Cellulosic Textiles—An Appealing Trend for Different Pharmaceutical Applications

Abstract

:1. Introduction

2. Origin of Cellulose and Its Physicochemical Properties

3. Preparation of Different Cellulose Polymorphs

4. Preparation of Specific Cellulose Types for Pharmaceutical Applications

4.1. Regenerated Cellulose Fibers (RCFs)

4.1.1. Production of Regenerated Cellulose Fibers (RCFs)

Conventional Techniques for Production of RCFs

Environmental-Friendly-Based Techniques for Production of RCFs

4.2. Cellulose Nanofibers (CNFs)

4.2.1. Production of CNFs

Mechanical Methods

Biological Methods

Physical Methods

Chemical Modification and Functionalization

- Oxidation of Cellulose

- Esterification of Cellulose

- Etherification of Cellulose

- Grafting of Cellulose

- Organic/Inorganic Hybridization of Cellulose

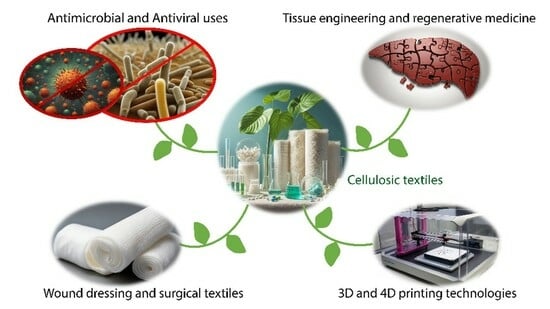

5. Pharmaceutical Applications of Cellulose-Based Textiles

5.1. Tissue Engineering and Regenerative Medicine

Advances in Cellulose-Based 3D and 4D Printing Technologies for Tissue Engineering

5.2. Antimicrobial Uses

5.2.1. Use of Metal Nanoparticles

5.2.2. Use of Natural Products

5.2.3. Use of Synthetic Compounds

5.3. Antiviral Studies

5.4. Wound Dressing

5.5. Surgical Uses

6. Regulatory and Safety Considerations Associated with the Use of Cellulose Textiles in Pharmaceutical Products

- -

- US Pharmacopeia (USP): The USP provides monographs and guidelines for various pharmaceutical ingredients and excipients. Cellulose textiles used in pharmaceutical applications must adhere to USP standards [238].

- -

- European Pharmacopoeia (Ph. Eur.): For pharmaceutical products intended for the European market, compliance with Ph. Eur. requirements is essential. The Ph. Eur. includes specific monographs on materials like cellulose and related substances [249].

- -

- FDA Regulations: In the United States, the Food and Drug Administration (FDA) sets strict regulations for materials used in pharmaceutical products. Cellulose textiles must comply with these regulations to ensure product safety.

- -

- Biocompatibility: Cellulose textiles should be evaluated for biocompatibility to ensure that they do not induce adverse reactions when they come into contact with pharmaceutical products or ultimately, with patients [250].

- -

- Compatibility with other ingredients: Cellulose textiles must not adversely affect the stability, efficacy, or quality of pharmaceutical formulations, and compatibility studies are essential [251].

- -

- Extractable and leachable: Cellulose textiles can release substances that may interact with pharmaceutical formulations. Analyzing them is crucial to identify any potential risks [252].

- -

- Particle contamination: Contamination by cellulose particles, such as fibers or fines, should be minimized to prevent impurities in pharmaceutical products [251].

- -

- Sterility: For certain pharmaceutical applications, such as wound dressings or surgical products, ensuring the sterility of cellulose textiles is of paramount importance [253].

7. Challenges and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Emam, H.E. Antimicrobial cellulosic textiles based on organic compounds. 3 Biotech 2019, 9, 29. [Google Scholar] [CrossRef]

- Tudoroiu, E.-E.; Dinu-Pîrvu, C.-E.; Albu Kaya, M.G.; Popa, L.; Anuța, V.; Prisada, R.M.; Ghica, M.V. An overview of cellulose derivatives-based dressings for wound-healing management. Pharmaceuticals 2021, 14, 1215. [Google Scholar] [CrossRef]

- Ciolacu, D.E.; Nicu, R.; Suflet, D.M.; Rusu, D.; Darie-Nita, R.N.; Simionescu, N.; Cazacu, G.; Ciolacu, F. Multifunctional Hydrogels Based on Cellulose and Modified Lignin for Advanced Wounds Management. Pharmaceutics 2023, 15, 2588. [Google Scholar] [CrossRef] [PubMed]

- Casanova, F.; Pereira, C.F.; Ribeiro, A.B.; Costa, E.M.; Freixo, R.; Castro, P.M.; Fernandes, J.C.; Pintado, M.; Ramos, Ó.L. Design of Innovative Biocompatible Cellulose Nanostructures for the Delivery and Sustained Release of Curcumin. Pharmaceutics 2023, 15, 981. [Google Scholar] [CrossRef]

- Rasheed, A. Classification of technical textiles. In Fibers for Technical Textiles; Ahmad, S., Rasheed, R., Nawab, Y., Eds.; Springer: Cham, Switzerland, 2020; pp. 49–64. [Google Scholar]

- Sinclair, R. Understanding textile fibres and their properties: What is a textile fibre? In Textiles and Fashion: Materials, Design and Technology, 1st ed.; Elseveir Science: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Sayyed, A.J.; Deshmukh, N.A.; Pinjari, D.V. A critical review of manufacturing processes used in regenerated cellulosic fibres: Viscose, cellulose acetate, cuprammonium, LiCl/DMAc, ionic liquids, and NMMO based lyocell. Cellulose 2019, 26, 2913–2940. [Google Scholar] [CrossRef]

- Shankar, S.; Rhim, J.-W. Preparation of nanocellulose from micro-crystalline cellulose: The effect on the performance and properties of agar-based composite films. Carbohydr. Polym. 2016, 135, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Kamel, R.; El-Wakil, N.A.; Dufresne, A.; Elkasabgy, N.A. Nanocellulose: From an agricultural waste to a valuable pharmaceutical ingredient. Int. J. Biol. Macromol. 2020, 163, 1579–1590. [Google Scholar] [CrossRef]

- Shokri, J.; Adibkia, K. Application of cellulose and cellulose derivatives in pharmaceutical industries. In Cellulose-Medical, Pharmaceutical and Electronic Applications; IntechOpen: London, UK, 2013. [Google Scholar]

- Kamel, S.; Ali, N.; Jahangir, K.; Shah, S.; El-Gendy, A. Pharmaceutical significance of cellulose: A review. Express Polym. Lett. 2008, 2, 758–778. [Google Scholar] [CrossRef]

- Kamel, R.; Elkasabgy, N.A. An Overview on the Pharmaceutical Applications of Nanocellulose. In Annual Plant: Sources of Fibres, Nanocellulose and Cellulosic Derivatives: Processing, Properties and Applications; Springer: Singapore, 2023; pp. 395–411. [Google Scholar]

- Kamel, R.; El-Wakil, N.A.; Abdelkhalek, A.A.; Elkasabgy, N.A. Nanofibrillated cellulose/cyclodextrin based 3D scaffolds loaded with raloxifene hydrochloride for bone regeneration. Int. J. Biol. Macromol. 2020, 156, 704–716. [Google Scholar] [CrossRef]

- Kamel, R.; El-Wakil, N.A.; Abdelkhalek, A.A.; Elkasabgy, N.A. Topical cellulose nanocrystals-stabilized nanoemulgel loaded with ciprofloxacin HCl with enhanced antibacterial activity and tissue regenerative properties. J. Drug Deliv. Sci. Technol. 2021, 64, 102553. [Google Scholar] [CrossRef]

- Kamel, R.; Mabrouk, M.; El-Sayed, S.A.; Beherei, H.H.; Abouzeid, R.E.; Abo El-Fadl, M.T.; Mahmoud, A.A.; Maged, A. Nanofibrillated cellulose/glucosamine 3D aerogel implants loaded with rosuvastatin and bioactive ceramic for dental socket preservation. Int. J. Pharm. 2022, 616, 121549. [Google Scholar] [CrossRef]

- El-Wakil, N.; Kamel, R.; Mahmoud, A.A.; Dufresne, A.; Abouzeid, R.E.; Abo El-Fadl, M.T.; Maged, A. Risedronate-loaded aerogel scaffolds for bone regeneration. Drug Deliv. 2023, 30, 51–63. [Google Scholar] [CrossRef]

- AbouSamra, M.M.; El Hoffy, N.M.; El-Wakil, N.A.; Awad, G.E.; Kamel, R. Computational investigation to design ofloxacin-loaded hybridized nanocellulose/lipid nanogels for accelerated skin repair. Gels 2022, 8, 593. [Google Scholar] [CrossRef] [PubMed]

- Kamel, R.; Afifi, S.M.; Abdou, A.M.; Esatbeyoglu, T.; AbouSamra, M.M. Nanolipogel loaded with tea tree oil for the management of burn: GC-MS analysis, in vitro and in vivo evaluation. Molecules 2022, 27, 6143. [Google Scholar] [CrossRef] [PubMed]

- Kamel, R.; El-Wakil, N.A.; Elkasabgy, N.A. Injectable hydrogel scaffolds composed of Nanocellulose derived from sugarcane bagasse and combined with calcium for Bone regeneration. Res. J. Pharm. Technol. 2023, 16, 3439–3450. [Google Scholar] [CrossRef]

- Caló, E.; Khutoryanskiy, V.V. Biomedical applications of hydrogels: A review of patents and commercial products. Eur. Polym. J. 2015, 65, 252–267. [Google Scholar] [CrossRef]

- Agarwal, T.; Subramanian, B.; Maiti, T.K. Liver Tissue Engineering: Challenges and Opportunities. ACS Biomater. Sci. Eng. 2019, 5, 4167–4182. [Google Scholar] [CrossRef]

- Leung, V.; Ko, F. Biomedical applications of nanofibers. Polym. Adv. Technol. 2011, 22, 350–365. [Google Scholar] [CrossRef]

- Calamak, S.; Shahbazi, R.; Eroglu, I.; Gultekinoglu, M.; Ulubayram, K. An overview of nanofiber-based antibacterial drug design. Expert Opin. Drug Discov. 2017, 12, 391–406. [Google Scholar] [CrossRef]

- Ong, X.-R.; Chen, A.X.; Li, N.; Yang, Y.Y.; Luo, H.-K. Nanocellulose: Recent advances toward biomedical applications. Small Sci. 2023, 3, 2200076. [Google Scholar] [CrossRef]

- Lin, N.; Dufresne, A. Nanocellulose in biomedicine: Current status and future prospect. Eur. Polym. J. 2014, 59, 302–325. [Google Scholar] [CrossRef]

- Andresen, M.; Stenstad, P.; Møretrø, T.; Langsrud, S.; Syverud, K.; Johansson, L.S.; Stenius, P. Nonleaching antimicrobial films prepared from surface-modified microfibrillated cellulose. Biomacromolecules 2007, 8, 2149–2155. [Google Scholar] [CrossRef]

- Molin, M.L.; Segat, B.; Garcia, M.C.F.; Pezzin, A.P.T.; Silveira, M.L.L.; Schneider, A.L.d.S. Development and characterization of bacterial cellulose membrane incorporated with Witch hazel extract. Matéria 2023, 28, e20230008. [Google Scholar] [CrossRef]

- Youdhestar; Mahar, F.K.; Das, G.; Tajammul, A.; Ahmed, F.; Khatri, M.; Khan, S.; Khatri, Z. Fabrication of ceftriaxone-loaded cellulose acetate and polyvinyl alcohol nanofibers and their antibacterial evaluation. Antibiotics 2022, 11, 352. [Google Scholar] [CrossRef]

- Liu, F.; Wang, Y.; Burkhart, T.A.; Gonzalez Penedo, M.F.; Ma, S. Advances in Biomedical Engineering and Biotechnology during 2013–2014. Bio-Med. Mater. Eng. 2014, 24, 1891–1894. [Google Scholar] [CrossRef]

- Jarvis, M. Cellulose stacks up. Nature 2003, 426, 611–612. [Google Scholar] [CrossRef] [PubMed]

- Pauly, M.; Keegstra, K. Cell-wall carbohydrates and their modification as a resource for biofuels. Plant J. 2008, 54, 559–568. [Google Scholar] [CrossRef] [PubMed]

- O’sullivan, A.C. Cellulose: The structure slowly unravels. Cellulose 1997, 4, 173–207. [Google Scholar] [CrossRef]

- Ilham, Z. Biomass classification and characterization for conversion to biofuels. In Value-Chain of Biofuels; Elsevier: Amsterdam, The Netherlands, 2022; pp. 69–87. [Google Scholar]

- Yoneda, Y.; Mereiter, K.; Jaeger, C.; Brecker, L.; Kosma, P.; Rosenau, T.; French, A. van der Waals versus hydrogen-bonding forces in a crystalline analog of cellotetraose: Cyclohexyl 4′-O-cyclohexyl β-d-cellobioside cyclohexane solvate. J. Am. Chem. Soc. 2008, 130, 16678–16690. [Google Scholar] [CrossRef]

- Kuga, S.; Takagi, S.; Brown Jr, R.M. Native folded-chain cellulose II. Polymer 1993, 34, 3293–3297. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H. X-ray diffraction study of bamboo fibers treated with NaOH. Fibers Polym. 2008, 9, 735–739. [Google Scholar] [CrossRef]

- Revol, J.F.; Goring, D. On the mechanism of the mercerization of cellulose in wood. J. Appl. Polym. Sci. 1981, 26, 1275–1282. [Google Scholar] [CrossRef]

- Kolpak, F.; Blackwell, J. Determination of the structure of cellulose II. Macromolecules 1976, 9, 273–278. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Jiang, T.; Liang, Y.; Zhu, W.; Inamdar, U.Y.; Pervez, M.N.; Navik, R.; Yang, X.; Cai, Y.; Naddeo, V. Combination of pre-and post-mercerization processes for cotton fabric. Materials 2022, 15, 2092. [Google Scholar] [CrossRef] [PubMed]

- Roche, E.; Chanzy, H. Electron microscopy study of the transformation of cellulose I into cellulose IIII in Valonia. Int. J. Biol. Macromol. 1981, 3, 201–206. [Google Scholar] [CrossRef]

- Hermans, P.; Weidinger, A. On the transformation of cellulose II into cellulose IV. J. Colloid Sci. 1946, 1, 495–504. [Google Scholar] [CrossRef]

- Srivastava, D.; Ahopelto, J.; Karttunen, A.J. Thermodynamic Properties of Crystalline Cellulose Allomorphs Studied with Dispersion-Corrected Density Functional Methods. Molecules 2022, 27, 6240. [Google Scholar] [CrossRef] [PubMed]

- Chopra, L. Extraction of cellulosic fibers from the natural resources: A short review. Mater. Today Proc. 2022, 48, 1265–1270. [Google Scholar] [CrossRef]

- Meyer, K.H.; Badenhuizen, N. Transformation of Hydrate Cellulose into Native Cellulose. Nature 1937, 140, 281–282. [Google Scholar] [CrossRef]

- Poursorkhabi, V.; Misra, M.; Mohanty, A.K. Extraction of lignin from a coproduct of the cellulosic ethanol industry and its thermal characterization. BioResources 2013, 8, 5083–5101. [Google Scholar] [CrossRef]

- Wada, M.; Heux, L.; Sugiyama, J. Polymorphism of cellulose I family: Reinvestigation of cellulose IVI. Biomacromolecules 2004, 5, 1385–1391. [Google Scholar] [CrossRef] [PubMed]

- Zahmatkesh, S.; Klemeš, J.J.; Bokhari, A.; Wang, C.; Sillanpaa, M.; Hasan, M.; Amesho, K.T. Critical role of Hyssop plant in the possible transmission of SARS-CoV-2 in contaminated human Feces and its implications for the prevention of the virus spread in sewage. Chemosphere 2022, 305, 135247. [Google Scholar] [CrossRef] [PubMed]

- Aziz, T.; Haq, F.; Farid, A.; Kiran, M.; Faisal, S.; Ullah, A.; Ullah, N.; Bokhari, A.; Mubashir, M.; Chuah, L.F. Challenges associated with cellulose composite material: Facet engineering and prospective. Environ. Res. 2023, 223, 115429. [Google Scholar] [CrossRef] [PubMed]

- Oprea, M.; Voicu, S.I. Recent advances in composites based on cellulose derivatives for biomedical applications. Carbohydr. Polym. 2020, 247, 116683. [Google Scholar] [CrossRef]

- Bergenstråhle, M.; Wohlert, J.; Himmel, M.E.; Brady, J.W. Simulation studies of the insolubility of cellulose. Carbohydr. Res. 2010, 345, 2060–2066. [Google Scholar] [CrossRef]

- Zimmermann, M.V.; Borsoi, C.; Lavoratti, A.; Zanini, M.; Zattera, A.J.; Santana, R.M.C. Drying techniques applied to cellulose nanofibers. J. Reinf. Plast. Compos. 2016, 35, 628–643. [Google Scholar] [CrossRef]

- Moser, C.; Henriksson, G.; Lindström, M. Improved dispersibility of once-dried cellulose nanofibers in the presence of glycerol. Nord. Pulp Pap. Res. J. 2018, 33, 647–650. [Google Scholar] [CrossRef]

- Diniz, J.; Gil, H.; Castro, J.A.A.M. Hornification—Its origin and interpretation in wood pulps. Wood Sci. Technol. 2004, 37, 489–494. [Google Scholar] [CrossRef]

- Hosseini, S.S.; Yamini, B.; Ichkitidze, L.; Asadi, M.; Fernandez, J.; Gholampour, S. Enhanced Ionic Polymer–Metal Composites with Nanocomposite Electrodes for Restoring Eyelid Movement of Patients with Ptosis. Nanomaterials 2023, 13, 473. [Google Scholar] [CrossRef]

- Stenton, M.; Houghton, J.A.; Kapsali, V.; Blackburn, R.S. The Potential for Regenerated Protein Fibres within a Circular Economy: Lessons from the Past Can Inform Sustainable Innovation in the Textiles Industry. Sustainability 2021, 13, 2328. [Google Scholar] [CrossRef]

- Woodings, C. Fibers, Regenerated Cellulose. In Kirk-Othmer Encyclopedia of Chemical Technology; Woodhead Publishing: Lenexa, KS, USA, 2003. [Google Scholar]

- Nguyen, P.Q.; Soenksen, L.R.; Donghia, N.M.; Angenent-Mari, N.M.; de Puig, H.; Huang, A.; Lee, R.; Slomovic, S.; Galbersanini, T.; Lansberry, G.; et al. Wearable materials with embedded synthetic biology sensors for biomolecule detection. Nat. Biotechnol. 2021, 39, 1366–1374. [Google Scholar] [CrossRef] [PubMed]

- Tu, H.; Li, X.; Liu, Y.; Luo, L.; Duan, B.; Zhang, R. Recent progress in regenerated cellulose-based fibers from alkali/urea system via spinning process. Carbohydr. Polym. 2022, 296, 119942. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.C.; Kim, D.; Lee, J.Y.; Zhai, L.; Kim, J. Effect of Wet Spinning and Stretching to Enhance Mechanical Properties of Cellulose Nanofiber Filament. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 567–575. [Google Scholar] [CrossRef]

- Navard, P. The European Polysaccharide Network of Excellence (EPNOE). Carbohydr. Polym. 2013, 93, 2. [Google Scholar] [CrossRef]

- Rana, S.; Pichandi, S.; Parveen, S.; Fangueiro, R. Regenerated Cellulosic Fibers and Their Implications on Sustainability; Springer: Singapore, 2014; pp. 239–276. [Google Scholar]

- Kostag, M.; Jedvert, K.; Malek, N. Cellulose Regeneration and Chemical Recycling: Closing the “Cellulose Gap” Using Environmentally Benign Solvents. Macromol. Mater. Eng. 2020, 305, 1900832. [Google Scholar] [CrossRef]

- DeFrates, K.G.; Moore, R.; Borgesi, J.; Lin, G.; Mulderig, T.; Beachley, V.; Hu, X. Protein-Based Fiber Materials in Medicine: A Review. Nanomaterials 2018, 8, 457. [Google Scholar] [CrossRef]

- Heinze, T.; Koschella, A. Solvents applied in the field of cellulose chemistry—A mini review. Polim.-Cienc. E Tecnol. 2005, 15, 84–90. [Google Scholar] [CrossRef]

- Chen, X.; Burger, C.; Wan, F.; Zhang, J.; Rong, L.; Hsiao, B.S.; Chu, B.; Cai, J.; Zhang, L. Structure Study of Cellulose Fibers Wet-Spun from Environmentally Friendly NaOH/Urea Aqueous Solutions. Biomacromolecules 2007, 8, 1918–1926. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M.K. Environmental impact assessment of man-made cellulose fibres. Resour. Conserv. Recycl. 2010, 55, 260–274. [Google Scholar] [CrossRef]

- Peng, H.; Dai, G.; Wang, S.; Xu, H. The evolution behavior and dissolution mechanism of cellulose in aqueous solvent. J. Mol. Liq. 2017, 241, 959–966. [Google Scholar] [CrossRef]

- Rosenau, T.; Potthast, A.; Sixta, H.; Kosma, P. The chemistry of side reactions and byproduct formation in the system NMMO/cellulose (Lyocell process). Prog. Polym. Sci. 2001, 26, 1763–1837. [Google Scholar] [CrossRef]

- Ingildeev, D.; Effenberger, F.; Bredereck, K.; Hermanutz, F. Comparison of direct solvents for regenerated cellulosic fibers via the lyocell process and by means of ionic liquids. J. Appl. Polym. Sci. 2013, 128, 4141–4150. [Google Scholar] [CrossRef]

- Tu, H.; Xie, K.; Ying, D.; Luo, L.; Liu, X.; Chen, F.; Duan, B.; Fu, Q.; Zhang, L. Green and Economical Strategy for Spinning Robust Cellulose Filaments. ACS Sustain. Chem. Eng. 2020, 8, 14927–14937. [Google Scholar] [CrossRef]

- Singh, S.K.; Savoy, A.W. Ionic liquids synthesis and applications: An overview. J. Mol. Liq. 2020, 297, 112038. [Google Scholar] [CrossRef]

- Mohd, N.; Draman, S.F.S.; Salleh, M.S.N.; Yusof, N.B. Dissolution of cellulose in ionic liquid: A review. AIP Conf. Proc. 2017, 1809, 020035. [Google Scholar] [CrossRef]

- Sashina, E. Design of ionic solvents for production of man-made cellulose and silk fibers. J. Text. Eng. Fash. Technol. 2019, 5, 94. [Google Scholar] [CrossRef]

- Wanasekara, N.D.; Michud, A.; Zhu, C.; Rahatekar, S.; Sixta, H.; Eichhorn, S.J. Deformation mechanisms in ionic liquid spun cellulose fibers. Polymer 2016, 99, 222–230. [Google Scholar] [CrossRef]

- Xu, J.; Hou, H.; Liu, B.; Hu, J. The integration of different pretreatments and ionic liquid processing of eucalyptus: Hemicellulosic products and regenerated cellulose fibers. Ind. Crops Prod. 2017, 101, 11–20. [Google Scholar] [CrossRef]

- Alam, M.N.; Christopher, L.P. A novel, cost-effective and eco-friendly method for preparation of textile fibers from cellulosic pulps. Carbohydr. Polym. 2017, 173, 253–258. [Google Scholar] [CrossRef]

- Fattahi Meyabadi, T.; Dadashian, F.; Mir Mohamad Sadeghi, G.; Ebrahimi Zanjani Asl, H. Spherical cellulose nanoparticles preparation from waste cotton using a green method. Powder Technol. 2014, 261, 232–240. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Qiu, Y.; Wang, H.; Chen, Y.; Jin, S.; Chen, S. Preparation of Nanofibers with Renewable Polymers and Their Application in Wound Dressing. Int. J. Polym. Sci. 2016, 2016, 4672839. [Google Scholar] [CrossRef]

- Spizzirri, U.G.; Aiello, F.; Carullo, G.; Facente, A.; Restuccia, D. Nanotechnologies: An Innovative Tool to Release Natural Extracts with Antimicrobial Properties. Pharmaceutics 2021, 13, 230. [Google Scholar] [CrossRef] [PubMed]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crops Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Davoudpour, Y.; Islam, M.N.; Mustapha, A.; Sudesh, K.; Dungani, R.; Jawaid, M. Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohydr. Polym. 2014, 99, 649–665. [Google Scholar] [CrossRef]

- John, R.; Mauricio, B.; Yhors, C. Current Trends in the Production of Cellulose Nanoparticles and Nanocomposites for Biomedical Applications. In Cellulose; Matheus, P., Heitor Luiz Ornaghi, J., Eds.; IntechOpen: Rijeka, Croatia, 2015; Chapter 8. [Google Scholar]

- Li, J.; Wei, X.; Wang, Q.; Chen, J.; Chang, G.; Kong, L.; Su, J.; Liu, Y. Homogeneous isolation of nanocellulose from sugarcane bagasse by high pressure homogenization. Carbohydr. Polym. 2012, 90, 1609–1613. [Google Scholar] [CrossRef] [PubMed]

- Asim, M. Nanocellulose: Preparation method and applications. In Cellulose-Reinforced Nanofibre Composites: Production Properties and Application; Mohammad Jawaid, S.B., Abdul Khalil, H.P.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 261–276. [Google Scholar]

- Hayashi, N.; Kondo, T.; Ishihara, M. Enzymatically produced nano-ordered short elements containing cellulose Iβ crystalline domains. Carbohydr. Polym. 2005, 61, 191–197. [Google Scholar] [CrossRef]

- Thi Thanh Hop, T.; Thi Mai, D.; Duc Cong, T.; Nhi, T.T.Y.; Duc Loi, V.; Thi Mai Huong, N.; Trinh Tung, N. A comprehensive study on preparation of nanocellulose from bleached wood pulps by TEMPO-mediated oxidation. Results Chem. 2022, 4, 100540. [Google Scholar] [CrossRef]

- Hubbe, M.; Rojas, O.; Lucia, L.; Sain, M. Cellulosic nanocomposites: A review. BioResources 2008, 3, 929–980. [Google Scholar]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Barhoum, A.; Xiaoqing, C.; Haoyi, L.; Samyn, P. Cellulose Nanofibers: Fabrication and Surface Functionalization Techniques. In Handbook of Nanofibers; Springer: Cham, Switzerland, 2018; pp. 1–41. [Google Scholar]

- Omran, A.A.B.; Mohammed, A.A.; Sapuan, S.; Ilyas, R.; Asyraf, M.; Rahimian Koloor, S.S.; Petrů, M. Micro-and nanocellulose in polymer composite materials: A review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef] [PubMed]

- Nune, S.; Rama, K.; Dirisala, V.; Chavali, M. Electrospinning of Collagen Nanofiber Scaffolds for Tissue Repair and Regeneration; Elsevier: Amsterdam, The Netherlands, 2017; pp. 281–311. [Google Scholar]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef] [PubMed]

- Nayak, R.; Padhye, R.; Kyratzis, I.L.; Truong, Y.B.; Arnold, L. Recent advances in nanofibre fabrication techniques. Text. Res. J. 2011, 82, 129–147. [Google Scholar] [CrossRef]

- Alghoraibi, I.; Alomari, S. Different Methods for Nanofiber Design and Fabrication. In Handbook of Nanofibers; Barhoum, A., Bechelany, M., Makhlouf, A.S.H., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 79–124. [Google Scholar]

- Zahmatkeshan, M.; Adel, M.; Bahrami, S.; Esmaeili, F.; Rezayat, S.M.; Saeedi, Y.; Mehravi, B.; Jameie, S.B.; Ashtari, K. Polymer-Based Nanofibers: Preparation, Fabrication, and Applications. In Handbook of Nanofibers; Barhoum, A., Bechelany, M., Makhlouf, A.S.H., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 215–261. [Google Scholar]

- Tan, X.; Rodrigue, D. A Review on Porous Polymeric Membrane Preparation. Part II: Production Techniques with Polyethylene, Polydimethylsiloxane, Polypropylene, Polyimide, and Polytetrafluoroethylene. Polymers 2019, 11, 1310. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.W.; Liu, S.J. Nanofibers used for delivery of antimicrobial agents. Nanomedicine 2015, 10, 1959–1971. [Google Scholar] [CrossRef]

- Stojanovska, E.; Canbay, E.; Pampal, E.S.; Calisir, M.D.; Agma, O.; Polat, Y.; Simsek, R.; Gundogdu, N.A.S.; Akgul, Y.; Kilic, A. A review on non-electro nanofibre spinning techniques. RSC Adv. 2016, 6, 83783–83801. [Google Scholar] [CrossRef]

- Li, D.; Zhang, W.; Sun, R.; Chen, G.; Fan, X.; Gou, L.; Mao, Y.; Zhao, K.; Tian, M. Soft-template construction of three-dimensionally ordered inverse opal structure from Li2FeSiO4/C composite nanofibers for high-rate lithium-ion batteries. Nanoscale 2016, 8, 12202–12214. [Google Scholar] [CrossRef]

- Meng, Y.; Gu, D.; Zhang, F.; Shi, Y.; Yang, H.; Li, Z.; Yu, C.; Tu, B.; Zhao, D. Ordered mesoporous polymers and homologous carbon frameworks: Amphiphilic surfactant templating and direct transformation. Angew. Chem. Int. Ed. 2005, 44, 7053–7059. [Google Scholar] [CrossRef]

- Poolakkandy, R.R.; Menamparambath, M.M. Soft-template-assisted synthesis: A promising approach for the fabrication of transition metal oxides. Nanoscale Adv. 2020, 2, 5015–5045. [Google Scholar] [CrossRef]

- Almetwally, A.A.; El-Sakhawy, M.; Elshakankery, M.; Kasem, M.H. Technology of nano-fibers: Production techniques and properties—Critical review. J. Text. Assoc. 2017, 78, 5–14. [Google Scholar]

- Sabzehmeidani, M.M.; Ghaedi, M. Chapter 5—Adsorbents based on nanofibers. In Interface Science and Technology; Ghaedi, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 33, pp. 389–443. [Google Scholar]

- Zugenmaier, P. Crystalline Cellulose and Derivatives: Characterization and Structures; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Zhang, J.; Elder, T.J.; Pu, Y.; Ragauskas, A.J. Facile synthesis of spherical cellulose nanoparticles. Carbohydr. Polym. 2007, 69, 607–611. [Google Scholar] [CrossRef]

- Yackel, E.C.; Kenyon, W.O. The oxidation of cellulose by nitrogen dioxide. J. Am. Chem. Soc. 1942, 64, 121–127. [Google Scholar] [CrossRef]

- Ruan, C.-Q.; Strømme, M.; Mihranyan, A.; Lindh, J. Favored surface-limited oxidation of cellulose with Oxone® in water. RSC Adv. 2017, 7, 40600–40607. [Google Scholar] [CrossRef]

- Isogai, A.; Hänninen, T.; Fujisawa, S.; Saito, T. Catalytic oxidation of cellulose with nitroxyl radicals under aqueous conditions. Prog. Polym. Sci. 2018, 86, 122–148. [Google Scholar] [CrossRef]

- Liu, P.; Pang, B.; Dechert, S.; Zhang, X.C.; Andreas, L.B.; Fischer, S.; Meyer, F.; Zhang, K. Structure selectivity of alkaline periodate oxidation on lignocellulose for facile isolation of cellulose nanocrystals. Angew. Chem. Int. Ed. 2020, 59, 3218–3225. [Google Scholar] [CrossRef]

- Masci, E.; Faillace, G.; Longoni, M. Use of oxidized regenerated cellulose to achieve hemostasis during laparoscopic cholecystectomy: A retrospective cohort analysis. BMC Res. Notes 2018, 11, 239. [Google Scholar] [CrossRef]

- Wu, Y.D.; He, J.M.; Huang, Y.D.; Wang, F.W.; Tang, F. Oxidation of regenerated cellulose with nitrogen dioxide/carbon tetrachloride. Fibers Polym. 2012, 13, 576–581. [Google Scholar] [CrossRef]

- Martina, B.; Kateřina, K.; Miloslava, R.; Jan, G.; Ruta, M. Oxycellulose: Significant characteristics in relation to its pharmaceutical and medical applications. Adv. Polym. Technol. J. Polym. Process. Inst. 2009, 28, 199–208. [Google Scholar] [CrossRef]

- Seddiqi, H.; Oliaei, E.; Honarkar, H.; Jin, J.; Geonzon, L.C.; Bacabac, R.G.; Klein-Nulend, J. Cellulose and its derivatives: Towards biomedical applications. Cellulose 2021, 28, 1893–1931. [Google Scholar] [CrossRef]

- Xiao, B.; Qian, Y.; Li, X.; Tao, Y.; Yi, Z.; Jiang, Q.; Luo, Y.; Yang, J. Enhancing the stability of planar perovskite solar cells by green and inexpensive cellulose acetate butyrate. J. Energy Chem. 2023, 76, 259–265. [Google Scholar] [CrossRef]

- Heinze, T.; Liebert, T. Unconventional methods in cellulose functionalization. Prog. Polym. Sci. 2001, 26, 1689–1762. [Google Scholar] [CrossRef]

- Coughlin, M.L.; Liberman, L.; Ertem, S.P.; Edmund, J.; Bates, F.S.; Lodge, T.P. Methyl cellulose solutions and gels: Fibril formation and gelation properties. Prog. Polym. Sci. 2021, 112, 101324. [Google Scholar] [CrossRef]

- Mondal, P.; Behera, P.K.; Singha, N.K. Macromolecular engineering in functional polymers via ‘click chemistry’using triazolinedione derivatives. Prog. Polym. Sci. 2021, 113, 101343. [Google Scholar] [CrossRef]

- Roy, D.; Semsarilar, M.; Guthrie, J.T.; Perrier, S. Cellulose modification by polymer grafting: A review. Chem. Soc. Rev. 2009, 38, 2046–2064. [Google Scholar] [CrossRef]

- Li, Y.; Tian, Y.; Zheng, W.; Feng, Y.; Huang, R.; Shao, J.; Tang, R.; Wang, P.; Jia, Y.; Zhang, J. Composites of bacterial cellulose and small molecule-decorated gold nanoparticles for treating Gram-Negative bacteria-infected wounds. Small 2017, 13, 1700130. [Google Scholar] [CrossRef]

- Oun, A.A.; Shankar, S.; Rhim, J.-W. Multifunctional nanocellulose/metal and metal oxide nanoparticle hybrid nanomaterials. Crit. Rev. Food Sci. Nutr. 2020, 60, 435–460. [Google Scholar] [CrossRef]

- Wang, C.; Bai, J.; Tian, P.; Xie, R.; Duan, Z.; Lv, Q.; Tao, Y. The application status of nanoscale cellulose-based hydrogels in tissue engineering and regenerative biomedicine. Front. Bioeng. Biotechnol. 2021, 9, 732513. [Google Scholar] [CrossRef]

- Fahma, F.; Lisdayana, N.; Abidin, Z.; Noviana, D.; Sari, Y.W.; Mukti, R.R.; Yunus, M.; Kusumaatmaja, A.; Kadja, G.T.M. Nanocellulose-based fibres derived from palm oil by-products and their in vitro biocompatibility analysis. J. Text. Inst. 2020, 111, 1354–1363. [Google Scholar] [CrossRef]

- Credou, J.; Berthelot, T. Cellulose: From biocompatible to bioactive material. J. Mater. Chem. B 2014, 2, 4767–4788. [Google Scholar] [CrossRef] [PubMed]

- Rostamitabar, M.; Subrahmanyam, R.; Gurikov, P.; Seide, G.; Jockenhoevel, S.; Ghazanfari, S. Cellulose aerogel micro fibers for drug delivery applications. Mater. Sci. Eng. C 2021, 127, 112196. [Google Scholar] [CrossRef]

- Iravani, S.; Varma, R.S. Cellulose-Based Composites as Scaffolds for Tissue Engineering: Recent Advances. Molecules 2022, 27, 8830. [Google Scholar] [CrossRef]

- Madub, K.; Goonoo, N.; Gimié, F.; Arsa, I.A.; Schönherr, H.; Bhaw-Luximon, A. Green seaweeds ulvan-cellulose scaffolds enhance in vitro cell growth and in vivo angiogenesis for skin tissue engineering. Carbohydr. Polym. 2021, 251, 117025. [Google Scholar] [CrossRef]

- Sumini, M.; Souza, C.R.d.; Andrade, G.J.S.; Oliveira, I.R.C.; Scandorieiro, S.; Tischer, C.A.; Kobayashi, R.K.T.; Nakazato, G. Cellulose Hydrogel with Hyaluronic Acid and Silver Nanoparticles: Sustained-Release Formulation with Antibacterial Properties against Pseudomonas aeruginosa. Antibiotics 2023, 12, 873. [Google Scholar] [CrossRef]

- Qian, J.; Dong, Q.; Chun, K.; Zhu, D.; Zhang, X.; Mao, Y.; Culver, J.N.; Tai, S.; German, J.R.; Dean, D.P. Highly stable, antiviral, antibacterial cotton textiles via molecular engineering. Nat. Nanotechnol. 2023, 18, 168–176. [Google Scholar] [CrossRef]

- Chabannes, M.; Ruel, K.; Yoshinaga, A.; Chabbert, B.; Jauneau, A.; Joseleau, J.P.; Boudet, A.M. In situ analysis of lignins in transgenic tobacco reveals a differential impact of individual transformations on the spatial patterns of lignin deposition at the cellular and subcellular levels. Plant J. 2001, 28, 271–282. [Google Scholar] [CrossRef]

- Gibson, L.J. The hierarchical structure and mechanics of plant materials. J. R. Soc. Interface 2012, 9, 2749–2766. [Google Scholar] [CrossRef]

- Benítez, A.; Walther, A. Cellulose nanofibril nanopapers and bioinspired nanocomposites: A review to understand the mechanical property space. J. Mater. Chem. A 2017, 5, 16003–16024. [Google Scholar] [CrossRef]

- Ciccocioppo, R.; Cantore, A.; Chaimov, D.; Orlando, G. Regenerative medicine: The red planet for clinicians. Intern. Emerg. Med. 2019, 14, 911–921. [Google Scholar] [CrossRef] [PubMed]

- Eldeeb, A.E.; Salah, S.; Elkasabgy, N.A. Biomaterials for Tissue Engineering Applications and Current Updates in the Field: A Comprehensive Review. AAPS PharmSciTech 2022, 23, 267. [Google Scholar] [CrossRef] [PubMed]

- Eldeeb, A.E.; Salah, S.; Mabrouk, M.; Amer, M.S.; Elkasabgy, N.A. Dual-drug delivery via zein in situ forming implants augmented with titanium-doped bioactive glass for bone regeneration: Preparation, in vitro characterization, and in vivo evaluation. Pharmaceutics 2022, 14, 274. [Google Scholar] [CrossRef]

- Abudula, T.; Saeed, U.; Memic, A.; Gauthaman, K.; Hussain, M.A.; Al-Turaif, H. Electrospun cellulose Nano fibril reinforced PLA/PBS composite scaffold for vascular tissue engineering. J. Polym. Res. 2019, 26, 110. [Google Scholar] [CrossRef]

- He, H.; Cheng, M.; Liang, Y.; Zhu, H.; Sun, Y.; Dong, D.; Wang, S. Intelligent cellulose nanofibers with excellent biocompatibility enable sustained antibacterial and drug release via a pH-responsive mechanism. J. Agric. Food Chem. 2020, 68, 3518–3527. [Google Scholar] [CrossRef] [PubMed]

- Maurmann, N.; Sperling, L.-E.; Pranke, P. Electrospun and electrosprayed scaffolds for tissue engineering. Adv. Exp. Med. Biol. 2018, 1078, 79–100. [Google Scholar] [PubMed]

- Katari, R.; Peloso, A.; Orlando, G. Tissue engineering and regenerative medicine: Semantic considerations for an evolving paradigm. Front. Bioeng. Biotechnol. 2015, 2, 57. [Google Scholar] [CrossRef] [PubMed]

- Guan, Q.-F.; Yang, H.-B.; Han, Z.-M.; Ling, Z.-C.; Yin, C.-H.; Yang, K.-P.; Zhao, Y.-X.; Yu, S.-H. Sustainable cellulose-nanofiber-based hydrogels. ACS Nano 2021, 15, 7889–7898. [Google Scholar] [CrossRef]

- Nonsuwan, P.; Matsugami, A.; Hayashi, F.; Hyon, S.-H.; Matsumura, K. Controlling the degradation of an oxidized dextran-based hydrogel independent of the mechanical properties. Carbohydr. Polym. 2019, 204, 131–141. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef] [PubMed]

- Adel, I.M.; ElMeligy, M.F.; Amer, M.S.; Elkasabgy, N.A. Polymeric nanocomposite hydrogel scaffold for jawbone regeneration: The role of rosuvastatin calcium-loaded silica nanoparticles. Int. J. Pharm. X 2023, 6, 100213. [Google Scholar] [CrossRef]

- Elkasabgy, N.A.; Mahmoud, A.A.; Shamma, R.N. Determination of cytocompatibility and osteogenesis properties of in situ forming collagen-based scaffolds loaded with bone synthesizing drug for bone tissue engineering. Int. J. Polym. Mater. Polym. Biomater. 2018, 67, 494–500. [Google Scholar] [CrossRef]

- Garai, S.; Sinha, A. Biomimetic nanocomposites of carboxymethyl cellulose–hydroxyapatite: Novel three dimensional load bearing bone grafts. Colloids Surf. B Biointerfaces 2014, 115, 182–190. [Google Scholar] [CrossRef] [PubMed]

- Park, M.; Lee, D.; Shin, S.; Hyun, J. Effect of negatively charged cellulose nanofibers on the dispersion of hydroxyapatite nanoparticles for scaffolds in bone tissue engineering. Colloids Surf. B Biointerfaces 2015, 130, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Patil, T.V.; Patel, D.K.; Dutta, S.D.; Ganguly, K.; Santra, T.S.; Lim, K.-T. Nanocellulose, a versatile platform: From the delivery of active molecules to tissue engineering applications. Bioact. Mater. 2022, 9, 566–589. [Google Scholar] [CrossRef] [PubMed]

- Sukul, M.; Nguyen, T.B.L.; Min, Y.-K.; Lee, S.-Y.; Lee, B.-T. Effect of Local Sustainable Release of BMP2-VEGF from Nano-Cellulose Loaded in Sponge Biphasic Calcium Phosphate on Bone Regeneration. Tissue Eng. Part A 2015, 21, 1822–1836. [Google Scholar] [CrossRef] [PubMed]

- Salama, A.; Abou-Zeid, R.E.; Cruz-Maya, I.; Guarino, V. Soy protein hydrolysate grafted cellulose nanofibrils with bioactive signals for bone repair and regeneration. Carbohydr. Polym. 2020, 229, 115472. [Google Scholar] [CrossRef] [PubMed]

- Hickey, R.J.; Pelling, A.E. Cellulose biomaterials for tissue engineering. Front. Bioeng. Biotechnol. 2019, 7, 45. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, P.K.; Adhikari, J.; Saha, P. Facile fabrication of electrospun regenerated cellulose nanofiber scaffold for potential bone-tissue engineering application. Int. J. Biol. Macromol. 2019, 122, 644–652. [Google Scholar] [CrossRef] [PubMed]

- Brohem, C.A.; da Silva Cardeal, L.B.; Tiago, M.; Soengas, M.S.; de Moraes Barros, S.B.; Maria-Engler, S.S. Artificial skin in perspective: Concepts and applications. Pigment Cell Melanoma Res. 2011, 24, 35–50. [Google Scholar] [CrossRef]

- Rho, K.S.; Jeong, L.; Lee, G.; Seo, B.-M.; Park, Y.J.; Hong, S.-D.; Roh, S.; Cho, J.J.; Park, W.H.; Min, B.-M. Electrospinning of collagen nanofibers: Effects on the behavior of normal human keratinocytes and early-stage wound healing. Biomaterials 2006, 27, 1452–1461. [Google Scholar] [CrossRef]

- Hu, M.S.; Maan, Z.N.; Wu, J.-C.; Rennert, R.C.; Hong, W.X.; Lai, T.S.; Cheung, A.T.; Walmsley, G.G.; Chung, M.T.; McArdle, A. Tissue engineering and regenerative repair in wound healing. Ann. Biomed. Eng. 2014, 42, 1494–1507. [Google Scholar] [CrossRef]

- Vig, K.; Chaudhari, A.; Tripathi, S.; Dixit, S.; Sahu, R.; Pillai, S.; Dennis, V.A.; Singh, S.R. Advances in skin regeneration using tissue engineering. Int. J. Mol. Sci. 2017, 18, 789. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Moser, C.; Lindström, M.E.; Henriksson, G.; Li, J. Cellulose nanofibers from softwood, hardwood, and tunicate: Preparation–structure–film performance interrelation. ACS Appl. Mater. Interfaces 2017, 9, 13508–13519. [Google Scholar] [CrossRef] [PubMed]

- Fukuya, M.N.; Senoo, K.; Kotera, M.; Yoshimoto, M.; Sakata, O. Change in the crystallite orientation of poly (ethylene oxide)/cellulose nanofiber composite films. Biomacromolecules 2017, 18, 4411–4415. [Google Scholar] [CrossRef] [PubMed]

- Bacakova, L.; Pajorova, J.; Bacakova, M.; Skogberg, A.; Kallio, P.; Kolarova, K.; Svorcik, V. Versatile application of nanocellulose: From industry to skin tissue engineering and wound healing. Nanomaterials 2019, 9, 164. [Google Scholar] [CrossRef] [PubMed]

- Savin, C.L.; Peptu, C.; Kroneková, Z.; Sedlačík, M.; Mrlik, M.; Sasinková, V.; Peptu, C.A.; Popa, M.; Mosnáček, J. Polyglobalide-based porous networks containing poly (ethylene glycol) structures prepared by photoinitiated thiol–ene coupling. Biomacromolecules 2018, 19, 3331–3342. [Google Scholar] [CrossRef] [PubMed]

- Amaral, H.R.; Wilson, J.A.; do Amaral, R.J.; Pasçu, I.; de Oliveira, F.C.; Kearney, C.J.; Freitas, J.C.; Heise, A. Synthesis of bilayer films from regenerated cellulose nanofibers and poly (globalide) for skin tissue engineering applications. Carbohydr. Polym. 2021, 252, 117201. [Google Scholar] [CrossRef]

- Xi, P.; Quan, F.; Sun, Y.; Jiang, Y. Cellulose nanofibers reinforced nanocomposites with high strength and toughness by tunable wet-drawing and ionic cross-linking method. Compos. Part B Eng. 2022, 242, 110078. [Google Scholar] [CrossRef]

- Guan, Q.-F.; Yang, H.-B.; Han, Z.-M.; Zhou, L.-C.; Zhu, Y.-B.; Ling, Z.-C.; Jiang, H.-B.; Wang, P.-F.; Ma, T.; Wu, H.-A. Lightweight, tough, and sustainable cellulose nanofiber-derived bulk structural materials with low thermal expansion coefficient. Sci. Adv. 2020, 6, eaaz1114. [Google Scholar] [CrossRef]

- Moon, S.M.; Heo, J.E.; Jeon, J.; Eom, T.; Jang, D.; Her, K.; Cho, W.; Woo, K.; Wie, J.J.; Shim, B.S. High crystallinity of tunicate cellulose nanofibers for high-performance engineering films. Carbohydr. Polym. 2021, 254, 117470. [Google Scholar] [CrossRef]

- Zhang, W.; Zhong, L.; Wang, T.; Jiang, Z.; Gao, X.; Zhang, L. Surface modification of cellulose nanofibers and their effects on the morphology and properties of polysulfone membranes. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 012016. [Google Scholar]

- Cheng, K.-C.; Huang, C.-F.; Wei, Y.; Hsu, S.-h. Novel chitosan–cellulose nanofiber self-healing hydrogels to correlate self-healing properties of hydrogels with neural regeneration effects. NPG Asia Mater. 2019, 11, 25. [Google Scholar] [CrossRef]

- Cui, S.; Zhang, S.; Coseri, S. An injectable and self-healing cellulose nanofiber-reinforced alginate hydrogel for bone repair. Carbohydr. Polym. 2023, 300, 120243. [Google Scholar] [CrossRef]

- Zong, S.; Wen, H.; Lv, H.; Li, T.; Tang, R.; Liu, L.; Jiang, J.; Wang, S.; Duan, J. Intelligent hydrogel with both redox and thermo-response based on cellulose nanofiber for controlled drug delivery. Carbohydr. Polym. 2022, 278, 118943. [Google Scholar] [CrossRef] [PubMed]

- Elafify, M.S.; Itagaki, T.; Elkasabgy, N.A.; Sayed, S.; Ito, Y.; Ueda, M. Reversible transformation of peptide assembly between densified-polysarcosine-driven kinetically and helix-orientation-driven thermodynamically stable morphologies. Biomater. Sci. 2023, 11, 6280–6286. [Google Scholar] [CrossRef] [PubMed]

- Abo Elela, M.M.; ElKasabgy, N.A.; Basalious, E.B. Bio-shielding in situ forming gels (BSIFG) loaded with lipospheres for depot injection of quetiapine fumarate: In vitro and in vivo evaluation. AAPS PharmSciTech 2017, 18, 2999–3010. [Google Scholar] [CrossRef] [PubMed]

- Tamay, D.G.; Dursun Usal, T.; Alagoz, A.S.; Yucel, D.; Hasirci, N.; Hasirci, V. 3D and 4D printing of polymers for tissue engineering applications. Front. Bioeng. Biotechnol. 2019, 7, 164. [Google Scholar] [CrossRef] [PubMed]

- Elkasabgy, N.A.; Mahmoud, A.A.; Maged, A. 3D printing: An appealing route for customized drug delivery systems. Int. J. Pharm. 2020, 588, 119732. [Google Scholar] [CrossRef] [PubMed]

- Mallakpour, S.; Tabesh, F.; Hussain, C.M. 3D and 4D printing: From innovation to evolution. Adv. Colloid Interface Sci. 2021, 294, 102482. [Google Scholar] [CrossRef] [PubMed]

- Pugliese, R.; Regondi, S. Artificial intelligence-empowered 3D and 4D printing technologies toward smarter biomedical materials and approaches. Polymers 2022, 14, 2794. [Google Scholar] [CrossRef] [PubMed]

- Elkasabgy, N.A.; Mahmoud, A.A. Fabrication strategies of scaffolds for delivering active ingredients for tissue engineering. AAPS PharmSciTech 2019, 20, 256. [Google Scholar] [CrossRef]

- Nishino, T.; Matsuda, I.; Hirao, K. All-cellulose composite. Macromolecules 2004, 37, 7683–7687. [Google Scholar] [CrossRef]

- Yuan, R.; Wu, K.; Fu, Q. 3D printing of all-regenerated cellulose material with truly 3D configuration: The critical role of cellulose microfiber. Carbohydr. Polym. 2022, 294, 119784. [Google Scholar] [CrossRef]

- Vinogradova, T.I.; Serdobintsev, M.S.; Korzhikova-Vlakh, E.G.; Korzhikov-Vlakh, V.A.; Kaftyrev, A.S.; Blum, N.M.; Semenova, N.Y.; Esmedlyaeva, D.S.; Dyakova, M.E.; Nashchekina, Y.A. Comparison of Autografts and Biodegradable 3D-Printed Composite Scaffolds with Osteoconductive Properties for Tissue Regeneration in Bone Tuberculosis. Biomedicines 2023, 11, 2229. [Google Scholar] [CrossRef] [PubMed]

- Dutta, S.D.; Patil, T.V.; Ganguly, K.; Randhawa, A.; Acharya, R.; Moniruzzaman, M.; Lim, K.-T. Trackable and highly fluorescent nanocellulose-based printable bio-resins for image-guided tissue regeneration. Carbohydr. Polym. 2023, 320, 121232. [Google Scholar] [CrossRef] [PubMed]

- Gauss, C.; Pickering, K.L.; Tshuma, J.; McDonald-Wharry, J. Production and Assessment of Poly (Lactic Acid) Matrix Composites Reinforced with Regenerated Cellulose Fibres for Fused Deposition Modelling. Polymers 2022, 14, 3991. [Google Scholar] [CrossRef]

- Gauss, C.; Pickering, K.; Barbier, M.; Miller, T. Additive manufacturing of hygromorphic structures using regenerated cellulose/PLA biocomposites. In Materials Today Proceedings; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Khalid, M.Y.; Arif, Z.U.; Noroozi, R.; Hossain, M.; Ramakrishna, S.; Umer, R. 3D/4D printing of cellulose nanocrystals-based biomaterials: Additives for sustainable applications. Int. J. Biol. Macromol. 2023, 251, 126287. [Google Scholar] [CrossRef] [PubMed]

- Gauss, C.; Pickering, K.L.; Muthe, L.P. The use of cellulose in bio-derived formulations for 3D/4D printing: A review. Compos. Part C Open Access 2021, 4, 100113. [Google Scholar] [CrossRef]

- Wu, J.; Zheng, Y.; Song, W.; Luan, J.; Wen, X.; Wu, Z.; Chen, X.; Wang, Q.; Guo, S. In situ synthesis of silver-nanoparticles/bacterial cellulose composites for slow-released antimicrobial wound dressing. Carbohydr. Polym. 2014, 102, 762–771. [Google Scholar] [CrossRef]

- Bodea, I.M.; Cătunescu, G.M.; Pop, C.R.; Fiț, N.I.; David, A.P.; Dudescu, M.C.; Stănilă, A.; Rotar, A.M.; Beteg, F.I. Antimicrobial properties of bacterial cellulose films enriched with bioactive herbal extracts obtained by microwave-assisted extraction. Polymers 2022, 14, 1435. [Google Scholar] [CrossRef]

- Rai, M.; Yadav, A.; Gade, A. Silver nanoparticles as a new generation of antimicrobials. Biotechnol. Adv. 2009, 27, 76–83. [Google Scholar] [CrossRef]

- Vaou, N.; Stavropoulou, E.; Voidarou, C.; Tsigalou, C.; Bezirtzoglou, E. Towards advances in medicinal plant antimicrobial activity: A review study on challenges and future perspectives. Microorganisms 2021, 9, 2041. [Google Scholar] [CrossRef]

- Ohta, Y.; Kondo, Y.; Kawada, K.; Teranaka, T.; Yoshino, N. Synthesis and antibacterial activity of quaternary ammonium salt-type antibacterial agents with a phosphate group. J. Oleo Sci. 2008, 57, 445–452. [Google Scholar] [CrossRef] [PubMed]

- Oprea, M.; Panaitescu, D.M. Nanocellulose hybrids with metal oxides nanoparticles for biomedical applications. Molecules 2020, 25, 4045. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Sun, H.; Tan, S.; Gao, J.; Fu, Y.; Liu, Z. Hydrothermal synthesis of Ag nanoparticles on the nanocellulose and their antibacterial study. Inorg. Chem. Commun. 2019, 100, 44–50. [Google Scholar] [CrossRef]

- Garza-Cervantes, J.A.; Mendiola-Garza, G.; de Melo, E.M.; Dugmore, T.I.; Matharu, A.S.; Morones-Ramirez, J.R. Antimicrobial activity of a silver-microfibrillated cellulose biocomposite against susceptible and resistant bacteria. Sci. Rep. 2020, 10, 7281. [Google Scholar] [CrossRef]

- Wasim, M.; Khan, M.R.; Mushtaq, M.; Naeem, A.; Han, M.; Wei, Q. Surface modification of bacterial cellulose by copper and zinc oxide sputter coating for UV-resistance/antistatic/antibacterial characteristics. Coatings 2020, 10, 364. [Google Scholar] [CrossRef]

- Du, P.; Xu, Y.; Shi, Y.; Xu, Q.; Xu, Y. Amino modified cellulose fibers loaded zinc oxide nanoparticles via paper-making wet-forming for antibacterial materials. Int. J. Biol. Macromol. 2023, 227, 795–804. [Google Scholar] [CrossRef]

- Supramaniam, J.; Low, D.Y.S.; Wong, S.K.; Tan, L.T.H.; Leo, B.F.; Goh, B.H.; Darji, D.; Mohd Rasdi, F.R.; Chan, K.G.; Lee, L.H. Facile synthesis and characterization of palm CNF-ZnO nanocomposites with antibacterial and reinforcing properties. Int. J. Mol. Sci. 2021, 22, 5781. [Google Scholar] [CrossRef]

- Hasan, M.S.; Al Foisal, J.; Khan, G.A.; Jahan, R.; Hasanuzzaman, M.; Alam, M.S.; Karim, M.M.; Gafur, M.; Khan, M.A.; Sabur, M.A. Microfibrillated cellulose-silver nanocomposite based PVA hydrogels and their enhanced physical, mechanical and antibacterial properties. J. Polym. Environ. 2022, 30, 2875–2887. [Google Scholar] [CrossRef]

- Shanmugam, C.; Sivasubramanian, G.; Govindhan, P.; Bera, P.; Baskaran, K.; Parameswaran, V.R.I. Antimicrobial and Free Radical Scavenging Activities of Cellulose/Silver-Nanocomposites with In Situ Generated Silver Nanoparticles Using Cissampelos Pareira Leaf Extract. J. Clust. Sci. 2022, 33, 1727–1737. [Google Scholar] [CrossRef]

- Silva, D.J.; Barbosa, R.F.; Souza, A.G.; Ferreira, R.R.; Camani, P.H.; Rosa, D.S. Morphological, UV blocking, and antimicrobial features of multifunctional cotton fibers coated with ZnO/Cu via sonochemistry. Mater. Chem. Phys. 2022, 286, 126210. [Google Scholar] [CrossRef]

- Yahia, I.S.; Shkir, M.; Keshk, S.M.A.S. Physicochemical properties of a nanocomposite (graphene oxide-hydroxyapatite-cellulose) immobilized by Ag nanoparticles for biomedical applications. Results Phys. 2020, 16, 102990. [Google Scholar] [CrossRef]

- Bhutiya, P.L.; Misra, N.; Rasheed, M.A.; Hasan, S.Z. Silver nanoparticles deposited algal nanofibrous cellulose sheet for antibacterial activity. BioNanoScience 2020, 10, 23–33. [Google Scholar] [CrossRef]

- Abd El-Hady, M.; Farouk, A.; Saeed, S.E.-S.; Zaghloul, S. Antibacterial and UV protection properties of modified cotton fabric using a Curcumin/TiO2 nanocomposite for medical textile applications. Polymers 2021, 13, 4027. [Google Scholar] [CrossRef] [PubMed]

- Seetha, J.; Mallavarapu, U.; Mesa, A. In situ green synthesis of antibacterial copper nanocomposite cotton fabrics using Achyranthes aspera leaf extract. J. Appl. Pharm. Sci. 2020, 10, 104–109. [Google Scholar]

- Balashanmugam, P.; Kalaichelvan, P.T. Biosynthesis characterization of silver nanoparticles using Cassia roxburghii DC. aqueous extract, and coated on cotton cloth for effective antibacterial activity. Int. J. Nanomed. 2015, 10, 87–97. [Google Scholar] [CrossRef] [PubMed]

- Asmat-Campos, D.; de Oca-Vásquez, G.M.; Rojas-Jaimes, J.; Delfín-Narciso, D.; Juárez-Cortijo, L.; Nazario-Naveda, R.; Menezes, D.B.; Pereira, R.; de la Cruz, M.S. Cu2O nanoparticles synthesized by green and chemical routes, and evaluation of their antibacterial and antifungal effect on functionalized textiles. Biotechnol. Rep. 2023, 37, e00785. [Google Scholar] [CrossRef] [PubMed]

- AL-Dharob, M.H.; Mouhamad, R.S.; Al Khafaji, K.A.; Al-Abodi, E.E. Antibacterial efficacy of cotton nanofiber soaked in Ag, ZnO and TiO2 nanoparticles. Chem. Int. 2022, 8, 58–67. [Google Scholar]

- Stefanovic, O.; Comic, L. Synergistic antibacterial interaction between Melissa officinalis extracts and antibiotics. J. Appl. Pharm. Sci. 2012, 2, 1–5. [Google Scholar]

- Merkl, R.; HRádkoVá, I.; FIlIp, V.; ŠMIdRkal, J. Antimicrobial and antioxidant properties of phenolic acids alkyl esters. Czech J. Food Sci. 2010, 28, 275–279. [Google Scholar] [CrossRef]

- Radulovic, N.; Blagojevic, P.; Stojanovic-Radic, Z.; Stojanovic, N. Antimicrobial plant metabolites: Structural diversity and mechanism of action. Curr. Med. Chem. 2013, 20, 932–952. [Google Scholar]

- Yan, Y.; Li, X.; Zhang, C.; Lv, L.; Gao, B.; Li, M. Research progress on antibacterial activities and mechanisms of natural alkaloids: A review. Antibiotics 2021, 10, 318. [Google Scholar] [CrossRef]

- Miklasińska-Majdanik, M.; Kępa, M.; Wojtyczka, R.D.; Idzik, D.; Wąsik, T.J. Phenolic compounds diminish antibiotic resistance of Staphylococcus aureus clinical strains. Int. J. Environ. Res. Public Health 2018, 15, 2321. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Kubec, R.; Musah, R.A. Antibacterial and antifungal activity of sulfur-containing compounds from Petiveria alliacea L. J. Ethnopharmacol. 2006, 104, 188–192. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Yang, L.; Wang, Y.; Ran, Y.; Li, S.; Ding, W. Preliminary studies on the antibacterial mechanism of a new plant-derived compound, 7-methoxycoumarin, against Ralstonia solanacearum. Front. Microbiol. 2021, 12, 697911. [Google Scholar] [CrossRef] [PubMed]

- El Fannassi, Y.; Gharsallaoui, A.; Khelissa, S.; El Amrani, M.A.; Suisse, I.; Sauthier, M.; Jama, C.; Boudra, S.; Chihib, N.-E. Complexation of Terpenes for the Production of New Antimicrobial and Antibiofilm Molecules and Their Encapsulation in Order to Improve Their Activities. Appl. Sci. 2023, 13, 9854. [Google Scholar] [CrossRef]

- Oprică, G.M.; Panaitescu, D.M.; Usurelu, C.D.; Vlăsceanu, G.M.; Stanescu, P.O.; Lixandru, B.E.; Vasile, V.; Gabor, A.R.; Nicolae, C.-A.; Ghiurea, M. Nanocellulose Sponges Containing Antibacterial Basil Extract. Int. J. Mol. Sci. 2023, 24, 11871. [Google Scholar] [CrossRef] [PubMed]

- Saleh, S.; Salama, A.; Ali, A.M.; Saleh, A.K.; Elhady, B.A.; Tolba, E. Egyptian propolis extract for functionalization of cellulose nanofiber/poly (vinyl alcohol) porous hydrogel along with characterization and biological applications. Sci. Rep. 2023, 13, 7739. [Google Scholar] [CrossRef]

- Hillyer, M.B.; Nam, S.; Condon, B.D. Intrafibrillar dispersion of cuprous oxide (Cu2O) nanoflowers within cotton cellulose fabrics for permanent antibacterial, antifungal and antiviral activity. Molecules 2022, 27, 7706. [Google Scholar] [CrossRef]

- Varaprasad, K.; Jayaramudu, T.; Kanikireddy, V.; Toro, C.; Sadiku, E.R. Alginate-based composite materials for wound dressing application:A mini review. Carbohydr. Polym. 2020, 236, 116025. [Google Scholar] [CrossRef]

- Rezvani Ghomi, E.; Khalili, S.; Nouri Khorasani, S.; Esmaeely Neisiany, R.; Ramakrishna, S. Wound dressings: Current advances and future directions. J. Appl. Polym. Sci. 2019, 136, 47738. [Google Scholar] [CrossRef]

- Luo, R.; Dai, J.; Zhang, J.; Li, Z. Accelerated Skin Wound Healing by Electrical Stimulation. Adv. Healthc. Mater. 2021, 10, 2100557. [Google Scholar] [CrossRef] [PubMed]

- Naskar, A.; Kim, K.S. Recent Advances in Nanomaterial-Based Wound-Healing Therapeutics. Pharmaceutics 2020, 12, 499. [Google Scholar] [CrossRef] [PubMed]

- Fatehi, P.; Abbasi, M. Medicinal plants used in wound dressings made of electrospun nanofibers. J. Tissue Eng. Regen. Med. 2020, 14, 1527–1548. [Google Scholar] [CrossRef] [PubMed]

- Gisby, J.; Bryant, J. Efficacy of a new cream formulation of mupirocin: Comparison with oral and topical agents in experimental skin infections. Antimicrob. Agents Chemother. 2000, 44, 255–260. [Google Scholar] [CrossRef] [PubMed]

- Ambekar, R.S.; Kandasubramanian, B. Advancements in nanofibers for wound dressing: A review. Eur. Polym. J. 2019, 117, 304–336. [Google Scholar] [CrossRef]

- Koushki, P.; Bahrami, S.H.; Ranjbar-Mohammadi, M. Coaxial nanofibers from poly(caprolactone)/poly(vinyl alcohol)/Thyme and their antibacterial properties. J. Ind. Text. 2016, 47, 834–852. [Google Scholar] [CrossRef]

- Adeli, H.; Khorasani, M.T.; Parvazinia, M. Wound dressing based on electrospun PVA/chitosan/starch nanofibrous mats: Fabrication, antibacterial and cytocompatibility evaluation and in vitro healing assay. Int. J. Biol. Macromol. 2019, 122, 238–254. [Google Scholar] [CrossRef]

- Savencu, I.; Iurian, S.; Porfire, A.; Bogdan, C.; Tomuță, I. Review of advances in polymeric wound dressing films. React. Funct. Polym. 2021, 168, 105059. [Google Scholar] [CrossRef]

- Intranuovo, F.; Gristina, R.; Brun, F.; Mohammadi, S.; Ceccone, G.; Sardella, E.; Rossi, F.; Tromba, G.; Favia, P. Plasma Modification of PCL Porous Scaffolds Fabricated by Solvent-Casting/Particulate-Leaching for Tissue Engineering. Plasma Process. Polym. 2014, 11, 184–195. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Thillaipandian, H.; Ritvic, V.; Premitha, R.; Dharshini, A.; Giri Dev, V.R. Facile and Cost-Effective Development of Silver based Cellulosic Wound Dressing using Electrospraying Process. J. Nat. Fibers 2021, 19, 7436–7444. [Google Scholar] [CrossRef]

- Beg, S.; Almalki, W.H.; Malik, A.; Farhan, M.; Aatif, M.; Rahman, Z.; Alruwaili, N.K.; Alrobaian, M.; Tarique, M.; Rahman, M. 3D printing for drug delivery and biomedical applications. Drug Discov. Today 2020, 25, 1668–1681. [Google Scholar] [CrossRef] [PubMed]

- Maver, T.; Smrke, D.M.; Kurečič, M.; Gradišnik, L.; Maver, U.; Kleinschek, K.S. Combining 3D printing and electrospinning for preparation of pain-relieving wound-dressing materials. J. Sol-Gel Sci. Technol. 2018, 88, 33–48. [Google Scholar] [CrossRef]

- Kupnik, K.; Primožič, M.; Kokol, V.; Leitgeb, M. Nanocellulose in Drug Delivery and Antimicrobially Active Materials. Polymers 2020, 12, 2825. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Dai, L.; Si, C.; Zeng, Z. Antibacterial and hemostatic hydrogel via nanocomposite from cellulose nanofibers. Carbohydr. Polym. 2018, 195, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Md Abu, T.; Zahan, K.A.; Rajaie, M.A.; Leong, C.R.; Ab Rashid, S.; Mohd nor Hamin, N.S.; Tan, W.-N.; Tong, W.Y. Nanocellulose as drug delivery system for honey as antimicrobial wound dressing. Mater. Today Proc. 2020, 31, 14–17. [Google Scholar] [CrossRef]

- Basu, A.; Lindh, J.; Ålander, E.; Strømme, M.; Ferraz, N. On the use of ion-crosslinked nanocellulose hydrogels for wound healing solutions: Physicochemical properties and application-oriented biocompatibility studies. Carbohydr. Polym. 2017, 174, 299–308. [Google Scholar] [CrossRef]

- Hakkarainen, T.; Koivuniemi, R.; Kosonen, M.; Escobedo-Lucea, C.; Sanz-Garcia, A.; Vuola, J.; Valtonen, J.; Tammela, P.; Mäkitie, A.; Luukko, K.; et al. Nanofibrillar cellulose wound dressing in skin graft donor site treatment. J. Control. Release Off. J. Control. Release Soc. 2016, 244 Pt B, 292–301. [Google Scholar] [CrossRef]

- Capozza, M.; Pansini, G.; Buccoliero, A.M.; Barbagli, G.; Ashraf-Noubari, B.; Mariotti, F.; Ammannati, F. Foreign body reaction mimicking intracranial abscess following the use of oxidized regenerated cellulose (SurgicelTM): Case report and literature review. Iran. J. Neurosurg. 2016, 2, 20–23. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.; Chen, S.; Zhang, X.; Ma, J.; He, J. Oxidized cellulose-based hemostatic materials. Carbohydr. Polym. 2020, 230, 115585. [Google Scholar] [CrossRef]

- Liu, J.; Lan, G.; Lu, B.; He, L.; Yu, K.; Chen, J.; Wang, T.; Dai, F.; Wu, D. Properties of a new hemostatic gauze prepared with in situ thrombin induction. Biomed. Phys. Eng. Express 2017, 3, 015001. [Google Scholar] [CrossRef]

- Cheng, W.; He, J.; Wu, Y.; Song, C.; Xie, S.; Huang, Y.; Fu, B. Preparation and characterization of oxidized regenerated cellulose film for hemostasis and the effect of blood on its surface. Cellulose 2013, 20, 2547–2558. [Google Scholar] [CrossRef]

- Sezer, U.A.; Kocer, Z.; Sahin, İ.; Aru, B.; Demirel, G.Y.; Sezer, S. Oxidized regenerated cellulose cross-linked gelatin microparticles for rapid and biocompatible hemostasis: A versatile cross-linking agent. Carbohydr. Polym. 2018, 200, 624–632. [Google Scholar] [CrossRef] [PubMed]

- Bazghaleh, A.A.; Dogolsar, M.A. Preparation of Degradable Oxidized Regenerated Cellulose Gauze by Zinc Modification on HNO 3/Cu Oxidized Viscose Fibers. Fibers Polym. 2019, 20, 1125–1135. [Google Scholar] [CrossRef]

- Hutchinson, R.W.; George, K.; Johns, D.; Craven, L.; Zhang, G.; Shnoda, P. Hemostatic efficacy and tissue reaction of oxidized regenerated cellulose hemostats. Cellulose 2013, 20, 537–545. [Google Scholar] [CrossRef]

- Mehdizadeh, M.; Yang, J. Design strategies and applications of tissue bioadhesives. Macromol. Biosci. 2013, 13, 271–288. [Google Scholar] [CrossRef]

- Zhang, W.; Ji, T.; Lyon, S.; Mehta, M.; Zheng, Y.; Deng, X.; Liu, A.; Shagan, A.; Mizrahi, B.; Kohane, D.S. Functionalized multiarmed polycaprolactones as biocompatible tissue adhesives. ACS Appl. Mater. Interfaces 2020, 12, 17314–17320. [Google Scholar] [CrossRef]

- Luo, J.-W.; Liu, C.; Wu, J.-H.; Lin, L.-X.; Fan, H.-M.; Zhao, D.-H.; Zhuang, Y.-Q.; Sun, Y.-L. In situ injectable hyaluronic acid/gelatin hydrogel for hemorrhage control. Mater. Sci. Eng. C 2019, 98, 628–634. [Google Scholar] [CrossRef]

- Czaja, W.K.; Young, D.J.; Kawecki, M.; Brown, R.M. The future prospects of microbial cellulose in biomedical applications. Biomacromolecules 2007, 8, 1–12. [Google Scholar] [CrossRef]

- Pinkas, O.; Haneman, O.; Chemke, O.; Zilberman, M. Fiber-reinforced composite hydrogels for bioadhesive and sealant applications. Polym. Adv. Technol. 2017, 28, 1162–1169. [Google Scholar] [CrossRef]

- Veigel, S.; Müller, U.; Keckes, J.; Obersriebnig, M.; Gindl-Altmutter, W. Cellulose nanofibrils as filler for adhesives: Effect on specific fracture energy of solid wood-adhesive bonds. Cellulose 2011, 18, 1227–1237. [Google Scholar] [CrossRef] [PubMed]

- European Pharmacopoeia Technical Guide for the Elaboration of Monographs on Medicinal Products Containing Chemically Defined Active Substances. 2020. Available online: https://www.edqm.eu/en/-/new-european-pharmacopoeia-technical-guide-for-the-elaboration-of-monographs-on-medicinal-products-containing-chemically-defined-active-substances-now-available (accessed on 5 October 2023).

- Qin, Y. Biocompatibility testing for medical textile products. Med. Text. Mater. 2016, 191–201. [Google Scholar] [CrossRef]

- Perez, M.; Maiguy-Foinard, A.; Barthélémy, C.; Décaudin, B.; Odou, P. Particulate matter in injectable drugs: Evaluation of risks to patients. Pharm. Technol. Hosp. Pharm. 2016, 1, 91–103. [Google Scholar] [CrossRef]

- Erdal, N.B.; Hakkarainen, M. Degradation of cellulose derivatives in laboratory, man-made, and natural environments. Biomacromolecules 2022, 23, 2713–2729. [Google Scholar] [CrossRef]

- Rogina-Car, B.; Pušić, T.; Dekanić, T. Impact of washing and sterilization on properties of fabrics used for medical applications. Indian J. Fibre Text. Res. 2016, 41, 426–431. [Google Scholar]

| Nanoparticles Used | Pathogens Combated | Final Product | Key Findings | Ref. |

|---|---|---|---|---|

| AgNPs | Pseudomonas aeruginosa | Topical hydrogel composed of nanocellulose and hyaluronic acid and loaded with AgNPs. | Bactericidal efficacy of 99.99%. | [129] |

| AgNPs | E.coli, S. aureus, P. aeruginosa. | Microfibrillated cellulose/silver nanocomposites hydrogels incorporated in polyvinyl alcohol hydrogel. | Significant antimicrobial activity. | [195] |

| AgNPs | E. coli, S. aureus, P. aeruginosa two clinical isolates multidrug resistant S. aureus and P. aeruginosa. | Orange peel cellulose bio-composites loaded with AgNPs | Excellent antimicrobial activity against both Gram-positive and Gram-negative strains. | [191] |

| AgNPs | S. aureus; E. coli; Vibrio cholera, P. aeruginosa, Bacillus subtilis; Enterococcus faecalis; Eubacteriumlentum; Staphylococcus epidhermis; Trichophytonrubru, Candida albicans, Aspergillus flaves, Trichophytonsimi, Trichophytonmentagrophytes | Regenerated cellulose matrix (leaf extract of Cissampelos pareira) loaded with AgNPs. | Antibacterial and antifungal properties were enhanced with increasing AgNO3 concentration. | [196] |

| ZnO and Cu NPs | E. coli | Cotton fibers loaded with ZnO and CuNPs. | The cotton fibers were effective against E. coli under photoirradiation. | [197] |

| AgNPs | S. aureus, E. coli C. albicans | Composite membranes based on Graphene oxide/hydroxyapatite/cellulose fibers containing AgNPs. | Strong antimicrobial activity. | [198] |

| AgNPs | S. aureus, E. coli | AgNPs-coated cellulose sheets | AgNs-coated cellulose sheet showed good antimicrobial properties against S. aureus: 54.5% and E. coli: 43.8%. | [199] |

| Titanium dioxide (TiO2NPs) | S. aureus, E. coli | Cotton fibers loaded with curcumin/TiO2 nanocomposite. | Results indicated that E coli had a higher response than S. aureus, which could be due to variations in bacterial cell wall organization structure. | [200] |

| CuNPs | S. aureus P. aeruginosa bac | Cotton fibers extracted from A. aspera and loaded with CuNPs. | Good antibacterial activity. | [201] |

| AgNPs | B. subtilis, S. aureus, M. luteus, P. aeruginosa, E. coli, E. aerogenes. | Cotton fibers extracted from Cassia roxburghii and loaded with AgNPs. | High antibacterial activity. | [202] |

| Cu2ONPs | E. coli, S. aureus, A. brasiliensis | Cellule textiles loaded with Cu2ONPs | All fabrics treated with Cu2ONPs exhibited a 100% inhibitory effect against E. coli and S. aureus. As for the antifungal effect against A. brasiliensis, Cu2ONPs-treated fabrics demonstrated notable antifungal activity. | [203] |

| AgNPs, ZnONPs and TiO2NPs | S. aureus, S. epidermidis | Cotton nanofibers (derived from Allium cepa) loaded with Ag, ZnO and TiO2 nanoparticles | Results demonstrated that bacterial growth of both S. aureus and S. epidermidis were diminished after treatment with cotton coated with silver or titanium NPs. | [204] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nocca, G.; Arcovito, A.; Elkasabgy, N.A.; Basha, M.; Giacon, N.; Mazzinelli, E.; Abdel-Maksoud, M.S.; Kamel, R. Cellulosic Textiles—An Appealing Trend for Different Pharmaceutical Applications. Pharmaceutics 2023, 15, 2738. https://0-doi-org.brum.beds.ac.uk/10.3390/pharmaceutics15122738

Nocca G, Arcovito A, Elkasabgy NA, Basha M, Giacon N, Mazzinelli E, Abdel-Maksoud MS, Kamel R. Cellulosic Textiles—An Appealing Trend for Different Pharmaceutical Applications. Pharmaceutics. 2023; 15(12):2738. https://0-doi-org.brum.beds.ac.uk/10.3390/pharmaceutics15122738

Chicago/Turabian StyleNocca, Giuseppina, Alessandro Arcovito, Nermeen A. Elkasabgy, Mona Basha, Noah Giacon, Elena Mazzinelli, Mohammed S. Abdel-Maksoud, and Rabab Kamel. 2023. "Cellulosic Textiles—An Appealing Trend for Different Pharmaceutical Applications" Pharmaceutics 15, no. 12: 2738. https://0-doi-org.brum.beds.ac.uk/10.3390/pharmaceutics15122738