low-velocity flexural impact response of fiber-reinforced aerated concrete. Cem. Concr. Compos. 2014, 49, 100–110. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, X.; Wang, X. Response of foam concrete-filled aluminum honeycombs subject to quasi-static and dynamic compression. Compos. Struct. 2020, 239, 112025. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, X.; Wang, X. Improving energy absorption capacity of foam concrete with gradient and layered architecture. Constr. Build. Mater. 2022, 319, 126140. [Google Scholar] [CrossRef]

- Wang, X.; Liu, L.; Shen, W. CFRP Reinforced Foam Concrete Subjected to Dynamic Compression at Medium Strain Rate. Materials 2020, 13, 10. [Google Scholar] [CrossRef] [Green Version]

| Density (kg/m3) | Yang’s Modules (GPa) | Compressive Strength (MPa) | Platform Stress (MPa) | Flexural Strength (MPa) |

|---|---|---|---|---|

| 820 | 880 | 5.28 | 2.82 | 0.74 |

| Density (g/cm3) | Sound Velocity (m/s) | Temperature (K) | Adiabatic Index | Initial Specific Internal Energy (J/kg) |

|---|---|---|---|---|

| 1.225 × 10−3 | 344 | 288 | 1.4 | 2.068 × 105 |

| Density (g/cm3) | Detonation Velocity (m/s) | C-J Pressure (GPa) | A (Gpa) | B (Gpa) | R1 | R2 | ω |

|---|---|---|---|---|---|---|---|

| 1.53 | 6641 | 18.5 | 329.92 | 3.3 | 4.15 | 0.9 | 0.35 |

| Density (g/cm3) | Compressive Strength (MPa) | Tensile Strength (MPa) | Shear Modulus (GPa) | A | N |

|---|---|---|---|---|---|

| 2.38 | 32.7 | 5.85 | 16.7 | 1.6 | 0.61 |

| Density (g/cm3) | Young’s Modulus (MPa) | Poisson Ratio | Yield Stress (MPa) | Tangent Modulus (MPa) |

|---|---|---|---|---|

| 7.80 | 210 | 0.3 | 414 | 1300 |

| Density (g/cm3) | Young’s Modulus (MPa) | Poisson Ratio | Tensile Stress Cutoff (MPa) | Damping Coefficient |

|---|---|---|---|---|

| 0.82 | 880 | 0.1 | 0.64 | 0.1 |

| Coating Thickness (mm) | Crushing Size (mm) | Spalling Size (mm) | The Exposed Length of Reinforcement (mm) | ||

|---|---|---|---|---|---|

| Experiment | Simulation | Experiment | Simulation | ||

| 0 | - | - | 248 × 240 × 40 | 268 × 252 × 42 | 168 |

| 10 | 386 × 352 × 10 | 362 × 362 × 10 | 352 × 406 × 45 | 348 × 342 × 48 | 286 |

| 20 | 330 × 343 × 20 | 326 × 310 × 20 | 138 × 132 × 20 | 146 × 138 × 22 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, W.; Huang, Z.; Zu, X.; Xiao, Q.; Jia, X. Influence Mechanism of Foamed Concrete Coating Thickness on the Blast Resistance of RC Walls. Materials 2022, 15, 5473. https://0-doi-org.brum.beds.ac.uk/10.3390/ma15165473

Shang W, Huang Z, Zu X, Xiao Q, Jia X. Influence Mechanism of Foamed Concrete Coating Thickness on the Blast Resistance of RC Walls. Materials. 2022; 15(16):5473. https://0-doi-org.brum.beds.ac.uk/10.3390/ma15165473

Chicago/Turabian StyleShang, Wei, Zhengxiang Huang, Xudong Zu, Qiangqiang Xiao, and Xin Jia. 2022. "Influence Mechanism of Foamed Concrete Coating Thickness on the Blast Resistance of RC Walls" Materials 15, no. 16: 5473. https://0-doi-org.brum.beds.ac.uk/10.3390/ma15165473