Assessment of Disintegration of Compostable Bioplastic Bags by Management of Electromechanical and Static Home Composters

Abstract

:1. Introduction

2. Materials and Methods

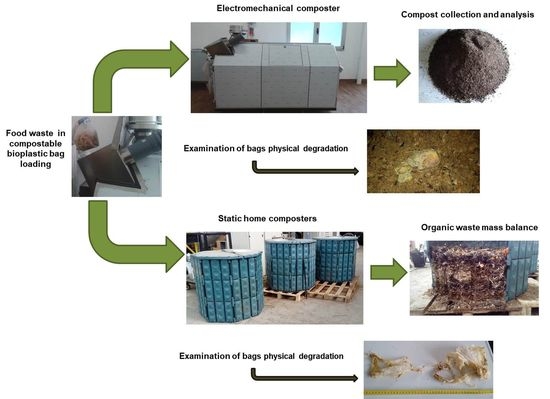

2.1. Experimental Setup

2.1.1. Community Composting

2.1.2. Home Composting

2.1.3. Compostable Bioplastic Bags

2.1.4. Measuring Instrumentation

2.2. Methods

2.2.1. Community Composting and Curing

2.2.2. Static Home Composting

2.2.3. Recovery of Compostable Bioplastic Bag Fragments

3. Results and Discussion

3.1. Experiments with the ECs

3.2. Home Composting

4. Conclusions

- The EC provided with inside moving parts was unfit, as the bags caused clogging and the risk of jamming.

- Thanks to the good aerobic conditions reached during the process, the EC degraded the bags up to 90 wt% of the initial amount introduced in 72 days, and the subsequent curing process completed the physical degradation of the residual fragments.

- Composting carried out by static home composters is greatly dependent on the external ambient temperature and operating conditions. In any case, a degradation of 90% to 96% was achieved, regardless of whether or not the composter was managed carefully.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ISPRA (Istituto Superiore per la Protezione e la Ricerca Ambientale. The Italian Institute for Environmental Protection and Research) Rapporto Rifiuti Urbani. Municipal Waste Report; Rapporti 313/2019; Edition 2019; ISPRA: Rome, Italy, 2019; ISBN 978-88-448-0971-3. (In Italian) [Google Scholar]

- Eurostat Statistical Book. Energy, Transport and Environmental Indicators. 2017. Available online: https://ec.europa.eu/eurostat/documents/3217494/8435375/KS-DK-17-001-EN-N.pdf/18d1ecfd-acd8-4390-ade6-e1f858d746da (accessed on 8 October 2020).

- Centemero, M. Qualità Organico da RD CIC Position Paper 2nd Version October 2009. Organic Waste Quality from Separate Collection. Available online: https://www.yumpu.com/it/document/view/37215489/nota-qualita-rd-organico-ott2009finalepdf-consorzio-italiano (accessed on 18 December 2020). (In Italian).

- European Bioplastic. Bioplastics Facts and Figures. 2020. Available online: https://docs.european-bioplastics.org/publications/EUBP_Facts_and_figures.pdf (accessed on 6 October 2020).

- UNI EN 13432-2002 Requirements for Packaging Recoverable through Composting and Biodegradation. Test Scheme and Evaluation Criteria for the Final Acceptance of Packaging; European Committee for Standardization: Brussels, Belgium, 2002.

- Italian National Law 27 December 2006, n. 296.

- Italian National Law 24 March 2012, n. 28.

- Italian National Law 3 August 2017, n. 123.

- Landolfo, P.; Musmeci, F. The community composting. Il compostaggio di comunità. EAI 2013, 5, 95–101. (In Italian) [Google Scholar]

- European Bioplastic. Home Composting of Compostable Bioplastics. 2018. Available online: https://docs.european-bioplastics.org/publications/pp/EUBP_PP_Home_composting.pdf (accessed on 8 October 2020).

- Rudnik, E.; Briassoulis, D. Degradation behaviour of poly (lactic acid) films and fibres in soil under Mediterranean field conditions and laboratory simulations testing. Ind. Crops Prod. 2011, 33, 648–658. [Google Scholar] [CrossRef]

- Italian National Law 28 December 2015, n. 221.

- Italian Ministry of Environment Decree 29 December 2016, n. 266.

- Bruni, C.; Akyol, Ç.; Cipolletta, G.; Eusebi, A.L.; Caniani, D.; Masi, S.; Colòn, J.; Fatone, F. Decentralized Community Composting: Past, Present and Future Aspects of Italy. Sustainability 2020, 12, 3319. [Google Scholar] [CrossRef] [Green Version]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef] [PubMed]

- Vaverková, M.; Adamcová, D. Biodegrability of bioplastic materials in a controlled composting environment. J. Ecol. Eng. 2015, 16, 155–160. [Google Scholar] [CrossRef]

- Ruggero, F.; Gori, R.; Lubello, C. Methodologies to assess biodegradation of bioplastics during aerobic composting and anaerobic digestion: A review. Waste Manag. Res. 2019, 37, 959–975. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahn, H.K.; Huda, M.S.; Smith, M.C.; Mulbry, W.; Schmidt, W.F.; Reeves, J.B., III. Biodegradability of injection molded bioplastic pots containing polylactic acid and poultry feather fiber. Bioresour. Technol. 2011, 102, 4930–4933. [Google Scholar] [CrossRef] [PubMed]

- Italian Standard UNI 11184:2016. Waste and Refuse Derived Fuels—Determination of Biological Stability by Dinamic Respirometric Index (DRI). Rifiuti e Combustibili Ricavati da Rifiuti—Determinazione Della Stabilità Biologica Mediante L’Indice di Respirazione Dinamico (IRD); UNI, Ente Italiano di Normazione: Rome, Italy, 2016. (In Italian) [Google Scholar]

- Adani, F.; Confalonieri, R.; Tambone, F. Dynamic Respiration Index as a Descriptor of the Biological Stability of Organic Wastes. J. Environ. Qual. 2004, 33, 1866–1876. [Google Scholar] [CrossRef] [PubMed]

- Bighanna Company Official Website. Available online: http://www.bighanna.com/how/ (accessed on 17 December 2020).

- Canditelli, M.; Coronidi, M.; Faustini, N.; Gravagno, M.; Landolfo, P.G.; Musmeci, F. Treatment of organic waste by means of community composters: ENEA experimental work. Trattamento dei rifiuti organici con compostatori di comunità: Sperimentazione ENEA. EAI Spec. 2016, 133–136. (In Italian) [Google Scholar]

- ISO 16929. Determination of the Degree of Disintegration of Plastic Materials under Defined Composting Conditions in a Pilot-Scale Test, 3rd ed.; International Organization for Standardization (ISO): Geneva, Switzerland, October 2019. [Google Scholar]

- ANPA (Agenzia Nazionale per la Protezione dell’Ambiente–Environmental Protection Italian National Agency). The Recovery of Organic Substance from Waste for the Production of Quality Amendments. Manuals and Guidelines 7/2002. Il Recupero di Sostanza Organica dai Rifiuti per la Produzione di Ammendanti di Qualità—Manuali e Linee Guida 7/2002; ANPA: Rome, Italy, 2002; ISBN 88-448-0052-7. (In Italian) [Google Scholar]

| Date (Elapsed Time) | Introduction of Compostable Bioplastic Bags |

|---|---|

| 1st day | 5 empty compostable bioplastic bags added to each static composter. |

| 15th day | 3 empty compostable bioplastic bags added and 2 compostable bioplastic bags filled with 1 kg of kitchen waste added to each static home composter. |

| 45th day | Compostable bioplastic bag fragments examined after completely emptying the static home composters |

| 85th day | 2 empty compostable bioplastic bags and 2 compostable bioplastic bags filled with 1 kg of kitchen waste added to each static home composter. |

| 175th day | End of the test: the static home composters were completely emptied and the compostable bioplastic bags fragments examined |

| Compostable Bioplastic Bags | Amount | Weight Loss |

|---|---|---|

| Compostable bioplastic bags initial weight (g) | 30 | - |

| Residual compostable bioplastic bags weight after 72 days (g) | 3.22 | 89 |

| Residual compostable bioplastic bags weight after 148 days (g) | n.d. | 100 |

| Parameters | Cured Heap |

|---|---|

| pH | 7.8 |

| Moisture (wt%) | 45 ± 0.2 |

| Final appearance | Granular, earthlike, |

| Odour | Agreeable |

| DRI (mg O2 kg SV−1 h−1) | 461 |

| Parameters | CMC | FVC | PMC |

|---|---|---|---|

| Total loaded food fraction (kg) | 292 | 377 | 258 |

| Total loaded bulking agent (kg) | 55 | 60 | 7 |

| Inoculum, i.e., cured compost (kg) | 11 | 11 | 0 |

| Watering (kg) | 55 | 16 | 0 |

| Total loaded amount (kg) | 358 | 448 | 265 |

| Total withdrawn amount (kg) | 89 | 162 | 58 |

| pH | 8.4 | 9.2 | 8.7 |

| Moisture (wt%) | 50 ± 20 | 75 ± 3 | 73 ± 3 |

| Appearance | Mixed mulch and cuttings | Dark, very humid | Mixed sludge |

| Odor | Agreeable | Rotten fruit | Pungent smell/rotten fruit |

| Composters Type | Time Period of Experiments | Compostable Bioplastic Bags Introduced | Compostable BioPlastic Bag Residues Removed (g) | Degradation Rate (wt%) | |

|---|---|---|---|---|---|

| Bag Number | Weight (g) | ||||

| PMC | First emptying (1st–45th day) | 10 | 50 | 24.0 | 52 |

| Whole set of experiments (1st–180th day) | 14 | 70 | 3.7 | 95 | |

| FVC | First emptying (1st–45th day) | 10 | 50 | 7.6 | 85 |

| Whole set of experiments (1st–180th day) | 14 | 70 | 7.2 | 90 | |

| CMC | First emptying (1st–45th day) | 10 | 50 | 11.3 | 77 |

| Whole set of experiments (1st–180th day) | 14 | 70 | 2.9 | 96 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cafiero, L.M.; Canditelli, M.; Musmeci, F.; Sagnotti, G.; Tuffi, R. Assessment of Disintegration of Compostable Bioplastic Bags by Management of Electromechanical and Static Home Composters. Sustainability 2021, 13, 263. https://0-doi-org.brum.beds.ac.uk/10.3390/su13010263

Cafiero LM, Canditelli M, Musmeci F, Sagnotti G, Tuffi R. Assessment of Disintegration of Compostable Bioplastic Bags by Management of Electromechanical and Static Home Composters. Sustainability. 2021; 13(1):263. https://0-doi-org.brum.beds.ac.uk/10.3390/su13010263

Chicago/Turabian StyleCafiero, Lorenzo Maria, Margherita Canditelli, Fabio Musmeci, Giulia Sagnotti, and Riccardo Tuffi. 2021. "Assessment of Disintegration of Compostable Bioplastic Bags by Management of Electromechanical and Static Home Composters" Sustainability 13, no. 1: 263. https://0-doi-org.brum.beds.ac.uk/10.3390/su13010263