1. Introduction

Solketal, a cyclic ketal of glycerol and acetone, is one of the most interesting and promising derivatives of bioglycerin. The interest in this compound is due to a number of specific reasons. First, the ketalization reaction as a whole proceeds easily, which means that it can be carried out with low consumption of materials and energy while obtaining high yields of the target substance [

1,

2]; for synthesis, crude glycerol can be used [

3,

4,

5,

6]. Secondly, solketal has a number of interesting applications. The industrial use of this compound as a component of green solvents for paints and coatings has been reported [

7]. In addition, solketal can be used as a component of biodiesel fuel [

8] or automotive gasoline [

9,

10,

11], and also act as an intermediate for the synthesis of higher acetals and glycerol ketals [

12], quinolones via Scraup reaction [

13], or in the joint synthesis of isopropanol and propylene glycol via solketal destructive hydrogenolysis [

14]. Thirdly, when using renewable raw materials, solketal can have a completely renewable nature.

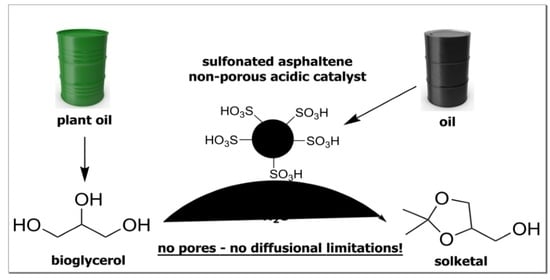

For the synthesis of solketal by the direct condensation of acetone with glycerol (

Scheme 1), a huge number of homogeneous and heterogeneous catalysts of various types have been proposed.

Among the commercially available materials, macroreticular ion exchange acids [

15,

16,

17], zeolite-based catalysts [

18], p-toluenesulfonic [

19], and sulfuric acid are often used [

1]. Further work in this area, thus, can be roughly divided into two categories. In the first case, the aim of such work should be to develop a catalyst that demonstrates increased activity in the ketalization reaction. Indeed, the nature of the reaction allows its rate to be increased without compromising the quality of the process: the reaction selectivity approaches 100%, and the heat effect of the reaction is very low [

1,

20]. The reduced activity of heterogeneous catalysts compared to homogeneous ones, in the general case, is associated with the presence of diffusion restrictions; therefore, a desire to increase the activity of the catalyst directs scientists towards the synthesis of materials with an extremely developed surface and highly active functional groups with respect to the reaction. For example, Vicente, Melero and the co-authors have obtained catalytically active materials based on the mesoporous silicas with the sulfonic functional groups. The materials’ specific surface area values were between 533 and 721 m

2 g

−1 and the mean pore size was between 81 and 92 nm. By their activity, the novel materials were comparable with the commercially available ones (with the same functional groups) [

21].

The inability to compare the catalytic activity of newly proposed materials with known ones is the main feature of the second category of scientific works concerning the catalytic synthesis of a solketal: in these, this reaction is used as a convenient system for testing the catalytic activity of a new material. The convenience of the reaction as a test system is due to the fact that catalysis in the ketalization reaction is nonspecific, the reaction rate is high, and activity can be detected even for relatively weakly acidic materials (such as montmorillonite K10) [

12,

22]. For example, Churipard et al. have synthesized mesoporous polymers and, after sulfonation with sulfuric acid, obtained catalytically active materials with specific surface area values between 314 and 363 m

2 g

−1 and a mean pore size of 10.6 nm. These materials were highly active in the synthesis of solketal, although they were not compared with other catalysts [

23]. A number of studies created with the analogous approach may be found in the scientific literature.

Hence, it should be concluded that the proposed catalysts should demonstrate such a high increase in activity compared to industrial samples that it would justify their use; the corresponding analysis is largely overlooked. Nevertheless, the traditional approach to heterogeneous catalysis is mainly traced: in order to achieve maximum activity, it is necessary to achieve the occurrence of a heterogeneous catalytic reaction in the kinetic region. To eliminate diffusion restrictions, a support is required, the porous structure of which would not create diffusional limitations. It is logical to conclude that the pore size of such a support should not be too small, with a maximally developed inner surface. At the same time, an alternative approach may well have the right to life: the catalyst may not have an inner surface and a porous structure at all, but can conduct a catalytic process due to functional groups localized on the outer surface of the granule. The main question is whether such a catalyst can have a high activity or a level of activity that is at least comparable to the activity of porous catalysts.

In this study, petroleum asphaltenes isolated from vacuum residue are considered as a starting material for the analysis of acid catalysts. Such polyaromatic hydrocarbons are formed in the oil industry as by-products, mainly in tar deasphalting plants; their further disposal is part of the more general problem of heavy oil residues disposal. It was shown earlier that by sulfonating asphaltenes, ion-exchange materials can be obtained that are applicable for water treatment [

24,

25,

26]; some preliminary data on the catalytic properties of these materials were also reported [

27]. In this work, the sulfonation of asphaltenes is used as an approach for the preparation of non-porous acid catalysts, as a result of which a set of samples with different sulfonation degrees was obtained. The obtained materials were characterized both by a number of physicochemical methods (acid-base titration, nitrogen adsorption, sulfur elemental analysis and high-resolution transmission electron microscopy with energy dispersive X-ray analysis (HR-TEM/EDX), and in relation to the catalytic activity in the synthesis of solketal, in order to determine the activity of a sulfonated heterogeneous catalyst with no inner surface.

2. Results and Discussion

Data on sulfur content and acid value for samples of sulfonated asphaltenes are presented in

Table 1 (the samples are called SA-τ, where SA refers to the “sulfonated asphaltene” and τ to the sulfonation time in minutes). With increasing sulfonation time, the mass fraction of sulfur in the material and its acid value (determined by titrimetry) increase. This dependence is clearly traced between the samples of initial asphaltenes (SA-0) and samples SA-5, SA-10, SA-30 and SA-60. For the SA-30 sample, the mass fraction of sulfur was higher than for the other samples; an analogous pattern of the non-linear dependence between the sulfur content and the sulfonation severity has been observed in our previous studies on asphaltenes sulfonation [

24,

26]. Further sulfonation (with a contact time of more than 60 min) does not lead to a noticeable increase in either the sulfur content or the total acid value of the material. Some additional increase in acid value is achieved with additional sulfonation with oleum within 60 min after sulfonation with sulfuric acid (sample SA-150/60), although the increase in acid value in this case is disproportionate to the increase in the mass fraction of sulfur. In general, the sulfur content in the sulfonated samples was of the same order of that previously reported by Yakubov for very similar tar-derived materials [

25].

Based on the data on the change in the mass fraction between the initial sample of asphaltenes and the sulfonated samples, the calculated acid values were obtained (the calculation was carried out on the assumption that all sulfur introduced into the material was presented in the form of SO

3H groups). As can be seen in

Table 1, in general, the discrepancy between the mean acid value (average of the calculated and the titrimetric values) and the individual values does not exceed 9.2 rel%. The exceptions are samples SA-90 and SA-120, for which the differences in acid value values are 16.7 and 13.4 rel%, respectively. One should also note that, in fact, not all the sulfur introduced onto the asphaltene matrix is responsible for the acid value [

26]. Taking into account the aforementioned consideration, as well as possible overlap in the errors of both analyzes, it can be concluded that the bulk of the sulfur introduced into the material is presented in the form of sulfo groups, which is highly typical for materials of this kind [

28].

Since granular asphaltenes undergo sulfonation, during processing functional groups can be distributed over the granules both homogeneously and over the surface (the latter option is possible if the sulfonating agent molecules are unable to diffuse into the asphaltene granules). As can be seen from the maps of the distribution of elements over the surface of materials (

Figure 1), oxygen and sulfur are uniformly distributed over granules of sulfoasphaltenes, regardless of the degree of sulfonation. Thus, the distribution of sulfo groups over the surface of the granules of the material can be considered homogeneous. The mass fractions of oxygen and sulfur increase with increasing sulfonation time (

Figure 2), which correlates with the results of determining the mass fraction of sulfur by the CHNS method (

Table 1). The lower mass fraction of sulfur obtained from the EDX method is evidence that this calculation does not include the nitrogen and metals present in petroleum asphaltenes. At the same time, the data on the sulfur content obtained by the EDX method have the same order as the data of the CHNS analysis.

When analyzing samples of sulfonated asphaltenes (SA-5, SA-10, SA-30 and SA-150) by the method of low-temperature nitrogen adsorption, it was found that the surface of the materials was not developed; the specific surface area was about 1.5 m

2 g

−1, which agrees with the literature data [

29].

For the purpose of comparison, several different acidic catalysts were employed (

Table 2).

As suggested above, the materials under study are granules without pores and inner surfaces and which are sulfonated uniformly along the outer surface. At the same time, if part of the sulfo groups penetrate into the granule during the sulfonation process, then, given the absence of pores, these groups should be less accessible to reagent molecules. A control experiment was carried out on sample SA-60, which was used as a catalyst for the ketalization of glycerol in the form of granules and fine powder. Under the reaction conditions (T = 40 °C, glycerol: Eq H+ = 2500 mol, acetone:glycerol:ethanol = 2:1:1 mol), the glycerol conversion after 60 min for the granular and powdery catalysts was 58 and 56%, respectively. The close conversion values confirm the assumption that, in sulfonated asphaltenes, active groups are concentrated on the granule surface.

To further compare the activity of different catalysts, a test was carried out to optimize the mixing conditions in the reactor in order to eliminate the possible effect of external diffusion restrictions. At a stirring rate above 1000 rpm (T = 40 °C, glycerol: Eq H

+ = 2500 mol, acetone:glycerol:ethanol = 2:1:1 mol), the effect of external diffusion on the reaction rate was eliminated (

Figure 3). Further experiments were carried out at a stirring speed of 1500 rpm.

Comparison of the catalytic activity of the known catalysts for glycerol ketalization, in general, led to predictable results. All heterogeneous catalysts were markedly less active than p-TSA, with the exception of the F-4SF/SiO

2 (

Table 3). The latter circumstance can be explained by the higher acidic strength of the functional groups of this Nafion-type material. A similar effect of the high activity of perfluorosulfonic polymers relative to non-fluorinated catalysts with SO

3H groups was observed both in the acetalization reaction [

32] and in the esterification of glucose with primary alcohols [

33]. BEA-40 zeolite was more active than BEA-25, which also correlated with the patterns described earlier [

18]. Mesoporous aluminosilicate Al-HMS(20) showed the lowest activity among heterogeneous catalysts, despite its developed porous structure that does not favor diffusional limitations. The activity of sulfonic cation exchanger A-36 was comparable to the activity of p-TSA only at sufficiently high conversion values, while the difference in the values at the initial stage of the reaction indicates a higher activity for homogeneous acid: the solketal yields after 15 min at 40 °C were 26.4 and 46.8 mol%, respectively. It is interesting to note that the activity of sulfonated coal, which has a developed porous structure, was close to that of macroporous sulfcationite: the solketal yield under the same conditions (T = 40 °C, τ = 15 min) was 26.8 mol%.

The activity of the sample of unsulfonated asphaltenes SA-0 in the ketalization reaction was very low: the solketal yield under standard conditions (T = 40 °C, τ = 15 min) was 0.8 mol%, and remained at the same level even when the reaction was continued for up to 60 min. This suggests that the acid value of the initial asphaltene sample was due to the presence of weak acidic groups (–COOH, Ph–OH) in the molecular structure, which are capable of catalyzing ketalization at a noticeable rate only at higher temperatures.

All samples of sulfonated asphaltenes showed high activity in relation to the reaction of glycerol ketalization. With an increase in the sulfonation time during the preparation of the catalyst, the activity practically did not change in the series from sample SA-10 to sample SA-150. The highest activity was characteristic of the samples with the minimum sulfonation time: SA-5, SA-10, and SA-30; the solketal yields after 15 min of reaction under standard conditions for these samples were 39.9 and 46.7 mol %, respectively. The data on the yield of the solketal for 30 min of the reaction confirm such a distribution of activity between the catalysts. The highest solketal yield (73.2 mol %) was obtained for the SA-5 catalyst with a reaction time of 60 min, approaching the value of the equilibrium yield [

20]; such high conversion values no longer allow a correct comparison of the catalyst activity. A further increase in the sulfonation time led to a slight decrease in activity, although in general it remained at the same level: for sample SA-150 (sulfonation with sulfuric acid for 150 min), the solketal yield after 15 min of reaction was 33.3 mol %. Further sulfonation with oleum (sample SA-150/60), although it led to an increase in the sulfur content in the material, did not allow a significant increase in the catalyst activity: the solketal yield after 15 min of reaction was 36.9 mol %, which is slightly less than for catalysts with a low degree of sulfonation. Thus, we can say that the catalysts obtained after short sulfonation times and with a lower surface density of sulfo groups have a higher activity than samples with a higher surface density of sulfo groups: the TON value clearly decreases when going from less sulfonated to more sulfonated samples.

It should be noted that the specific activity of catalysts SA-5, SA-30, and SA-10 approached the activity of a homogeneous acidic catalyst p-TSA with a similar functional group. This circumstance confirms the almost complete absence of intradiffusion restrictions upon catalysis with sulfoasphaltenes, which is in good agreement with the hypothesis put forward earlier that these materials have no inner surface. Thus, the high activity of the proposed materials is explained by the fact that possible intradiffusion restrictions on the reaction rate are eliminated—not by obtaining a material with a developed inner surface, but by completely eliminating the porous structure as such. Of course, at first glance, such an approach seems irrational: it seems that a catalyst operating exclusively on the surface of a granule can never be as efficient as a catalyst with a developed inner surface.

Calculation data for catalyst weight specific productivity after 15 min of reaction (

Table 3) show that p-TSA is the most productive catalyst; among heterogeneous catalysts, A-36 has the highest productivity, which is a consequence of the high acid value of this material (about 5.1 meq g

−1). The specific productivity of other catalysts is significantly lower: even a very active catalyst based on the perfluorosulfopolymer F-4SF/SiO

2 has a very low specific productivity (0.45 meq mg

−1) due to the low total acid value of the material. It should be noted that the specific weight productivity per unit mass of sulfoasphaltene catalysts ranges between 34 and 69% of the productivity of sulfonic cation exchanger A-36. Since sulfonation with sulfuric acid, carried out over 60 min, does not significantly increase the acid value of the material, as well as additional sulfonation with oleum, the obtained acid value values can be considered as the maximum achievable for non-porous asphaltene granules. Higher acid values of sulfonic cation exchangers are determined by the more developed matrix surface available for sulfonation. However, given the potential cheapness of the asphaltene-derived acidic materials, they can offer a robust alternative to both the polystyrene-DVB ion-exchange resins and the sulfonated coals.

It should be noted that certain specific productivity values were quite close to the values obtained for the synthesis of solketal in a flow reactor by Dmitriev et al. [

1]. Thus, the specific productivity for BEA-40 and A-36 calculated from the solketal yield after 15 min was 0.69 and 3.74 mmol s

−1 g

−1, whereas the corresponding reported values were 1.0 and 3.2 mmol s

−1 g

−1, respectively.

To further compare the activity of the catalysts used, kinetic experiments were carried out at reaction temperatures of 30, 40 and 50 °C (reaction time 5 min). Based on the data obtained, the level of dependency of the solketal yield on temperature was obtained, from which the values of the apparent activation energy of the reaction were calculated (

Table 4). The lowest value of the activation energy (14.5 kJ mol

−1) was characteristic of the homogeneous p-TSA catalyst. The activation energy of the reaction in the presence of sulfonic cation exchanger A-36 was 27.3 kJ mol

−1, which is approximately half the value of 55.6 kJ mol

−1 reported by Nanda et al. for a ketalization reaction under the same conditions and in the presence of A-35 sulfonic cation exchanger with similar properties [

20]. This effect, in Nanda et al.’s experiment, can be explained by the possible presence of intradiffusion inhibition, which causes a decrease in the apparent activation energy. Among the heterogeneous catalysts, samples SA-5, SA-30, and SA-150/60 (18.0, 20.5 and 18.1 kJ mol

−1, respectively) were characterized by the closest values. For the rest of the materials from the sulfoasphaltene group, the values ranged from 21.6 to 35.2 kJ mol

−1. The activation energy for sulfonated carbon (SC), which has the same functional groups as sulfoasphaltenes, but also a well-developed porous structure, was of the same order of magnitude (28.2 kJ mol

−1). Among other materials, only the F-4SF/SiO

2 sample showed a close activation energy (19.6 kJ mol

−1); in this case, the absence of diffusion restrictions in the developed porous structure of silica gel, in combination with the high catalytic activity of the perfluorosulfopolymer, was probably manifested. Aluminosilicate materials with a well-developed porous structure—zeolites of the BEA type and synthetic aluminosilicate Al-HMS (20)—had lower activity at higher activation energies, which is a consequence of the lower activity of the functional groups of these materials in the ketalization reaction compared to SO

3H groups.

For carbonaceous heterogeneous catalysts possessing the SO

3H functional groups, the Hammett function usually amounts to −8 ≤

H0 ≤ −11 (comparable with the value for the concentrated H

2SO

4) [

28]; the same region of the

H0 values is reported for the Amberlyst 15 sulfonic cation exchange resin, the H

2SO

4-treated SiO

2 and TiO

2, and for the homogeneous xylene sulfonic acid [

34]. Based on these data, one could assume that the similarity of the functional groups of the sulfonated asphaltenes, sulfonated charcoal, Amberlyst 15 and the p-TSA allows one to suppose that their

H0 functions are close to the aforementioned range. It is also known that the acid strength of Nafion-type materials is close to that of sulfuric acid (

H0 ≈ −12), so these catalysts with close activation energy values (18–30 kJ mol

−1) could be assumed to have similar acid strengths. However, the experimental determination of the acid strength for the sulfonated asphaltene samples remains of interest.

For materials with SO

3H groups on a carbon carrier, the acid leaching phenomenon is often characteristic, accompanied by a partial loss of material activity. To assess the stability of the sulfoasphaltenes obtained in this study, a control experiment was carried out with a sample of SA-150 asphaltenes (

Figure 4). A portion of the catalyst (taken into the reaction in the form of granules) was separated from the reaction mixture after 60 min of reaction, and the reaction mixture was returned to the same reactor, after which the monitoring of the reaction progress was continued. The solketal yield in the mixture immediately before the separation of the catalyst was 44.6%; an hour after the reaction mixture was returned to the reactor, the yield was 44.8%. The absence of significant differences in the solketal yields allows us to conclude that there was no noticeable acid leaching in the specified conditions.

Since acidic catalysts based on sulfonated asphaltenes demonstrated high activity and specific productivity per unit weight in the glycerol ketalization reaction, in order to further assess the applicability of these materials as acetalization catalysts, their resistance to deactivation under reaction conditions was then assessed.

The reusability test carried out for this showed that the activity of the SA-150 catalyst slightly increased in each subsequent catalytic cycle, exceeding the initial value by 1.2 times in the fifth cycle (

Figure 5). Only in the sixth cycle was a slight relative decrease in activity (compared to the foregoing cycle) detected, although its value was still at the level of 1.14 from the value of the first cycle. Thus, the activity of the catalyst did not decrease below the initial one, at least upon reaching the total turnover number (TON) of 7247. The acid value determined for the spent catalyst isolated from the sixth cycle (2.32 meq g

−1) indicates that no substantial deactivation of the SO

3H groups took place during the test (the deviation between the acid values of the fresh and the spent SA-150 samples was about 3.3 rel%). This suggests a sufficiently high resistance of the catalyst to deactivation under the conditions of the glycerol ketalization reaction with acetone.

3. Materials and Methods

3.1. Reagents

For the catalytic tests, glycerol and acetone (analytical grade, Komponent-Reaktiv, Moscow, Russia) were used without any other purification. Ethanol added to reaction mixtures for homogenization (analytical grade, Komponent-Reaktiv, Moscow, Russia) was absolutized over metallic sodium and stored over the 3A molecular sieves. The standard feed reaction mixture (acetone:ethanol:glycerol = 1:2:1 mol) was prepared once and stored over the 3A molecular sieves to preserve it from possible water accumulation. For the treatment of the reaction mixture aliquots taken out of the reactor, sodium carbonate (Na2CO3) was used (Komponent-Reaktiv, Moscow, Russia).

For the GC quantification method, butanol-1 (analytical grade, Komponent-Reaktiv, Moscow, Russia) was used as an internal standard without any additional purification.

For the synthesis of the sulfonated asphaltenes, sulfuric acid (95.6%, Sigma Aldrich, St. Louis, MO, USA) and oleum (30%, Sigma-Aldrich, St. Louis, MO, USA) were used as the sulfonating agents.

3.2. Catalysts

Commercially available p-toluenesulfonic acid (p-TSA, reagent grade, Komponent-Reaktiv, Moscow, Russia), ion-exchange resins Amberlyst 36 Dry and Amberlyst 45 Dry (samples were kindly provided for testing by Dow Europe GmbH, Moscow, Russia), zeolites CP814 (BEA-25) and CP811 (BEA-40) (Zeolyst International, Kansas City, Kansas, USA), montmorillonite K-10 (Acros, Antwerpen, Belgium) were used in the catalytic tests. Prior to use, montmorillonite granules were grained to give a disperse powder and calcined in air at 300 °C. The sulfonic acid cation exchange resins were used without further preparation. The zeolites were calcined at 550 °C for 10 h before use.

The syntheses and the characterization procedures of the lab-prepared catalysts have been reported elsewhere for the mesoporous aluminosilica Al-HMS (20) with the Si/Al = 20 [

30], the SiO

2-supported F-4SF perfluoropolymer (10 wt% of the supported polymer) [

18] and the sulfonated coal [

31].

The asphaltenes were isolated from the vacuum residue (JSC Taneko, Nizhnekamsk, Russia) in accordance with the ASTM D4124-09 procedure [

26]. The asphatlenes sulfonation was performed in accordance with the following procedure: to 140 g of sulfuric acid, 7 g of asphaltenes (0.4–0.5 mm fraction) were added under continuous stirring. The reaction was further run in a round-bottomed flask equipped with a reflux condenser under the temperature of 80 °C for 5, 10, 30, 60, 90, 120 and 150 min. Upon the completion of the reaction, the reaction mixture was diluted with 9 L of distilled water. The solid precipitate was vacuum filtered and washed with distilled water until neutral reaction.

The additional treatment with oleum was performed as follows: after 150 min of the reaction with sulfuric acid, 70 mL of oleum was added dropwise during the following 40 min. After that, stirring was continued for 1 h and then the sulfonated material was recovered in a similar manner.

3.3. Catalysts Characterization

The total acid value of the sulfonated coals was determined by the titrimetric method: sulfonated coal (0.5 g) was reacted with 50 mL of a 0.1 M aqueous solution of sodium hydroxide, after which the NaOH content in the resulting solution was determined by titration with a 0.1 M hydrochloric acid solution (two parallel experiments) with phenolphthalein.

The characteristics of the porous structure were evaluated by the analysis of low-temperature nitrogen adsorption (ASAP 2020, Micromeritics, Norcross, GA, USA).

The sulfur content in the original asphaltenes and the obtained sulfonated samples were determined by the CHNS analysis (Thermo Flash 2000 analyzer, Waltham, MA, USA).

The sulfonated asphaltenes samples were characterized by means of a high resolution transmission electron microscopy (TEM). For transmission electron microscopy, a FEI Tecnai Osiris TEM (FEI Company, Hillsboro, OR, USA) with an accelerating voltage of 200 keV was used. For the SA samples, EDX mapping microphotographs were obtained.

3.4. Experimental Procedure

The experiments of the ketalization of glycerol with acetone under atmospheric pressure were carried out in a glass reactor (internal volume, 20 cm3) equipped with a thermostating jacket and a reflux condenser. The previously prepared feed reaction mixture (glycerol:acetone:ethanol = 1:2:1 mol) was used. A magnetic stir bar and the reactant mixture (7 mL) were placed in the reactor and the thermostat was turned on. After reaching the set temperature (30, 40 or 50 °C), a catalyst charge was introduced into the reactor. The catalyst amount was calculated for each catalyst with respect to its total acid value (mmol g−1) in order to maintain the equal molar ratio between the total amount of glycerol and the catalyst acid sites (glycerol:Eq H+ = 2500 mol) in every experimental run. The catalyst introduction moment was taken as the initial reaction time. Stirring was periodically terminated to take aliquots of a 0.05–0.1 mL volume, which were ‘quenched’ with two drops of a saturated sodium carbonate water solution and then analyzed by GLC.

The following sampling protocol was applied: each run was repeated twice; each sample was analyzed either 2 or 3 times to obtain the appropriate standard deviation (about 0.5–0.8 mol% of the solketal yield).

The leaching test was performed for the SA-150 sample (glycerol:Eq H+ = 2500 mol) at 40 °C. The reaction progress was monitored at 5, 15, 30 and 60 min of the reaction time, and then the catalyst was separated from the reaction mixture via vacuum filtration, while the reactor was quickly flushed with acetone in order to remove the remaining catalyst particles. The filtered reaction mixture was returned to the reactor, the stirring was turned on, and the reaction progress was further monitored via GC.

The reusability test was performed for the SA-150 sample (glycerol:Eq H+ = 2500 mol) at 40 °C in 6 repeating runs (reaction time, 60 min). After each run, the catalyst was separated from the reaction mixture by centrifugation, thoroughly washed with acetone, and dried in argon. The amount of the spent catalyst (via weighing) and of the reaction mixture (via dosing by volume) taken for the next run were calculated to provide the same feed-to-catalyst ratio.

The reaction mixture composition was analyzed with the use of the GC-FID (‘Kristalluks-4000M’ gas chromatograph, Meta-Khrom, Yoshkar-Ola, Russia) equipped with a ‘Restek Rtx-Wax’ 60 m/0.53 mm/1.00 μm column (Restek, Bellefonte, PA, USA), and helium as the carrier gas. Butanol-1 (analytical grade, Komponent-Reaktiv, Moscow, Russia) was used as the internal standard for the quantification.

4. Conclusions

In the present study, samples of heterogeneous catalysts based on sulfonated asphaltenes isolated from vacuum residue were obtained and characterized. The separated asphaltenes were sulfonated with sulfuric acid at a contact time of 5 to 150 min. With an increase in the sulfonation time to 60 min, an increase in the acid value of the material (from 1.06 to 2.58 mmol g−1) and the total sulfur content (from 3.97 wt% for the initial asphaltenes to 11.27 wt% for the most sulfonated sample) was observed. A further increase in acid value (up to 2.91 mmol g−1) could be achieved by additional sulfonation with oleum for 60 min.

The characterization of the obtained materials by the HR-TEM method showed that the SO3H groups introduced at the sulfonation stage were uniformly distributed over the surface of the sulfoasphaltene granules. The specific surface area of sulfoasphaltenes determined by the method of low-temperature nitrogen adsorption did not exceed 1.67 m2 g−1, which suggested the almost complete absence of an internal porous structure. Thus, the resulting material consisted of monolithic granules without internal pores, sulfonated evenly over the external surface. This assumption was confirmed by the absence of a difference in catalytic activity between the catalyst in the form of granules and in the form of a fine powder.

The activity of catalysts based on sulfonated asphaltenes in the solketal synthesis reaction was determined and compared with the activity of other acidic catalysts. The highest activity values were characteristic of the least sulfonated samples, SA-5 and SA-10, as well as for the additionally sulfonated sample SA-150/60 with oleum: the values of TON at the reaction time of 15 min were 998, 1168 and 923, respectively. A higher specific activity was recorded only for the homogeneous catalyst p-TSA (TON15 = 1170) and the heterogeneous catalyst based on the perfluorosulfopolymer F-4SF/SiO2 (TON15 = 1178). The activity of such well-known heterogeneous catalysts as BEA-40 zeolite and the montmorillonite K-10 was somewhat lower (TON15 = 660, 985 and 410, respectively). Sulfonated carbon with a developed porous structure and -SO3H-functional groups had the same specific activity (TON15 = 670), as styrene-DVB sulfonic cation exchange resin ‘Amberlyst 36′ (TON15 = 660).

The catalysts were also compared in terms of the specific productivity per unit mass of the material for 15 min of reaction. The most productive heterogeneous catalyst was found to be Amberlyst 36 (3.37 mmol g−1). The productivity of the sulfoasphaltene catalysts reached 2.55 mmol g−1 for sample SA-150/60, additionally sulfonated with oleum, which was 75% of the productivity of the polymeric ion exchanger. The productivity of the remaining heterogeneous catalysts did not exceed 0.62 mmol g−1. The high activity of the sulfoasphaltene catalysts was also confirmed by calculating the values of the apparent activation energy: the value of Ea ranged from 18.0 to 25.5 kJ mol−1 for the sulfoasphaltene catalysts, which was lower than the values for zeolite BEA-40 (28.7 kJ mol−1) and sulfonic ion exchange resin Amberlyst 36 (27.3 kJ mol−1), and approaches the value obtained for a homogeneous catalytic reaction in the presence of p-TSA (14.5 kJ mol−1). The SA-150 catalyst based on sulfonated asphaltenes showed the absence of acid leaching and deactivation until reaching a total TON = 7247 within six reaction cycles.

Taking into account the good catalytic properties of the considered materials and their wide availability, they can be considered as potential catalysts for the synthesis of solketal or homologous acetals by the acid-catalytic condensation of carbonyl compounds with alcohols.