Evolution of the Microstructure and Mechanical Performance of As-Sprayed and Annealed Silicon Coating on Melt-Infiltrated Silicon Carbide Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Preparation

2.2. Analysis Methods

3. Results and Discussions

3.1. Surface Microstructures

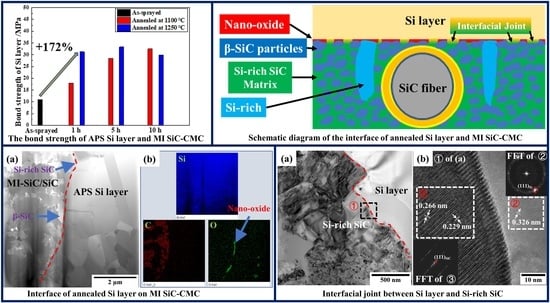

3.2. Cross-Sectional Microstructures

3.3. Microstructures at the Interface

3.4. Mechanical Properties of the Silicon Layer

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, K.N. Yb2Si2O7 Environmental barrier coatings with reduced bond coat oxidation rates via chemical modifications for long life. J. Am. Ceram. Soc. 2018, 102, 1507–1521. [Google Scholar] [CrossRef]

- Deijkers, J.A.; Wadley, H.N.G. A duplex bond coat approach to environmental barrier coating systems. Acta Mater. 2021, 217, 117167. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, L.; Liu, Q.; Cheng, L.; Wang, Y. Calcium–magnesium–aluminosilicate corrosion behaviors of rare-earth disilicates at 1400 °C. J. Eur. Ceram. Soc. 2013, 33, 3419–3428. [Google Scholar] [CrossRef]

- Nistal, A.; García, E.; García-Diego, C.; Osendi, M.I.; Miranzo, P. Flame spraying of adherent silicon coatings on SiC substrates. Surf. Coat. Technol. 2015, 270, 8–15. [Google Scholar] [CrossRef]

- Lee, K.N.; Fox, D.S.; Eldridge, J.I.; Zhu, D.; Robinson, R.C.; Bansal, N.P.; Miller, R.A. Upper Temperature Limit of Environmental Barrier Coatings Based on Mullite and BSAS. J. Am. Ceram. Soc. 2003, 86, 1299–1306. [Google Scholar] [CrossRef] [Green Version]

- Cojocaru, C.V.; Kruger, S.E.; Moreau, C.; Lima, R.S. Elastic Modulus Evolution and Behavior of Si/Mullite/BSAS-Based Environmental Barrier Coatings Exposed to High Temperature in Water Vapor Environment. J. Therm. Spray Technol. 2011, 20, 92–99. [Google Scholar] [CrossRef] [Green Version]

- Cojocaru, C.V.; Lévesque, D.; Moreau, C.; Lima, R.S. Performance of thermally sprayed Si/mullite/BSAS environmental barrier coatings exposed to thermal cycling in water vapor environment. Surf. Coat. Technol. 2013, 216, 215–223. [Google Scholar] [CrossRef]

- García, E.; Miranzo, P.; Osendi, M.I. The Prospect of Y2SiO5-Based Materials as Protective Layer in Environmental Barrier Coatings. J. Therm. Spray Technol. 2013, 22, 680–689. [Google Scholar] [CrossRef]

- Richards, B.T.; Wadley, H.N.G. Plasma spray deposition of tri-layer environmental barrier coatings. J. Eur. Ceram. Soc. 2014, 34, 3069–3083. [Google Scholar] [CrossRef]

- Niu, Y.; Liu, X.; Ding, C. Phase composition and microstructure of silicon coatings deposited by air plasma spraying. Surf. Coat. Technol. 2006, 201, 1660–1665. [Google Scholar] [CrossRef]

- Bansal, N.P. (Ed.) . Handbook of Ceramic Composites; Springer: Boston, MA, USA, 2005. [Google Scholar] [CrossRef]

- Newton, C.D.; Jeffs, S.P.; Gale, L.; Pattison, S.; Bache, M.R. Determining the interlaminar tensile strength of a SiCf/SiC ceramic matrix composite through diametrical compression testing. J. Eur. Ceram. Soc. 2023, 43, 2951–2957. [Google Scholar] [CrossRef]

- Sharpe, W.N.; Yuan, B.; Vaidyanathan, R.; Edwards, R.L. Measurements of Young’s modulus, Poisson’s ratio, and tensile strength of polysilicon. In Proceedings of the IEEE the Tenth Annual International Workshop on Micro Electro Mechanical Systems. An Investigation of Micro Structures, Sensors, Actuators, Machines and Robots, Nagoya, Japan, 26–30 January 1997; pp. 424–429. [Google Scholar] [CrossRef]

- Sharpe, W.N.; Turner, K.T.; Edwards, R.L. Tensile testing of polysilicon. Exp. Mech. 1999, 39, 162–170. [Google Scholar] [CrossRef]

- Dubelman, S.; Raghunathan, N.; Peroulis, D.; Chen, W. The Development of a High Rate Tensile Testing System for Micro Scaled Single Crystal Silicon Specimens. Exp. Mech. 2014, 54, 413–419. [Google Scholar] [CrossRef]

- Yang, H.; Yang, Y.; Cao, X.; Huang, X.; Li, Y. Thermal shock resistance and bonding strength of tri-layer Yb2SiO5/mullite/Si coating on SiCf/SiC composites. Ceram. Int. 2020, 46, 27292–27298. [Google Scholar] [CrossRef]

- Huang, J.; Liu, R.; Hu, Q.; Guo, X.; Li, G.; Tu, Y.; Lu, X.; Xu, M.; Deng, L.; Jiang, J.; et al. High temperature abradable sealing coating for SiCf/SiC ceramic matrix composites. Ceram. Int. 2023, 49, 1779–1790. [Google Scholar] [CrossRef]

- Niu, Y.; Liu, X.; Zheng, X.; Ji, H.; Ding, C. Microstructure and Properties Characterization of Silicon Coatings Prepared by Vacuum Plasma Spraying Technology. J. Therm. Spray Technol. 2009, 18, 427–434. [Google Scholar] [CrossRef]

- Lee, K.N.; Zhu, D.; Lima, R.S. Perspectives on Environmental Barrier Coatings (EBCs) Manufactured via Air Plasma Spray (APS) on Ceramic Matrix Composites (CMCs): A Tutorial Paper. J. Therm. Spray Technol. 2021, 30, 40–58. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, T.-Y.; Wong, M.; Zohar, Y. Residual-stress relaxation in polysilicon thin films by high-temperature rapid thermal annealing. Sens. Actuators A Phys. 1998, 64, 109–115. [Google Scholar] [CrossRef]

- Guo, M.; Cui, Y.; Wang, C.; Jiao, J.; Bi, X.; Tao, C. Characterization and Control of Residual Stress in Plasma-Sprayed Silicon Coatings on SiC/SiC Composites. Coatings 2023, 13, 674. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.-H.; Wang, G.-Q.; Bo, Y.-F.; Yang, G.-J. Improving oxidation resistance of Si coating by isolated-particle healing. Corros. Commun. 2022, 8, 9–17. [Google Scholar] [CrossRef]

- Hartman, K.; Bertoni, M.; Serdy, J.; Buonassisi, T. Dislocation density reduction in multicrystalline silicon solar cell material by high temperature annealing. Appl. Phys. Lett. 2008, 93, 122108. [Google Scholar] [CrossRef]

- Kayed, K.; Kurd, D.B. The Effect of Annealing Temperature on the Structural and Optical Properties of Si/SiO2 Composites Synthesized by Thermal Oxidation of Silicon Wafers. Silicon 2022, 14, 5157–5163. [Google Scholar] [CrossRef]

- Beausir, B.; Fundenberger, J.-J. Analysis Tools for Electron and X-ray Diffraction, ATEX-Software; Université de Lorraine: Metz, France, 2017; Available online: www.atex-software.eu (accessed on 20 December 2022).

- Mauer, G.; Vaßen, R.; Zimmermann, S.; Biermordt, T.; Heinrich, M.; Marques, J.-L.; Landes, K.; Schein, J. Investigation and Comparison of In-Flight Particle Velocity During the Plasma-Spray Process as Measured by Laser Doppler Anemometry and DPV-2000. J. Therm. Spray Technol. 2013, 22, 892–900. [Google Scholar] [CrossRef]

- Ding, Q.; Tan, X.; Jiang, L.; Fan, X.; He, B.; Wang, C.; Zhuo, X.; Zhou, K.; Zhang, X. High-temperature performances of Si-HfO2-based environmental barrier coatings via atmospheric plasma spraying. Ceram. Int. 2022, 48, 23127–23136. [Google Scholar] [CrossRef]

- Li, G.; Lu, X.; Huang, J.; Dong, S.; Deng, L.; Jiang, J.; Cao, X. Thermal cycling behavior and failure mechanism of the Si-HfO2 environmental barrier coating bond coats prepared by atmospheric plasma spraying. J. Alloys Compd. 2022, 913, 165319. [Google Scholar] [CrossRef]

- Liang, S.; Yan, W. Study on the micro-structure and the nano-indentation responses of laser solid formed epitaxial Ni-based superalloy. J. Alloys Compd. 2022, 921, 166091. [Google Scholar] [CrossRef]

- Li, W.; Vittorietti, M.; Jongbloed, G.; Sietsma, J. The combined influence of grain size distribution and dislocation density on hardness of interstitial free steel. J. Mater. Sci. Technol. 2020, 45, 35–43. [Google Scholar] [CrossRef]

- Saastamoinen, A.; Kaijalainen, A.; Porter, D.; Suikkanen, P.; Yang, J.-R.; Tsai, Y.-T. The effect of finish rolling temperature and tempering on the microstructure, mechanical properties and dislocation density of direct-quenched steel. Mater. Charact. 2018, 139, 1–10. [Google Scholar] [CrossRef]

- Thirathipviwat, P.; Song, G.; Bednarcik, J.; Kühn, U.; Gemming, T.; Nielsch, K.; Han, J. Compositional complexity dependence of dislocation density and mechanical properties in high entropy alloy systems. Prog. Nat. Sci. Mater. Int. 2020, 30, 545–551. [Google Scholar] [CrossRef]

- Nye, J.F. Some geometrical relations in dislocated crystals. Acta Metall. 1953, 1, 153–162. [Google Scholar] [CrossRef]

- Kundu, A.; Field, D.P. Geometrically Necessary Dislocation Density Evolution in Interstitial Free Steel at Small Plastic Strains. Met. Mater. Trans. A 2018, 49, 3274–3282. [Google Scholar] [CrossRef]

- Pantleon, W. Resolving the geometrically necessary dislocation content by conventional electron backscattering diffraction. Scr. Mater. 2008, 58, 994–997. [Google Scholar] [CrossRef]

- Lee, S.P.; Katoh, Y.; Kohyama, A. Development of SiCf/SiC Composites by the Melt Infiltration Process. In Ceramic Transactions Series; Kohyama, A., Singh, M., Lin, H.-T., Katoh, Y., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 115–122. [Google Scholar] [CrossRef]

- Xia, X.; Deng, J.; Kou, S.; Luan, C.; Fan, S.; Wang, P.; Cheng, L.; Zhang, L. Microstructure and properties of pressure-less joining of SiCf/SiC composites by Ti–Si alloys. Ceram. Int. 2022, 48, 22387–22400. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, L.C. Deformation mechanisms at pop-out in monocrystalline silicon under nanoindentation. Acta Mater. 2009, 57, 2148–2153. [Google Scholar] [CrossRef]

- Mesquita-Guimarães, J.; García, E.; Miranzo, P.; Osendi, M.I.; Cojocaru, C.V.; Lima, R.S. Mullite–YSZ multilayered environmental barrier coatings tested in cycling conditions under water vapor atmosphere. Surf. Coat. Technol. 2012, 209, 103–109. [Google Scholar] [CrossRef]

| Items | APS |

|---|---|

| Current, A | 380 |

| Argon, sccm | 35,000 |

| Hydrogen, sccm | 6000 |

| Feedstock, g/min | 25 |

| Distance, m | 0.1 |

| Position | wt% of Oxygen | Annealing Condition |

|---|---|---|

| A | 20.11 | 1100 °C/1 h |

| B | 35.99 | 1100 °C/10 h |

| C | 20.84 | 1250 °C/1 h |

| D | 45.01 | 1250 °C/10 h |

| wt% of Oxygen on the Surface | wt% of Oxygen in the Cross-Section | Condition |

|---|---|---|

| 10.08 | 0.71 | As-sprayed |

| 18.60 | 2.58 | 1100 °C/1 h |

| 27.94 | 3.25 | 1100 °C/5 h |

| 29.11 | 3.26 | 1100 °C/10 h |

| 26.95 | 2.43 | 1250 °C/1 h |

| 44.69 | 3.37 | 1250 °C/5 h |

| 44.23 | 3.29 | 1250 °C/10 h |

| The Average Grain Size (µm) | Average GND Density (m−2) | Condition |

|---|---|---|

| 1.351 | 5.686 × 1014 | As sprayed |

| 1.417 | 8.967 × 1014 | 1100 °C/1 h |

| 1.420 | 9.011 × 1014 | 1100 °C/5 h |

| 1.424 | 9.102 × 1014 | 1100 °C/10 h |

| 1.535 | 7.433 × 1014 | 1250 °C/1 h |

| 1.590 | 7.381 × 1014 | 1250 °C/5 h |

| 1.611 | 7.412 × 1014 | 1250 °C/10 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, M.; Cui, Y.; Wang, C.; Jiao, J.; Bi, X.; Tao, C. Evolution of the Microstructure and Mechanical Performance of As-Sprayed and Annealed Silicon Coating on Melt-Infiltrated Silicon Carbide Composites. Materials 2023, 16, 4407. https://0-doi-org.brum.beds.ac.uk/10.3390/ma16124407

Guo M, Cui Y, Wang C, Jiao J, Bi X, Tao C. Evolution of the Microstructure and Mechanical Performance of As-Sprayed and Annealed Silicon Coating on Melt-Infiltrated Silicon Carbide Composites. Materials. 2023; 16(12):4407. https://0-doi-org.brum.beds.ac.uk/10.3390/ma16124407

Chicago/Turabian StyleGuo, Mengqiu, Yongjing Cui, Changliang Wang, Jian Jiao, Xiaofang Bi, and Chunhu Tao. 2023. "Evolution of the Microstructure and Mechanical Performance of As-Sprayed and Annealed Silicon Coating on Melt-Infiltrated Silicon Carbide Composites" Materials 16, no. 12: 4407. https://0-doi-org.brum.beds.ac.uk/10.3390/ma16124407