Photoelectrocatalytic Oxidation of Sulfamethazine on TiO2 Electrodes

Abstract

:1. Introduction

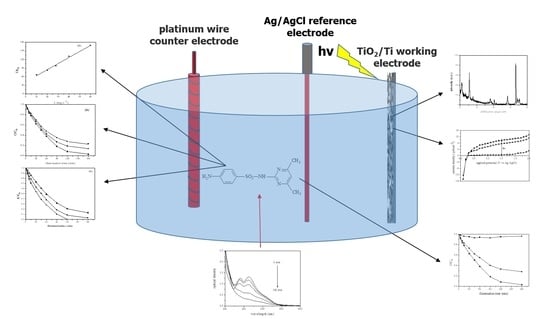

2. Results

2.1. Photoelectrochemical Behavior of the TiO2/Ti Electrode in Supporting Electrolyte

2.2. Bulk Photoelectrocatalytic Oxidation of Sulfamethazine at the TiO2/Ti Electrodes

2.3. The Effect of pH on the Degradation of Sulfamethazine

2.4. The Effect of the Type of the Electrodes on the Degradation of Sulfamethazine

3. Materials and Methods

3.1. Chemicals

3.2. TiO2/Ti Electrode Preparation

3.3. Experimental Setup and Procedures

3.4. Analytical Methods

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Council of the European Union. Council Directive 2000/60/EC of October 2000 establishing a framework for Community action in the field of water policy. Off. J. Eur. Union 2000, L327, 1–72. [Google Scholar]

- Herrmann, J.-M. Photocatalysis fundamentals revisited to avoid several misconceptions. Appl. Catal. B 2010, 99, 461–468. [Google Scholar] [CrossRef]

- Friedmann, D.; Mendiveb, C.; Bahnemann, D. TiO2 for water treatment: Parameters affecting the kinetics and mechanisms of photocatalysis. Appl. Catal. B 2010, 99, 398–406. [Google Scholar] [CrossRef]

- Kaneko, M.; Okura, I.E. (Eds.) Photocatalysis: Science and Technology; Springer: New York, NY, USA, 2002; ISBN 3-540-43473-9. [Google Scholar]

- Xin, Y.; Liu, H.; Han, L.; Zhou, Y. Comparative study of photocatalytic and photoelectrocatalytic properties of alachlor using different morphology TiO2/Ti photoelectrodes. J. Hazard. Mater. 2011, 192, 1812–1818. [Google Scholar] [CrossRef]

- Brugnera, M.F.; Rajeshwar, K.; Cardoso, J.C.; Zanoni, M.V.B. Bisphenol A removal from wastewater using self-organized TiO2 nanotubular array electrodes. Chemosphere 2010, 78, 569–575. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Jia, J.; Zhong, D.; Wang, Y. Degradation of dye wastewater in a thin-film photoelectrocatalytic (PEC) reactor with slant-placed TiO2/Ti anode. Chem. Eng. J. 2009, 150, 302–307. [Google Scholar] [CrossRef]

- Krýsa, J.; Zlamal, M.; Waldner, G. Effect of oxidisable substrates on the photoelectrocatalytic properties of thermally grown and particulate TiO2 layers. J. Appl. Electrochem. 2007, 37, 1313–1319. [Google Scholar] [CrossRef]

- Tzeng, T.W.; Wang, S.L.; Chen, C.C.; Tan, C.C.; Liu, Y.T.; Chen, T.Y.; Tzou, Y.M.; Chen, C.C.; Hung, J.T. Photolysis and photocatalytic decomposition of sulfamethazine antibiotics in an aqueous solution with TiO2. RSC Adv. 2016, 6, 69301–69310. [Google Scholar] [CrossRef]

- Aissani, T.; Yahiaoui, I.; Boudrahem, F.; Ait Chikh, S.; Aissani-Benissad, F.; Amrane, A. The combination of photocatalysis process (UV/TiO2(P25) and UV/ZnO) with activated sludge culture for the degradation of sulfamethazine. Sep. Sci. Technol. 2018, 53, 1423–1433. [Google Scholar] [CrossRef]

- Fukahori, S.; Fujiwara, T. Modeling of sulfonamide antibiotic removal by TiO2/high-silica zeolite HSZ-385 composite. J. Hazard. Mater. 2014, 272, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Vanlalhmingmawia, C.; Tiwari, D.; Kim, D.J. Novel nanocomposite thin film in the efficient removal of antibiotics using visible light: Insights of photocatalytic reactions and stability of thin film in real water implications. Environ. Res. 2023, 218, 115007. [Google Scholar] [CrossRef]

- Zhang, Y.; He, Z.; Zhou, J.; Huang, Y.; Li, W.; Li, Y.; Li, Y.; Bi, H.; Chang, F.; Zhang, H.; et al. Amorphous Co@TiO2 heterojunctions: A high-performance and stable catalyst for the efficient degradation of sulfamethazine via peroxymonosulfate activation. Chemosphere 2022, 307, 135681. [Google Scholar] [CrossRef]

- Fukahori, S.; Fujiwara, T. Photocatalytic decomposition behavior and reaction pathway of sulfamethazine antibiotic using TiO2. J. Environ. Manag. 2015, 157, 103–110. [Google Scholar] [CrossRef] [Green Version]

- Babić, S.; Zrnčić, M.; Ljubas, D.; Ćurković, L.; Škorić, I. Photolytic and thin TiO2 film assisted photocatalytic degradation of sulfamethazine in aqueous solution. Environ. Sci. Pollut. Res. 2015, 22, 11372–11386. [Google Scholar] [CrossRef] [PubMed]

- Jia, M.; Yang, Z.; Xu, H.; Song, P.; Xiong, W.; Cao, J.; Zhang, Y.; Xiang, Y.; Hu, J.; Zhou, C.; et al. Integrating N and F co-doped TiO2 nanotubes with ZIF-8 as photoelectrode for enhanced photo-electrocatalytic degradation of sulfamethazine. Chem. Eng. J. 2020, 388, 124388. [Google Scholar] [CrossRef]

- Zhang, J. Degradation mechanism of Sulfa drugs based on theoretical prediction and experimental examination in TiO2 suspension. Res. Chem. Intermed. 2014, 40, 1089–1102. [Google Scholar] [CrossRef]

- Hu, Z.; Liang, R.; Song, X.; Wu, H.; Sun, J.; Liu, J.; Zhou, M.; Arotiba, O.A. Efficient Bias-Free Degradation of Sulfamethazine by TiO2 Nanoneedle Arrays Photoanode and Co3O4 Photocathode System under LED-Light Irradiation. Catalysts 2023, 13, 327. [Google Scholar] [CrossRef]

- Zhou, Q.; Fang, Z. Highly sensitive determination of sulfonamides in environmental water samples by sodium dodecylbenzene sulfonate enhanced micro-solid phase extraction combined with high performance liquid chromatography. Talanta 2015, 141, 170–174. [Google Scholar] [CrossRef]

- Zeng, X.; Shu, S.; Meng, Y.; Wang, H.; Wang, Y. Enhanced photocatalytic degradation of sulfamethazine by g-C3N4/Cu, N-TiO2 composites under simulated sunlight irradiation. Chem. Eng. J. 2023, 456, 141105. [Google Scholar] [CrossRef]

- Qi, L.; Zhang, H.; Xiao, C.; Ni, L.; Chen, S.; Qi, J.; Zhou, Y.; Zhu, Z.; Li, J. Improvement of peroxymonosulfate utilization efficiency for sulfamethazine degradation by photo-electron activating peroxymonosulfate: Performance and mechanism. J. Colloid Interface Sci. 2023, 633, 411–423. [Google Scholar] [CrossRef]

- Wang, N.; Li, X.; Yang, Y.; Guo, T.; Zhuang, X.; Ji, S.; Zhang, T.; Shang, Y.; Zhou, Z. Enhanced photocatalytic degradation of sulfamethazine by Bi-doped TiO2 nano-composites supported by powdered activated carbon under visible light irradiation. Sep. Purif. Technol. 2019, 211, 673–683. [Google Scholar] [CrossRef]

- Fouad, K.; Gar Alalm, M.; Bassyouni, M.; Saleh, M.Y. A novel photocatalytic reactor for the extended reuse of W–TiO2 in the degradation of sulfamethazine. Chemosphere 2020, 257, 127270. [Google Scholar] [CrossRef] [PubMed]

- Mendiola-Alvarez, S.Y.; Hernández-Ramírez, A.; Guzmán-Mar, J.L.; Maya-Treviño, M.L.; Caballero-Quintero, A.; Hinojosa-Reyes, L. A novel P-doped Fe2O3 -TiO2 mixed oxide: Synthesis, characterization and photocatalytic activity under visible radiation. Catal. Today 2019, 328, 91–98. [Google Scholar] [CrossRef]

- Payan, A.; Akbar Isari, A.; Gholizade, N. Catalytic decomposition of sulfamethazine antibiotic and pharmaceutical wastewater using Cu-TiO2@functionalized SWCNT ternary porous nanocomposite: Influential factors, mechanism, and pathway studies. Chem. Eng. J. 2019, 361, 1121–1141. [Google Scholar] [CrossRef]

- Ji, H.; Du, P.; Zhao, D.; Li, S.; Sun, F.; Duin, E.C.; Liu, W. 2D/1D graphitic carbon nitride/titanate nanotubes heterostructure for efficient photocatalysis of sulfamethazine under solar light: Catalytic “hot spots” at the rutile–anatase–titanate interfaces. Appl. Catal. B 2020, 263, 118357. [Google Scholar] [CrossRef]

- Vilar, V.J.P.; Pillai, S.C.; Poulios, I.; Mantzavinos, D.; Pintar, A. Advanced oxidation processes: Recent achievements and perspectives. Environ. Sci. Pollut. Res. 2020, 27, 22141–22143. [Google Scholar] [CrossRef]

- Wu, H.; Hu, Z.; Liang, R.; Nkwachukwu, O.V.; Arotiba, O.A.; Zhou, M. Novel Bi2Sn2O7 quantum dots/TiO2 nanotube arrays S-scheme heterojunction for enhanced photoelectrocatalytic degradation of sulfamethazine. Appl. Catal. B 2023, 321, 122053. [Google Scholar] [CrossRef]

- Candia-Onfray, C.; Irikura, K.; Calzadilla, W.; Rojas, S.; Boldrin Zanoni, M.V.; Salazar, R. Degradation of contaminants of emerging concern in a secondary effluent using synthesized MOF-derived photoanodes: A comparative study between photo-, electro- and photoelectrocatalysis. Chemosphere 2023, 315, 137683. [Google Scholar] [CrossRef]

- Braun, A.M.; Maurette, M.; Oliveros, E. Photochemical Technology; Wiley: New York, NY, USA, 1991. [Google Scholar]

- Licht, S. Semiconductor Electrodes and Photoelectrochemistry. In Encyclopedia of Electrochemistry; Bard, A., Stratmann, M., Eds.; Wiley-VCH: Weinheim, Germany, 2002; Volume 6. [Google Scholar]

- Memming, R. Semiconductor Electrochemistry; Wiley-VCH: Weinheim, Germany, 2001. [Google Scholar]

- Pleskov, Y.; Gurevich, Y. Semiconductor Photoelectrochemistry; Springer: New York, NY, USA, 1986. [Google Scholar]

- Mintsouli, I.; Philippidis, N.; Poulios, I.; Sotiropoulos, S. Photoelectrochemical characterisation of thermal and particulate titanium dioxide electrodes. J. Appl. Electrochem. 2006, 36, 463–474. [Google Scholar] [CrossRef]

- Alulema-Pullupaxi, P.; Espinoza-Montero, P.J.; Sigcha-Pallo, C.; Vargas, R.; Fernández, L.; Peralta-Hernández, J.M.; Paz, J.L. Fundamentals and applications of photoelectrocatalysis as an efficient process to remove pollutants from water: A review. Chemosphere 2021, 281, 130821. [Google Scholar] [CrossRef]

- Daghrir, R.; Drogui, P.; Robert, D. Photoelectrocatalytic technologies for environmental applications. J. Photochem. Photobiool. A 2012, 238, 41–52. [Google Scholar] [CrossRef]

- Cunningham, J.; Al-Sayyed, G.; Srijaranai, S. Adsorption of model pollutants onto TiO2 particles in relation to photoremedation of contaminated water. In Aquatic and Surface Photochemistry; Helz, G., Zepp, R., Crosby, D., Eds.; Chapter 2; CRC Press: Boca Raton, FL, USA, 1994; pp. 317–348. [Google Scholar]

- Turchi, C.S.; Ollis, D.F. Photocatalytic degradation of organic-water contaminants—mechanisms involving hydroxyl radical attack. J. Catal. 1990, 122, 178–192. [Google Scholar] [CrossRef]

- Akpan, U.G.; Hameed, B.H. Parameters affecting the photocatalytic degradation of dyes using TiO2-based photocatalysts: A review. J. Hazard. Mater. 2009, 170, 520–529. [Google Scholar] [CrossRef]

- Kesselman, J.; Lewis, N.; Hoffmann, M. Photoelectrochemical degradation of 4-chlorocatechol at TiO2 electrodes: Comparison between sorption and reactivity. Environ. Sci. Technol. 1997, 31, 2298. [Google Scholar] [CrossRef]

- Yang, S.; Liu, Y.; Sun, C. Preparation of anatase TiO2/Ti nanotube-like electrodes and their high photoelectrocatalytic activity for the degradation of PCP in aqueous solution. Appl. Catal. A Gen. 2006, 301, 284–291. [Google Scholar] [CrossRef]

- Kim, D.H.; Anderson, M.A. Solution factors affecting the photocatalytic and photoelectrocatalytic degradation of formic acid using supported TiO2 thin films. J. Photochem. Photobiol. A 1996, 94, 221–229. [Google Scholar] [CrossRef]

- Liu, X.; Ji, H.; Li, S.; Liu, W. Graphene modified anatase/titanate nanosheets with enhanced photocatalytic activity for efficient degradation of sulfamethazine under simulated solar light. Chemosphere 2019, 233, 198–206. [Google Scholar] [CrossRef] [PubMed]

- Ayala-Durán, S.C.; Hammer, P.; Pupo Nogueira, R.F. Surface composition and catalytic activity of an iron mining residue for simultaneous degradation of sulfonamide antibiotics. Environ. Sci. Pollut. Res. 2020, 27, 1710–1720. [Google Scholar] [CrossRef]

- Kraeutler, B.; Bard, A.J. Heterogeneous photocatalytic preparation of supported catalysts—Photodeposition of platinum on TiO2 powder and other substrates. J. Am. Chem. Soc. 1978, 100, 4317–4318. [Google Scholar] [CrossRef]

- Zhao, W.; Duan, J.; Ji, B.; Ma, L.; Yang, Z. Novel formation of large area N-TiO2/graphene layered materials and enhanced photocatalytic degradation of antibiotics. J. Environ. Chem. Eng. 2020, 8, 102206. [Google Scholar] [CrossRef]

- Philippidis, N.; Nikolakaki, E.; Sotiropoulos, S.; Poulios, I. Photoelectrocatalytic inactivation of E. coli XL-1 blue colonies in water. J. Chem. Technol. Biotechnol. 2010, 85, 1054–1060. [Google Scholar] [CrossRef]

- Philippidis, N.; Sotiropoulos, S.; Efstathiou, A.; Poulios, I. Photoelectrocatalytic degradation of the insecticide imidacloprid using TiO2/Ti electrodes. J. Photochem. Photobiol. 2009, 204, 129–136. [Google Scholar] [CrossRef]

| Experimental Conditions | Apparent Rate Constant of Degradation k × 103 (min−1) | Apparent Rate Constant of Mineralization kDOC × 103 (min−1) |

|---|---|---|

| Photoelectrocatalytic, pH = 5.6, +1.5 V vs. Ag/AgCl | 15.65 ± 0.28 | 4.63 ± 0.06 |

| Photoelectrocatalytic, pH = 3, +1.5 V vs. Ag/AgCl | 20.84 ± 0.30 | 5.78 ± 0.09 |

| Photoelectrocatalytic, pH = 9, +1.5 V vs. Ag/AgCl | 11.7 ± 0.34 | 2.97 ± 0.31 |

| Electrochemical, +1.5 V vs. Ag/AgCl | 2.65 ± 0.34 | - |

| Photocatalytic, pH = 5.6 | 10.2 ± 0.42 | 1.55 ± 0.22 |

| TiO2/Pt, Photoelectrocatalytic, pH = 5.6, +1.5 V vs. Ag/AgCl | 28.32 ± 1.16 | 8.51 ± 0.74 |

| Thermal-TiO2/Ti, Photoelectrocatalytic, pH = 5.6, +1.5 V vs. Ag/AgCl | 16.62 ± 1.83 | 0.95 ± 0.06 |

| Photoelectrocatalytic, pH = 5.6, +0 V vs. Ag/AgCl | 12.74 ± 1.36 | 1.85 ± 0.12 |

| Photoelectrocatalytic, pH = 5.6, +1.0 V vs. Ag/AgCl | 13.49 ± 1.6 | 2.32 ± 0.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Philippidis, N.; Pavlidou, E.; Sotiropoulos, S.; Kokkinos, P.; Mantzavinos, D.; Poulios, I. Photoelectrocatalytic Oxidation of Sulfamethazine on TiO2 Electrodes. Catalysts 2023, 13, 1189. https://0-doi-org.brum.beds.ac.uk/10.3390/catal13081189

Philippidis N, Pavlidou E, Sotiropoulos S, Kokkinos P, Mantzavinos D, Poulios I. Photoelectrocatalytic Oxidation of Sulfamethazine on TiO2 Electrodes. Catalysts. 2023; 13(8):1189. https://0-doi-org.brum.beds.ac.uk/10.3390/catal13081189

Chicago/Turabian StylePhilippidis, Nikolaos, Eleni Pavlidou, Sotiris Sotiropoulos, Petros Kokkinos, Dionissios Mantzavinos, and Ioannis Poulios. 2023. "Photoelectrocatalytic Oxidation of Sulfamethazine on TiO2 Electrodes" Catalysts 13, no. 8: 1189. https://0-doi-org.brum.beds.ac.uk/10.3390/catal13081189