Influence of Different Percentages of Binders on the Physico-Mechanical Properties of Rhizophora spp. Particleboard as Natural-Based Tissue-Equivalent Phantom for Radiation Dosimetry Applications

Abstract

:1. Introduction

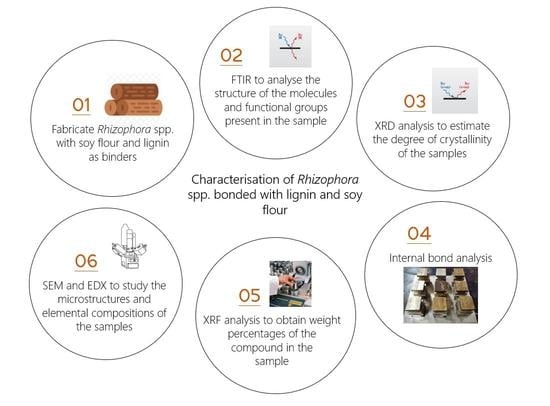

2. Materials and Methods

2.1. Sample Preparation of Rhizophora spp. Particleboard Bonded with Lignin and Soy Flour

2.2. Fourier Transform Infrared (FTIR) Analysis

2.3. X-ray Diffraction (XRD) Analysis

2.4. Analysis of Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray (EDX)

2.5. X-ray Fluorescence (XRF) Analysis Using Omnian Analysis Software

2.6. Internal Bonding Analysis

3. Results and Discussion

3.1. Evaluation of Functional Group using FTIR Analysis

3.2. Evaluation of XRD Spectrum

3.3. Evaluation of SEM Analysis

3.4. Evaluation of EDX Analysis

3.5. Evaluation of the XRF Analysis

3.6. Internal Bond Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ritchie, H.; Roser, M. Plastic pollution. Our World Data. 2018. Available online: https://ourworldindata.org/plastic-pollution (accessed on 2 June 2021).

- Gay, D.; Hoa, S.V.S.; Tsai, W. Composite Materials: Design and Applications; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Mathur, V.K. Composite materials from local resources. Constr. Build. Mater. 2006, 20, 470–477. [Google Scholar] [CrossRef]

- Jawaid, M.; Thariq, M. Sustainable Composites for Aerospace Applications; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Balakrishnan, P.; John, M.J.; Pothen, L.; Sreekala, M.S.; Thomas, S. Natural fibre and polymer matrix composites and their applications in aerospace engineering. In Advanced Composite Materials for Aerospace Engineering; Rana, S., Fangueiro, E., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 365–383. [Google Scholar]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent progress of reinforcement materials: A comprehensive overview of composite materials. J. Mater. Res. Technol. 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- Zuber, S.H.; Hashikin, N.; Mohd Yusof, M.F.; Hashim, R. Lignin and soy flour as adhesive materials in the fabrication of Rhizophora spp. particleboard for medical physics applications. J. Adhes. 2020. [Google Scholar] [CrossRef]

- Zuber, S.H.; Hashikin, N.A.A.; Mohd Yusof, M.F.; Hashim, R. Physical and mechanical properties of soy-lignin bonded Rhizophora spp. particleboard as a tissue-equivalent phantom material. Bioresources 2020, 15, 3. [Google Scholar] [CrossRef]

- Yusof, M.F.M.; Hashim, R.; Tajuddin, A.; Bauk, A.S.; Sulaiman, O. Characterization of tannin-added Rhizophora spp. particleboards as phantom materials for photon beams. Ind. Crops. Prod. 2017, 95, 467–474. [Google Scholar] [CrossRef]

- Samson, D.; Shukri, A.; Jafri, M.Z.M.; Hashim, R.; Aziz, M.Z.A.; Yusof, M.F.M. Tissue equivalent materials from SPC-SPI/NAOH/IA-PAE bonded mangrove wood characterized for radiation therapy dosimetry. Sci. Proc. Ser. 2020, 2, 115–120. [Google Scholar]

- Yusof, M.F.M.; Khatijah Abd Hamid, P.N.; Tajuddin, A.A.; Abdullah, R.; Hashim, R.; Bauk, S.; Isa, N.M.; Md Isa, M.J. Characterization and attenuation study on tannin-added Rhizophora spp. particleboard at high energy photon and electron. In Proceedings of the AIP Conference 2017, Selangor, Malaysia, 8–10 August 2016; Volume 1799, p. 40002. [Google Scholar]

- Samson, D.O.; Jafri, M.M.; Hashim, R.; Sulaiman, O.; Aziz, M.Z.A.; Yusof, M.F.M.; Shukri, A. Rhizophora SPP particleboards incorporating defatted soy flour bonded with NaOH/IA-PAE: Towards a water equivalent phantom material. Radiat. Phys. Chem. 2020, 176, 109057. [Google Scholar] [CrossRef]

- Said, M.; Seman, N.; Jaafar, H. Characterization of human head phantom based on its dielectric properties for wideband microwave Imaging application. J. Teknol. 2015, 73. [Google Scholar] [CrossRef] [Green Version]

- Dinulović, M.; Rašuo, B. Dielectric modeling of multiphase composites. Compos. Struct. 2011, 93, 3209–3215. [Google Scholar] [CrossRef]

- Tousi, E.T.; Hashim, R.; Bauk, S.; Jaafar, M.S.; Abuarra, A.M.H.; Ababneh, B. Some properties of particleboards produced from Rhizophora spp. as a tissue-equivalent phantom material bonded with Eremurus spp. Measurement 2014, 54, 14–21. [Google Scholar] [CrossRef]

- Pizzi, A. Wood products and green chemistry. Ann. For. Sci. 2016, 73, 185–203. [Google Scholar] [CrossRef] [Green Version]

- Kent, J.A. Kent and Riegel’s Handbook of Industrial Chemistry and Biotechnology; Springer: Berlin/Heidelberg, Germany, 2007; Volume 1665. [Google Scholar]

- Frihart, C.R. Potential for Biobased adhesives in wood bonding. In Proceedings of the 59th International Convention of Society of Wood Science and Technology, Curitiba, Brazil, 6–10 March 2016; pp. 84–91. [Google Scholar]

- Ferdosian, F.; Pan, Z.; Gao, G.; Zhao, B. Bio-based adhesives and evaluation for wood composites application. Polymers 2017, 9, 70. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hashim, R.; Nadhari, W.N.A.W.; Sulaiman, O.; Kawamura, F.; Hiziroglu, S.; Sato, M.; Tanaka, R. Characterization of raw materials and manufactured binderless particleboard from oil palm biomass. Mater. Des. 2011, 32, 246–254. [Google Scholar] [CrossRef]

- Bertaud, F.; Tapin-Lingua, S.; Pizzi, A.; Navarrete, P.; Petit-Conil, M. Development of green adhesives for fibreboard manufacturing, using tannins and lignin from pulp mill residues. Cellul. Chem. Technol. 2012, 46, 449–455. [Google Scholar]

- Bosetti, C.; McLaughlin, J.K.; Tarone, R.E.; Pira, E.; La Vecchia, C. Formaldehyde and cancer risk: A quantitative review of cohort studies through 2006. Ann. Oncol. 2008, 19, 29–43. [Google Scholar] [CrossRef]

- Dongre, P.; Driscoll, M.; Amidon, T.; Bujanovic, B. Lignin-furfural based adhesives. Energies 2015, 8, 7897–7914. [Google Scholar] [CrossRef] [Green Version]

- Frihart, C.R.; Lorenz, L. Protein modifiers generally provide limited improvement in wood bond strength of soy flour adhesives. For. Prod. 2013, 63, 138–142. [Google Scholar] [CrossRef]

- Frihart, C.R.; Hunt, C.G. Adhesives with wood materials-bond formation and performance. In Wood Handbook: Wood as an Engineering Material; Forest Products Laboratory: Madison, WI, USA, 2010. [Google Scholar]

- Frihart, C.R.; Satori, H. Soy flour dispersibility and performance as wood adhesive. J. Adhes. Sci. Technol. 2013, 27, 2043–2052. [Google Scholar] [CrossRef] [Green Version]

- Frihart, C.R.; Wescott, J.M. Improved water resistance of bio-based adhesives for wood bonding. In Proceedings of the ICECFOP1-1st International Conference on Environmentally-Compatible Forest Products: Fernando Pessoa University, Oporto, Portugal, 22–24 September 2004; Edicoes Universidade Fernando Pessoa: Porto, Portugal, 2004; pp. 293–302. [Google Scholar]

- Hojilla-Evangelista, M.P. Adhesive qualities of soybean protein-based foamed plywood glues. J. Am. Oil Chem. Soc. 2002, 79, 1145–1149. [Google Scholar] [CrossRef]

- Khosravi, S.; Khabbaz, F.; Nordqvist, P.; Johansson, M. Protein-based adhesives for particleboards. Ind. Crops Prod. 2010, 32, 275–283. [Google Scholar] [CrossRef] [Green Version]

- Sjöström, E.; Alén, R. Analytical Methods in Wood Chemistry, Pulping, and Papermaking; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Hu, F.; Ragauskas, A. Pretreatment and lignocellulosic chemistry. Bioenergy Res. 2012, 5, 1043–1066. [Google Scholar] [CrossRef]

- Kubo, S.; Kadla, J.F. Poly (ethylene oxide)/organosolv lignin blends: Relationship between thermal properties, chemical structure, and blend behavior. Macromolecules 2004, 37, 6904–6911. [Google Scholar] [CrossRef]

- Kubo, S.; Kadla, J.F. Lignin-based carbon fibers: Effect of synthetic polymer blending on fiber properties. J. Polym. Environ. 2005, 13, 97–105. [Google Scholar] [CrossRef]

- Pizzi, A.; Salvadó, J. Lignin-based wood panel adhesives without formaldehyd. Holz Roh Werkst. 2007, 65, 65. [Google Scholar]

- Montané, D.; Torné-Fernández, V.; Fierro, V. Activated carbons from lignin: Kinetic modeling of the pyrolysis of Kraft lignin activated with phosphoric acid. Chem. Eng. J. 2005, 106, 1–12. [Google Scholar] [CrossRef]

- Hemmilä, V.; Trischler, J.; Sandberg, D. Lignin: An adhesive raw material of the future or waste of research energy? In Proceedings of the Northern European Network for Wood Science and Engineering, Hannover, Germany, 11–12 September 2013; pp. 98–103. [Google Scholar]

- Çetin, N.S.; Özmen, N. Studies on lignin-based adhesives for particleboard panels. Turk. J. Agric. For. 2003, 27, 183–189. [Google Scholar]

- Gosselink, R.J.; Van Dam, J.E.; De Jong, E.; Gellerstedt, G.; Scott, E.L.; Sanders, J.P. Effect of periodate on lignin for wood adhesive application. Holzforschung 2011, 65, 155–162. [Google Scholar] [CrossRef]

- Martínez, C.; Sedano, M.; Munro, A.; López, P.; Pizzi, A. Evaluation of some synthetic oligolignols as adhesives: A molecular docking study. J. Adhes. Sci. Technol. 2010, 24, 1739–1751. [Google Scholar] [CrossRef]

- Zhang, W.; Ma, Y.; Wang, C.; Li, S.; Zhang, M.; Chu, F. Preparation and properties of lignin–phenol–formaldehyde resins based on different biorefinery residues of agricultural biomass. Ind. Crops Prod. 2013, 43, 326–333. [Google Scholar] [CrossRef]

- Abraham, E.; Deepa, B.; Pothan, L.; Jacob, M.; Thomas, S.; Cvelbar, U.; Anandjiwala, R. Extraction of nanocellulose fibrils from lignocellulosic fibres: A novel approach. Carbohydr. Polym. 2011, 86, 1468–1475. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, W.; Zhang, X.; Zhang, X.; Lu, C.; Deng, Y. Extraction of cellulose nanofibrils from dry softwood pulp using high shear homogenization. Carbohydr. Polym. 2013, 97, 695–702. [Google Scholar] [CrossRef]

- Khan, A.; Khan, R.A.; Salmieri, S.; Le Tien, C.; Riedl, B.; Bouchard, J.; Lacroix, M. Mechanical and barrier properties of nanocrystalline cellulose reinforced chitosan based nanocomposite films. Carbohydr. Polym. 2012, 90, 1601–1608. [Google Scholar] [CrossRef]

- Samson, D.O.; Shukri, A.; Jafri, M.Z.M.; Hashim, R.; Sulaiman, O.; Aziz, M.Z.A.; Yusof, M.F.M. Characterization of Rhizophora SPP. Particleboards with SOY protein isolate modified with NaOH/IA-PAE adhesive for use as phantom material at photon energies of 16.59–25.26 keV. Nucl. Eng. Technol. 2020, 53, 216–233. [Google Scholar] [CrossRef]

- Adhesive Bonding; William Andrew Publishing: Boston, MA, USA, 2009; pp. 145–173.

- Sarkanen, K.V.; Ludwig, C.H. Liguins. Occurrence, Formation, Structure, and Reactions; John Wiley & Sons: Hoboken, NJ, USA, 1971. [Google Scholar]

- Kim, K.H.; Akase, Z.; Suzuki, T.; Shindo, D. Charging effects on SEM/SIM contrast of metal/insulator system in various metallic coating conditions. Mater. Trans. 2010, 10, 1080–1083. [Google Scholar] [CrossRef] [Green Version]

- Hansen, C.M. 50 Years with solubility parameters—Past and future. Prog. Org. Coat. 2004, 51, 77–84. [Google Scholar] [CrossRef]

- Yemele, M.C.N.; Cloutier, A.; Diouf, P.N.; Koubaa, A.; Blanchet, P.; Stefanovic, T. Physical and mechanical properties of particleboard made from extracted black spruce and trembling aspen bark. For. Prod. J. 2008, 58, 38–46. [Google Scholar]

- Hansen, C.M. Hansen Solubility Parameters: A User’s Handbook; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Cwa, C.W.S. Kayu Tropika Sebagai Bahantara Setaraan Tisu Untuk Kajian Dosmteri. Master’s Thesis, Universiti Sains Malaysia, Kuala Lumpur, Malaysia, 1993. (In Malay). [Google Scholar]

- Marashdeh, M.W.; Hashim, R.; Tajuddin, A.A.; Bauk, S.; Sulaiman, O. Effect of particle size on the characterization of binderless particleboard made from Rhizophora SPP. Mangrove wood for use as phantom material. BioResources 2011, 6, 4028–4044. [Google Scholar]

- Japan Standard Association. Japanese Industrial Standard for Particle Board JIS A 5908; Japanese Standard Association: Jepang, Japan, 2003. [Google Scholar]

| Samples | Calcium Oxide (CaO) | Potassium Oxide (K2O) | Chlorine (Cl) | Sodium Oxide (Na2O) | Others |

|---|---|---|---|---|---|

| 0% binder | 52.744 | 5.241 | 17.705 | 6.355 | 17.955 |

| 6% binders | 42.740 | 14.883 | 12.947 | 5.036 | 24.394 |

| 12% binders | 40.319 | 18.399 | 11.623 | 4.708 | 24.951 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuber, S.H.; Hashikin, N.A.A.; Yusof, M.F.M.; Aziz, M.Z.A.; Hashim, R. Influence of Different Percentages of Binders on the Physico-Mechanical Properties of Rhizophora spp. Particleboard as Natural-Based Tissue-Equivalent Phantom for Radiation Dosimetry Applications. Polymers 2021, 13, 1868. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13111868

Zuber SH, Hashikin NAA, Yusof MFM, Aziz MZA, Hashim R. Influence of Different Percentages of Binders on the Physico-Mechanical Properties of Rhizophora spp. Particleboard as Natural-Based Tissue-Equivalent Phantom for Radiation Dosimetry Applications. Polymers. 2021; 13(11):1868. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13111868

Chicago/Turabian StyleZuber, Siti Hajar, Nurul Ab. Aziz Hashikin, Mohd Fahmi Mohd Yusof, Mohd Zahri Abdul Aziz, and Rokiah Hashim. 2021. "Influence of Different Percentages of Binders on the Physico-Mechanical Properties of Rhizophora spp. Particleboard as Natural-Based Tissue-Equivalent Phantom for Radiation Dosimetry Applications" Polymers 13, no. 11: 1868. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13111868