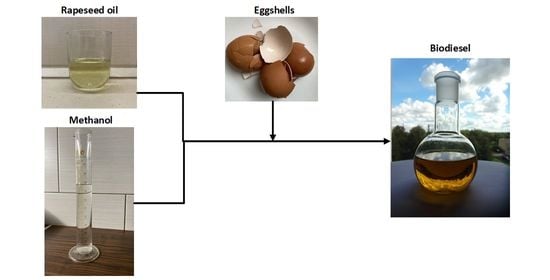

Effectiveness of Eggshells as Natural Heterogeneous Catalysts for Transesterification of Rapeseed Oil with Methanol

Abstract

:1. Introduction

2. Results and Discussion

2.1. Eggshells Preparation

2.2. Modeling and Determination of Optimal Reaction Conditions Using Response Surface Methodology

2.3. Optimization of Rapeseed Oil Transesterification

2.4. Physical and Chemical Properties of Produced Biodiesel

3. Materials and Methods

3.1. Preparation of the Catalyst

3.2. Determination of CaO in Eggshells

3.3. Transesterification of Rapeseed Oil

3.4. Gas Chromatography

3.5. Response Surface Analysis

3.6. Determination of Physical and Chemical Properties of Biodiesel

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ACEA. 2021. Available online: https://www.acea.auto/figure/fuel-types-of-new-passenger-cars-in-eu/ (accessed on 5 October 2021).

- React Power Team. How Engines Evolved with The Agricultural Industry. 2019. Available online: https://www.reactpower.com/blog/how-engines-evolved-with-the-agricultural-industry/ (accessed on 19 October 2021).

- Chiche, A.; Andruetto, C.; Lagergren, C.; Lindbergh, G.; Stenius, I.; Peretti, L. Feasibility and impact of a Swedish fuel cell-powered rescue boat. Ocean Eng. 2021, 234, 109259. [Google Scholar] [CrossRef]

- Vishal, D.; Dubey, S.; Goyal, R.; Dwivedi, G.; Baredar, P.; Chhabra, M. Optimization of alkali-catalyzed transesterification of rubber oil for biodiesel production & its impact on engine performance. Renew. Energy 2020, 158, 167–180. [Google Scholar]

- Anantapinitwatna, A.; Ngaosuwan, K.; Kiatkittipong, W.; Wongsawaeng, D.; Anantpinijwatna, A.; Quitain, A.T.; Assabumrungrat, S. Water influence on the kinetics of transesterification using CaO catalyst to produce biodiesel. Fuel 2021, 296, 120653. [Google Scholar] [CrossRef]

- Marinković, D.M.; Stanković, M.V.; Veličković, A.V.; Avramović, J.M.; Miladinović, M.R.; Stamenković, O.O.; Veljković, V.B.; Jovanović, D.M. Calcium oxide as a promising heterogeneous catalyst for biodiesel production: Current state and perspectives. Renew. Sustain. Energy Rev. 2016, 56, 1387–1408. [Google Scholar] [CrossRef]

- Shahbandeh, M. Egg Production: Leading Countries Worldwide 2018. Statista. 2020. Available online: https://0-www-statista-com.brum.beds.ac.uk/statistics/263971/top-10-countries-worldwide-in-egg-production/ (accessed on 26 October 2021).

- Laca, A.; Laca, A.; Díaz, M. Eggshell waste as catalyst: A review. J. Environ. Manag. 2017, 197, 351–359. [Google Scholar] [CrossRef]

- Available online: https://www.hartmann-packaging.com/world/think-news/2-2021-european-egg-market/ (accessed on 15 November 2021).

- Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_20_420 (accessed on 23 September 2020).

- Gao, Y.; Xu, C. Synthesis of dimethyl carbonate over waste eggshell catalyst. Catal. Today 2012, 190, 107–111. [Google Scholar] [CrossRef]

- Quina, M.J.; Soares, M.A.R.; Quinta-Ferreira, R. Applications of industrial eggshell as a valuable anthropogenic resource. Resour. Conserv. Recycl. 2017, 123, 176–186. [Google Scholar] [CrossRef]

- Aditya, S.; Stephen, J.; Radhakrishnan, M. Utilization of eggshell waste in calcium-fortified foods and other industrial applications: A review. Trends Food Sci. Technol. 2021, 115, 422–432. [Google Scholar] [CrossRef]

- Bartter, J.; Diffey, H.; Yeung, Y.H.; O’Leary, F.; Häsler, B.; Maulaga, W.; Alders, R. Use of chicken eggshell to improve dietary calcium intake in rural sub-Saharan Africa. Matern. Child Nutr. 2018, 3, e12649. [Google Scholar] [CrossRef] [Green Version]

- Brun, L.R.; Lupo, M.; Delorenzi, D.A.; Di Loreto, V.E.; Rigalli, A. Chicken eggshell as suitable calcium source at home. Int. J. Food Sci. Nutr. 2013, 64, 740–743. [Google Scholar] [CrossRef]

- Gaide, I.; Makareviciene, V.; Sendzikiene, E.; Kazancev, K. Natural Rocks–Heterogeneous Catalysts for Oil Transesterification in Biodiesel Synthesis. Catalysts 2021, 11, 384. [Google Scholar] [CrossRef]

- Ramesh, S.; Natasha, A.N.; Tan, C.Y.; Bang, L.T.; Ramesh, S.; Ching, C.Y.; Thambinayagam, C.H. Direct conversion of eggshell to hydroxyapatite ceramic by a sintering method. Ceram. Int. 2016, 42, 7824–7829. [Google Scholar] [CrossRef]

- Wei, Z.; Xu, C. Application of waste eggshell as low-cost solid catalyst for biodiesel production. Bioresour. Technol. 2009, 100, 2883–2885. [Google Scholar] [CrossRef] [PubMed]

- Goli, J.; Sahu, O. Development of heterogeneous alkali catalyst fromwaste chicken eggshell for biodiesel production. Renew. Energy 2018, 128, 142–154. [Google Scholar] [CrossRef]

- Granados, L.M.; Poves, Z.M.D.; Alonso, M.D.; Mariscal, R.; Galisteo, C.F.; Tost, M.R.; Santamaria, J.; Fierro, G.L.J. Biodiesel from sunflower oil by using activated calcium oxide. Appl. Catal. B Environ. 2007, 73, 317–326. [Google Scholar] [CrossRef]

- Ahmad, S.; Chaudhary, S.; Pathak, V.V.; Kothari, R.; Tyagi, V.V. Optimization of direct transesterification of Chlorella pyrenoidosa catalyzed by waste egg shell based heterogenous nano—CaO catalyst. Renew. Energy 2020, 160, 86–97. [Google Scholar] [CrossRef]

- Correia, L.M.; Cecilia, J.A.; Rodríguez-Castellón, E.; Cavalcante, C.L.; Vieira, R.S. Relevance of the Physicochemical Properties of Calcined Quail Eggshell (CaO) as a Catalyst for Biodiesel Production. J. Chem. 2017, 2017, 5679512. [Google Scholar]

- Kamaronzaman, M.F.F.; Kahar, H.; Hassan, N.; Hanafi, M.F.; Sapawe, N. Optimization of biodiesel production from waste cooking oil using eggshell catalyst. Mater. Today Proc. 2020, 31, 324–328. [Google Scholar] [CrossRef]

- Khemthong, P.; Luadthong, C.; Nualpaeng, W.; Changsuwan, P.; Tongprem, P.; Viriya-Empikul, N. Industrial eggshell wastes as the heterogeneous catalysts for microwave-assisted biodiesel production. Catal. Today 2010, 190, 112–126. [Google Scholar] [CrossRef]

- Kumar, H.; Renita, A.A.; Anderson, A. Response surface optimization for biodiesel production from waste cooking oil utilizing eggshells as heterogeneous catalyst. Mater. Today Proc. 2021, 47, 1054–1058. [Google Scholar] [CrossRef]

- Niju, S.; Begum, M.S.; Anantharaman, N. Modification of egg shell and its application in biodiesel production. J. Saudi Chem. Soc. 2014, 18, 702–706. [Google Scholar] [CrossRef] [Green Version]

- Correia, L.M.; Saboya, R.M.A.; de Susa Campelo, N.; Cecilia, J.A.; Rodrguez-Castelln, E.; Cavalcante, C.L.; Vieira, M.R.S. Characterization of calcium oxide catalysts from natural sources and their application in the transesterification of sunflower oil. Bioresour. Technol. 2014, 151, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Piker, A.; Tabah, B.; Perkas, N.; Gedanken, A. A green and low-cost room temperature biodiesel production method from waste oil using egg shells as catalyst. Fuel 2016, 182, 34–41. [Google Scholar] [CrossRef]

- Montgomery, D. Design and Analysis of Experiments; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

| No | A: Methanol-to-Oil Molar Ratio, mol/mol | B: Catalyst Amount, wt% | C: Duration, h | Predicted Ester Yield, wt% | Experimental Ester Yield, wt% |

|---|---|---|---|---|---|

| 1 | 4.00 | 4.00 | 4.00 | 3.19 | 11.44 ± 0.89 |

| 2 | 16.00 | 4.00 | 4.00 | 2.32 | 8.12 ± 0.66 |

| 3 | 4.00 | 10.00 | 4.00 | 60.05 | 65.97 ± 0.69 |

| 4 | 16.00 | 10.00 | 4.00 | 12.83 | 15.50 ± 0.34 |

| 5 | 4.00 | 4.00 | 10.00 | 25.41 | 32.51 ± 0.46 |

| 6 | 16.00 | 4.00 | 10.00 | 71.66 | 75.26 ± 0.29 |

| 7 | 4.00 | 10.00 | 10.00 | 95.93 | 99.50 ± 0.67 |

| 8 | 16.00 | 10.00 | 10.00 | 95.83 | 97.28 ± 0.36 |

| 9 | 1.60 | 7.00 | 7.00 | 38.28 | 25.17 ± 0.46 |

| 10 | 18.40 | 7.00 | 7.00 | 37.61 | 32.36 ± 0.56 |

| 11 | 10.00 | 2.80 | 7.00 | 47.95 | 35.87 ± 0.87 |

| 12 | 10.00 | 11.20 | 7.00 | 98.66 | 98.72 ± 1.23 |

| 13 | 10.00 | 7.00 | 2.80 | 32.00 | 20.34 ± 0.65 |

| 14 | 10.00 | 7.00 | 11.20 | 98.95 | 98.76 ± 0.94 |

| 15 | 10.00 | 7.00 | 7.00 | 89.53 | 92.45 ± 0.75 |

| 16 | 10.00 | 7.00 | 7.00 | 89.53 | 89.56 ± 0.69 |

| 17 | 10.00 | 7.00 | 7.00 | 89.53 | 92.56 ± 0.47 |

| 18 | 10.00 | 7.00 | 7.00 | 89.53 | 90.78 ± 0.34 |

| 19 | 10.00 | 7.00 | 7.00 | 89.53 | 91.89 ± 0.67 |

| 20 | 10.00 | 7.00 | 7.00 | 89.53 | 91.34 ± 0.63 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F | |

|---|---|---|---|---|---|---|

| Model | 23,650.36 | 9 | 2627.82 | 30.08 | <0.0001 | Significant |

| A-butanol-to-oil molar ratio | 0.70 | 1 | 0.70 | 8.022 × 10−3 | 0.9304 | |

| B-temperature | 4891.10 | 1 | 4891.10 | 56.00 | <0.0001 | |

| C-catalyst | 8249.05 | 1 | 8249.05 | 94.44 | <0.0001 | |

| AB | 1073.93 | 1 | 1073.93 | 12.29 | 0.0057 | |

| AC | 1110.38 | 1 | 1110.38 | 12.71 | 0.0051 | |

| BC | 93.23 | 1 | 93.23 | 1.07 | 0.3259 | |

| A2 | 5824.04 | 1 | 5824.04 | 66.68 | <0.0001 | |

| B2 | 382.59 | 1 | 382.59 | 4.38 | 0.0628 | |

| C2 | 938.00 | 1 | 938.00 | 10.74 | 0.0083 | |

| Residual | 873.48 | 10 | 87.35 | |||

| Lack of Fit | 871.48 | 5 | 174.30 | 435.74 | <0.0001 | Not significant |

| Pure Error | 2.00 | 5 | 0.40 | 30.08 | ||

| Cor Total | 24,523.83 | 19 | 2627.82 |

| Variable | Value | Variable | Value |

|---|---|---|---|

| Std. Dev. | 10.60 | R-Squared | 0.9450 |

| Mean | 63.53 | Adj R-Squared | 0.9129 |

| C.V. % | 16.69 | Pred R-Squared | 0.8597 |

| PRESS | 3440.17 | Adeq Precision | 16.926 |

| Methanol-to-Oil Molar Ratio, mol/mol | Eggshells Concentration, wt% (from Oil Mass) | Reaction Duration, h | Predicted Ester Yield, wt% | Experimental Ester Yield, wt% |

|---|---|---|---|---|

| 10.93:1 | 6.80 | 9.48 | 98.95 | 97.79 ± 0.32 |

| Oil | Temperature, °C | Eggshells Amount | Reaction Duration, h | Methanol-to-Oil Molar Ratio, mol/mol | Ester Yield, wt% | Reference |

|---|---|---|---|---|---|---|

| Sunflower | 60 | 2 wt% | 2 | 10.5:1 | 99.00 ± 0.02 | [22] |

| Sunflower | 60 | 3 wt% | 3 | 9:1 | 97.75 | [27] |

| Soybean | 65 | 3 wt% | 3 | 9:1 | 95 | [18] |

| Soybean | 25 | 5.8 wt% | 11 | 6:1 | 97 | [28] |

| Soybean | 57.5 | 7 wt% | 3 | 10:1 | 93 | [19] |

| Waste frying oil | 65 | 5 wt% | 2 | 20:1 | 45.52 | [23] |

| Waste frying oil | 65 | 5 wt% | 1 | 12:1 | 94.52 | [26] |

| Waste cooking | 50 | 5 g | 2 | 6:1 | 21 | [25] |

| Parameter | Units | EN 14214 Requirements | Rapeseed Oil Methyl Esters |

|---|---|---|---|

| Ester content | % | min 96.5 | 97.79 ± 0.32 |

| Density at 15 °C | kg m−3 | min 860 max 900 | 885 ± 0.24 |

| Viscosity at 40 °C | mm2 s−1 | min 3.50 max 5.00 | 4.83 ± 0.02 |

| Acid value | mg KOHg−1 | max 0.5 | 0.39 ± 0.002 |

| Sulfur content | mg kg−1 | max 10 | 7.2 ± 0.05 |

| Moisture content | mg kg−1 | max 500 | 228 ± 0.34 |

| Iodine value | g J2100−1 g−1 | max 120 | 117 ± 0.18 |

| Linolenic acid methyl esters content | % | max 12.0 | 9.5 ± 0.07 |

| Monoglyceride content | % | max 0.8 | 0.47 ± 0.04 |

| Diglyceride content | % | max 0.2 | 0.09 ± 0.01 |

| Triglyceride content | % | max 0.2 | 0.04 ± 0 |

| Free glycerol content | % | max 0.2 | 0.02 ± 0 |

| Total glycerol content | % | max 0.25 | 0.22 ± 0.15 |

| Methanol content | % | max 0.2 | 0.08 ± 0.001 |

| Phosphorus content, ppm | 10 | 8 ± 0.05 | |

| Oxidation stability 110 °C | h | min 8 | 8.3 ± 0.1 |

| Cetane number | - | min 51 | 53.8 ± 0.15 |

| Cold filter plugging point | °C | −5 °C (in summer) −32 °C (in winter) | −10 ± 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaide, I.; Makareviciene, V.; Sendzikiene, E. Effectiveness of Eggshells as Natural Heterogeneous Catalysts for Transesterification of Rapeseed Oil with Methanol. Catalysts 2022, 12, 246. https://0-doi-org.brum.beds.ac.uk/10.3390/catal12030246

Gaide I, Makareviciene V, Sendzikiene E. Effectiveness of Eggshells as Natural Heterogeneous Catalysts for Transesterification of Rapeseed Oil with Methanol. Catalysts. 2022; 12(3):246. https://0-doi-org.brum.beds.ac.uk/10.3390/catal12030246

Chicago/Turabian StyleGaide, Ieva, Violeta Makareviciene, and Egle Sendzikiene. 2022. "Effectiveness of Eggshells as Natural Heterogeneous Catalysts for Transesterification of Rapeseed Oil with Methanol" Catalysts 12, no. 3: 246. https://0-doi-org.brum.beds.ac.uk/10.3390/catal12030246