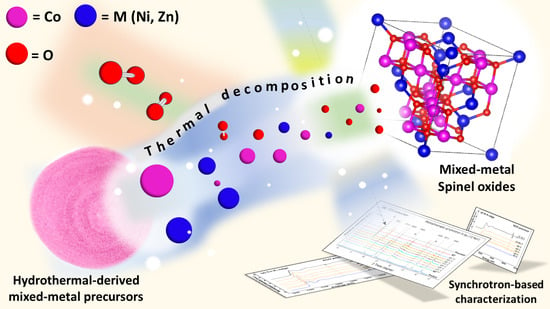

Oxidative Thermal Conversion of Hydrothermal Derived Precursors toward the Mixed-Metal Cobaltite Spinel Oxides (ZnCo2O4 and NiCo2O4): In-Situ Investigation by Synchrotron-Radiation XRD and XAS Techniques

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Synthesis

2.2. Phase Transformation Study

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dubal, D.; Gomez-Romero, P.; Sankapal, B.R.; Holze, R. Nickel cobaltite as an emerging material for supercapacitors: An overview. Nano Energy 2015, 11, 377–399. [Google Scholar] [CrossRef]

- Wang, R.; Wu, J. 5—Structure and Basic Properties of Ternary Metal Oxides and Their Prospects for Application in Supercapacitors. In Metal Oxides in Supercapacitors; Dubal, D.P., Gomez-Romero, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 99–132. [Google Scholar]

- Ru, Q.; Zhao, D.; Guo, L.; Hu, S.; Hou, X. Three-dimensional rose-like ZnCo2O4 as a binder-free anode for sodium ion batteries. J. Mater. Sci. Mater. Electron. 2017, 28, 15451–15456. [Google Scholar] [CrossRef]

- Loche, D.; Marras, C.; Carta, D.; Casula, M.F.; Mountjoy, G.; Corrias, A. Cation distribution and vacancies in nickel cobaltite. Phys. Chem. Chem. Phys. 2017, 19, 16775–16784. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marco, J.; Gancedo, J.; Gracia, M.; Gautier, J.; Ríos, E.; Berry, F. Characterization of the Nickel Cobaltite, NiCo2O4, Prepared by Several Methods: An XRD, XANES, EXAFS, and XPS Study. J. Solid State Chem. 2000, 153, 74–81. [Google Scholar] [CrossRef]

- Wu, Z.; Zhu, Y.; Ji, X. NiCo2O4-based materials for electrochemical supercapacitors. J. Mater. Chem. A 2014, 2, 14759–14772. [Google Scholar] [CrossRef]

- Smart, E.L.; Moore, E.A. Solid State Chemistry: An Introduction; Chapman & Hall: London, UK, 1995. [Google Scholar]

- Zhu, J.; Gao, Q. Mesoporous MCo2O4 (M = Cu, Mn and Ni) spinels: Structural replication, characterization and catalytic application in CO oxidation. Microporous Mesoporous Mater. 2009, 124, 144–152. [Google Scholar] [CrossRef]

- Naveen, A.N.; Selladurai, S. Tailoring structural, optical and magnetic properties of spinel type cobalt oxide (Co3O4) by manganese doping. Phys. B Condens. Matter 2015, 457, 251–262. [Google Scholar] [CrossRef]

- Lakehal, A.; Benrabah, B.; Bouaza, A.; Dalache, C.; Hadj, B. Tuning of the physical properties by various transition metal doping in Co3O4: TM (TM = Ni, Mn, Cu) thin films: A comparative study. Chin. J. Phys. 2018, 56, 1845–1852. [Google Scholar] [CrossRef]

- Lakehal, A.; Bedhiaf, B.; Bouaza, A.; Hadj, B.; Ammari, A.; Dalache, C. Structural, optical and electrical properties of Ni-doped Co3O4 prepared via Sol-Gel technique. Mater. Res. 2018, 21. [Google Scholar] [CrossRef]

- Paudel, T.R.; Zakutayev, A.; Lany, S.; D’Avezac, M.; Zunger, A. Doping Rules and Doping Prototypes in A2BO4 Spinel Oxides. Adv. Funct. Mater. 2011, 21, 4493–4501. [Google Scholar] [CrossRef]

- Li, Y.; Dai, H. Recent advances in zinc–air batteries. Chem. Soc. Rev. 2014, 43, 5257–5275. [Google Scholar] [CrossRef] [Green Version]

- Hong, W.T.; Risch, M.; Stoerzinger, K.A.; Grimaud, A.; Suntivichb, J.; Shao-Horn, Y. Toward the rational design of non-precious transition metal oxides for oxygen electrocatalysis. Energy Environ. Sci. 2015, 8, 1404–1427. [Google Scholar] [CrossRef] [Green Version]

- Osgood, H.; Devaguptapu, S.V.; Xu, H.; Cho, J.; Wu, G. Transition metal (Fe, Co, Ni, and Mn) oxides for oxygen reduction and evolution bifunctional catalysts in alkaline media. Nano Today 2016, 11, 601–625. [Google Scholar] [CrossRef]

- Vij, V.; Sultan, S.; Harzandi, A.M.; Meena, A.; Tiwari, J.N.; Lee, W.-G.; Yoon, T.; Kim, K.S. Nickel-Based Electrocatalysts for Energy-Related Applications: Oxygen Reduction, Oxygen Evolution, and Hydrogen Evolution Reactions. ACS Catal. 2017, 7, 7196–7225. [Google Scholar] [CrossRef]

- Al Zoubi, W.; Yoon, D.K.; Kim, Y.G.; Ko, Y.G. Fabrication of organic-inorganic hybrid materials on metal surface for optimizing electrochemical performance. J. Colloid Interface Sci. 2020, 573, 31–44. [Google Scholar] [CrossRef] [PubMed]

- Al Zoubi, W.; Kamil, M.P.; Fatimah, S.; Nashrah, N.; Ko, Y.G. Recent advances in hybrid organic-inorganic materials with spatial architecture for state-of-the-art applications. Prog. Mater. Sci. 2020, 112, 100663. [Google Scholar] [CrossRef]

- Cabo, M.; Pellicer, E.; Rossinyol, E.; Castell, O.; Surinñach, S.; Baroó, M.D. Mesoporous NiCo2O4 Spinel: Influence of Calcination Temperature over Phase Purity and Thermal Stability. Cryst. Growth Des. 2009, 9, 4814–4821. [Google Scholar] [CrossRef]

- Ding, R.; Qi, L.; Jia, M.; Wang, H. Simple hydrothermal synthesis of mesoporous spinel NiCo2O4 nanoparticles and their catalytic behavior in CH3OH electro-oxidation and H2O2 electro-reduction. Catal. Sci. Technol. 2013, 3, 3207–3215. [Google Scholar] [CrossRef]

- Che, H.; Liu, A.; Zhang, X.; Mu, J.; Bai, Y.; Hou, J. Three-dimensional hierarchical ZnCo2O4 flower-like microspheres assembled from porous nanosheets: Hydrothermal synthesis and electrochemical properties. Ceram. Int. 2015, 41, 7556–7564. [Google Scholar] [CrossRef]

- Hu, X.; Huang, H.; Zhang, J.; Shi, J.; Zhu, S.; Su, N. Controllable hydrothermal-assisted synthesis of mesoporous Co3O4 nanosheets. RSC Adv. 2015, 5, 99899–99906. [Google Scholar] [CrossRef]

- Deeloed, W.; Wattanathana, W.; Jantaratana, P.; Prompinit, P.; Wannapaiboon, S.; Singkammo, S.; Sattayaporn, S.; Laobuthee, A.; Suramitr, S.; Hanlumyuang, Y. A systematic variation in cationic distribution and its influence on the magnetization of mixed-metal (nickel and zinc) cobaltite spinels. Mater. Res. Express 2020, 7, 096104. [Google Scholar] [CrossRef]

- Cao, X.; Yang, Y.; Li, A. Facile Synthesis of Porous ZnCo2O4 Nanosheets and the Superior Electrochemical Properties for Sodium Ion Batteries. Nanomaterials 2018, 8, 377. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Li, J.; Chen, S.; Li, B.; Zhu, G.; Wang, F.; Zhang, Y. Facile preparation of monodisperse NiCo2O4 porous microcubes as a high capacity anode material for lithium ion batteries. Inorg. Chem. Front. 2017, 5, 559–567. [Google Scholar] [CrossRef]

- Cook, D.S.; Wu, Y.; Lienau, K.; Moré, R.; Kashtiban, R.J.; Magdysyuk, O.V.; Patzke, G.R.; Walton, R.I. Time-Resolved Powder X-ray Diffraction of the Solvothermal Crystallization of Cobalt Gallate Spinel Photocatalyst Reveals Transient Layered Double Hydroxides. Chem. Mater. 2017, 29, 5053–5057. [Google Scholar] [CrossRef] [Green Version]

- Moorhouse, S.J.; Wu, Y.; Buckley, H.C.; O’Hare, D. Time-resolved in situ powder X-ray diffraction reveals the mechanisms of molten salt synthesis. Chem. Commun. 2016, 52, 13865–13868. [Google Scholar] [CrossRef]

- Philippot, G.; Boejesen, E.D.; Elissalde, C.; Maglione, M.; Aymonier, C.; Iversen, B.B. Insights into BaTi1−yZryO3 (0 ≤ y ≤ 1) Synthesis under Supercritical Fluid Conditions. Chem. Mater. 2016, 28, 3391–3400. [Google Scholar] [CrossRef]

- Chen, J.; Weidner, D.J.; Parise, J.B.; Vaughan, M.T.; Raterron, P. Observation of Cation Reordering during the Olivine-Spinel Transition in Fayalite by In Situ Synchrotron X-ray Diffraction at High Pressure and Temperature. Phys. Rev. Lett. 2001, 86, 4072–4075. [Google Scholar] [CrossRef]

- Mittal, J. Recent progress in the synthesis of Layered Double Hydroxides and their application for the adsorptive removal of dyes: A review. J. Environ. Manag. 2021, 295, 113017. [Google Scholar] [CrossRef]

- Karmakar, A.; Karthick, K.; Sankar, S.S.; Kumaravel, S.; Madhu, R.; Kundu, S. A vast exploration of improvising synthetic strategies for enhancing the OER kinetics of LDH structures: A review. J. Mater. Chem. A 2020, 9, 1314–1352. [Google Scholar] [CrossRef]

- Chaillot, D.; Bennici, S.; Brendlé, J. Layered double hydroxides and LDH-derived materials in chosen environmental applications: A review. Environ. Sci. Pollut. Res. 2020, 28, 24375–24405. [Google Scholar] [CrossRef]

- Kim, N.-I.; Sa, Y.J.; Yoo, T.S.; Choi, S.R.; Afzal, R.A.; Choi, T.; Seo, Y.-S.; Lee, K.-S.; Hwang, J.Y.; Choi, W.S.; et al. Oxygen-deficient triple perovskites as highly active and durable bifunctional electrocatalysts for oxygen electrode reactions. Sci. Adv. 2018, 4, eaap9360. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, H.J.; Yoon, H.; Ju, B.; Kim, D. Highly Efficient Perovskite-Based Electrocatalysts for Water Oxidation in Acidic Environments: A Mini Review. Adv. Energy Mater. 2021, 11, 2002428. [Google Scholar] [CrossRef]

- Xue, Y.; Sun, S.; Wang, Q.; Dong, Z.; Liu, Z. Transition metal oxide-based oxygen reduction reaction electrocatalysts for energy conversion systems with aqueous electrolytes. J. Mater. Chem. A 2018, 6, 10595–10626. [Google Scholar] [CrossRef]

- Dai, Y.; Yu, J.; Ni, M.; Shao, Z. Rational design of spinel oxides as bifunctional oxygen electrocatalysts for rechargeable Zn-air batteries. Chem. Phys. Rev. 2020, 1, 011303. [Google Scholar] [CrossRef]

- Priamushko, T.; Guillet-Nicolas, R.; Yu, M.; Doyle, M.; Weidenthaler, C.; Tüysüz, H.; Kleitz, F. Nanocast Mixed Ni–Co–Mn Oxides with Controlled Surface and Pore Structure for Electrochemical Oxygen Evolution Reaction. ACS Appl. Energy Mater. 2020, 3, 5597–5609. [Google Scholar] [CrossRef]

- Veerabhadrappa, M.G.; Maroto-Valer, M.M.; Chen, Y.; Garcia, S. Layered Double Hydroxides-Based Mixed Metal Oxides: Development of Novel Structured Sorbents for CO2 Capture Applications. ACS Appl. Mater. Interfaces 2021, 13, 11805–11813. [Google Scholar] [CrossRef]

- Manohara, G.V.; Norris, D.; Maroto-Valer, M.M.; Garcia, S. Acetate intercalated Mg–Al layered double hydroxides (LDHs) through modified amide hydrolysis: A new route to synthesize novel mixed metal oxides (MMOs) for CO2 capture. Dalton Trans. 2021, 50, 7474–7483. [Google Scholar] [CrossRef]

- Maksoud, M.I.A.A.; Fahim, R.A.; Shalan, A.E.; Elkodous, M.A.; Olojede, S.O.; Osman, A.I.; Farrell, C.; Al-Muhtaseb, A.H.; Awed, A.S.; Ashour, A.H.; et al. Advanced materials and technologies for supercapacitors used in energy conversion and storage: A review. Environ. Chem. Lett. 2020, 19, 375–439. [Google Scholar] [CrossRef]

- Chen, D.; Chen, C.; Baiyee, Z.M.; Shao, Z.; Ciucci, F. Nonstoichiometric Oxides as Low-Cost and Highly-Efficient Oxygen Reduction/Evolution Catalysts for Low-Temperature Electrochemical Devices. Chem. Rev. 2015, 115, 9869–9921. [Google Scholar] [CrossRef]

- Kangvansura, P.; Schulz, H.; Suramitr, A.; Poo-Arporn, Y.; Viravathana, P.; Worayingyong, A. Reduced cobalt phases of ZrO2 and Ru/ZrO2 promoted cobalt catalysts and product distributions from Fischer–Tropsch synthesis. Mater. Sci. Eng. B 2014, 190, 82–89. [Google Scholar] [CrossRef]

- Wannapaiboon, S.; Schneemann, A.; Hante, I.; Tu, M.; Epp, K.; Semrau, A.L.; Sternemann, C.; Paulus, M.; Baxter, S.; Kieslich, G.; et al. Control of structural flexibility of layered-pillared metal-organic frameworks anchored at surfaces. Nat. Commun. 2019, 10, 346. [Google Scholar] [CrossRef] [PubMed]

- Poo-Arporn, Y.; Palangsuntikul, R. In Situ X-ray Absorption Near Edge Structure Study of Amorphous-TiO2 Phase Transformation. J. Nanosci. Nanotechnol. 2016, 16, 6551–6554. [Google Scholar] [CrossRef] [PubMed]

- Poo-Arporn, Y.; Chirawatkul, P.; Saengsui, W.; Chotiwan, S.; Kityakarn, S.; Klinkhieo, S.; Hormes, J.; Songsiriritthigul, P. Time-resolved XAS (Bonn-SUT-SLRI) beamline at SLRI. J. Synchrotron Radiat. 2012, 19, 937–943. [Google Scholar] [CrossRef] [PubMed]

- Wei, T.-Y.; Chen, C.-H.; Chien, H.-C.; Lu, S.-Y.; Hu, C.-C. A Cost-Effective Supercapacitor Material of Ultrahigh Specific Capacitances: Spinel Nickel Cobaltite Aerogels from an Epoxide-Driven Sol-Gel Process. Adv. Mater. 2010, 22, 347–351. [Google Scholar] [CrossRef]

- Castorina, E.; Ingall, E.D.; Morton, P.L.; Tavakoli, D.A.; Lai, B. Zinc K-edge XANES spectroscopy of mineral and organic standards. J. Synchrotron Radiat. 2019, 26, 1302–1309. [Google Scholar] [CrossRef] [Green Version]

- Ha, D.-H.; Moreau, L.M.; Honrao, S.; Hennig, R.G.; Robinson, R.D. The Oxidation of Cobalt Nanoparticles into Kirkendall-Hollowed CoO and Co3O4: The Diffusion Mechanisms and Atomic Structural Transformations. J. Phys. Chem. C 2013, 117, 14303–14312. [Google Scholar] [CrossRef]

- Smart, E.L.; Moore, E.A. Solid State Chemistry: An Introduction, 4th ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- West, A.R. Solid State Chemistry and Its Applications, 2nd ed.; John Wiley & Sons: Chichester, UK, 2014. [Google Scholar]

- Johnsen, R.E.; Norby, P. A comparativein situ Rietveld refinement study: Thermal decomposition and transformation of CoAl and CoZnAl layered double hydroxides. J. Appl. Crystallogr. 2008, 41, 991–1002. [Google Scholar] [CrossRef]

- Furnish, M.D.; Bassett, W.A. Investigation of the mechanism of the olivine-spinel transition in fayalite by synchrotron radiation. J. Geophys. Res. Space Phys. 1983, 88, 10333–10341. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deeloed, W.; Hanlumyuang, Y.; Limphirat, W.; Suramitr, S.; Chansaenpak, K.; Kanjanaboos, P.; Wannapaiboon, S.; Wattanathana, W. Oxidative Thermal Conversion of Hydrothermal Derived Precursors toward the Mixed-Metal Cobaltite Spinel Oxides (ZnCo2O4 and NiCo2O4): In-Situ Investigation by Synchrotron-Radiation XRD and XAS Techniques. Crystals 2021, 11, 1256. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11101256

Deeloed W, Hanlumyuang Y, Limphirat W, Suramitr S, Chansaenpak K, Kanjanaboos P, Wannapaiboon S, Wattanathana W. Oxidative Thermal Conversion of Hydrothermal Derived Precursors toward the Mixed-Metal Cobaltite Spinel Oxides (ZnCo2O4 and NiCo2O4): In-Situ Investigation by Synchrotron-Radiation XRD and XAS Techniques. Crystals. 2021; 11(10):1256. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11101256

Chicago/Turabian StyleDeeloed, Wanchai, Yuranan Hanlumyuang, Wanwisa Limphirat, Songwut Suramitr, Kantapat Chansaenpak, Pongsakorn Kanjanaboos, Suttipong Wannapaiboon, and Worawat Wattanathana. 2021. "Oxidative Thermal Conversion of Hydrothermal Derived Precursors toward the Mixed-Metal Cobaltite Spinel Oxides (ZnCo2O4 and NiCo2O4): In-Situ Investigation by Synchrotron-Radiation XRD and XAS Techniques" Crystals 11, no. 10: 1256. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11101256