One Surface Treatment, Multiple Possibilities: Broadening the Use-Potential of Para-Aramid Fibers with Mechanical Adhesion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Aramid Surface Modification

2.2. Interfacial Shear Strength

2.3. Microscopy

2.4. FTIR Spectroscopy

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karger-Kocsis, J.; Mahmood, H.; Pegoretti, A. Recent advances in fiber/matrix interphase engineering for polymer composites. Prog. Mater. Sci. 2015, 73, 1–43. [Google Scholar] [CrossRef]

- Jesson, D.A.; Watts, J.F. The Interface and Interphase in Polymer Matrix Composites: Effect on Mechanical Properties and Methods for Identification. Polym. Rev. 2012, 52, 321–354. [Google Scholar] [CrossRef]

- Tam, T.; Bhatnagar, A. High-performance ballistic fibers and tapes. In Lightweight Ballistic Composites, 2nd ed.; Bhatnagar, A., Ed.; Woodhead Publishing: Duxford, UK, 2016; pp. 1–39. [Google Scholar]

- Chang, K.K.; Fibers, A. ASM Handbooks; Miracle, D.B., Donaldson, S.L., Eds.; Composites, ASM International: Materials Park, OH, USA, 2001; Volume 21, pp. 41–45. [Google Scholar]

- Qi, G.; Zhang, B.; Du, S.; Yu, Y. Estimation of aramid fiber/epoxy interfacial properties by fiber bundle tests and multiscale modeling considering the fiber skin/core structure. Compos. Struct. 2017, 167, 1–10. [Google Scholar] [CrossRef]

- Luo, S.; Ooij, W.J.V. Surface modification of textile fibers for improvement of adhesion to polymeric matrices: A review. J. Adhes. Sci. Technol. 2002, 16, 1715–1735. [Google Scholar] [CrossRef]

- Sun, J.; Yao, L.; Sun, S.; Qiu, Y. ESR study of atmospheric pressure plasma jet irradiated aramid fibers. Surf. Coat. Technol. 2011, 205, 5312–5317. [Google Scholar] [CrossRef]

- Wang, J.; Chen, P.; Xiong, X.; Jia, C.; Yu, Q.; Ma, K. Interface characteristic of aramid fiber reinforced poly(phthalazinone ether sulfone ketone) composite. Surf. Interface Anal. 2017, 49, 788–793. [Google Scholar] [CrossRef]

- Tie-Min, L.; Yuan-Suo, Z.; Jie, H. Surface modification of Aramid fibers with new chemical method for improving interfacial bonding strength with epoxy resin. J. Appl. Polym. Sci. 2010, 118, 2541–2552. [Google Scholar]

- Gao, B.; Zhang, R.; Gao, F.; He, M.; Wang, C.; Liu, L.; Zhao, L.; Cui, H. Interfacial Microstructure and Enhanced Mechanical Properties of Carbon Fiber Composites Caused by Growing Generation 1–4 Dendritic Poly(amidoamine) on a Fiber Surface. Langmuir 2016, 32, 8339–8349. [Google Scholar] [CrossRef] [PubMed]

- Sa, R.; Yan, Y.; Wei, Z.; Zhang, L.; Wang, W.; Tian, M. Surface Modification of Aramid Fibers by Bio-Inspired Poly(dopamine) and Epoxy Functionalized Silane Grafting. ACS Appl. Mater. Interfaces 2014, 6, 21730–21738. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Zhang, C.; Wang, Y.; Li, P.; Yu, Y.; Jia, X.; Liu, H.; Yang, X.; Xue, Z.; Ryu, S. Interface correlation and toughness matching of phosphoric acid functionalized Kevlar fiber and epoxy matrix for filament winding composites. Compos. Sci. Technol. 2008, 68, 3208–3214. [Google Scholar] [CrossRef]

- Lv, J.; Cheng, Z.; Wu, H.; He, T.; Qin, J.; Liu, X. In-situ polymerization and covalent modification on aramid fiber surface via direct fluorination for interfacial enhancement. Compos. Part B Eng. 2020, 182, 107608. [Google Scholar] [CrossRef]

- Yue, C.Y.; Padmanabhan, K. Interfacial studies on surface modified Kevlar fibre/epoxy matrix composites. Compos. Part B Eng. 1999, 30, 205–217. [Google Scholar] [CrossRef]

- Zhang, S.; Li, M.; Cheng, K.; Lu, S. A facile method to prepare PEG coatings on the fiber surface by the reconstruction of hydrogen bonds for enhancing the interfacial strength of fibers and resins. Colloids Surf. A Physicochem. Eng. Asp. 2020, 589, 124426. [Google Scholar] [CrossRef]

- Loureiro, L.; Carvalho, V.H.; Bettini, S.H.P. Reuse of p-aramid from industrial waste as reinforcement fiber in polyamide 6.6. Polym. Test. 2016, 56, 124–130. [Google Scholar] [CrossRef]

- Palola, S.; Vuorinen, J.; Noordermeer, J.W.M.; Sarlin, E. Development in Additive Methods in Aramid Fiber Surface Modification to Increase Fiber-Matrix Adhesion: A Review. Coatings 2020, 10, 556. [Google Scholar] [CrossRef]

- Hazarika, A.; Deka, B.K.; Kim, D.; Kong, K.; Park, Y.; Park, H.W. Growth of aligned ZnO nanorods on woven Kevlar® fiber and its performance in woven Kevlar® fiber/polyester composites. Compos. Part A Appl. Sci. Manuf. 2015, 78, 284–293. [Google Scholar] [CrossRef]

- Malakooti, M.H.; Hwang, H.; Goulbourne, N.C.; Sodano, H.A. Role of ZnO nanowire arrays on the impact response of aramid fabrics. Compos. Part B Eng. 2017, 127, 222–231. [Google Scholar] [CrossRef]

- Ehlert, G.J.; Sodano, H.A. Zinc oxide nanowire interphase for enhanced interfacial strength in lightweight polymer fiber composites. ACS Appl. Mater. Interfaces 2009, 1, 1827–1833. [Google Scholar] [CrossRef] [PubMed]

- Patterson, B.A.; Sodano, H.A. Enhanced Interfacial Strength and UV Shielding of Aramid Fiber Composites through ZnO Nanoparticle Sizing. ACS Appl. Mater. Interfaces 2016, 8, 33963–33971. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Zhang, L.; Jiang, C.; Dai, Y.; Meng, C.; Luo, L.; Liu, X. Aramid fiber with excellent interfacial properties suitable for resin composite in a wide polarity range. Chem. Eng. J. 2018, 347, 483–492. [Google Scholar] [CrossRef]

- Wang, B.; Duan, Y.; Zhang, J. Titanium dioxide nanoparticles-coated aramid fiber showing enhanced interfacial strength and UV resistance properties. Mater. Des. 2016, 103, 330–338. [Google Scholar] [CrossRef]

- Gonzalez-Chi, P.I.; Rodríguez-Uicab, O.; Martin-Barrera, C.; Uribe-Calderon, J.; Canché-Escamilla, G.; Yazdani-Pedram, M.; May-Pat, A.; Avilés, F. Influence of aramid fiber treatment and carbon nanotubes on the interfacial strength of polypropylene hierarchical composites. Compos. Part B Eng. 2017, 122, 16–22. [Google Scholar] [CrossRef]

- Hazarika, A.; Deka, B.K.; Kim, D.; Park, Y.; Park, H.W. Microwave-induced hierarchical iron-carbon nanotubes nanostructures anchored on polypyrrole/graphene oxide-grafted woven Kevlar® fiber. Compos. Sci. Technol. 2016, 129, 137–145. [Google Scholar] [CrossRef]

- Chen, W.; Qian, X.; He, X.; Liu, Z.; Liu, J. Surface modification of Kevlar by grafting carbon nanotubes. J. Appl. Polym. Sci. 2011, 123, 1983–1990. [Google Scholar] [CrossRef]

- Nasser, J.; Lin, J.; Steinke, K.; Sodano, H.A. Enhanced interfacial strength of aramid fiber reinforced composites through adsorbed aramid nanofiber coatings. Compos. Sci. Technol. 2019, 174, 125–133. [Google Scholar] [CrossRef]

- Yang, M.; Cao, K.; Sui, L.; Qi, Y.; Zhu, J.; Waas, A.; Arruda, E.M.; Kieffer, J.; Thouless, M.D.; Kotov, N.A. Dispersions of Aramid Nanofibers: A New Nanoscale Building Block. ACS Nano 2011, 5, 6945–6954. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Patterson, B.A.; Malakooti, M.H.; Lin, J.; Okorom, A.; Sodano, H.A. Aramid nanofibers for multiscale fiber reinforcement of polymer composites. Compos. Sci. Technol. 2018, 161, 92–99. [Google Scholar] [CrossRef]

- Nasser, J.; Groo, L.; Zhang, L.; Sodano, H. Laser induced graphene fibers for multifunctional aramid fiber reinforced composite. Carbon 2020, 158, 146–156. [Google Scholar] [CrossRef]

- Li, H.; Xu, Y.; Zhang, T.; Niu, K.; Wang, Y.; Zhao, Y.; Zhang, B. Interfacial adhesion and shear behaviors of aramid fiber/polyamide 6 composites under different thermal treatments. Polym. Test. 2020, 81, 106209. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, X.; Lv, J.; Liu, Y.; Liu, X. Constructing a new tear-resistant skin for aramid fiber to enhance composites interfacial performance based on the interfacial shear stability. Appl. Surf. Sci. 2021, 544, 148935. [Google Scholar] [CrossRef]

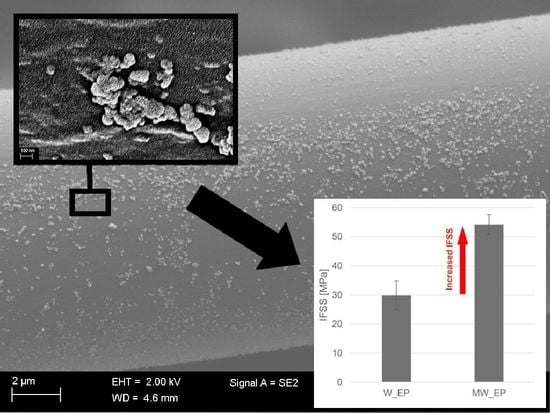

- Palola, S.; Sarlin, E.; Azari, S.K.; Koutsos, V.; Vuorinen, J. Microwave induced hierarchical nanostructures on aramid fibers and their influence on adhesion properties in a rubber matrix. Appl. Surf. Sci. 2017, 410, 145–153. [Google Scholar] [CrossRef] [Green Version]

- Laurikainen, P.; Kakkonen, M.; von Essen, M.; Tanhuanpää, O.; Kallio, P.; Sarlin, E. Identification and compensation of error sources in the microbond test utilising a reliable high-throughput device. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105988. [Google Scholar] [CrossRef]

- Miller, B.; Muri, P.; Rebenfel, L. A microbond method for determination of the shear strength of a fiber/resin interface. Compos. Sci. Technol. 1987, 28, 17–32. [Google Scholar] [CrossRef]

- Nečas, D.; Klapetek, P. Gwyddion: An open-source software for SPM data analysis. Cent. Eur. J. Phys. 2012, 10, 181–188. [Google Scholar] [CrossRef]

- EsB Detector—Make Sub-Surface Information and Nano-Scale Composition Visible; Carl Zeiss Microscopy GmbH: Oberkochen, Germany, 2016.

- Bajpai, R.; Wagner, H.D. Fast growth of carbon nanotubes using a microwave oven. Carbon 2015, 82, 327–336. [Google Scholar] [CrossRef]

- He, S.; Sun, G.X.; Cheng, X.D.; Dai, H.M.; Chen, X.F. Nanoporous SiO2 grafted aramid fibers with low thermal conductivity. Compos. Sci. Technol. 2017, 146, 91–98. [Google Scholar] [CrossRef]

- Li, Y.; Luo, Z.; Yang, L.; Li, X.; Xiang, K. Study on Surface Properties of Aramid Fiber Modified in Supercritical Carbon Dioxide by Glycidyl-POSS. Polymers 2018, 11, 700. [Google Scholar] [CrossRef] [Green Version]

- Shebanov, S.M.; Novikov, I.K.; Pavlikov, A.V.; Anańin, O.B.; Gerasimov, I.A. IR and Raman Spectra of Modern Aramid Fibers. Fibre Chem. 2016, 48, 158–164. [Google Scholar] [CrossRef]

- Mosadegh, M.; Mahdavi, H. Chemical Functionalization of Graphene Oxide by Poly(styrene sulfonate) Using Atom Transfer Radical and Free Radical Polymerization: A Comparative Study. Polym. Plast. Technol. Eng. 2017, 56, 1247–1258. [Google Scholar] [CrossRef]

- Raja, P.M.V.; Barron, A.R. IR Spectroscopy. 2019. Available online: https://chem.libretexts.org/@go/page/167013 (accessed on 3 June 2021).

- Wang, C.; Liu, C.R. Transcrystallization of polypropylene composites: Nucleating ability of fibres. Polymer 1999, 40, 289–298. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Fuchs, P.F. Investigation of adhesion properties in load coupling applications for flexible composites. Mater. Today Proc. 2020, 34, 41–46. [Google Scholar] [CrossRef]

| Sample Name | Matrix Material | Washing | Microwave Treatment |

|---|---|---|---|

| EP_W | epoxy | YES | NO |

| EP_MW | epoxy | YES | YES |

| PP_W | polypropylene | YES | NO |

| PP_MW | polypropylene | YES | YES |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palola, S.; Javanshour, F.; Kolahgar Azari, S.; Koutsos, V.; Sarlin, E. One Surface Treatment, Multiple Possibilities: Broadening the Use-Potential of Para-Aramid Fibers with Mechanical Adhesion. Polymers 2021, 13, 3114. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13183114

Palola S, Javanshour F, Kolahgar Azari S, Koutsos V, Sarlin E. One Surface Treatment, Multiple Possibilities: Broadening the Use-Potential of Para-Aramid Fibers with Mechanical Adhesion. Polymers. 2021; 13(18):3114. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13183114

Chicago/Turabian StylePalola, Sarianna, Farzin Javanshour, Shadi Kolahgar Azari, Vasileios Koutsos, and Essi Sarlin. 2021. "One Surface Treatment, Multiple Possibilities: Broadening the Use-Potential of Para-Aramid Fibers with Mechanical Adhesion" Polymers 13, no. 18: 3114. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13183114