Combined Use of GPR and Other NDTs for Road Pavement Assessment: An Overview

Abstract

:1. Introduction

2. Types of Pavements and Most Frequent Distresses

2.1. Superficial Distresses

2.1.1. Flexible Pavements

- Deformation

- Rutting: Grooves and surface depression in the wheel path may be caused by insufficient pavement thickness, weak asphalt mixtures, a lack of compaction, instability of the base surface or heavy traffic.

- Depressions: A depression (also called a bird- bath) is a localized displacement or low spot, with limited size, on the pavement surface. It results from a settlement of the subgrade or the result of improper compaction during construction.

- Swelling: An upward bulge in the surface layer is typically accompanied by surface cracking. It is generally caused by swelling of the subgrade or frost heave.

- Shoving and corrugation: A form of plastic movement in the surface layer that creates a localized bulging of the pavement typified by waves (shoving) or transverse ripples (corrugation). They are usually caused by traffic action (accelerations and decelerations points) combined with other pavement failures such as too soft asphalt, too much fine aggregate, rounded or coarse aggregate, poor bond between layers or too much, as well as a weak granular base or excessive moisture in the subgrade.

- Bumps and sags: Bumps are small localized upward displacements of the pavement surface, while sags are small, localized settlements of the road surface. Several factors can cause bumping in flexible pavements, such as frost heaves (due to expansion), plant roots growing under the pavement or tenting at cracks and joints.

- Cracking

- Longitudinal cracking: Cracks are predominantly parallel to the centerline or lateral. They are usually caused by differential volume changes in the subgrade, shrinkage due to temperature fluctuations, reflection at joints or poor construction of the longitudinal joint in the pavement surface or between two bands of bituminous mixtures.

- Transverse cracking: Cracks that extend perpendicular to the centerline or laydown direction of the road. Usually, this type of cracking is caused by shrinkage due to temperature changes and reflection of a crack or joint in an underlying pavement layer.

- Fatigue cracking (alligator, map or crocodile cracking): Series of interconnected cracks resembling the crocodile skin, with pieces generally less than 0.5 m on the longest side. This distress occurs only in areas subjected to repeated traffic loading or an increase in loading (e.g., wheel paths) together with a lack of bearing capacity or thickness, inadequate compaction, poor drainage or loss of base or subgrade support.

- Block cracking: Series of interconnected cracks that form in a roughly rectangular pattern with blocks ranging in size from 0.3 to 3 m. These cracks are generally due to asphalt binder aging or poor quality, the reflection of cracks in an underlying pavement layer, and shrinkage of the asphalt binder. Unlike fatigue cracking, block cracking is not load associated and occurs over a large portion of the pavement area.

- Slippage cracking: Sliding cracks that look similar to a crescent or a half-moon. This is typically caused by poor bonds between layers and accelerates in pavement areas under high stress, such as vehicle acceleration/deceleration.

- Edge cracking: Cracks located within 0.3 to 0.5 m of the outer edge of the pavement. This distress is typically due to fatigue or deformation of the pavement surface caused by passing heavy vehicles or a surface course excessively rigid compared to the underlying layers.

- Reflection cracking: Cracks that form in an overlay of a deteriorated asphalt pavement. This distress may be caused by the shifting or movement of the underlying old pavement.

- Disintegration

- Raveling and weathering: They are the disintegration of the pavement surface because of the dislodgement of aggregate particles. These distresses indicate an aging or hardening binder, aggregate segregation, and a lack of compaction. Raveling may also be caused by certain types of vehicles such as tracked vehicles and studded tires.

- Potholes: Localized disintegration of the pavement surface in the form of small bowl-shaped holes (usually less than 750 mm in diameter). Typically produced by the continued deterioration of another type of distress, such as fatigue cracking, raveling or failed patching. Continuous traffic together with insufficient pavement thickness and insufficient drainage stimulate pothole formation.

- Polished aggregates: Areas of pavement where the surface aggregates wear down to a smooth texture (there are no rough or angular aggregate particles). This defect may be reflected in a reduction in skid resistance or surface friction, and it is normally due to repeated traffic actions, especially if the aggregate is susceptible to abrasion.

- Patching: The result of repairing localized pavement defects (e.g., filling potholes or other pavement disintegration) or road works (e.g., piping). It is considered a defect because, when pavements are patched, some distress may begin to occur, influenced by compaction and the quality of the surrounding or underlying layers.

- Bleeding

2.1.2. Rigid Pavements

- Deformation

- Faulting: This is a difference in elevation between the joints mainly caused by settlement due to a weak foundation or pumping of subbase fine materials due to traffic loading. Additionally, changes in weather conditions and moisture cause curling or wrapping of the slab edges.

- Cracking

- Longitudinal cracking: Cracks along the slab in the direction of the traffic, mainly caused by traffic, thermal or moisture fatigue, but also by an inappropriate distribution of joints. These cracks can evolve into map or slab cracking.

- Durability cracking: Series of closely spaced cracks near a joint, crack, or free edge (corner), caused by freeze–thaw expansion that breaks concrete. Its evolution can generate spalling and disintegration.

- Transverse cracks: Cracks are predominantly perpendicular to the road axis, mainly motivated by a thermal gradient, poor thickness of the slab or inappropriate joints distribution. As longitudinal cracks, these cracks can evolve into map or slab cracking.

- Map cracking or crazing: A series of upper surface cracks, where longitudinal ones are larger, and the transverse ones interconnect them. Usually results from improper curing and/or finishing of the concrete, poor thickness, alkali–silica reactivity, or traffic fatigue. This failure can lead to scaling of the surface.

- Joint-related deficiencies

- Joint spalling: A break in the edge of pavement within 50–60 cm of transverse and longitudinal joints. This does not usually extend vertically through the pavement but at an angle through the joint. Joint spalling is mainly due to infiltration of incompressible materials or weaknesses in the concrete at the joint combined with excessive stresses in the joint caused by traffic loads. Additionally, water accumulation in pavement joints can cause spalling due to freeze–thaw action.

- Pumping: This is the draining of subsurface water and subbase fine materials from the pavement foundation through joints or cracks. This is caused by the deflection of the slab under repeated moving loads. Pumping near the joint is caused by poor sealing and causes voids and a loss of support, and it will eventually lead to cracking or settling and faulting.

- Disintegration

- Popouts: Loss of aggregates from the surface, ranging from 25 to 100 mm in diameter, leaving small divots or pock marks. Usually caused by poor mixture or poor aggregate durability and overloads.

- Blow-ups or buckling: Upward slab movement and buckling or shattering that occurs usually at a joint or transverse crack. This distress can be accelerated by joint spalling, durability cracks and freeze–thaw expansion.

- Polished aggregates: Areas of pavement where the mortar or aggregate extending above the asphalt binder wear down to a smooth texture (there are no rough or angular aggregate particles). The causes are aggregates with poor abrasion resistance, traffic fatigue or improper curing.

- Scaling: Deterioration of the surface course or wearing surface. Caused by improper curing or finishing (too much mortar or faulty sand) and freeze–thaw expansion.

- Patching: Portion of or whole slab replaced by new material (sometimes asphalt concrete) to repair localized pavement defects.

2.2. Internal Failures

2.2.1. Layer Thickness Deficiency

2.2.2. Moisture and Saturated Media

2.2.3. Non-Compaction and Porosity Changes

2.2.4. Debonding

2.2.5. Settlement and Sinkholes/Voids

2.2.6. Corrosion

2.2.7. Delamination

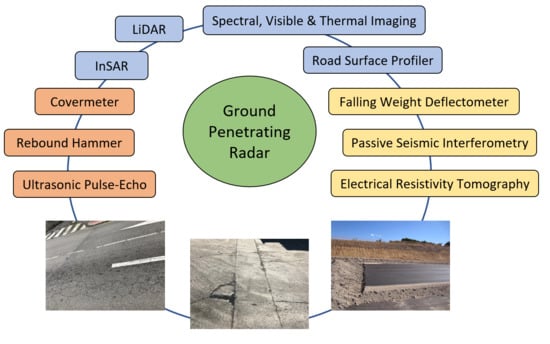

3. Non-Destructive Testing Commonly Used on Pavement Assessment

3.1. Interferometric Synthetic Aperture Radar

3.2. Imaging Techniques

3.2.1. Spectral Imaging

3.2.2. Visible Imaging

- Potholes,

- Cracks,

- Bleeding, and

- Polished aggregates.

3.2.3. Infrared Thermography Imaging

3.3. Light Detection and Ranging

- Rutting measurement [82], and

3.4. Profilometer

- Inertial unit (accelerometer) combined with the Quarter-Car System (QCS) and a laser height sensor to balance vertical vehicle motion.

- Distance Measuring Device (DMI) to measure the distance. For instance, an odometer or GPS.

- A system to collect and store the data.

3.5. Ground-Penetrating Radar

3.6. Deflectometers

3.7. Passive Seismic Interferometry

3.8. Electrical Resistivity Tomography

3.9. Rebound Hammer

- Uniformity and quality of the cement concrete [172].

3.10. Covermeter

3.11. Ultrasonic Pulse-Echo Test

4. Methodology for Reviewing Process

- We used Scopus and Web of Science databases to retrieve the related research publications. A set of keywords of non-destructive tests relevant to our review topic were used to cover a broad area of research articles.

- We considered manuscripts such as review articles, original research, technical notes, and case studies when they matched the search criteria. Then, the redundant or irrelevant publications were excluded from the initial review list based on reading the title and abstract of each publication. For example, publications related to cultural heritage preservation were excluded, as they are not relevant to our review.

- Publications list was from Open Access articles, and our institutional available publishers (Elsevier, IEEE Xplore, ASCE, Springer, and Taylor & Francis).

- A total of 122 publications were relevant to the review topic including 25 articles that were added from the references during the review process, but only 32 articles were selected for the detailed review in Section 5. The selection criteria were based on the completeness and contribution of the work and the overall quality of the research.

5. Review of Combination of GPR with Other NDTs on Pavement Assessment

6. Final Remarks and Further Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hossain, U.; Wong, J.J.; Ng, S.T.; Wang, Y. Sustainable design of pavement systems in highly urbanized context: A lifecycle assessment. J. Environ. Manag. 2022, 305, 114410. [Google Scholar] [CrossRef] [PubMed]

- Rasol, M.; Pais, J.C.; Pérez-Gracia, V.; Solla, M.; Fernandes, F.M.; Fontul, S.; Ayala-Cabrera, D.; Schmidt, F.; Assadollahi, H. GPR monitoring for road transport infrastructure: A systematic review and machine learning insights. Constr. Build. Mater. 2022, 324, 126686. [Google Scholar] [CrossRef]

- Rasol, M.; Pérez-Gracia, V.; Solla, M.; Pais, J.C.; Fernandes, F.M.; Santos, C. An experimental and numerical approach to combine Ground Penetrating Radar and computational modeling for the identification of early cracking in cement concrete pavements. NDT E Int. 2020, 115, 102293. [Google Scholar] [CrossRef]

- Kheradmandi, N.; Mehranfar, V. A critical review and comparative study on image segmentation-based techniques for pavement crack detection. Constr. Build. Mater. 2022, 321, 126162. [Google Scholar] [CrossRef]

- Lai, W.W.-L.; Dérobert, X.; Annan, P. A review of Ground Penetrating Radar application in civil engineering: A 30-year journey from Locating and Testing to Imaging and Diagnosis. NDT E Int. 2018, 96, 58–78. [Google Scholar] [CrossRef]

- Solla, M.; Pérez-Gracia, V.; Fontul, S. A Review of GPR Application on Transport Infrastructures: Troubleshooting and Best Practices. Remote Sens. 2021, 13, 672. [Google Scholar] [CrossRef]

- Proto, M.; Bavusi, M.; Bernini, R.; Bigagli, L.; Bost, M.; Bourquin, F.; Cottineau, L.-M.; Cuomo, V.; Della Vecchia, P.; Dolce, M.; et al. Transport Infrastructure Surveillance and Monitoring by Electromagnetic Sensing: The ISTIMES Project. Sensors 2010, 10, 10620–10639. [Google Scholar] [CrossRef]

- Maser, K.R. Non-Destructive Measurement of Pavement Layer Thickness; Californian Department of Transportation. 2003. Available online: https://0-scholar-google-com.brum.beds.ac.uk/scholar?cluster=9227942454363219310 (accessed on 28 August 2022).

- Fernandes, F.M.; Pais, J.C. Laboratory observation of cracks in road pavements with GPR. Constr. Build. Mater. 2017, 154, 1130–1138. [Google Scholar] [CrossRef]

- Marecos, V.; Solla, M.; Fontul, S.; Antunes, V. Assessing the pavement subgrade by combining different non-destructive methods. Constr. Build. Mater. 2017, 135, 76–85. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, X.; Li, W.; Zhang, S.; Jia, Y. Automatic detection of moisture damages in asphalt pavements from GPR data with deep CNN and IRS method. Autom. Constr. 2020, 113, 103119. [Google Scholar] [CrossRef]

- ASTM. Standard Practice for Roads and Parking Lots Pavement Condition Index Surveys; ASTM International: West Conshohocken, PA, USA, 2020; Volume D6433. [Google Scholar] [CrossRef]

- Abdelmawla, A.; Kim, S. Prediction of subgrade soil density using dielectric constant of soils. In Eleventh International Conference on the Bearing Capacity of Roads, Railways and Airfields; CRC Press: London, UK, 2021; Volume 1, pp. 448–457. ISBN 9781003222880. [Google Scholar] [CrossRef]

- Hall, K.D.; Schwartz, C.W. Development of Structural Design Guidelines for Porous Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 197–206. [Google Scholar] [CrossRef]

- Dérobert, X.; Baltazart, V.; Simonin, J.-M.; Todkar, S.; Norgeot, C.; Hui, H.-Y. GPR Monitoring of Artificial Debonded Pavement Structures throughout Its Life Cycle during Accelerated Pavement Testing. Remote Sens. 2021, 13, 1474. [Google Scholar] [CrossRef]

- Petit, C.; Chabot, A.; Destrée, A.; Raab, C. Recommendation of RILEM TC 241-MCD on interface debonding testing in pavements. Mater. Struct. 2018, 51, 96. [Google Scholar] [CrossRef]

- Capozzoli, L.; De Martino, G.; Polemio, M.; Rizzo, E. Geophysical Techniques for Monitoring Settlement Phenomena Occurring in Reinforced Concrete Buildings. Surv. Geophys. 2019, 41, 575–604. [Google Scholar] [CrossRef]

- Chai, M.; Mu, Y.; Zhang, J.; Ma, W.; Liu, G.; Chen, J. Characteristics of Asphalt Pavement Damage in Degrading Permafrost Regions: Case Study of the Qinghai–Tibet Highway, China. J. Cold Reg. Eng. 2018, 32, 05018003. [Google Scholar] [CrossRef]

- Zaki, A.; Johari, M.A.M.; Hussin, W.M.A.W.; Jusman, Y. Experimental Assessment of Rebar Corrosion in Concrete Slab Using Ground Penetrating Radar (GPR). Int. J. Corros. 2018, 2018, 5389829. [Google Scholar] [CrossRef]

- Sossa, V.; Pérez-Gracia, V.; González-Drigo, R.; Rasol, M.A. Lab Non Destructive Test to Analyze the Effect of Corrosion on Ground Penetrating Radar Scans. Remote. Sens. 2019, 11, 2814. [Google Scholar] [CrossRef]

- Ahmad, S. Reinforcement corrosion in concrete structures, its monitoring and service life prediction––A review. Cem. Concr. Compos. 2003, 25, 459–471. [Google Scholar] [CrossRef]

- Zollinger, D.G.; Senadheera, S.P.; Tang, T. Spalling of Continuously Reinforced Concrete Pavements. J. Transp. Eng. 1994, 120, 394–411. [Google Scholar] [CrossRef]

- Moropoulou, A.; Avdelidis, N.; Koui, M.; Kakaras, K. An application of thermography for detection of delaminations in airport pavements. NDT E Int. 2001, 34, 329–335. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Evaluating Asphalt-Covered Concrete Bridge Decks Using Ground Penetrating Radar; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar] [CrossRef]

- Dinh, K.; Gucunski, N. Factors affecting the detectability of concrete delamination in GPR images. Constr. Build. Mater. 2020, 274, 121837. [Google Scholar] [CrossRef]

- Pepe, A.; Calò, F. A Review of Interferometric Synthetic Aperture RADAR (InSAR) Multi-Track Approaches for the Retrieval of Earth’s Surface Displacements. Appl. Sci. 2017, 7, 1264. [Google Scholar] [CrossRef]

- Karamvasis, K.; Karathanassi, V. Deformation effects of dams on coastal regions using Sentinel-1 IW TOPS time series: The West Lesvos, Greece Case. In Proceedings of the International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences-ISPRS Archives, Tshwane, South Africa, 8–12 May 2017; Volume 42, pp. 91–96. [Google Scholar] [CrossRef]

- D’Amico, F.; Gagliardi, V.; Bianchini Ciampoli, L.; Tosti, F. Integration of InSAR and GPR techniques for monitoring transition areas in railway bridges. NDT E Int. 2020, 115, 102291. [Google Scholar] [CrossRef]

- Gagliardi, V.; Ciampoli, L.B.; Trevisani, S.; D’Amico, F.; Alani, A.M.; Benedetto, A.; Tosti, F. Testing Sentinel-1 SAR Interferometry Data for Airport Runway Monitoring: A Geostatistical Analysis. Sensors 2021, 21, 5769. [Google Scholar] [CrossRef]

- Busetti, A.; Calligaris, C.; Forte, E.; Areggi, G.; Mocnik, A.; Zini, L. Non-Invasive Methodological Approach to Detect and Characterize High-Risk Sinkholes in Urban Cover Evaporite Karst: Integrated Reflection Seismics, PS-InSAR, Leveling, 3D-GPR and Ancillary Data. A NE Italian Case Study. Remote Sens. 2020, 12, 3814. [Google Scholar] [CrossRef]

- Tosti, F.; Gagliardi, V.; D’Amico, F.; Alani, A.M. Transport infrastructure monitoring by data fusion of GPR and SAR imagery information. Transp. Res. Procedia 2020, 45, 771–778. [Google Scholar] [CrossRef]

- Alani, A.M.; Tosti, F.; Bianchini Ciampoli, L.; Gagliardi, V.; Benedetto, A. An integrated investigative approach in health monitoring of masonry arch bridges using GPR and InSAR technologies. NDT E Int. 2020, 115, 102288. [Google Scholar] [CrossRef]

- Ozden, A.; Faghri, A.; Li, M.; Tabrizi, K. Evaluation of Synthetic Aperture Radar Satellite Remote Sensing for Pavement and Infrastructure Monitoring. Procedia Eng. 2016, 145, 752–759. [Google Scholar] [CrossRef]

- Macchiarulo, V.; Milillo, P.; DeJong, M.J.; Martí, J.G.; Sánchez, J.; Giardina, G. Integrated InSAR monitoring and structural assessment of tunnelling-induced building deformations. Struct. Control Health Monit. 2021, 28, e2781. [Google Scholar] [CrossRef]

- Gao, M.; Gong, H.; Chen, B.; Zhou, C.; Chen, W.; Liang, Y.; Shi, M.; Si, Y. InSAR time-series investigation of long-term ground displacement at Beijing Capital International Airport, China. Tectonophysics 2016, 691, 271–281. [Google Scholar] [CrossRef]

- Talib, O.-C.; Shimon, W.; Sarah, K.; Tonian, R. Detection of sinkhole activity in West-Central Florida using InSAR time series observations. Remote Sens. Environ. 2021, 269, 112793. [Google Scholar] [CrossRef]

- Gutiérrez, F.; Galve, J.P.; Lucha, P.; Castañeda, C.; Bonachea, J.; Guerrero, J. Integrating geomorphological mapping, trenching, InSAR and GPR for the identification and characterization of sinkholes: A review and application in the mantled evaporite karst of the Ebro Valley (NE Spain). Geomorphology 2011, 134, 144–156. [Google Scholar] [CrossRef]

- Slatton, K.; Crawford, M.; Evans, B. Fusing interferometric radar and laser altimeter data to estimate surface topography and vegetation heights. IEEE Trans. Geosci. Remote Sens. 2001, 39, 2470–2482. [Google Scholar] [CrossRef]

- Pappalardo, G.; Mineo, S.; Angrisani, A.C.; Di Martire, D.; Calcaterra, D. Combining field data with infrared thermography and DInSAR surveys to evaluate the activity of landslides: The case study of Randazzo Landslide (NE Sicily). Landslides 2018, 15, 2173–2193. [Google Scholar] [CrossRef]

- Hubatka, F. Identification of ground instability in the housing estate complex based on georadar and satellite radar interferometry. Acta Geodyn. et Geomater. 2021, 18, 231–240. [Google Scholar] [CrossRef]

- Martel, R.; Castellazzi, P.; Gloaguen, E.; Trépanier, L.; Garfias, J. ERT, GPR, InSAR, and tracer tests to characterize karst aquifer systems under urban areas: The case of Quebec City. Geomorphology 2018, 310, 45–56. [Google Scholar] [CrossRef] [Green Version]

- Norezan, N.N.M.; Sulaiman, S.A.; Samad, A.M.; Salleh, Z.M. Hyperspectral Imaging Sensor in Civil Structure. In Proceedings of the 2021 IEEE 12th Control and System Graduate Research Colloquium, ICSGRC 2021-Proceedings, Shah Alam, Malaysia, 7 August 2021; Institute of Electrical and Electronics Engineers Inc.: Petaling, Malaysia, 2021; pp. 154–159. [Google Scholar] [CrossRef]

- Nsengiyumva, W.; Zhong, S.; Lin, J.; Zhang, Q.; Zhong, J.; Huang, Y. Advances, limitations and prospects of nondestructive testing and evaluation of thick composites and sandwich structures: A state-of-the-art review. Compos. Struct. 2020, 256, 112951. [Google Scholar] [CrossRef]

- Schnebele, E.; Tanyu, B.F.; Cervone, G.; Waters, N. Review of remote sensing methodologies for pavement management and assessment. Eur. Transp. Res. Rev. 2015, 7, 7. [Google Scholar] [CrossRef]

- Garini, Y.; Young, I.T.; McNamara, G. Spectral imaging: Principles and applications. Cytom. Part A 2006, 69, 735–747. [Google Scholar] [CrossRef]

- Abdellatif, M.; Peel, H.; Cohn, A.G.; Fuentes, R. Pavement Crack Detection from Hyperspectral Images Using A Novel Asphalt Crack Index. Remote. Sens. 2020, 12, 3084. [Google Scholar] [CrossRef]

- Falade, A.H.; Olajuyigbe, O.E.; Oni, A.G.; Falola, H.O.; Ige, A.P.; Ogundipe, E.O. Integrated magnetic and electrical resistivity investigation for assessment of the causes of road pavement failure along the Ife-Osogbo Highway, Southwestern Nigeria. Model. Earth Syst. Environ. 2020, 7, 1425–1441. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, X.; Cervone, G.; Yang, L. Detection of Asphalt Pavement Potholes and Cracks Based on the Unmanned Aerial Vehicle Multispectral Imagery. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2018, 11, 3701–3712. [Google Scholar] [CrossRef]

- Riese, F.M.; Keller, S. Fusion of Hyper Spectral and Ground Penetrating Radar Data to Estimate Soil Moisture. In Proceedings of the Workshop on Hyperspectral Image and Signal Processing, Evolution in Remote Sensing, Amsterdam, The Netherlands, 23–26 September 2018; Volume 2018. [Google Scholar] [CrossRef]

- Abdellatif, M.; Peel, H.; Cohn, A.G.; Fuentes, R. Hyperspectral imaging for autonomous inspection of road pavement defects. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction, ISARC 2019, Banff, AL, Canada, 21–24 May 2019; International Association for Automation and Robotics in Construction: Bratislava, Slovakia; pp. 384–392. [Google Scholar] [CrossRef]

- Elaksher, A.F. Fusion of hyperspectral images and lidar-based dems for coastal mapping. Opt. Lasers Eng. 2008, 46, 493–498. [Google Scholar] [CrossRef] [Green Version]

- Mozzi, P.; Fontana, A.; Ferrarese, F.; Ninfo, A.; Campana, S.; Francese, R. The Roman City of Altinum, Venice Lagoon, from Remote Sensing and Geophysical Prospection. Archaeol. Prospect. 2015, 23, 27–44. [Google Scholar] [CrossRef]

- Agapiou, A.; Lysandrou, V.; Sarris, A.; Papadopoulos, N.; Hadjimitsis, D.G. Fusion of Satellite Multispectral Images Based on Ground-Penetrating Radar (GPR) Data for the Investigation of Buried Concealed Archaeological Remains. Geosciences 2017, 7, 40. [Google Scholar] [CrossRef]

- Ragnoli, A.; De Blasiis, M.R.; Di Benedetto, A. Pavement Distress Detection Methods: A Review. Infrastructures 2018, 3, 58. [Google Scholar] [CrossRef]

- Mathavan, S.; Rahman, M.; Kamal, K. Use of a Self-Organizing Map for Crack Detection in Highly Textured Pavement Images. J. Infrastruct. Syst. 2015, 21, 04014052. [Google Scholar] [CrossRef]

- Cohen, B.; Ye, S.; Karaman, G.; Khan, F.; Bartoli, I.; Pradhan, A.; Ellemberg, A.; Moon, F.; Gurian, P.; Kontsos, A.; et al. Design and implementation of an integrated operations and preservation performance monitoring system for asset management of major bridges. In Proceedings of the EWSHM-7th European Workshop on Structural Health Monitoring, INRIA, Nantes, France, 8–11 July 2014; pp. 1521–1528. [Google Scholar]

- Puente, I.; Solla, M.; González-Jorge, H.; Arias, P. NDT Documentation and Evaluation of the Roman Bridge of Lugo Using GPR and Mobile and Static LiDAR. J. Perform. Constr. Facil. 2015, 29, 0000531. [Google Scholar] [CrossRef]

- Li, S.; Yuan, C.; Liu, D.; Cai, H. Integrated Processing of Image and GPR Data for Automated Pothole Detection. J. Comput. Civ. Eng. 2016, 30, 0000582. [Google Scholar] [CrossRef]

- Garrido, I.; Lagüela, S.; Otero, R.; Arias, P. Thermographic methodologies used in infrastructure inspection: A review—data acquisition procedures. Infrared Phys. Technol. 2020, 111, 103481. [Google Scholar] [CrossRef]

- Garrido, I.; Lagüela, S.; Arias, P. Infrared Thermography’s Application to Infrastructure Inspections. Infrastructures 2018, 3, 35. [Google Scholar] [CrossRef]

- Lu, Y.; Golrokh, A.J.; Islam, A. Concrete Pavement Service Condition Assessment Using Infrared Thermography. Adv. Mater. Sci. Eng. 2017, 2017, 3829340. [Google Scholar] [CrossRef]

- Omar, T.; Nehdi, M.L. Remote sensing of concrete bridge decks using unmanned aerial vehicle infrared thermography. Autom. Constr. 2017, 83, 360–371. [Google Scholar] [CrossRef]

- Hiasa, S.; Karaaslan, E.; Shattenkirk, W.; Mildner, C.; Catbas, F.N. Bridge Inspection and Condition Assessment Using Image-Based Technologies with UAVs. In Proceedings of the Structures Congress 2018: Bridges, Transportation Structures, and Nonbuilding Structures—Selected Papers from the Structures Congress, Fort Worth, TX, USA, 19–21 April 2018. [Google Scholar]

- Bagavathiappan, S.; Lahiri, B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring—A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Watase, A.; Birgul, R.; Hiasa, S.; Matsumoto, M.; Mitani, K.; Catbas, F.N. Practical identification of favorable time windows for infrared thermography for concrete bridge evaluation. Constr. Build. Mater. 2015, 101, 1016–1030. [Google Scholar] [CrossRef]

- Ellenberg, A.; Kontsos, A.; Moon, F.; Bartoli, I. Bridge deck delamination identification from unmanned aerial vehicle infrared imagery. Autom. Constr. 2016, 72, 155–165. [Google Scholar] [CrossRef]

- Dhakal, N.; Elseifi, M.A. Use of Infrared Thermography to Detect Thermal Segregation in Asphalt Overlay and Reflective Cracking Potential. J. Mater. Civ. Eng. 2016, 28, 0001413. [Google Scholar] [CrossRef]

- Solla, M.; Lagüela, S.; González-Jorge, H.; Arias, P. Approach to identify cracking in asphalt pavement using GPR and infrared thermographic methods: Preliminary findings. NDT E Int. 2014, 62, 55–65. [Google Scholar] [CrossRef]

- Vyas, V.; Patil, V.J.; Singh, A.P.; Srivastava, A. Application of infrared thermography for debonding detection in asphalt pavements. J. Civ. Struct. Health Monit. 2019, 9, 325–337. [Google Scholar] [CrossRef]

- Lagüela, S.; Solla, M.; Puente, I.; Prego, F.J. Joint use of GPR, IRT and TLS techniques for the integral damage detection in paving. Constr. Build. Mater. 2018, 174, 749–760. [Google Scholar] [CrossRef]

- Nuzzo, L.; Calia, A.; Liberatore, D.; Masini, N.; Rizzo, E. Integration of ground-penetrating radar, ultrasonic tests and infrared thermography for the analysis of a precious medieval rose window. Adv. Geosci. 2010, 24, 69–82. [Google Scholar] [CrossRef]

- Büyüköztürk, O. Imaging of concrete structures. NDT E Int. 1998, 31, 233–243. [Google Scholar] [CrossRef]

- Breysse, D.; Klysz, G.; Dérobert, X.; Sirieix, C.; Lataste, J. How to combine several non-destructive techniques for a better assessment of concrete structures. Cem. Concr. Res. 2008, 38, 783–793. [Google Scholar] [CrossRef]

- Soilán, M.; Sánchez-Rodríguez, A.; del Río-Barral, P.; Perez-Collazo, C.; Arias, P.; Riveiro, B. Review of Laser Scanning Technologies and Their Applications for Road and Railway Infrastructure Monitoring. Infrastructures 2019, 4, 58. [Google Scholar] [CrossRef]

- Guan, H.; Li, J.; Cao, S.; Yu, Y. Use of mobile LiDAR in road information inventory: A review. Int. J. Image Data Fusion 2016, 7, 219–242. [Google Scholar] [CrossRef]

- Yu, Y.; Li, J.; Guan, H.; Wang, C. 3D crack skeleton extraction from mobile LiDAR point clouds. In Proceedings of the International Geoscience and Remote Sensing Symposium (IGARSS), Quebec City, QC, Canada, 13–18 July 2014; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2014; pp. 914–917. [Google Scholar] [CrossRef]

- Díaz-Vilariño, L.; González-Jorge, H.; Bueno, M.; Arias, P.; Puente, I. Automatic classification of urban pavements using mobile LiDAR data and roughness descriptors. Constr. Build. Mater. 2016, 102, 208–215. [Google Scholar] [CrossRef]

- Guan, H.; Li, J.; Yu, Y.; Chapman, M.; Wang, H.; Wang, C.; Zhai, R. Iterative Tensor Voting for Pavement Crack Extraction Using Mobile Laser Scanning Data. IEEE Trans. Geosci. Remote Sens. 2014, 53, 1527–1537. [Google Scholar] [CrossRef]

- Chen, X.; Li, J. A feasibility study on use of generic mobile laser scanning system for detecting asphalt pavement cracks. ISPRS Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2016, XLI-B1, 545–549. [Google Scholar] [CrossRef]

- Wu, H.; Yao, L.; Xu, Z.; Li, Y.; Ao, X.; Chen, Q.; Li, Z.; Meng, B. Road pothole extraction and safety evaluation by integration of point cloud and images derived from mobile mapping sensors. Adv. Eng. Informatics 2019, 42, 100936. [Google Scholar] [CrossRef]

- De Blasiis, M.R.; Di Benedetto, A.; Fiani, M. Mobile Laser Scanning Data for the Evaluation of Pavement Surface Distress. Remote Sens. 2020, 12, 942. [Google Scholar] [CrossRef]

- Gézero, L.; Antunes, C. Road Rutting Measurement Using Mobile LiDAR Systems Point Cloud. ISPRS Int. J. Geo-Inf. 2019, 8, 404. [Google Scholar] [CrossRef]

- De Blasiis, M.; Di Benedetto, A.; Fiani, M.; Garozzo, M. Assessing of the Road Pavement Roughness by Means of LiDAR Technology. Coatings 2020, 11, 17. [Google Scholar] [CrossRef]

- Chang, P.C.; Liu, S.C. Recent Research in Nondestructive Evaluation of Civil Infrastructures. J. Mater. Civ. Eng. 2003, 15, 298–304. [Google Scholar] [CrossRef]

- Puente, I.; Solla, M.; González-Jorge, H.; Arias, P. Validation of mobile LiDAR surveying for measuring pavement layer thicknesses and volumes. NDT E Int. 2013, 60, 70–76. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Loizos, A.; Plati, C. Integrating Pavement Sensing Data for Pavement Condition Evaluation. Sensors 2021, 21, 3104. [Google Scholar] [CrossRef]

- Prasad, J.R.; Kanuganti, S.; Bhanegaonkar, P.N.; Sarkar, A.K.; Arkatkar, S. Development of Relationship between Roughness (IRI) and Visible Surface Distresses: A Study on PMGSY Roads. Procedia Soc. Behav. Sci. 2013, 104, 322–331. [Google Scholar] [CrossRef]

- Pitoňák, M.; Filipovsky, J. GPR Application—Non-destructive Technology for Verification of Thicknesses of Newly Paved Roads in Slovakia. Procedia Eng. 2016, 153, 537–549. [Google Scholar] [CrossRef]

- Uzarowski, L.; Henderson, V.; Rizvi, R.; Mohammad, K.; Lakkavalli, V. Use of FWD, GPR and IP in combination on complex pavement projects-including case studies. In Proceedings of the 2016 Transportation Association of Canada’s Conference and Exhibition, TAC 2016, Toronto, ON, Canada, 25–28 September 2016; Transportation Association of Canada: Ottawa, ON, Canada, 2016. [Google Scholar]

- Kırbaş, U. IRI Sensitivity to the Influence of Surface Distress on Flexible Pavements. Coatings 2018, 8, 271. [Google Scholar] [CrossRef]

- Hasanuddin; Setyawan, A.; Yulianto, B. Evaluation of Road Performance Based on International Roughness Index and Falling Weight Deflectometer. IOP Conf. Series Mater. Sci. Eng. 2018, 333, 012090. [Google Scholar] [CrossRef]

- Šroubek, F.; Šorel, M.; Žák, J. Precise International Roughness Index Calculation. Int. J. Pavement Res. Technol. 2021, 1–7. [Google Scholar] [CrossRef]

- Pedret Rodés, J.; Martínez Reguero, A.; Pérez-Gracia, V. GPR Spectra for Monitoring Asphalt Pavements. Remote Sens. 2020, 12, 1749. [Google Scholar] [CrossRef]

- Tighe, S.; Li, N.; Falls, L.C.; Haas, R. Incorporating Road Safety into Pavement Management. Transp. Res. Rec. J. Transp. Res. Board 2000, 1699, 1–10. [Google Scholar] [CrossRef]

- Nekula, L.; Stryk, J.; Nekulova, P.; Brezina, I. Potential improvement in data interpretation regarding simultaneous measurement of friction coefficient and IRI. In Proceedings of the Symposium on Pavement Surface Characteristics (SURF), Brisbane, QLD, Australia, 2–4 May 2018. [Google Scholar]

- Imam, R.; Murad, Y.; Asi, I.; Shatnawi, A. Predicting Pavement Condition Index from International Roughness Index using Gene Expression Programming. Innov. Infrastruct. Solutions 2021, 6, 139. [Google Scholar] [CrossRef]

- Cruz, O.G.D.; Mendoza, C.A.; Lopez, K.D. International Roughness Index as Road Performance Indicator: A Literature Review. IOP Conf. Series Earth Environ. Sci. 2021, 822, 012016. [Google Scholar] [CrossRef]

- Rasol, M.; Schmidt, F.; Ientile, S.; Adelaide, L.; Nedjar, B.; Kane, M.; Chevalier, C. Progress and Monitoring Opportunities of Skid Resistance in Road Transport: A Critical Review and Road Sensors. Remote Sens. 2021, 13, 3729. [Google Scholar] [CrossRef]

- Gökalp, I.; Uz, V.E.; Saltan, M. A laboratory evaluation on skid resistance performance of surface coatings manufactured by both natural aggregates and by-products. In Bearing Capacity of Roads, Railways and Airfields; CRC Press: London, UK, 2017; pp. 929–934. ISBN 9781138295957. [Google Scholar]

- Rukavina, T.; Domitrović, J.; Krnić, L.; Krpan, M. Evaluation of Pavement Bearing Capacity by FWD-Example from Practice. In Proceedings of the 26th World Road Congress, Abu Dhabi, United Arab Emirates, 6–10 October 2019. [Google Scholar]

- Daniels, D.J. (Ed.) Ground Penetrating Radar; Institution of Engineering and Technology: London, UK, 2004; ISBN 9780444533487. [Google Scholar]

- Benedetto, A.; Benedetto, F. Application Field-Specific Synthesizing of Sensing Technology: Civil Engineering Application of Ground-Penetrating Radar Sensing Technology. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; Volume 13, pp. 393–425. ISBN 9780080965338. [Google Scholar]

- Pajewski, L.; Fontul, S.; Solla, M. Ground-penetrating radar for the evaluation and monitoring of transport infrastructures. In Innovation in Near-Surface Geophysics. Instrumentation, Application, and Data Processing Methods; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Hu, J.; Vennapusa, P.K.R.; White, D.J.; Beresnev, I. Pavement thickness and stabilised foundation layer assessment using ground-coupled GPR. Nondestruct. Test. Evaluation 2015, 31, 267–287. [Google Scholar] [CrossRef]

- Diamanti, N.; Redman, D. Field observations and numerical models of GPR response from vertical pavement cracks. J. Appl. Geophys. 2012, 81, 106–116. [Google Scholar] [CrossRef]

- Fernandes, F.M.; Fernandes, A.; Pais, J. Assessment of the density and moisture content of asphalt mixtures of road pavements. Constr. Build. Mater. 2017, 154, 1216–1225. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Lahouar, S. Measuring layer thicknesses with GPR–Theory to practice. Constr. Build. Mater. 2005, 19, 763–772. [Google Scholar] [CrossRef]

- Loizos, A.; Plati, C. Accuracy of pavement thicknesses estimation using different ground penetrating radar analysis approaches. NDT E Int. 2007, 40, 147–157. [Google Scholar] [CrossRef]

- Varela-González, M.; Solla, M.; Martínez-Sánchez, J.; Arias, P. A semi-automatic processing and visualisation tool for ground-penetrating radar pavement thickness data. Autom. Constr. 2014, 45, 42–49. [Google Scholar] [CrossRef]

- Chen, D.-H.; Hong, F.; Zhou, W.; Ying, P. Estimating the hotmix asphalt air voids from ground penetrating radar. NDT E Int. 2014, 68, 120–127. [Google Scholar] [CrossRef]

- Hoegh, K.; Khazanovich, L.; Dai, S.; Yu, T. Evaluating asphalt concrete air void variation via GPR antenna array data. Case Stud. Nondestruct. Test. Eval. 2015, 3, 27–33. [Google Scholar] [CrossRef]

- Cueto, M.; Olona, J.; Fernández-Viejo, G.; Pando, L.; López-Fernández, C. Karst-induced sinkhole detection using an integrated geophysical survey: A case study along the Riyadh Metro Line 3 (Saudi Arabia). Near Surf. Geophys. 2018, 16, 270–281. [Google Scholar] [CrossRef]

- Solla, M.; Fernández, N. GPR analysis to detect subsidence: A case study on a loaded reinforced concrete pavement. Int. J. Pavement Eng. 2022, 1–15. [Google Scholar] [CrossRef]

- Alani, A.M.; Aboutalebi, M.; Kilic, G. Applications of ground penetrating radar (GPR) in bridge deck monitoring and assessment. J. Appl. Geophys. 2013, 97, 45–54. [Google Scholar] [CrossRef]

- Dinh, K.; Gucunski, N.; Duong, T.H. An algorithm for automatic localization and detection of rebars from GPR data of concrete bridge decks. Autom. Constr. 2018, 89, 292–298. [Google Scholar] [CrossRef]

- Liu, H.; Lin, C.; Cui, J.; Fan, L.; Xie, X.; Spencer, B.F. Detection and localization of rebar in concrete by deep learning using ground penetrating radar. Autom. Constr. 2020, 118, 103279. [Google Scholar] [CrossRef]

- Hugenschmidt, J.; Loser, R. Detection of chlorides and moisture in concrete structures with ground penetrating radar. Mater. Struct. 2007, 41, 785–792. [Google Scholar] [CrossRef]

- Klysz, G.; Balayssac, J.-P. Determination of volumetric water content of concrete using ground-penetrating radar. Cem. Concr. Res. 2007, 37, 1164–1171. [Google Scholar] [CrossRef]

- Kaplanvural, I.; Pekşen, E.; Özkap, K. Volumetric water content estimation of C-30 concrete using GPR. Constr. Build. Mater. 2018, 166, 141–146. [Google Scholar] [CrossRef]

- Gómez-Ortiz, D.; Martín-Crespo, T. Assessing the risk of subsidence of a sinkhole collapse using ground penetrating radar and electrical resistivity tomography. Eng. Geol. 2012, 149-150, 1–12. [Google Scholar] [CrossRef]

- Whiteley, R.J.; Kelly, R.B.; Stewart, S.B. Case studies of geophysical imaging for road foundation design on soft soils and embankment risk assessment. Explor. Geophys. 2015, 46, 394–402. [Google Scholar] [CrossRef]

- Prego, F.J.; Nieto, L.; Solla, M.; Puente, I. A mobile android tool for simplified GPR data processing in construction applications. Autom. Constr. 2018, 89, 170–182. [Google Scholar] [CrossRef]

- Pearson, D. Deterioration and Maintenance of Pavements, 1st ed.; ICE Publishing: London, UK, 2011. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Measuring Deflections with a Light Weight Deflectometer (LWD); ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Ceylan, H.; Kim, S.; Yang, S. 3—Wireless MEMS for transportation infrastructure health monitoring. In Wireless MEMS Networks and Applications; Uttamchandani, D., Ed.; Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Cambridge, UK, 2017; pp. 53–76. ISBN 978-0-08-100449-4. [Google Scholar] [CrossRef]

- Fontul, S. Structural Evaluation of Flexible Pavements Using Non-Destructive Tests. Ph.D. Thesis, University of Coimbra, Coimbra, Portugal, 2004. [Google Scholar]

- Tarefder, R.A.; Ahmed, M.U. Consistency and accuracy of selected FWD backcalculation software for computing layer modulus of airport pavements. Int. J. Geotech. Eng. 2013, 7, 21–35. [Google Scholar] [CrossRef]

- Scullion, T.; Saarenketo, T. Integrating ground penetrating radar and falling weight deflectometer technologies in pavement evaluation. In Nondestructive Testing of Pavements and Backcalculation of Moduli; ASTM International: West Conshohocken, PA, USA, 2000; Volume 3. [Google Scholar] [CrossRef]

- Mehta, Y.; Roque, R. Evaluation of FWD Data for Determination of Layer Moduli of Pavements. J. Mater. Civ. Eng. 2003, 15, 25–31. [Google Scholar] [CrossRef]

- Korsgaard, H.C.; Pedersen, J.P.; Rasmussen, M. Rehabilitation by cracking and seating of concrete pavement optimized by FWD analysis. In Proceedings of the 7th International Conference on the Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway, 27–29 July 2005. [Google Scholar]

- Qiu, X.; Yang, Q.; Wang, F. Diagnostic analysis of dynamic deflection for cracked asphalt pavements under FWD impulsive loading. J. Vibroengineering 2014, 16, 2426–2437. [Google Scholar]

- Shoukry, S.N.; Martinelli, D.R.; Selezneva, O.I. Dynamic Performance of Composite Pavements Under Impact. Transp. Res. Rec. J. Transp. Res. Board 1997, 1570, 163–171. [Google Scholar] [CrossRef]

- Al Hakim, B.; Cheung, L.W.; Armitage, R.J. Use of FWD Data for Prediction of Bonding Between Pavement Layers. Int. J. Pavement Eng. 1999, 1, 49–59. [Google Scholar] [CrossRef]

- Nabizadeh, H.; Hajj, E.Y.; Siddharthan, R.V.; Elfass, S.; Nimeri, M. Application of falling weight deflectometer for the estimation of in-situ shear strength parameters of subgrade layer. In Proceedings of the 10th International Conference on the Bearing Capacity of Roads, Railways and Airfields, BCRRA 2017, Athens, Greece, 28–30 June 2017; CRC Press/Balkema: Boca Raton, FL, USA, 2017; pp. 743–749. [Google Scholar] [CrossRef]

- Calhoon, T.; Zegeye, E.; Velasquez, R.; Calvert, J. Using Falling Weight Deflectometer (FWD) and Ground Penetrating Radar (GPR) to monitor the effects of seasonal moisture variation on the structural capacity of pavements. Constr. Build. Mater. 2022, 351, 128831. [Google Scholar] [CrossRef]

- Marecos, V.; Fontul, S.; de Lurdes Antunes, M.; Solla, M. Evaluation of a highway pavement using non-destructive tests: Falling Weight Deflectometer and Ground Penetrating Radar. Constr. Build. Mater. 2017, 154, 1164–1172. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, Q.; Wu, W.; Liu, J. Structural condition assessment and fatigue stress analysis of cement concrete pavement based on the GPR and FWD. Constr. Build. Mater. 2022, 328, 127044. [Google Scholar] [CrossRef]

- Maser, K.; Schmalzer, P.; Shaw, W.; Carmichael, A. Integration of Traffic Speed Deflectometer and Ground-Penetrating Radar for Network-Level Roadway Structure Evaluation. Transp. Res. Rec. J. Transp. Res. Board 2017, 2639, 55–63. [Google Scholar] [CrossRef]

- Katicha, S.; Flintsch, G.; Diefenderfer, B. Ten Years of Traffic Speed Deflectometer Research in the United States: A Review. Transp. Res. Rec. J. Transp. Res. Board 2022. [Google Scholar] [CrossRef]

- Flintsch, G.W.; McGhee, K.K. Quality Management of Pavement Condition Data Collection; The National Academies Press: Washington, DC, USA, 2009. [Google Scholar] [CrossRef]

- Elbagalati, O.; Mousa, M.; Elseifi, M.A.; Gaspard, K.; Zhang, Z. Development of a methodology to backcalculate pavement layer moduli using the traffic speed deflectometer. Can. J. Civ. Eng. 2018, 45, 377–385. [Google Scholar] [CrossRef]

- De Ridder, S.A.L. Passive Seismic Surface-Wave Interferometry for Reservoir-Scale Imaging; Department of Geophysics, Stanford University: Stanford, CA, USA, 2014. [Google Scholar]

- Picotti, S.; Francese, R.; Giorgi, M.; Pettenati, F.; Carcione, J.M. Estimation of glacier thicknesses and basal properties using the horizontal-to-vertical component spectral ratio (HVSR) technique from passive seismic data. J. Glaciol. 2017, 63, 229–248. [Google Scholar] [CrossRef] [Green Version]

- Alfaro, A.; Pujades, L.G.; Goula, X.; Susagna, T.; Navarro, M.; Sanchez, J.; Canas, J.A. Preliminary Map of Soil’s Predominant Periods in Barcelona Using Microtremors. Pure Appl. Geophys. 2001, 158, 2499–2511. [Google Scholar] [CrossRef]

- Gouveia, F.; Gomes, R.C.; Lopes, I. Shallow and in depth seismic testing in urban environment: A case study in Lisbon Miocene stiff soils using joint inversion of active and passive Rayleigh wave measurements. J. Appl. Geophys. 2019, 169, 199–213. [Google Scholar] [CrossRef]

- Levenberg, E.; Garg, N. Estimating the coefficient of at-rest earth pressure in granular pavement layers. Transp. Geotech. 2014, 1, 21–30. [Google Scholar] [CrossRef]

- Erhan, S.; Dicleli, M. Effect of dynamic soil–bridge interaction modeling assumptions on the calculated seismic response of integral bridges. Soil Dyn. Earthq. Eng. 2014, 66, 42–55. [Google Scholar] [CrossRef]

- Wang, Y.; Tran, K.T.; Horhota, D. Road sinkhole detection with 2D ambient noise tomography. Geophys. 2021, 86, KS123–KS135. [Google Scholar] [CrossRef]

- Salinas Naval, V.; Santos-Assunçao, S.; Pérez-Gracia, V. GPR Clutter Amplitude Processing to Detect Shallow Geological Targets. Remote. Sens. 2018, 10, 88. [Google Scholar] [CrossRef]

- Attwa, M.; Ali, H. Resistivity characterization of aquifer in coastal semiarid areas: An approach for hydrogeological evaluation. In Groundwater in the Nile Delta; Springer International Publishing: Cham, Switzerland, 2019; Volume 73, pp. 213–233. ISBN 978-3-319-94283-4. [Google Scholar] [CrossRef]

- Szalai, S.; Novák, A.; Szarka, L. Depth of Investigation and Vertical Resolution of Surface Geoelectric Arrays. J. Environ. Eng. Geophys. 2009, 14, 15–23. [Google Scholar] [CrossRef]

- Ward, S.H. Resistivity and Induced Polarization Methods. Environ. Geophys. 1990, 147–190. [Google Scholar] [CrossRef]

- Ducut, J.D.; Alipio, M.; Go, P.J.; Ii, R.C.; Vicerra, R.R.; Bandala, A.; Dadios, E. A Review of Electrical Resistivity Tomography Applications in Underground Imaging and Object Detection. Displays 2022, 73, 102208. [Google Scholar] [CrossRef]

- Park, C.-S.; Jeong, J.-H.; Park, H.-W.; Kim, K. Experimental Study on Electrode Method for Electrical Resistivity Survey to Detect Cavities under Road Pavements. Sustainability 2017, 9, 2320. [Google Scholar] [CrossRef]

- Ozegin, K.O.; Oseghale, A.; Okolie, E.C.; Ujuanbi, O. Integration of very low-frequency electromagnetic (VLF- EM) and electrical resistivity methods in mapping subsurface geologic structures favourable to road failures. Int. J. Water Resour. Environ. Eng. 2011, 3, 126–131. [Google Scholar]

- Adeyemo, I.; Omosuyi, G. Geophysical investigation of road pavement instability along part of Akure-Owo express way, Southwestern Nigeria. Am. J. Sci. Ind. Res. 2012, 3, 191–197. [Google Scholar] [CrossRef]

- Peter, J.E.; Rafiu, A.A.; Udensi, E.E.; Salako, K.A.; Alhassan, U.D.; Adetona, A.A. 2D Electrical Resistivity Imaging Investigation on Causes of Road Failure Along Kutigi Street, Minna, North Central, Nigeria. Am. J. Innov. Res. Appl. Sci. 2018, 6, 221–226. [Google Scholar]

- Victor, E.; Mamah, L. Geophysical investigation of road failure the case of Opoji in Nigeria. Int. J. Sci. Eng. Res. 2014, 5, 1769–1779. [Google Scholar]

- Tejero, A.; Chávez, R.E.; Urbieta, J.; Flores-Márquez, E.L. Cavity Detection in the Southwestern Hilly Portion of Mexico City by Resistivity Imaging. J. Environ. Eng. Geophys. 2002, 7, 130–139. [Google Scholar] [CrossRef]

- Kaufmann, G. Geophysical mapping of solution and collapse sinkholes. J. Appl. Geophys. 2014, 111, 271–288. [Google Scholar] [CrossRef]

- Carbonel, D.; Rodríguez-Tribaldos, V.; Gutiérrez, F.; Galve, J.P.; Guerrero, J.; Zarroca, M.; Roqué, C.; Linares, R.; McCalpin, J.P.; Acosta, E. Investigating a damaging buried sinkhole cluster in an urban area (Zaragoza city, NE Spain) integrating multiple techniques: Geomorphological surveys, DInSAR, DEMs, GPR, ERT, and trenching. Geomorphology 2015, 229, 3–16. [Google Scholar] [CrossRef]

- Ungureanu, C.; Priceputu, A.; Bugea, A.L.; Chirică, A. Use of electric resistivity tomography (ERT) for detecting underground voids on highly anthropized urban construction sites. Procedia Eng. 2017, 209, 202–209. [Google Scholar] [CrossRef]

- Chouteau, M.; Vallieres, S.; Miralles, M. Assessment of continuous resistivity profiling for the characterization of paved roads. In Proceedings of the AGU Spring Meeting Abstracts, San Francisco, CA, USA, 15–19 December 2004; Volume 2004, p. NS43A-03. [Google Scholar]

- Fontul, S.; Mínguez, R.; Solla, M.; Santos-Assunção, S. The use of geophysics for the condition assessment of railway infrastructure. Non-Destr. Tech. Eval. Struct. Infrastruct. 2016, 11, 195–212. [Google Scholar] [CrossRef]

- Amran, T.S.T.; Amin, M.S.M.; Ahmad, M.R.; Azreen, N.M.; Sani, S.; Adnan, M.A.K.; A Razak, N.; Sayuti, S. NDT methods in inspecting road and highway structures. IOP Conf. Series Mater. Sci. Eng. 2021, 1106, 012034. [Google Scholar] [CrossRef]

- BSI BS EN 12504-2:2012; Testing Concrete in Structures: Part 2: Non-destructive Testing-Determination of Rebound Number. British Standards Institution: London, UK, 2012.

- Rasol, M.A. Applied Nonlinear Seismic Performance and Retrofitting of the Building; Pomogaibog, O., Ed.; “LAP” Lambert Publishing Company: București, Romania, 2014; ISBN 978-3-659-20739-6. [Google Scholar] [CrossRef]

- Wróblewska, J.; Kowalski, R. Assessing concrete strength in fire-damaged structures. Constr. Build. Mater. 2020, 254, 119122. [Google Scholar] [CrossRef]

- Tay, D.; Tam, C. In situ investigation of the strength of deteriorated concrete. Constr. Build. Mater. 1996, 10, 17–26. [Google Scholar] [CrossRef]

- Kowalski, R.; Wróblewska, J. Application of a Sclerometer to the Preliminary Assessment of Concrete Quality in Structures After Fire. Arch. Civ. Eng. 2018, 64, 171–186. [Google Scholar] [CrossRef]

- Panedpojaman, P.; Tonnayopas, D. Rebound hammer test to estimate compressive strength of heat exposed concrete. Constr. Build. Mater. 2018, 172, 387–395. [Google Scholar] [CrossRef]

- Murthi, P.; Poongodi, K.; Gobinath, R. Correlation between rebound hammer number and mechanical properties of steel fibre reinforced pavement quality concrete. Mater. Today Proc. 2020, 39, 142–147. [Google Scholar] [CrossRef]

- Jain, A.; Kathuria, A.; Kumar, A.; Verma, Y.; Murari, K. Combined Use of Non-Destructive Tests for Assessment of Strength of Concrete in Structure. Procedia Eng. 2013, 54, 241–251. [Google Scholar] [CrossRef]

- Galvão, J.; Flores-Colen, I.; de Brito, J.; Veiga, M. Variability of in-situ testing on rendered walls in natural ageing conditions—Rebound hammer and ultrasound techniques. Constr. Build. Mater. 2018, 170, 167–181. [Google Scholar] [CrossRef]

- Shubbar, A.; Al-Khafaji, Z.; Nasr, M.; Falah, M. Using non-destructive tests for evaluating flyover footbridge: Case study. Knowl. Based Eng. Sci. 2020, 1, 23–39. [Google Scholar] [CrossRef]

- Dérobert, X.; Aubagnac, C.; Abraham, O. Comparison of NDT techniques on a post-tensioned beam before its autopsy. NDT E Int. 2002, 35, 541–548. [Google Scholar] [CrossRef]

- Mezgeen, A.R.; Serhan, S. Ozgur Eren Comparison between Static and Dynamic Seismic Performance Analysis of Reinforced Concrete Structure through a Case Study of “Seaside Hotel”. In Proceedings of the 1st International Conference on Engineering and Innovative Technology, SU-ICEIT 2016, Kurdistan, Iraq, 12–14 April 2016; Volume 28, pp. 96–103. [Google Scholar] [CrossRef]

- Agred, K.; Klysz, G.; Balayssac, J.-P. Location of reinforcement and moisture assessment in reinforced concrete with a double receiver GPR antenna. Constr. Build. Mater. 2018, 188, 1119–1127. [Google Scholar] [CrossRef]

- James, A.; Bazarchi, E.; Chiniforush, A.A.; Aghdam, P.P.; Hosseini, M.R.; Akbarnezhad, A.; Martek, I.; Ghodoosi, F. Rebar corrosion detection, protection, and rehabilitation of reinforced concrete structures in coastal environments: A review. Constr. Build. Mater. 2019, 126, 1026–1039. [Google Scholar] [CrossRef]

- Yücel, O. Ferroscan and radar based detection and analysis technologies for non-destructive testing. In Proceedings of the SMAR 2015—Third Conference on Smart Monitoring, Assesment and Rehabilitation of Civil Structures, Antalya, Turkey, 7–9 September 2015. [Google Scholar]

- Rasol, M. Seismic Performance Assessment and Strengthening of a Multi-Story RC Building through a Case Study of “Seaside Hotel”; Eastern Mediterranean University (EMU): Famagusta, Cyprus, 2014. [Google Scholar]

- Lee, Y.-J.; Lee, J.-R.; Ihn, J.-B. Composite repair patch evaluation using pulse-echo laser ultrasonic correlation mapping method. Compos. Struct. 2018, 204, 395–401. [Google Scholar] [CrossRef]

- Simonin, J.M.; Villain, G. Detection and Survey of Interface Defects within a Pavement Structure with Ultrasonic Pulse Echo. In RILEM Bookseries; Springer: Maastricht, The Netherlands, 2016; Volume 13, pp. 673–678. [Google Scholar]

- Krause, M.; Bärmann, M.; Frielinghaus, R.; Kretzschmar, F.; Kroggel, O.; Langenberg, K.; Maierhofer, C.; Müller, W.; Neisecke, J.; Schickert, M.; et al. Comparison of pulse-echo methods for testing concrete. NDT E Int. 1997, 30, 195–204. [Google Scholar] [CrossRef]

- Chen, H.; Nie, X.; Gan, S.; Zhao, Y.; Qiu, H. Interfacial imperfection detection for steel-concrete composite structures using NDT techniques: A state-of-the-art review. Eng. Struct. 2021, 245, 112778. [Google Scholar] [CrossRef]

- Laureti, S.; Ricci, M.; Mohamed, M.; Senni, L.; Davis, L.; Hutchins, D. Detection of rebars in concrete using advanced ultrasonic pulse compression techniques. Ultrasonics 2017, 85, 31–38. [Google Scholar] [CrossRef]

- Ito, Y.; Uomoto, T. Nondestructive testing method of concrete using impact acoustics. NDT E Int. 1997, 30, 217–222. [Google Scholar] [CrossRef]

- Janků, M.; Cikrle, P.; Grošek, J.; Anton, O.; Stryk, J. Comparison of infrared thermography, ground-penetrating radar and ultrasonic pulse echo for detecting delaminations in concrete bridges. Constr. Build. Mater. 2019, 225, 1098–1111. [Google Scholar] [CrossRef]

- Andrade, C.; Alonso, C.; Molina, F.J. Cover cracking as a function of bar corrosion: Part I-Experimental test. Mater. Struct. 1993, 26, 453–464. [Google Scholar] [CrossRef]

- Miró, M.; Eiras, J.; Poveda, P.; Climent, M.; Ramis, J. Detecting cracks due to steel corrosion in reinforced cement mortar using intermodulation generation of ultrasonic waves. Constr. Build. Mater. 2021, 286, 122915. [Google Scholar] [CrossRef]

- Fritsch, C.; Veca, A. Detecting small flaws near the interface in pulse-echo. Ultrasonics 2004, 42, 797–801. [Google Scholar] [CrossRef]

- Huang, Y.; Turner, J.A.; Song, Y.; Ni, P.; Li, X. Enhanced ultrasonic detection of near-surface flaws using transverse-wave backscatter. Ultrasonics 2019, 98, 20–27. [Google Scholar] [CrossRef]

- Khalili, M.; Karakouzian, M. Feasibility of ultrasonic measurements for characterizing rheological properties of asphalt binders. Constr. Build. Mater. 2015, 75, 220–226. [Google Scholar] [CrossRef]

- Liu, X.; Sun, D.; Liu, D.; Meng, K.; Ni, C.; Shao, Z.; Sun, L. Simulation of ultrasonic propagation in porous cellular concrete materials. Constr. Build. Mater. 2021, 285, 122852. [Google Scholar] [CrossRef]

- Choi, W.Y.; Park, K.K. Array type miniaturized ultrasonic sensors to detect urban sinkholes. Measurement 2019, 141, 371–379. [Google Scholar] [CrossRef]

- Seo, H.; Lee, K.; Jhang, K.-Y. In-Line Ultrasonic Monitoring for Sediments Stuck on Inner Wall of a Polyvinyl Chloride Pipe. Sci. World J. 2014, 2014, 731621. [Google Scholar] [CrossRef] [PubMed]

- Álvarez-Arenas, T.G.; Camacho, J. Air-Coupled and Resonant Pulse-Echo Ultrasonic Technique. Sensors 2019, 19, 2221. [Google Scholar] [CrossRef] [PubMed]

- Pospisil, K.; Manychova, M.; Stryk, J.; Korenska, M.; Matula, R.; Svoboda, V. Diagnostics of Reinforcement Conditions in Concrete Structures by GPR, Impact-Echo Method and Metal Magnetic Memory Method. Remote Sens. 2021, 13, 952. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Ponniah, J.; Cascante, G. Field condition assessment of longitudinal joints in asphalt pavements using seismic wave technology. In Proceedings of the TAC/ATC 2008—2008 Annual Conference and Exhibition of the Transportation Association of Canada: Transportation—A Key to a Sustainable Future, Toronto, ON, Canada, 21–24 September 2008; Volume 2124. [Google Scholar]

- Xiong, C.; Yu, J.; Zhang, X. Use of NDT systems to investigate pavement reconstruction needs and improve maintenance treatment decision-making. Int. J. Pavement Eng. 2021, 1–15. [Google Scholar] [CrossRef]

- Lin, S.-J.; Liu, T.-Y.; Chou, N.N.; Chen, P.-H.; Liao, C.-L. Soil Improvement and Inspection Techniques for the Base Course of Rigid Pavement for an Airport Runway. J. Perform. Constr. Facil. 2021, 35, 06021001. [Google Scholar] [CrossRef]

- Chen, D.-H.; Bilyeu, J.; Scullion, T.; Nazarian, S.; Chiu, C.-T. Failure Investigation of a Foamed-Asphalt Highway Project. J. Infrastruct. Syst. 2006, 12, 33–40. [Google Scholar] [CrossRef]

- Chen, D.H.; Scullion, T. Forensic Investigations of Roadway Pavement Failures. J. Perform. Constr. Facil. 2008, 22, 35–44. [Google Scholar] [CrossRef]

- Chen, D.-H.; Si, Z.; Saribudak, M. Roadway Heaving Caused by High Organic Matter. J. Perform. Constr. Facil. 2009, 23, 100–108. [Google Scholar] [CrossRef]

- Zegeye-Teshale, E.; Calhoon, T.; Johnson, E.; Dai, S. Application of Advanced Multi-Sensor Non-Destructive Testing System for the Evaluation of Pavements Affected by Transverse Crack-Heaving. Transp. Res. Rec. J. Transp. Res. Board 2021, 2675, 1149–1162. [Google Scholar] [CrossRef]

- Li, M.; Anderson, N.; Sneed, L.; Torgashov, E. Condition assessment of concrete pavements using both ground penetrating radar and stress-wave based techniques. J. Appl. Geophys. 2016, 135, 297–308. [Google Scholar] [CrossRef]

- Razak, N.A.; Senin, S.F.; Hamid, R. Detection of Sizes and Locations Air Voids in Reinforced Concrete Slab using Ground Penetrating Radar and Impact-Echo Methods. J. Teknol. 2015, 74, 4553. [Google Scholar] [CrossRef]

- Maser, K.; Martino, N.; Doughty, J.; Birken, R. Understanding and Detecting Bridge Deck Deterioration with Ground-Penetrating Radar. Transp. Res. Rec. J. Transp. Res. Board 2012, 2313, 116–123. [Google Scholar] [CrossRef]

- Robison, T.W.; Barnes, C.L.; Tinkey, Y.; Tanner, J.E. Evaluating Concrete Damage in Bridge Decks with and without Overlays Using Nondestructive Testing Procedures. J. Test. Evaluation 2019, 48, 20180555. [Google Scholar] [CrossRef]

- Scott, M.; Rezaizadeh, A.; Delahaza, A.; Santos, C.; Moore, M.; Graybeal, B.; Washer, G. A comparison of nondestructive evaluation methods for bridge deck assessment. NDT E Int. 2003, 36, 245–255. [Google Scholar] [CrossRef]

- Slabej, M.; Grinč, M.; Kováč, M.; Decký, M.; Šedivý, Š. Non-invasive diagnostic methods for investigating the quality of Zilina airport’s runway. Contrib. Geophys. Geod. 2015, 45, 237–254. [Google Scholar] [CrossRef]

- Abu Dabous, S.; Yaghi, S.; Alkass, S.; Moselhi, O. Concrete bridge deck condition assessment using IR Thermography and Ground Penetrating Radar technologies. Autom. Constr. 2017, 81, 340–354. [Google Scholar] [CrossRef]

- Omar, T.; Nehdi, M.L.; Zayed, T. Rational Condition Assessment of RC Bridge Decks Subjected to Corrosion-Induced Delamination. J. Mater. Civ. Eng. 2018, 30, 04017259. [Google Scholar] [CrossRef]

- Kushwaha, S.K.P.; Raghavendra, S.; Pande, H.; Agrawal, S. Analysis and Integration of Surface and Subsurface Information of Different Bridges. J. Indian Soc. Remote Sens. 2019, 48, 315–331. [Google Scholar] [CrossRef]

- Baek, J.; Al-Qadi, I.L.; Xie, W.; Buttlar, W.G. In Situ Assessment of Interlayer Systems to Abate Reflective Cracking in Hot-Mix Asphalt Overlays. Transp. Res. Rec. J. Transp. Res. Board 2008, 2084, 104–113. [Google Scholar] [CrossRef]

- Diallo, M.C.; Cheng, L.Z.; Rosa, E.; Gunther, C.; Chouteau, M. Integrated GPR and ERT data interpretation for bedrock identification at Cléricy, Québec, Canada. Eng. Geol. 2018, 248, 230–241. [Google Scholar] [CrossRef]

- Miśkiewicz, M.; Daszkiewicz, K.; Lachowicz, J.; Tysiac, P.; Jaskula, P.; Wilde, K. Nondestructive methods complemented by FEM calculations in diagnostics of cracks in bridge approach pavement. Autom. Constr. 2021, 128, 103753. [Google Scholar] [CrossRef]

- Wiwatrojanagul, P.; Sahamitmongkol, R.; Tangtermsirikul, S. A method to detect lap splice in reinforced concrete using a combination of covermeter and GPR. Constr. Build. Mater. 2018, 173, 481–494. [Google Scholar] [CrossRef]

- De Giorgi, L.; Leucci, G. Detection of Hazardous Cavities Below a Road Using Combined Geophysical Methods. Surv. Geophys. 2014, 35, 1003–1021. [Google Scholar] [CrossRef]

- Orlando, L.; Cardarelli, E.; Cercato, M.; De Donno, G.; Di Giambattista, L. Pavement testing by integrated geophysical methods: Feasibility, resolution and diagnostic potential. J. Appl. Geophys. 2017, 136, 462–473. [Google Scholar] [CrossRef]

- Shrestha, S.; Katicha, S.W.; Flintsch, G.W.; Thyagarajan, S. Application of Traffic Speed Deflectometer for Network-Level Pavement Management. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 348–359. [Google Scholar] [CrossRef]

- D’Amico, F.; Ciampoli, L.B.; Di Benedetto, A.; Bertolini, L.; Napolitano, A. Integrating Non-Destructive Surveys into a Preliminary BIM-Oriented Digital Model for Possible Future Application in Road Pavements Management. Infrastructures 2022, 7, 10. [Google Scholar] [CrossRef]

- La, H.M.; Gucunski, N.; Kee, S.-H.; Van Nguyen, L. Data analysis and visualization for the bridge deck inspection and evaluation robotic system. Vis. Eng. 2015, 3, 6. [Google Scholar] [CrossRef]

- Gucunski, N.; Basily, B.; Kim, J.; Yi, J.; Duong, T.; Dinh, K.; Kee, S.-H.; Maher, A. RABIT: Implementation, performance validation and integration with other robotic platforms for improved management of bridge decks. Int. J. Intell. Robot. Appl. 2017, 1, 271–286. [Google Scholar] [CrossRef]

- Gibb, S.; La, H.M.; Le, T.; Nguyen, L.; Schmid, R.; Pham, H. Nondestructive evaluation sensor fusion with autonomous robotic system for civil infrastructure inspection. J. Field Robot. 2018, 35, 988–1004. [Google Scholar] [CrossRef]

- Dong, Z.; Ye, S.; Gao, Y.; Fang, G.; Zhang, X.; Xue, Z.; Zhang, T. Rapid Detection Methods for Asphalt Pavement Thicknesses and Defects by a Vehicle-Mounted Ground Penetrating Radar (GPR) System. Sensors 2016, 16, 2067. [Google Scholar] [CrossRef]

- Gao, Y.; Qian, S.; Li, Z.; Wang, P.; Wang, F.; He, Q. Digital Twin and Its Application in Transportation Infrastructure. In Proceedings of the IEEE International Conference on Digital Twins & Parallel Intelligence, Beijing, China, 15 July–15 August 2021; pp. 298–301. [Google Scholar] [CrossRef]

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging Digital Twin Technology in Model-Based Systems Engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef] [Green Version]

| Techniques | Damage/Dimension | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Superficial Deformation & Disintegration | Cracking | Layer Thickness Deficiency | Bearing Capacity | Soil-Foundation & Bedrock Structure | Voids & Cavities | Subsidence & Sinkholes | Debonding & Delamination | Concrete Cover Depth | Concrete Quality & Strength | Rebar Detection & Corrosion | Moisture | |

| InSAR | ✔ | ✔ | ||||||||||

| Spectral imaging | ✔ | ✔ | ✔ | |||||||||

| RGB imaging | ✔ | ✔ | ||||||||||

| IRT imaging | ✔ | ✔ | ✔ | ✔ | ||||||||

| LiDAR | ✔ | ✔ | ||||||||||

| Profilometer | ✔ | ✔ | ||||||||||

| GPR | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Deflectometers | ✔ | ✔ | ✔ | ✔ | ||||||||

| PSI | ✔ | ✔ | ✔ | |||||||||

| ERT | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| Rebound Hammer | ✔ | |||||||||||

| Covermeter | ✔ | ✔ | ||||||||||

| Ultrasonics | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Objective | NDTs | GPR Antennas | Findings | Publisher | Reference |

|---|---|---|---|---|---|

| To establish a maintenance treatment decision-making system using the NDT technology based on an expressway | RSP, FWD, 3D GPR | Ground-coupled antennas with a frequency bandwidth of 200–3000 MHz (antennas separation of 7.5 cm) | FWD was able to determine the modulus of each structural layer (bearing capacity evaluation), but the deflection values obtained cannot describe the level of the integrity of the pavement structure nor the existence of internal defects and extent. 3D GPR measured the thickness of each structural layer (to determine thickness deficiency) and to detect the internal damage distribution (crack rate ratio) in the pavement structure (width and weight of damage). | Taylor & Francis | [200] |

| To demonstrate the power of integrating multi-sensing data in the framework of pavement conditions. The test site was an interurban motorway | RSP, FWD, GPR | Air-coupled antennas (frequency antenna not provided) | The modeling approach presented demonstrated (i) the material moduli estimated through back-calculation (deflectometric data integrated with GPR-based thicknesses), based on the multi-layer elastic theory, showed a interquartile range of RMS varying from 2.3 (25%) to 4.9 (75%); (ii) that the IRI is a significant predictor of critical subgrade strains (with p values less than 0.05). | MDPI | [86] |

| To provide a method to improve the soil condition under the rigid pavement of a damaged airport runway: the underpanel grouting method (UPGM) and its verification by two inspection techniques, GPR and FWD | FWD, GPR | Ground-coupled antennas (frequency antenna not provided) | GPR was used to measure the layers’ boundaries of the soil after grouting. No noticeable thickness deviation was observed with GPR. The FWD showed that deflections were significantly reduced after grouting. Thus, the combination of both techniques has demonstrated the efficiency and effectiveness of the UPGM. | ASCE | [201] |

| To assess the bearing capacity of a flexible highway pavement. The importance of using GPR measured thickness in the back-calculation process (to obtain layers’ elastic moduli) is addressed in this study | FWD, GPR | Air-coupled bistatic antennas with a central frequency of 1.0 GHz | For a road extension of 31 km, the results showed that 70% of the GPR thicknesses estimated were under the design thickness, and almost ⅔ of the section would have a significant error in the pavement response models if GPR-estimated thickness is not used. | Elsevier | [136] |

| To investigate the cause of structural distress (cracking and rutting) in a foamed-asphalt warranty project | FWD, GPR, seismic | Not provided | The section showing severe distress demonstrated higher FWD deflections (three to 4-fold higher). The SPA (Seismic Pavement Analyzer) has shown much lower base moduli in the distressed area than in the intact locations. DCP (Dynamic Cone Penetrometer) demonstrated that the base in the distressed area was loose and lacked cohesion. However, SPA has indicated that the subgrade modulus is uniform throughout the project, which suggests that the distress is not associated with variations in subgrade strength. GPR was used to evaluate moisture content at distressed areas, but significant variations were not observed (as supported by laboratory testing). The combination has shown that failure is associated with the base (foamed asphalt) lack of strength. | ASCE | [202] |

| To investigate the integrated approach of GPR and FWD to locate failure in roadway pavements. Three different case studies are addressed | FWD GPR | Air-coupled bistatic antennas with a central frequency of 1.0 GHz | GPR was able to detect; Project 1—(i) the extent of stripping problems at various depths and high porosity that caused delamination, (ii) high dielectric measurements indicating wet base, and (iii) a poorly compacted AC layer and poor longitudinal joints; Project 2—(i) a porous layer (high reflections) causing debonding and surface distress; Project 3—(i) a poorly compacted AC layer (high air void content) and wet base. FWD was able to detect: Project 1—(i) that the areas with high deflections have stripping (from GPR), (ii) base stiffness, (iii) inadequate pavement structure (or bearing capacity); Project 2—(i) loss of support or weak structure (high deflections), and (ii) thinner layers (debonding). | ASCE | [203] |

| To investigate the premature pavement failure of heaving and cracking on a roadway | RSP, FWD, GPR, ERT | Air-coupled bistatic antennas with a central frequency of 1.0 GHz | GPR has detected approximately 84% of the bumps/dips detected by the profiler (RSP). Moreover, there was a section of the roadway showing the same GPR signature (not identified by the RSP) that could indicate further heave in the future. FWD and complementary DCP showed that the heaved/cracked areas are losing structural load support most probably due to ineffective stabilization. As GPR does not penetrate through the clay layer, ERT was able to map the soil strata, identifying anomalies with high organic contents. It was concluded that heaving was caused by high organic content. | ASCE | [204] |

| To develop a rapid testing methodology and testing parameters to assist in detecting and quantifying tented cracks in asphalt pavements by using a multi-sensor non-destructive testing system with a single positioning and navigation system | GPR, LiDAR, IRT, video cameras, IRI | GSSI 400 MHz ground-coupled antenna | The study introduced two parameters; peak height value (PHV) and spacing between two consecutive peaks (SBP) to assess the intensity and frequency of tented cracks; (i) these parameters have a strong relationship to the ride quality indicator IRI; (ii) these parameters can be used to determine the extent and location of critically affected segments of the road; (iii) GPR, LIDAR, video, thermal, the IRI, and pavement inspection data were used to successfully validate the parameters, which were obtained from surface profile measurements; further; (iv) GPR can be used to detect moisture conditions that contributes to the formation of the tented cracks. | SAGE Publications Inc | [205] |

| To assess the condition of visible deteriorated concrete pavement that includes a layer of concrete, a granular base and their interface (with presence of air voids at the interface) | GPR, IE, USW | Bistatic ground-coupled antennas with a central frequency of 1.5 GHz | GPR was able to accurately estimate pavement thickness and to locate air voids between concrete and granular base layers. The USW allowed estimating the dynamic elastic modulus and wave phase velocities of the concrete, although the existence of air voids at the interface could affect these results (more affected at full wavelength range). The IE was fairly accurate in estimating thickness of concrete pavements, but as in the USW method, these estimations could be affected when using the full wavelength range. | Elsevier | [206] |

| To compare the GPR and IE methods in detecting the size and depth of air voids in concrete slabs | GPR, IE | Antenna with a central frequency of 1.6 GHz | GPR can accurately estimate both the air voids diameters and depths, while the IE is only able to determine voids depths. GPR was able to detect air voids larger than 20 mm in diameter with −8.9 to 30% error. The void depth estimation by GPR was more accurate only for larger voids (up to 67 mm), while IE was more accurate in estimating depths for smaller sizes. This later could be caused by the presence of moisture content in the slab attenuating GPR signals, in addition to the frequency resolution (with a theoretical minimum diameter of 15.6 mm). | Penerbit UTM Press | [207] |

| To evaluate deteriorated bridge deck slabs through the combination of NDT methods: GPR, hammer sounding (RH), ultrasonic impact-echo, and half-cell potential (HCP) | GPR, RH, IE, HCP | Multiple ground- and air-coupled GPR systems, which ranged from 1.0 to 2.6 GHz | GPR created GPR condition (delamination) maps and corrosion (through signal attenuation). The IE was able to estimate thicknesses and to detect delamination. The RH detected spalled areas and delamination. HCP was able to detect corrosion. The correlation between different NDTs was analyzed, resulting in 90.2% for GPR vs. HCP, 79.3% for GPR vs. IE, and 76.4% for HPC vs. IE. | SAGE Publications Inc | [208] |

| To evaluate bridge deck condition using combined NDTs. Three different case studies on bridge decks are addressed | GPR, IE, IRT | 1.5 GHz ground-coupled antenna and 1.0 GHz air-coupled (horn) antenna | Damage maps were created for each technique, and it was found that IE, IRT, and GPR methods correlated well. The IE and IRT methods have estimated similar levels of damages, while GPR estimations were significantly lower (most probably due to debonding and signal attenuation caused by excesses of moisture and chloride contents). However, the IE method is preferred over IRT imaging because it was less subjective to weather conditions, and its analysis was more quantitative than IRT. Comparing the field time for each technique, IE and IRT have comparable times, although the IRT processing was considerably higher. Regarding GPR, the field time should be lower, but it can be larger due to obstacles in the road surface that makes the data acquisition process difficult. | ASNT | [209] |

| To assess the capabilities of different methods (chain drag, GPR and impact-echo) used to evaluate a concrete bridge deck showing corrosion-induced delamination, and validation with coring | GPR, IE, chain drag | A ground-coupled antenna with a 1.5 GHz center frequency, and an array of 64 air-coupled antennas with 2.4 GHz center frequency | The acoustic techniques, chain drag and IE, showed results consistent with coring. Nevertheless, the chain drag is susceptible to errors due to subjective interpretation, and the IE method, although more quantitative, is extremely time-consuming and the results are not always conclusive. The GPR method demonstrated its capability to detect delamination, even through asphalt-overlaid decks. | Elsevier | [210] |

| To measure the depth and size of cavities in concrete panel, through the combination of three different NDTs and validation with coring | GPR, IRT, UPE | Ground-coupled (dipole) antennas with 2.6 and 1.5 GHz | Field measurements revealed the limited capability of GPR to detect cavities beneath the surface, whereas UPE completely failed to detect cavities. Conversely, IRT was successful at detecting cavities near the surface under convenient weather conditions. GPR and UPE detect defects deeper inside material, while IRT is incapable to determine depths. GPR is rather accurate to determine depths (for defects not too close to the surface), and IRT is the most suitable to detect defects at lowest depths. The fastest method during field work was IRT, while GPR was the most time-consuming. For GPR depth estimations, the dielectric properties of media need to be calibrated. UPE was unable to detect shallow cavities or provide overestimated values. | Elsevier | [188] |

| To propose a new surveying methodology aiming to evaluate the structural integrity in masonry arch bridges based on the integration of multi-source, multi-scale and multi-temporal radar data | GPR, INSAR | Array with 8 double-polarized antennas with 2 GHz center frequency (10 cm spacing), and dual-frequency 200 and 600 MHz antenna system | GPR provided subsurface geometry of the superstructure (asphalt layer thicknesses and base/masonry boundaries) and exact positioning of the structural ties. High frequencies to detect thicknesses and low frequencies to detect structural ties. InSAR (PSI technique) was able to measure structural displacements mainly caused by flooding. | Elsevier | [32] |

| To investigate a sinkhole in an urban area using different NDTs | GPR, INSAR, LiDAR, ERT | Shielded ground-coupled antennas with 180 MHz center frequency | InSAR (DInSAR technique) was able to estimate subsidence and deformation rates in the zone. DEM (Digital Elevation Model), from LiDAR data, allowed assessing the topographic changes by anthropogenic infill of the sinkholes and ground leveling. GPR identified a concealed sinkhole that seems to be affected by the highest subsidence rate detected by DInSAR. Moreover, GPR revealed that subsidence was mainly caused by sagging. However, GPR was affected by the presence of highly conductive anthropogenic deposits and the gardened areas of the park. ERT detected subvertical discontinuities and faults related to the development of a concealed sinkhole, although this method was restricted by urban elements. | Elsevier | [161] |

| To detect sinkholes in urban areas through an integrated and non-invasive multi-scale approach combining seismic reflection, InSAR, topographic leveling and 3D GPR | GPR, INSAR, reflection seismic | Array with 5 transmitting and 4 receiving 400 MHz shielded antennas (8 cm spacing) | Reflection seismic allowed identifying, from top to bottom: a sediment layer, the bedrock and a deeper layer of evaporites (exceeding 60 m); showing this later poor geotechnical properties and sinking. InSAR (PSI technique) was able to measure a vertical downward displacement due to ground instability. Reflection seismic was validated using coring/borehole, while InSAR was validated with leveling techniques. InSAR identifies critical areas of deformation but is not able to detect sinkholes. GPR was useful to detect surface breaks, sinkholes, and down-dipping layers (sinking areas) related to the presence of forming sinkholes. Furthermore, the use of 3D GPR allows obtaining the 3D depth volumes of deterioration. The penetration depth of GPR was more limited than reflection seismic (the evaporite layer was only detected by seismic). With InSAR it is possible to delineate the area affected by subsidence phenomena, especially in urban areas where the presence of targets (e.g., buildings) allows an excellent coverage; but for vegetated and cultivated areas, GPR is recommended (especially in roads or grasslands). | MDPI | [30] |