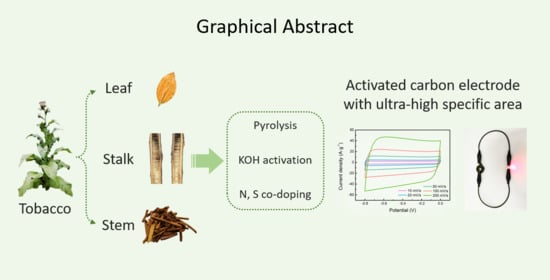

N, S-Codoped Activated Carbon Material with Ultra-High Surface Area for High-Performance Supercapacitors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Activated Tobacco Carbon (ATC)

2.3. Synthesis of N, S-Codoped Activated Carbon (NS-ATC)

2.4. Characterization

3. Results and Discussion

3.1. Morphology and Structure of ATC-X Materials

3.2. Electrochemical Performance of ATC-X Materials

3.3. The Effect of N, S-Codoping

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Baliga, V.; Sharma, R.; Miser, D.; McGrath, T.; Hajaligol, M. Physical characterization of pyrolyzed tobacco and tobacco components. J. Anal. Appl. Pyrolysis 2003, 66, 191–215. [Google Scholar] [CrossRef]

- Salanne, M.; Rotenberg, B.; Naoi, K.; Kaneko, K.; Taberna, P.-L.; Grey, C.P.; Dunn, B.; Simon, P. Efficient storage mechanisms for building better supercapacitors. Nat. Energy 2016, 1, 16070. [Google Scholar] [CrossRef]

- Zhai, Y.; Dou, Y.; Zhao, D.; Fulvio, P.F.; Mayes, R.T.; Dai, S. Carbon Materials for Chemical Capacitive Energy Storage. Adv. Mater. 2011, 23, 4828–4850. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Han, K.; Li, S.; Li, M.; Li, J.; Ren, K. Synthesis of garlic skin-derived 3D hierarchical porous carbon for high-performance supercapacitors. Nanoscale 2018, 10, 2427–2437. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Xiao, W.; Zhou, W.; Chen, S.; Zhang, Y. Hierarchical Porous Carbon Derived from Sichuan Pepper for High-Performance Symmetric Supercapacitor with Decent Rate Capability and Cycling Stability. Nanomaterials 2019, 9, 553. [Google Scholar] [CrossRef] [Green Version]

- Peng, L.; Liang, Y.; Dong, H.; Hu, H.; Zhao, X.; Cai, Y.; Xiao, Y.; Liu, Y.; Zheng, M. Super-hierarchical porous carbons derived from mixed biomass wastes by a stepwise removal strategy for high-performance supercapacitors. J. Power Sources 2018, 377, 151–160. [Google Scholar] [CrossRef]

- Ghosh, S.; Barg, S.; Jeong, S.M.; Ostrikov, K.K. Heteroatom-Doped and Oxygen-Functionalized Nanocarbons for High-Performance Supercapacitors. Adv. Energy Mater. 2020, 10, 2001239. [Google Scholar] [CrossRef]

- China Statistical Yearbook 2019. Available online: http://www.stats.gov.cn/tjsj/ndsj/2019/indexeh.htm (accessed on 6 August 2020).

- Seremeta, D.C.H.; da Silva, C.P.; Zittel, R.; de Campos, S.X. Pb2+ adsorption by a compost obtained from the treatment of tobacco from smuggled cigarettes and industrial sewage sludge. Environ. Sci. Pollut. Res. 2019, 26, 797–805. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, J.; Liu, G.; Yang, H.; Liu, W.; Wang, L.; Kong, C.; Zheng, D.; Yang, J.; Deng, L.; et al. Co-digestion of tobacco waste with different agricultural biomass feedstocks and the inhibition of tobacco viruses by anaerobic digestion. Bioresour. Technol. 2015, 189, 210–216. [Google Scholar] [CrossRef]

- Cong, K.; Han, F.; Zhang, Y.; Li, Q. The investigation of co-combustion characteristics of tobacco stalk and low rank coal using a macro-TGA. Fuel 2019, 237, 126–132. [Google Scholar] [CrossRef]

- Ma, X.; Li, L.; Chen, R.; Wang, C.; Zhou, K.; Li, H. Porous carbon materials based on biomass for acetone adsorption: Effect of surface chemistry and porous structure. Appl. Surf. Sci. 2018, 459, 657–664. [Google Scholar] [CrossRef]

- Yi, M.; Chen, Y. Enhanced phosphate adsorption on Ca-Mg-loaded biochar derived from tobacco stems. Water Sci. Technol. 2018, 78, 2427–2436. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Li, L.; Chen, R.; Wang, C.; Li, H.; Li, H. A MIL-101 Composite Doped with Porous Carbon from Tobacco Stem for Enhanced Acetone Uptake at Normal Temperature. Ind. Eng. Chem. Res. 2018, 57, 6226–6235. [Google Scholar] [CrossRef]

- Kleszyk, P.; Ratajczak, P.; Skowron, P.; Jagiello, J.; Abbas, Q.; Frąckowiak, E.; Béguin, F. Carbons with narrow pore size distribution prepared by simultaneous carbonization and self-activation of tobacco stems and their application to supercapacitors. Carbon 2015, 81, 148–157. [Google Scholar] [CrossRef]

- Zhong, M.; Guan, J.; Sun, J.; Guo, H.; Xiao, Z.; Zhou, N.; Gui, Q.; Gong, D. Carbon nanodot-decorated alveolate N, O, S tridoped hierarchical porous carbon as efficient electrocatalysis of polysulfide conversion for lithium-sulfur batteries. Electrochim. Acta 2019, 299, 600–609. [Google Scholar] [CrossRef]

- Zhao, Y.-Q.; Lu, M.; Tao, P.-Y.; Zhang, Y.-J.; Gong, X.-T.; Yang, Z.; Zhang, G.-Q.; Li, H.-L. Hierarchically porous and heteroatom doped carbon derived from tobacco rods for supercapacitors. J. Power Sources 2016, 307, 391–400. [Google Scholar] [CrossRef]

- Zi, W.; Chen, Y.; Pan, Y.; Zhang, Y.; He, Y.; Wang, Q. Pyrolysis, morphology and microwave absorption properties of tobacco stem materials. Sci. Total Environ. 2019, 683, 341–350. [Google Scholar] [CrossRef]

- Yi, H.; Deng, H.; Yang, L.; Tang, X.L.; Yu, Q.; Ye, Z. Preparation of Activated Carbons from Tobacco Stems by Potassium Hydroxide Activation and Phosphine Adsorption. Sep. Sci. Technol. 2013, 48, 813–819. [Google Scholar] [CrossRef]

- Wang, J.; Kaskel, S. KOH activation of carbon-based materials for energy storage. J. Mater. Chem. 2012, 22, 23710. [Google Scholar] [CrossRef]

- Chen, H.; Xiong, Y.; Yu, T.; Zhu, P.; Yan, X.; Wang, Z.; Guan, S. Boron and nitrogen co-doped porous carbon with a high concentration of boron and its superior capacitive behavior. Carbon 2017, 113, 266–273. [Google Scholar] [CrossRef]

- Yu, Q.; Zhao, H.; Zhao, H.; Sun, S.; Ji, X.; Li, M.; Wang, Y. Preparation of tobacco-stem activated carbon from using response surface methodology and its application for water vapor adsorption in solar drying system. Sol. Energy 2019, 177, 324–336. [Google Scholar] [CrossRef]

- Ding, M.; Wei, B.; Zhang, Z.; She, S.; Huang, L.; Ge, S.; Sheng, L. Effect of potassium organic and inorganic salts on thermal decomposition of reconstituted tobacco sheet. J. Anal. Calorim. 2017, 129, 975–984. [Google Scholar] [CrossRef]

- Baek, J.; Shin, H.-S.; Chung, D.C.; Kim, B.-J. Studies on the correlation between nanostructure and pore development of polymeric precursor-based activated hard carbons: II. Transmission electron microscopy and Raman spectroscopy studies. J. Ind. Eng. Chem. 2017, 54, 324–331. [Google Scholar] [CrossRef]

- Zheng, S.; Zheng, L.; Zhu, Z.; Chen, J.; Kang, J.; Huang, Z.; Yang, D. MoS2 Nanosheet Arrays Rooted on Hollow rGO Spheres as Bifunctional Hydrogen Evolution Catalyst and Supercapacitor Electrode. Nano-Micro Lett. 2018, 10, 62. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chmiola, J.; Yushin, G.; Dash, R.; Gogotsi, Y. Effect of pore size and surface area of carbide derived carbons on specific capacitance. J. Power Sources 2006, 158, 765–772. [Google Scholar] [CrossRef]

- Liu, Y.; Xiao, Z.; Liu, Y.; Fan, L.Z. Biowaste-derived 3D honeycomb-like porous carbon with binary-heteroatom doping for high-performance flexible solid-state supercapacitors. J. Mater. Chem. A 2017, 6, 160–166. [Google Scholar] [CrossRef]

- Huang, Y.; Peng, L.; Liu, Y.; Zhao, G.; Chen, J.Y.; Yu, G. Biobased Nano Porous Active Carbon Fibers for High-Performance Supercapacitors. ACS Appl. Mater. Interfaces 2016, 8, 15205–15215. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Han, J.; Ding, B.; Nie, P.; Pan, J.; Dou, H.; Li, H.; Zhang, X. Biomass-derived porous carbon materials with sulfur and nitrogen dual-doping for energy storage. Green Chem. 2015, 17, 1668–1674. [Google Scholar] [CrossRef]

- Zheng, L.; Xia, K.; Han, B.; Zhou, C.; Gao, Q.; Wang, H.; Pu, S.; Wu, J. N/P Codoped Porous Carbon-Coated Graphene Nanohybrid as a High-Performance Electrode for Supercapacitors. ACS Appl. Nano Mater. 2018, 1, 6742–6751. [Google Scholar] [CrossRef]

- Wu, F.; Gao, J.; Zhai, X.; Xie, M.; Sun, Y.; Kang, H.; Tian, Q.; Qiu, H. Hierarchical porous carbon microrods derived from albizia flowers for high performance supercapacitors. Carbon 2019. [Google Scholar] [CrossRef]

- Qian, W.; Sun, F.; Xu, Y.; Qiu, L.; Liu, C.; Wang, S.; Yan, F. Human hair-derived carbon flakes for electrochemical supercapacitors. Energy Environ. Sci. 2014, 7, 379–386. [Google Scholar] [CrossRef]

- Xia, X.; Liu, H.; Shi, L.; He, Y. Tobacco Stem-Based Activated Carbons for High Performance Supercapacitors. J. Mater. Eng Perform. 2012, 21, 1956–1961. [Google Scholar] [CrossRef]

- Chen, R.; Li, L.; Liu, Z.; Lu, M.; Wang, C.; Li, H.; Ma, W.; Wang, S. Preparation and characterization of activated carbons from tobacco stem by chemical activation. J. Air Waste Manag. Assoc. 2017, 67, 713–724. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Si, W.; Zhou, J.; Zhang, S.; Li, S.; Xing, W.; Zhuo, S. Tunable N-doped or dual N, S-doped activated hydrothermal carbons derived from human hair and glucose for supercapacitor applications. Electrochim. Acta 2013, 107, 397–405. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Q.; Chen, C.-M.; Zhang, B.; Reiche, S.; Wang, A.; Zhang, T.; Schlögl, R.; Sheng Su, D. Aromatic sulfide, sulfoxide, and sulfone mediated mesoporous carbon monolith for use in supercapacitor. Nano Energy 2012, 1, 624–630. [Google Scholar] [CrossRef]

- El-Sawy, A.M.; Mosa, I.M.; Su, D.; Guild, C.J.; Khalid, S.; Joesten, R.; Rusling, J.F.; Suib, S.L. Controlling the Active Sites of Sulfur-Doped Carbon Nanotube–Graphene Nanolobes for Highly Efficient Oxygen Evolution and Reduction Catalysis. Adv. Energy Mater. 2016, 6, 1501966. [Google Scholar] [CrossRef]

- Wang, T.; Wang, L.-X.; Wu, D.-L.; Xia, W.; Jia, D.-Z. Interaction between Nitrogen and Sulfur in Co-Doped Graphene and Synergetic Effect in Supercapacitor. Sci. Rep. 2015, 5, 9591. [Google Scholar] [CrossRef]

- Li, X.; Xu, Y.; Li, Y.; Fan, X.; Zhang, G.; Zhang, F.; Peng, W. Increasing the heteroatoms doping percentages of graphene by porous engineering for enhanced electrocatalytic activities. J. Colloid Interface Sci. 2020, 577, 101–108. [Google Scholar] [CrossRef]

- Fan, B.; Yan, J.; Hu, A.; Liu, Z.; Li, W.; Li, Y.; Xu, Y.; Zhang, Y.; Tang, Q.; Chen, X.; et al. High-performance potassium ion capacitors enabled by hierarchical porous, large interlayer spacing, active site rich-nitrogen, and sulfur Co-doped carbon. Carbon 2020, 164, 1–11. [Google Scholar] [CrossRef]

| Samples | C (wt%) | O (wt%) | K (wt%) | Cl (wt%) | P | Ca | Mg | Sn |

|---|---|---|---|---|---|---|---|---|

| ash | / | 49.23 | 25.17 | 2.77 | 1.53 | 1.27 | 1.07 | 0.7 |

| TC-550 | 90.82 | 6.50 | 2.19 | 0.48 | / | / | / | / |

| SBET (m2·g−1) | KOH: Precursor (Mass Ratio) | Specific Capacitance (F·g−1) | Electrolyte | Raw Material | Number |

|---|---|---|---|---|---|

| 1909 | 2:1 | 248 (1 A·g−1) | 6 M KOH | corncob sponge | [27] |

| 2294 | 6:1 | 225 (0.5 A·g−1) | 6 M KOH | sawdust | [28] |

| 655.4 | 3:1 | 202 (0.5 A·g−1) | 6 M KOH | broad beans | [29] |

| 596 | 2:1 | 201 (0.5 A·g−1) | 6 M KOH | graphene | [30] |

| 2757.63 | 3:1 | 390 (1 A·g−1) | 6 M KOH | albizia flowers | [31] |

| 1306 | 2:1 | 340 (1 A·g−1) | 6 M KOH | Human hair | [32] |

| 3326.7 | 4:1 | 190 (1 mA·cm−2) | 1 M LiPF6-EC/DMC/DEC | Tobacco stem | [33] |

| 2115 | 3:1 | 287 (0.5 A·g−1) | 6 M KOH | Tobacco stem | [17] |

| 3177 | 3:1 | 281.3 (1 A·g−1) | 6 M KOH | Tobacco stalk | This work |

| Samples | C (wt%) | O (wt%) | N (wt%) | S (wt%) |

|---|---|---|---|---|

| ATC-3 | 88.29 | 11.71 | - | - |

| NS-ATC-3 | 90.47 | 5.27 | 3.75 | 0.51 |

| NS-ATC-4 | 88.08 | 5.65 | 5.46 | 0.81 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Q.; Ma, Z.; Chen, J.; Huang, Z.; Fang, Z.; Zhang, P.; Lin, Z.; Cui, J. N, S-Codoped Activated Carbon Material with Ultra-High Surface Area for High-Performance Supercapacitors. Polymers 2020, 12, 1982. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12091982

Yuan Q, Ma Z, Chen J, Huang Z, Fang Z, Zhang P, Lin Z, Cui J. N, S-Codoped Activated Carbon Material with Ultra-High Surface Area for High-Performance Supercapacitors. Polymers. 2020; 12(9):1982. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12091982

Chicago/Turabian StyleYuan, Qinghua, Zhuwen Ma, Junbiao Chen, Zhenrui Huang, Zeming Fang, Peng Zhang, Zhidan Lin, and Jie Cui. 2020. "N, S-Codoped Activated Carbon Material with Ultra-High Surface Area for High-Performance Supercapacitors" Polymers 12, no. 9: 1982. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12091982