Fabrication of Sub-Micron Polymer Waveguides through Two-Photon Polymerization in Polydimethylsiloxane

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemical Scheme

2.2. Materials

2.3. Sample Preparation

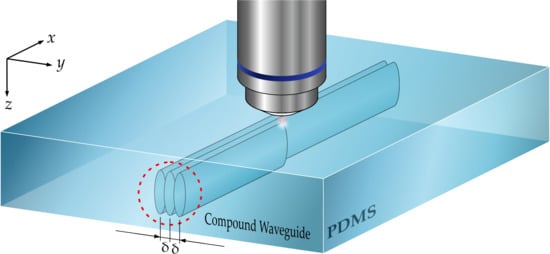

2.4. Waveguide Fabrication

2.5. Waveguide Characterization

3. Results

3.1. Simple Waveguides

3.2. Compound Waveguides

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Amiri, I.S.; Azzuhri, S.R.B.; Jalil, M.A.; Hairi, H.M.; Ali, J.; Bunruangses, M.; Yupapin, P. Introduction to Photonics: Principles and the Most Recent Applications of Microstructures. Micromachines 2018, 9, 452. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Selvaraja, S.K.; Sethi, P. Review on Optical Waveguides. In Emerging Waveguide Technology; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Jen, A.K.-Y.; Dalton, L.R. Polymer-Based Optical Waveguides: Materials, Processing, and Devices. Adv. Mater. 2002, 14, 1339–1365. [Google Scholar] [CrossRef]

- Tong, X.C. Polymer-Based Optical Waveguides. In Advanced Materials for Integrated Optical Waveguides; Springer International Publishing: Cham, Switzerland, 2014; pp. 377–418. [Google Scholar] [CrossRef]

- Han, X.-Y.; Wu, Z.-L.; Yang, S.-C.; Shen, F.-F.; Liang, Y.-X.; Wang, L.-H.; Wang, J.-Y.; Ren, J.; Jia, L.-Y.; Zhang, H.; et al. Recent Progress of Imprinted Polymer Photonic Waveguide Devices and Applications. Polymers 2018, 10, 603. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nieweglowski, K.; Lorenz, L.; Lüngen, S.; Tiedje, T.; Wolter, K.-J.; Bock, K. Optical coupling with flexible polymer waveguides for chip-to-chip interconnects in electronic systems. Microelectron. Reliab. 2018, 84, 121–126. [Google Scholar] [CrossRef]

- Dangel, R.; Hofrichter, J.; Horst, F.; Jubin, D.; La Porta, A.; Meier, N.; Soganci, I.M.; Weiss, J.; Offrein, B.J. Polymer waveguides for electro-optical integration in data centers and high-performance computers. Opt. Express 2015, 23, 4736–4750. [Google Scholar] [CrossRef]

- Sima, F.; Sugioka, K.; Vázquez Rebeca, M.; Osellame, R.; Kelemen, L.; Ormos, P. Three-dimensional femtosecond laser processing for lab-on-a-chip applications. Nanophotonics 2018, 7, 613. [Google Scholar] [CrossRef]

- Parks, J.W.; Schmidt, H. Flexible optofluidic waveguide platform with multi-dimensional reconfigurability. Sci. Rep. 2016, 6, 33008. [Google Scholar] [CrossRef] [PubMed]

- Choi, M.; Humar, M.; Kim, S.; Yun, S.-H. Step-Index Optical Fiber Made of Biocompatible Hydrogels. Adv. Mater. 2015, 27, 4081–4086. [Google Scholar] [CrossRef] [PubMed]

- Yetisen, A.K.; Jiang, N.; Fallahi, A.; Montelongo, Y.; Ruiz-Esparza, G.U.; Tamayol, A.; Zhang, Y.S.; Mahmood, I.; Yang, S.A.; Kim, K.S.; et al. Glucose-Sensitive Hydrogel Optical Fibers Functionalized with Phenylboronic Acid. Adv. Mater. 2017, 29, 1606380. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, B.; Yang, C.; Dai, Q.; Kong, L. Stretchable and Temperature-Sensitive Polymer Optical Fibers for Wearable Health Monitoring. Adv. Funct. Mater. 2019, 29, 1902898. [Google Scholar] [CrossRef]

- Jorfi, M.; Voirin, G.; Foster, E.J.; Weder, C. Physiologically responsive, mechanically adaptive polymer optical fibers for optogenetics. Opt. Lett. 2014, 39, 2872–2875. [Google Scholar] [CrossRef]

- Park, S.; Guo, Y.; Jia, X.; Choe, H.K.; Grena, B.; Kang, J.; Park, J.; Lu, C.; Canales, A.; Chen, R.; et al. One-step optogenetics with multifunctional flexible polymer fibers. Nat. Neurosci. 2017, 20, 612–619. [Google Scholar] [CrossRef]

- Rubehn, B.; Wolff, S.B.E.; Tovote, P.; Schuettler, M.; Lüthi, A.; Stieglitz, T. Polymer-based shaft microelectrodes with optical and fluidic capabilities as a tool for optogenetics. In Proceedings of the 2011 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Boston, MA, USA, 30 August–3 September 2011; pp. 2969–2972. [Google Scholar]

- Zgraggen, E.; Soganci, I.M.; Horst, F.; Porta, A.L.; Dangel, R.; Offrein, B.J.; Snow, S.A.; Young, J.K.; Swatowski, B.W.; Amb, C.M.; et al. Laser Direct Writing of Single-Mode Polysiloxane Optical Waveguides and Devices. J. Lightwave Technol. 2014, 32, 3036–3042. [Google Scholar] [CrossRef]

- Wang, S.; Vaidyanathan, V.; Borden, B. Polymer optical channel waveguide components fabricated by using a laser direct writing system. J. Appl. Sci. Eng. Technol. 2009, 3, 47–52. [Google Scholar]

- Elmogi, A.; Bosman, E.; Missinne, J.; Van Steenberge, G. Comparison of epoxy-and siloxane-based single-mode optical waveguides defined by direct-write lithography. Opt. Mater. 2016, 52, 26–31. [Google Scholar] [CrossRef]

- Prajzler, V.; Nekvindova, P.; Hyps, P.; Lyutakov, O.; Jeřabek, V.z. Flexible polymer planar optical waveguides. Radioengineering 2014, 23, 776–782. [Google Scholar]

- Chang-Yen, D.A.; Eich, R.K.; Gale, B.K. A monolithic PDMS waveguide system fabricated using soft-lithography techniques. J. Lightwave Technol. 2005, 23, 2088–2093. [Google Scholar] [CrossRef] [Green Version]

- Cai, Z.; Qiu, W.; Shao, G.; Wang, W. A new fabrication method for all-PDMS waveguides. Sens. Actuators A Phys. 2013, 204, 44–47. [Google Scholar] [CrossRef]

- Kee, J.; Poenar, D.; Neuzil, P.; Yobas, L. Design and fabrication of Poly(dimethylsiloxane) single-mode rib waveguide. Opt. Express 2009, 17, 11739–11746. [Google Scholar] [CrossRef] [PubMed]

- Malinauskas, M.; Farsari, M.; Piskarskas, A.; Juodkazis, S. Ultrafast laser nanostructuring of photopolymers: A decade of advances. Phys. Rep. 2013, 533, 1–31. [Google Scholar] [CrossRef]

- Panusa, G.; Pu, Y.; Wang, J.; Moser, C.; Psaltis, D. Photoinitiator-free multi-photon fabrication of compact optical waveguides in polydimethylsiloxane. Opt. Mater. Express 2019, 9, 128–138. [Google Scholar] [CrossRef]

- Kewitsch, A.S.; Yariv, A. Self-focusing and self-trapping of optical beams upon photopolymerization. Opt. Lett. 1996, 21, 24–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cumpston, B.H.; Ananthavel, S.P.; Barlow, S.; Dyer, D.L.; Ehrlich, J.E.; Erskine, L.L.; Heikal, A.A.; Kuebler, S.M.; Lee, I.Y.S.; McCord-Maughon, D.; et al. Two-photon polymerization initiators for three-dimensional optical data storage and microfabrication. Nature 1999, 398, 51–54. [Google Scholar] [CrossRef]

- Schafer, K.J.; Hales, J.M.; Balu, M.; Belfield, K.D.; Van Stryland, E.W.; Hagan, D.J. Two-photon absorption cross-sections of common photoinitiators. J. Photochem. Photobiol. A Chem. 2004, 162, 497–502. [Google Scholar] [CrossRef]

- Li, Z.; Pucher, N.; Cicha, K.; Torgersen, J.; Ligon, S.C.; Ajami, A.; Husinsky, W.; Rosspeintner, A.; Vauthey, E.; Naumov, S.; et al. A Straightforward Synthesis and Structure–Activity Relationship of Highly Efficient Initiators for Two-Photon Polymerization. Macromolecules 2013, 46, 352–361. [Google Scholar] [CrossRef]

- Stankova, N.E.; Atanasov, P.A.; Nikov, R.G.; Nikov, R.G.; Nedyalkov, N.N.; Stoyanchov, T.R.; Fukata, N.; Kolev, K.N.; Valova, E.I.; Georgieva, J.S.; et al. Optical properties of polydimethylsiloxane (PDMS) during nanosecond laser processing. Appl. Surf. Sci. 2016, 374, 96–103. [Google Scholar] [CrossRef]

- Odian, G.G. Principles of Polymerization; Wiley-Interscience: Hoboken, NJ, USA, 2004. [Google Scholar]

- Barr, S.; Hill, E.; Bayat, A. Patterning of novel breast implant surfaces by enhancing silicone biocompatibility, using biomimetic topographies. Eplasty 2010, 10, e31. [Google Scholar]

- Jiang, L.J.; Zhou, Y.S.; Xiong, W.; Gao, Y.; Huang, X.; Jiang, L.; Baldacchini, T.; Silvain, J.F.; Lu, Y.F. Two-photon polymerization: Investigation of chemical and mechanical properties of resins using Raman microspectroscopy. Opt. Lett. 2014, 39, 3034–3037. [Google Scholar] [CrossRef] [Green Version]

- Antikainen, A.; Essiambre, R.-J.; Agrawal, G.P. Determination of modes of elliptical waveguides with ellipse transformation perturbation theory. Optica 2017, 4, 1510–1513. [Google Scholar] [CrossRef]

- Feng, T.; Sahoo, P.K.; Arteaga-Sierra, F.R.; Dorrer, C.; Qiao, J. Pulse-propagation modeling and experiment for femtosecond-laser writing of waveguide in Nd: YAG. Crystals 2019, 9, 434. [Google Scholar] [CrossRef] [Green Version]

- Sumetsky, M. How thin can a microfiber be and still guide light? Opt. Lett. 2006, 31, 870–872. [Google Scholar] [CrossRef]

- Bhanu, V.A.; Kishore, K. Role of oxygen in polymerization reactions. Chem. Rev. 1991, 91, 99–117. [Google Scholar] [CrossRef]

| Transmission Loss (dB/cm) | |||

|---|---|---|---|

| Wavelength Range (nm) | Single-Track | Double-Track | Triple-Track |

| 535/43 | 14.2 ± 2.9 | 6.5 ± 2.0 | 12.4 ± 0.3 |

| 561/14 | 13.5 ± 3.9 | 5.6 ± 1.7 | 10.8 ± 0.9 |

| 592/43 | 13.2 ± 3.4 | 4.5 ± 1.0 | 7.5 ± 0.7 |

| 609/54 | 12.6 ± 3.0 | 4.5 ± 0.9 | 6.6 ± 0.6 |

| 679/41 | 12.6 ± 2.3 | 2.6 ± 0.5 | 2.3 ± 0.4 |

| 710/10 | - | 2.2 ± 1.7 | 0.1 ± 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panusa, G.; Pu, Y.; Wang, J.; Moser, C.; Psaltis, D. Fabrication of Sub-Micron Polymer Waveguides through Two-Photon Polymerization in Polydimethylsiloxane. Polymers 2020, 12, 2485. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12112485

Panusa G, Pu Y, Wang J, Moser C, Psaltis D. Fabrication of Sub-Micron Polymer Waveguides through Two-Photon Polymerization in Polydimethylsiloxane. Polymers. 2020; 12(11):2485. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12112485

Chicago/Turabian StylePanusa, Giulia, Ye Pu, Jieping Wang, Christophe Moser, and Demetri Psaltis. 2020. "Fabrication of Sub-Micron Polymer Waveguides through Two-Photon Polymerization in Polydimethylsiloxane" Polymers 12, no. 11: 2485. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12112485