KrF Laser and Plasma Exposure of PDMS–Carbon Composite and Its Antibacterial Properties

Abstract

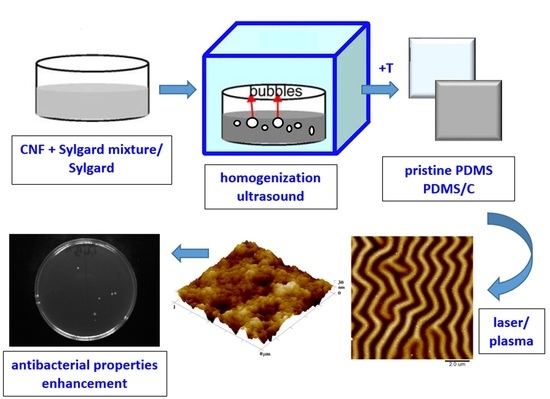

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Foil Preparation

2.3. Surface Modification

2.4. Analytical Methods

2.5. Antibacterial Study

3. Results

3.1. Surface Morphology of Plasma-Treated Samples

3.2. Surface Chemistry of Plasma-Treated Samples

3.3. High-Energy Excimer Treatment

3.4. Antibacterial Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hiremath, N.; Bhat, G. High-performance carbon nanofibers and nanotubes. In Structure and Properties of High-Performance Fibers; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 79–109. [Google Scholar]

- Ponnamma, D.; Ninan, N.; Thomas, S. Carbon Nanotube Tube Filled Polymer Nanocomposites and Their Applications in Tissue Engineering. In Applications of Nanomaterials; Elsevier BV: Amsterdam, The Netherlands, 2018; pp. 391–414. [Google Scholar]

- Koo, J.H. Fundamentals, Properties, and Applications of Polymer Nanocomposites; Cambridge University Press (CUP): Cambridge, UK, 2016. [Google Scholar]

- AfzaliTabar, M.; Alaei, M.; Khojasteh, R.R.; Motiee, F.; Rashidi, A. Preference of multi-walled carbon nanotube (MWCNT) to single-walled carbon nanotube (SWCNT) and activated carbon for preparing silica nanohybrid pickering emulsion for chemical enhanced oil recovery (C-EOR). J. Solid State Chem. 2017, 245, 164–173. [Google Scholar] [CrossRef]

- Giusca, C.E.; Tison, Y.; Silva, S.R.P. Evidence for metal-semiconductor transitions in twisted and collapsed double-walled carbon nanotubes by scanning tunneling microscopy. Nano Lett. 2008, 8, 3350–3356. [Google Scholar] [CrossRef] [PubMed]

- Gaynor, W.; Burkhard, G.F.; McGehee, M.D.; Peumans, P. Smooth nanowire/polymer composite transparent electrodes. Adv. Mater. 2011, 23, 2905–2910. [Google Scholar] [CrossRef] [PubMed]

- Alberto, M.; Bhavsar, R.; Luque-Alleda, J.M.; Prestat, E.; Gao, L.; Budd, P.M.; Vijayaraghavan, A.; Szekely, G.; Holmes, S.M.; Gorgojo, P. Study on the formation of thin film nanocomposite (TFN) membranes of polymers of intrinsic microporosity and graphene-like fillers: Effect of lateral flake size and chemical functionalization. J. Membrane Sci. 2018, 565, 390–401. [Google Scholar] [CrossRef]

- Xu, D.; Liu, H.; Yang, L.; Wang, Z. Fabrication of superhydrophobic surfaces with non-aligned alkyl-modified multi-wall carbon nanotubes. Carbon 2006, 44, 3226–3231. [Google Scholar] [CrossRef]

- Luo, C.; Zuo, X.; Wang, L.; Wang, E.; Song, S.; Wang, J.; Wang, J.; Fan, C.; Cao, Y. Flexible carbon nanotube−polymer composite films with high conductivity and superhydrophobicity made by solution process. Nano Lett. 2008, 8, 4454–4458. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Z.; Men, X.; Xu, X. Fabrication of stable, transparent and superhydrophobic nanocomposite films with polystyrene functionalized carbon nanotubes. Appl. Surf. Sci. 2009, 255, 9244–9247. [Google Scholar] [CrossRef]

- Wu, T.; Pan, Y.; Li, L. Fabrication of superhydrophobic hybrids from multiwalled carbon nanotubes and poly(vinylidene fluoride). Colloids Surfaces A Physicochem. Eng. Asp. 2011, 384, 47–52. [Google Scholar] [CrossRef]

- Wang, K.; Hu, N.-X.; Xu, G.; Qi, Y. Stable superhydrophobic composite coatings made from an aqueous dispersion of carbon nanotubes and a fluoropolymer. Carbon 2011, 49, 1769–1774. [Google Scholar] [CrossRef]

- Yao, H.; Chu, C.-C.; Sue, H.-J.; Nishimura, R. Electrically conductive superhydrophobic octadecylamine-functionalized multiwall carbon nanotube films. Carbon 2013, 53, 366–373. [Google Scholar] [CrossRef]

- Sethi, S.; Dhinojwala, A. Superhydrophobic conductive carbon nanotube coatings for steel. Langmuir 2009, 25, 4311–4313. [Google Scholar] [CrossRef]

- Wang, C.-F.; Chen, W.-Y.; Cheng, H.-Z.; Fu, S.-L. Pressure-proof superhydrophobic films from flexible carbon nanotube/polymer coatings. J. Phys. Chem. C 2010, 114, 15607–15611. [Google Scholar] [CrossRef]

- Ci, L.; Suhr, J.; Pushparaj, V.; Zhang, X.; Ajayan, P.M. Continuous carbon nanotube reinforced composites. Nano Lett. 2008, 8, 2762–2766. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.J.; Kranz, M.; Kim, S.H.; Allen, M.G. Micropatternable elastic electrets based on a PDMS/carbon nanotube composite. J. Micromech. Microeng. 2010, 20, 104003. [Google Scholar] [CrossRef]

- Jung, H.; Moon, J.-H.; Baek, D.-H.; Lee, J.-H.; Choi, Y.-Y.; Hong, J.-S.; Lee, S.-H. CNT/PDMS composite flexible dry electrodesfor long-term ECG monitoring. IEEE Trans. Biomed. Eng. 2012, 59, 1472–1479. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.-F.; Teo, M.K.; Yang, C. Superhydrophobic carbon nanotube/polydimethylsiloxane composite coatings. Mater. Sci. Technol. 2015, 31, 1745–1748. [Google Scholar] [CrossRef]

- Hu, H.; Zhao, Z.; Wan, W.; Gogotsi, Y.; Qiu, J. Polymer/Graphene hybrid aerogel with high compressibility, conductivity, and “sticky” superhydrophobicity. ACS Appl. Mater. Interfaces 2014, 6, 3242–3249. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Cai, J.; Ding, Z.; Li, Z. TiO2/RGO composite aerogels with controllable and continuously tunable surface wettability for varied aqueous photocatalysis. Appl. Catal. B Environ. 2015, 174–175, 421–426. [Google Scholar] [CrossRef]

- Eduok, U.; Faye, O.; Szpunar, J. Recent developments and applications of protective silicone coatings: A review of PDMS functional materials. Prog. Org. Coat. 2017, 111, 124–163. [Google Scholar] [CrossRef]

- Wolf, M.P.; Salieb-Beugelaar, G.B.; Hunziker, P. PDMS with designer functionalities—Properties, modifications strategies, and applications. Prog. Polym. Sci. 2018, 83, 97–134. [Google Scholar] [CrossRef]

- Van Kooten, T.G.; Whitesides, J.F.; von Recum, A.F. Influence of silicone (PDMS) surface texture on human skin fibroblast proliferation as determined by cell cycle analysis. J. Biomed. Mater. Res. 1998, 43, 1–14. [Google Scholar] [CrossRef]

- Kim, S.-J.; Lee, D.-S.; Kim, I.-G.; Sohn, N.-W.; Park, J.-Y.; Choi, B.-K.; Kim, S.-W. Evaluation of the biocompatibility of a coating material for an implantable bladder volume sensor. Kaohsiung J. Med. Sci. 2012, 28, 123–129. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gunatillake, P.; Adhikari, R. Nondegradable synthetic polymers for medical devices and implants. In Biosynthetic Polymers for Medical Applications; Elsevier BV: Amsterdam, The Netherlands, 2016; pp. 33–62. [Google Scholar]

- Willerth, S. Engineering Neural Tissue from Stem Cells; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Yong, J.; Chen, F.; Yang, Q.; Hou, X. Femtosecond laser controlled wettability of solid surfaces. Soft Matter 2015, 11, 8897–8906. [Google Scholar] [CrossRef] [Green Version]

- Slepička, P.; Neděla, O.; Kasálková, N.S.; Sajdl, P.; Švorčík, V. Periodic nanostructure induced on PEN surface by KrF laser irradiation. Int. J. Nanotechnol. 2017, 14, 399. [Google Scholar] [CrossRef]

- Fajstavr, D.; Neznalová, K.; Švorčík, V.; Slepička, P. LIPSS structures induced on graphene-polystyrene composite. Materials 2019, 12, 3460. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Slepičková Kasálková, N.; Slepička, P.; Švorčík, V. Carbon Nanostructures, Nanolayers, and Their Composites. Nanomaterials 2021, 11, 2368. [Google Scholar] [CrossRef]

- Slepička, P.; Neznalová, K.; Fajstavr, D.; Švorčík, V. Nanostructuring of honeycomb-like polystyrene with excimer laser. Prog. Org. Coat. 2020, 145, 105670. [Google Scholar] [CrossRef]

- Guittard, F.; Darmanin, T. Bioinspired Superhydrophobic Surfaces: Advances and Applications with Metallic and Inorganic Materials; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Kaimlová, M.; Nemogová, I.; Kolarova, K.; Slepička, P.; Švorčík, V.; Siegel, J. Optimization of silver nanowire formation on laser processed PEN: Surface properties and antibacterial effects. Appl. Surf. Sci. 2019, 473, 516–526. [Google Scholar] [CrossRef]

- Rebollar, E.; Frischauf, I.; Olbrich, M.; Peterbauer, T.; Hering, S.; Preiner, J.; Hinterdorfer, P.; Romanin, C.; Heitz, J. Proliferation of aligned mammalian cells on laser-nanostructured polystyrene. Biomaterials 2008, 29, 1796–1806. [Google Scholar] [CrossRef]

- Fajstavr, D.; Neznalová, K.; Kasálková, N.S.; Rimpelová, S.; Kubičíková, K.; Švorčík, V.; Slepička, P. Nanostructured polystyrene doped with acetylsalicylic acid and its antibacterial properties. Materials 2020, 13, 3609. [Google Scholar] [CrossRef]

- Neděla, O.; Slepička, P.; Kasalkova, N.S.; Sajdl, P.; Kolská, Z.; Rimpelová, S.; Švorčík, V. Antibacterial properties of angle-dependent nanopatterns on polystyrene. React. Funct. Polym. 2019, 136, 173–180. [Google Scholar] [CrossRef]

- Slepička, P.; Siegel, J.; Lyutakov, O.; Kasálková, N.S.; Kolská, Z.; Bačáková, L.; Švorčík, V. Polymer nanostructures for bioapplications induced by laser treatment. Biotechnol. Adv. 2018, 36, 839–855. [Google Scholar] [CrossRef] [PubMed]

- Balasubramaniam, B.; Prateek; Ranjan, S.; Saraf, M.; Kar, P.; Singh, S.P.; Thakur, V.K.; Singh, A.; Gupta, R.K. Antibacterial and antiviral functional materials: Chemistry and biological activity toward tackling COVID-19-like pandemics. ACS Pharmacol. Transl. Sci. 2021, 4, 8–54. [Google Scholar] [CrossRef] [PubMed]

- Lišková, J.; Kasálková, N.S.; Slepička, P.; Švorčík, V.; Bačáková, L. Heat-treated carbon coatings on poly (l-lactide) foils for tissue engineering. Mater. Sci. Eng. C 2019, 100, 117–128. [Google Scholar] [CrossRef]

- Slepička, P.; Trostová, S.; Kasálková, N.S.; Kolská, Z.; Malinský, P.; Macková, A.; Bačáková, L.; Švorčík, V. Nanostructuring of polymethylpentene by plasma and heat treatment for improved biocompatibility. Polym. Degrad. Stab. 2012, 97, 1075–1082. [Google Scholar] [CrossRef]

- Slepička, P.; Hurtuková, K.; Fajstavr, D.; Slepičková Kasálková, N.; Lyutakov, O.; Švorčík, V. Carbon-gold nanocomposite induced by unique high energy laser single-shot annealing. Mater. Lett. 2021, 301, 130256. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fajstavr, D.; Frýdlová, B.; Rimpelová, S.; Kasálková, N.S.; Sajdl, P.; Švorčík, V.; Slepička, P. KrF Laser and Plasma Exposure of PDMS–Carbon Composite and Its Antibacterial Properties. Materials 2022, 15, 839. https://0-doi-org.brum.beds.ac.uk/10.3390/ma15030839

Fajstavr D, Frýdlová B, Rimpelová S, Kasálková NS, Sajdl P, Švorčík V, Slepička P. KrF Laser and Plasma Exposure of PDMS–Carbon Composite and Its Antibacterial Properties. Materials. 2022; 15(3):839. https://0-doi-org.brum.beds.ac.uk/10.3390/ma15030839

Chicago/Turabian StyleFajstavr, Dominik, Bára Frýdlová, Silvie Rimpelová, Nikola Slepičková Kasálková, Petr Sajdl, Václav Švorčík, and Petr Slepička. 2022. "KrF Laser and Plasma Exposure of PDMS–Carbon Composite and Its Antibacterial Properties" Materials 15, no. 3: 839. https://0-doi-org.brum.beds.ac.uk/10.3390/ma15030839