Surface Modified Nanocellulose and Its Reinforcement in Natural Rubber Matrix Nanocomposites: A Review

Abstract

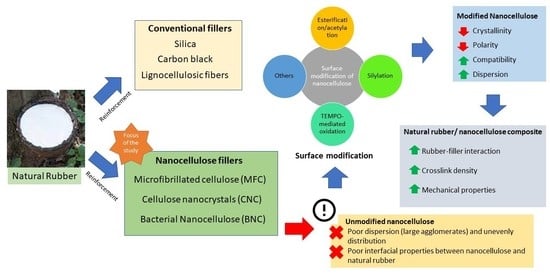

:1. Introduction

2. Conventional Fillers for Natural Rubber Nanocomposite

2.1. Carbon Black

2.2. Silica

| Filler/Source | Treatments | Variables | Properties Tested and Findings | References |

|---|---|---|---|---|

| Silica fume | - | Silica loading (10, 20, 30, 40, 50 phr) | Curing Characteristic The cure time of all the reinforced composites increased with the increase in silica fume loading Tensile Strength and Modulus Composite added with 20 phr silica showed improved tensile strength. The tensile strength dropped slightly with further increase of silica fume loading. However, the composite’s modulus increased proportionally with silica fume loading. Tear Strength Tear strength increased up to 20 phr of silica fume loading and then decreased with further increases in loading. | [17] |

| Silica, Silica-graphene oxide (SiO2@GO) | - | Silica loading of 3 phr | Tensile strength, Modulus and Elongation at Break Composite added with silica exhibited insignificant change in tensile strength due to the low content of silica used. However, composite consisted of hybrid silica-graphene oxide filler, showed an increase in tensile strength, elongation at break, and modulus. | [18] |

| Silica from sugarcane bagasse ash | Drying technique | Freeze drying (FD) and heat drying (HD) | Curing Characteristic Scorch time of the rubber composites increased with an increase in silica content. Tensile Strength Tensile strength of the tested composites increased with increase in silica content but tended to reduce slightly at higher silica content. Modulus, Hardness and Elongation at Break The modulus and hardness of rubber composite increased while elongation at break decreased with an increase in silica content | [19] |

| Silica, styrene | - | Particle size | Tensile Strength, Modulus and Hardness All the mechanical properties of reinforced natural rubber increased compared to rubber compound without reinforcement. | [20] |

| Silica -precipitated silica (PS), autonomous monodisperse silica (AS) | Silane treatment | Silica dimension and polydispersity | Tensile Strength and Abrasive Resistance PS reinforced rubber showed better tensile strength and abrasive resistance than AS reinforced rubber. | [21] |

| Silica from rice husk | Alkali treatment | Silica loading of 60 phr | Curing Characteristic The result shows that the curing time of the rubber composites decrease with increasing silica loading. Tensile Strength The tensile strength was determined at the break point of the specimen. Results show the addition of silica in natural rubber matrix resulted in the improvement in the tensile properties Tear Strength and Hardness The addition of silica as filler increases the tear strength as well as the hardness of the rubber composite as the silica loading increases. | [22] |

| Precipitated silica (PSi) and fly ash silica (FASi) | - | Silica loading of 0–75 phr | Curing Characteristic The cure time and minimum and maximum torques of the rubber compounds were unaffected by silica loadings from 0 to 30 phr, and above these concentrations, the values progressively increased with increasing PSi loading but the FASi remained the same. 0 to 30 phr FASi could be recommended to natural rubber but not styrene–butadiene rubber Tensile Strength and Elongation at Break The tensile strength and elongation at break of rubber composite filled with untreated silica decreased with increasing silica content. | [23] |

2.3. Lignocellulosic Fibre

| Lignocellulosic Fiber/Filler | Treatments | Variables | Properties Tested and Findings | References |

|---|---|---|---|---|

| Torrefied almond shells (TAS) and torrefied rice hulls (TRH) | torrefaction | Carbon black to torrefied filler loadings ratio (40:20, 30:30, 20:40) | Curing Characteristic The curing time increased with higher loadings of both torrefied fillers. Tensile Strength and Modulus Generally, carbon black filled composite showed better mechanical properties than torrefied filler reinfored composite. The tensile strength of TAS filled natural rubber composite decreased with decreasing carbon black to torrefied filler ratio, while TRH filled natural rubber composite and reached the lowest tensile strength at 30:30 ratio before increasing significantly at 40:20 ratio. The modulus of TAS filled natural rubber composite showed similar trend with its tensile strength. On the other hand, the modulus of TRH rubber composite showed the lowest modulus at 40:20 ratio before increasing gradually at 30:30 and 20:40 ratio. | [25] |

| Horsetail (Equisetum Arvense) | Horsetail filler loading (10, 20, 30, 40 50 phr) | Elongation at Break The elongation at break increases with increasing horsetail loading from 10 phr to 50 phr. Tensile Strength Tensile strength of rubber composite reinforced with horsetail show higher value than the pure natural rubber sample. Initially, tensile strength increases with the addition of horsetail filler then drop slightly as the loading increases. | [26] | |

| Cereal straw | Silane treatment | Silanes coupling agents (PTES, VTES, TESPTS), filler loading (10, 20, 30 phr) | Elongation at Break The elongation at break decreased with increasing cereal straw filler from 10 to 30 phr) Tensile Strength Rubber composites with silanes modified filler show improved tensile strength compared to composite with unmodified filler and the control specimens. The tensile strength increased and peaked at 10 phr loading and decreased with higher filler content. | [27] |

| Hemp fibre | Silane (Si69) and permanganate (KMnO4) treatment | Filler loading (5, 10, 15 phr) | Curing Characteristic Generally, the curing time of rubber composites increases with increasing hemp loading. The curing time for rubber composites filled with both silane or permanganate treated fibre is longer than the untreated counterparts. Tensile Strength and Modulus This finding shows increased tensile strength of silane treated fibre rubber composites compared with untreated and permanganate treated hemp fiber filled rubber composites. Tensile strength increased with filler loading and peaked at 10 phr before showing a decrease trend at 15 phr. The modulus however demonstrated an continual increase trend with higher filler loading. | [28] |

| Coconut shell powder | Alkali treatment | Filler loading (10, 20, 30, 40 phr) | Curing Characteristic Curing time was found to decrease consistently with increasing filler loading Tensile Strength and Modulus Tensile strength of the natural rubber composite was highest at 10 phr loading and decreased with increasing filler loading of 20 to 40 phr. Generally, the modulus showed similar trend with tensile strength. | [29] |

| Rice husk | Electron beam irradiation | Irradiation dosage | Tensile Strength and Modulus Max stress increases with irradiation dosage until about 20 kGy and decreases with further increase of radiation. However, the modulus seems to maximize at about 30 kGy of radiation. | [30] |

| Wood flour | Corona treatment in air and in ammonia | Filler loading (10, 20, 30, 40, 50, 60, 70 phr) | Curing Characteristics The higher the filler loading the longer the curing time. Nonetheless, the addition of treated wood flour treated with corona in air and ammonia did not significantly affect the vulcanization process of the rubber matrix. Tensile Strength and Modulus The tensile strength increased with filler laoding at 10 phr and decreased consistently with filler loading of 20, 30, 40 and 50 phr. However, the tensile strength increased again at 70 phr filler loading | [31] |

| Oil palm wood flour | Filler loading | Tensile Strength and Modulus The results show that increasing the concentration of oil palm wood flour increases the tensile modulus. However, the tensile strength and the elongation at break show a reverse trend. | [32] |

3. Types of Nanocellulose Fillers from Natural Fiber

3.1. Microfibrillated Cellulose (MFC)

3.2. Cellulose Nanocrystals (CNCs)

3.3. Bacterial Nanocellulose (BNC)

4. Surface Modification of Nanocellulose for Natural Rubber Nanocomposites

4.1. Esterification

4.2. Silylation

4.3. TEMPO-Mediated Oxidation

4.4. Other Modifications

5. Conclusions, Challenges and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Beilen, J.B.; Poirier, Y. Establishment of new crops for the production of natural rubber. Trends Biotechnol. 2007, 25, 22–29. [Google Scholar] [CrossRef]

- Cornish, K. Similarities and differences in rubber biochemistry among plant species. Phytochemistry 2001, 57, 1123–1134. [Google Scholar] [CrossRef]

- Cataldo, F. Guayule rubber: A new possible world scenario for the production of natural rubber. Prog. Rubber Plast. Technol. 2000, 16, 31–59. [Google Scholar]

- Wikipedia. Natural Rubber. Available online: https://en.wikipedia.org/wiki/Natural_rubber (accessed on 2 September 2021).

- Statista. Leading Natural Rubber Producing Countries Worldwide in 2019 and 2020. Available online: https://0-www-statista-com.brum.beds.ac.uk/statistics/275397/caoutchouc-production-in-leading-countries/ (accessed on 29 August 2021).

- Mordor Intelligence. Natural Rubber Market—Growth, Trends, COVID-19 Impact, and Forecasts (2021–2026). Available online: https://www.mordorintelligence.com/industry-reports/natural-rubber-market (accessed on 23 August 2021).

- Expert Market Research. Global Natural Rubber Market Outlook. Available online: https://www.expertmarketresearch.com/reports/natural-rubber-market (accessed on 11 September 2021).

- Mariano, M.; El Kissi, N.; Dufresne, A. Cellulose nanocrystal reinforced oxidized natural rubber nanocomposites. Carbohydr. Polym. 2016, 137, 174–183. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Fan, M.; Chen, L.; Zhuang, J. Lignocellulosic fibre mediated rubber composites: An overview. Compos. Part B Eng. 2015, 76, 180–191. [Google Scholar] [CrossRef]

- Low, D.Y.S.; Supramaniam, J.; Soottitantawat, A.; Charinpanitkul, T.; Tanthapanichakoon, W.; Tan, K.W.; Tang, S.Y. Recent developments in nanocellulose-reinforced rubber matrix composites: A review. Polymers 2021, 13, 550. [Google Scholar] [CrossRef] [PubMed]

- Kargarzadeh, H.; Mariano, M.; Huang, J.; Lin, N.; Ahmad, I.; Dufresne, A.; Thomas, S. Recent developments on nanocellulose reinforced polymer nanocomposites: A review. Polymer 2017, 132, 368–393. [Google Scholar] [CrossRef]

- Nunes, R.C. Rubber Nanocomposites with Nanocellulose. In Progress in Rubber Nanocomposites; Thomas, S., Maria, H.J., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 463–494. [Google Scholar]

- Sivaselvi, K.; Varma, V.S.; Harikumar, A.; Jayaprakash, A.; Sankar, S.; Krishna, C.Y.; Gopal, K. Improving the mechanical properties of natural rubber composite with carbon black (N220) as filler. Mater. Today Proc. 2021, 42, 921–925. [Google Scholar] [CrossRef]

- Salaeh, S.; Nakason, C. Influence of modified natural rubber and structure of carbon black on properties of natural rubber compounds. Polym. Compos. 2012, 33, 489–500. [Google Scholar] [CrossRef]

- Choi, S.S.; Nah, C.; Jo, B.W. Properties of natural rubber composites reinforced with silica or carbon black: Influence of cure accelerator content and filler dispersion. Polym. Int. 2003, 52, 1382–1389. [Google Scholar] [CrossRef]

- Abdul Wahab, M.K.; Ismail, H.; Othman, N. Effects of dynamic vulcanization on the physical, mechanical, and morphological properties of high-density polyethylene/(natural rubber)/(thermoplastic tapioca starch) blends. J. Vinyl Addit. Technol. 2012, 18, 192–197. [Google Scholar] [CrossRef]

- Dileep, P.; Varghese, G.A.; Sivakumar, S.; Narayanankutty, S.K. An innovative approach to utilize waste silica fume from zirconia industry to prepare high performance natural rubber composites for multi-functional applications. Polym. Test. 2020, 81, 106172. [Google Scholar] [CrossRef]

- Charoenchai, M.; Tangbunsuk, S.; Keawwattana, W. Silica-graphene oxide nanohybrids as reinforcing filler for natural rubber. J. Polym. Res. 2020, 27, 1–16. [Google Scholar] [CrossRef]

- Boonmee, A.; Jarukumjorn, K. Preparation and characterization of silica nanoparticles from sugarcane bagasse ash for using as a filler in natural rubber composites. Polym. Bull. 2020, 77, 3457–3472. [Google Scholar] [CrossRef]

- Thuong, N.T.; Dung, T.A.; Yusof, N.H.; Kawahara, S. Controlling the size of silica nanoparticles in filler nanomatrix structure of natural rubber. Polymer 2020, 195, 122444. [Google Scholar] [CrossRef]

- Xia, L.; Song, J.; Wang, H.; Kan, Z. Silica nanoparticles reinforced natural rubber latex composites: The effects of silica dimension and polydispersity on performance. J. Appl. Polym. Sci. 2019, 136, 47449. [Google Scholar] [CrossRef]

- Ahmed, K.; Nizami, S.S.; Riza, N.Z. Reinforcement of natural rubber hybrid composites based on marble sludge/Silica and marble sludge/rice husk derived silica. J. Adv. Res. 2014, 5, 165–173. [Google Scholar] [CrossRef] [Green Version]

- Sombatsompop, N.; Thongsang, S.; Markpin, T.; Wimolmala, E. Fly ash particles and precipitated silica as fillers in rubbers. I. Untreated fillers in natural rubber and styrene–butadiene rubber compounds. J. Appl. Polym. Sci. 2004, 93, 2119–2130. [Google Scholar]

- Sadequl, A.M.; Poh, B.T.; Ishiaku, U.S. Effect of filler loading on the mechanical properties of epoxidized natural rubber (ENR 25) compared with natural rubber (SMR L). Int. J. Polym. Mater. 1999, 43, 261–278. [Google Scholar] [CrossRef]

- Torres, L.F.; McCaffrey, Z.; Washington, W.; Williams, T.G.; Wood, D.F.; Orts, W.J.; McMahan, C.M. Torrefied agro-industrial residue as filler in natural rubber compounds. J. Appl. Polym. Sci. 2021, 138, 50684. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Czylkowska, A.; Strzelec, K. Horsetail (Equisetum arvense) as a functional filler for natural rubber biocomposites. Materials 2020, 13, 2526. [Google Scholar] [CrossRef] [PubMed]

- Miedzianowska, J.; Masłowski, M.; Rybiński, P.; Strzelec, K. Properties of chemically modified (selected silanes) lignocellulosic filler and its application in natural rubber biocomposites. Materials 2020, 13, 4163. [Google Scholar] [CrossRef]

- Moonart, U.; Utara, S. Effect of surface treatments and filler loading on the properties of hemp fiber/natural rubber composites. Cellulose 2019, 26, 7271–7295. [Google Scholar] [CrossRef]

- Sareena, C.; Ramesan, M.T.; Purushothaman, E. Utilization of coconut shell powder as a novel filler in natural rubber. J. Reinf. Plast. Compos. 2012, 31, 533–547. [Google Scholar] [CrossRef]

- Chong, E.L.; Ahmad, I.; Dahlan, H.M.; Abdullah, I. Reinforcement of natural rubber/high density polyethylene blends with electron beam irradiated liquid natural rubber-coated rice husk. Radiat. Phys. Chem. 2010, 79, 906–911. [Google Scholar] [CrossRef]

- Vladkova, T.G.; Dineff, P.D.; Gospodinova, D.N.; Avramova, I. Wood flour: New filler for the rubber processing industry. IV. Cure characteristics and mechanical properties of natural rubber compounds filled by non-modified or corona treated wood flour. J. Appl. Polym. Sci. 2006, 101, 651–658. [Google Scholar] [CrossRef]

- Ismail, H.; Nurdin, H.I. Tensile properties and scanning electron microscopy examination of the fracture surface of oil palm wood flour/natural rubber composites. Iran. Polym. J. 1998, 7, 53–58. [Google Scholar]

- Kulshrestha, U.; Gupta, T.; Kumawat, P.; Jaiswal, H.; Ghosh, S.B.; Sharma, N.N. Cellulose nanofibre enabled natural rubber composites: Microstructure, curing behaviour and dynamic mechanical properties. Polym. Test. 2020, 90, 106676. [Google Scholar] [CrossRef]

- Kanoth, P.B.; Claudino, M.; Johansson, M.; Berglund, L.A.; Zhou, Q. Biocomposites from natural rubber: Synergistic effects of functionalized cellulose nanocrystals as both reinforcing and cross-linking agents via free-radical thiol–ene chemistry. ACS Appl. Mater. Interfaces 2015, 7, 16303–16310. [Google Scholar] [CrossRef]

- Harwood, J.A.C.; Mullins, L.; Payne, A.R. Stress softening in natural rubber vulcanizates. Part ii. Stress softening effects in pure gum and filler loaded rubbers. J. Appl. Polym. Sci. 1965, 9, 3011–3021. [Google Scholar] [CrossRef]

- Zinge, C.; Kandasubramanian, B. Nanocellulose based biodegradable polymers. Eur. Polym. J. 2020, 133, 109758. [Google Scholar] [CrossRef]

- Zhang, K.; Barhoum, A.; Xiaoqing, C.; Li, H.; Samyn, P. Cellulose Nanofibers: Fabrication and Surface Functionalization Techniques. In Handbook of Nanofibers; Barhoum, A., Bechelany, M., Makhlouf, A.S.H., Eds.; Springer Nature Switzerland AG: Cham, Switzerland, 2019; pp. 409–449. [Google Scholar]

- Gopakumar, D.A.; Thomas, S.; Grohens, Y. Nanocelluloses as Innovative Polymers for Membrane Applications. In Multifunctional Polymeric Nanocomposites Based on Cellulosic Reinforcements; Puglia, D., Fortunati, E., Kenny, J.M., Eds.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 253–275. [Google Scholar]

- Supramaniam, J.; Wong, S.K.; Leo, B.F.; Tan, L.T.H.; Goh, B.H.; Tang, S.Y. Unravelling the swelling behaviour and antibacterial activity of palm cellulose nanofiber-based metallic nanocomposites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 778, 012027. [Google Scholar] [CrossRef]

- Mokhena, T.C.; John, M.J. Cellulose nanomaterials: New generation materials for solving global issues. Cellulose 2019, 27, 1149–1194. [Google Scholar] [CrossRef]

- Muqeet, M.; Mahar, R.B.; Gadhi, T.A.; Halima, N.B. Insight into cellulose-based-nanomaterials—A pursuit of environmental remedies. Int. J. Biol. Macromol. 2020, 163, 1480–1486. [Google Scholar] [CrossRef] [PubMed]

- George, J.; Sabapathi, S.N. Cellulose nanocrystals: Synthesis, functional properties, and applications. Nanotechnol. Sci. Appl. 2015, 8, 45–54. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef]

- Vollick, B.; Kuo, P.Y.; Alizadehgiashi, M.; Yan, N.; Kumacheva, E. From structure to properties of composite films derived from cellulose nanocrystals. ACS Omega 2017, 2, 5928–5934. [Google Scholar] [CrossRef] [PubMed]

- Leng, J.; Li, G.; Ji, X.; Yuan, Z.; Fu, Y.; Li, H.; Qin, M.; Moehwald, H. Flexible latex photonic films with tunable structural colors templated by cellulose nanocrystals. J. Mater. Chem. C 2018, 6, 2396–2406. [Google Scholar] [CrossRef]

- Farooq, A.; Patoary, M.K.; Zhang, M.; Mussana, H.; Li, M.; Naeem, M.A.; Mushtaq, M.; Farooq, A.; Liu, L. Cellulose from sources to nanocellulose and an overview of synthesis and properties of nanocellulose/zinc oxide nanocomposite materials. Int. J. Biol. Macromol. 2020, 154, 1050–1073. [Google Scholar] [CrossRef]

- Stanisławska, A. Bacterial Nanocellulose as a Microbiological Derived Nanomaterial. Adv. Mater. Sci. 2016, 16, 45–57. [Google Scholar] [CrossRef] [Green Version]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S.; et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef] [Green Version]

- Gelir, A.; Yargi, O.; Yuksel, S.A. Elucidation of the pore size and temperature dependence of the oxygen diffusion into porous silicon. Thin Solid Films 2017, 636, 602–607. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Mariano, M.; Gopakumar, D.; Ahmad, I.; Thomas, S.; Dufresne, A.; Huang, J.; Lin, N. Advances in cellulose nanomaterials. Cellulose 2018, 25, 2151–2189. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Daver, F.; Ivanova, E.P.; Habibi, Y.; Adhikari, B. Surface modifications of nanocellulose: From synthesis to high-performance nanocomposites. Prog. Polym. Sci. 2021, 119, 101418. [Google Scholar] [CrossRef]

- Xu, S.H.; Gu, J.; Luo, Y.F.; Jia, D.M. Effects of partial replacement of silica with surface modified nanocrystalline cellulose on properties of natural rubber nanocomposites. Express Polym. Lett. 2012, 6, 14–25. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Sheltami, R.M.; Ahmad, I.; Abdullah, I.; Dufresne, A. Cellulose nanocrystal reinforced liquid natural rubber toughened unsaturated polyester: Effects of filler content and surface treatment on its morphological, thermal, mechanical, and viscoelastic properties. Polymer 2015, 71, 51–59. [Google Scholar] [CrossRef]

- Singh, S.; Dhakar, G.L.; Kapgate, B.P.; Maji, P.K.; Verma, C.; Chhajed, M.; Rajkumar, K.; Das, C. Synthesis and chemical modification of crystalline nanocellulose to reinforce natural rubber composites. Polym. Adv. Technol. 2020, 31, 3059–3069. [Google Scholar] [CrossRef]

- Somseemee, O.; Sae-Oui, P.; Siriwong, C. Reinforcement of surface-modified cellulose nanofibrils extracted from Napier grass stem in natural rubber composites. Ind. Crops Prod. 2021, 171, 113881. [Google Scholar] [CrossRef]

- Mahendra, I.P.; Wirjosentono, B.; Tamrin, T.; Ismail, H.; Mendez, J.A.; Causin, V. The effect of nanocrystalline cellulose and TEMPO-oxidized nanocellulose on the compatibility of polypropylene/cyclic natural rubber blends. J. Thermoplast. Compos. Mater. 2020. published online. [Google Scholar] [CrossRef]

- Noguchi, T.; Niihara, K.I.; Kurashima, A.; Iwamoto, R.; Miura, T.; Koyama, A.; Endo, M.; Marubayashi, H.; Kumagai, A.; Jinnai, H.; et al. Cellulose nanofiber-reinforced rubber composites prepared by TEMPO-functionalization and elastic kneading. Compos. Sci. Technol. 2021, 210, 108815. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Pignon, F.; Do Rego, A.M.; Belgacem, M.N. Influence of ionic interactions between nanofibrillated cellulose and latex on the ensuing composite properties. Compos. Part B Eng. 2016, 85, 188–195. [Google Scholar] [CrossRef]

- Kato, H.; Nakatsubo, F.; Abe, K.; Yano, H. Crosslinking via sulfur vulcanization of natural rubber and cellulose nanofibers incorporating unsaturated fatty acids. RSC Adv. 2015, 5, 29814–29819. [Google Scholar] [CrossRef]

- Jiang, W.; Shen, P.; Yi, J.; Li, L.; Wu, C.; Gu, J. Surface modification of nanocrystalline cellulose and its application in natural rubber composites. J. Appl. Polym. Sci. 2020, 137, 49163. [Google Scholar] [CrossRef]

- Trovatti, E.; Carvalho, A.J.F.; Ribeiro, S.J.L.; Gandini, A. Simple green approach to reinforce natural rubber with bacterial cellulose nanofibers. Biomacromolecules 2013, 14, 2667–2674. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Md Tahir, P.; Lum, W.C.; Tan, L.P.; Bawon, P.; Park, B.-D.; Osman Al Edrus, S.S.; Abdullah, U.H. A review on citric acid as green modifying agent and binder for wood. Polymers 2020, 12, 1692. [Google Scholar] [CrossRef]

- Saini, S.; Belgacem, M.N.; Bras, J. Effect of variable aminoalkyl chains on chemical grafting of cellulose nanofiber and their antimicrobial activity. Mater. Sci. Eng. C 2017, 75, 760–768. [Google Scholar] [CrossRef] [PubMed]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Wolfgang, G.; Bacher, M.; Edler, M.; Griesser, T. Surface chemical functionalization of cellulose nanocrystals by 3-aminopropyltriethoxysilane. Int. J. Biol. Macromol. 2018, 106, 1288–1296. [Google Scholar] [CrossRef] [PubMed]

- Kargarzadeh, H.; Sheltami, R.M.; Ahmad, I.; Abdullah, I.; Dufresne, A. Cellulose nanocrystal: A promising toughening agent for unsaturated polyester nanocomposite. Polymer 2015, 56, 346–357. [Google Scholar] [CrossRef]

- Pierre, G.; Punta, C.; Delattre, C.; Melone, L.; Dubessay, P.; Fiorati, A.; Pastori, N.; Galante, Y.M.; Michaud, P. TEMPO-mediated oxidation of polysaccharides: An ongoing story. Carbohydr. Polym. 2017, 165, 71–85. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Isogai, A.; Zhou, Y. Diverse nanocelluloses prepared from TEMPO-oxidized wood cellulose fibers: Nanonetworks, nanofibers, and nanocrystals. Curr. Opin. Solid State Mater. Sci. 2019, 23, 101–106. [Google Scholar] [CrossRef]

- Markets and Markets. Industrial Rubber Market by Application (Automotive, Building & Construction, Industrial Manufacturing, Polymer Modification, Wire & Cable, Electrical & Electronics, Bitumen Modification), Type, Product, and Region—Global Forecast to 2022. Available online: https://www.marketsandmarkets.com/Market-Reports/industrial-rubber-market-42187401.html (accessed on 23 August 2021).

- Oksman, K. Nanocelluloses and their use in composite materials. Express Polym. Lett. 2012, 6, 687. [Google Scholar] [CrossRef]

- Siro, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Roy, K.; Pongwisuthiruchte, A.; Debnath, S.C.; Potiyaraj, P. Application of cellulose as green filler for the development of sustainable rubber technology. Curr. Res. Green Sustain. Chem. 2021, 4, 100140. [Google Scholar] [CrossRef]

- Dominic, M.; Joseph, R.; Begum, P.S.; Kanoth, B.P.; Chandra, J.; Thomas, S. Green tire technology: Effect of rice husk derived nanocellulose (RHNC) in replacing carbon black (CB) in natural rubber (NR) compounding. Carbohydr. Polym. 2020, 230, 115620. [Google Scholar] [CrossRef] [PubMed]

| Filler/Source | Treatments | Variables | Properties Tested and Findings | References |

|---|---|---|---|---|

| Carbon black (N220), silica | - | Carbon black to silica ratio (30:15, 40:15, 50:15) | Tensile and Tear Strength Generally, tensile and tear strength increased as the carbon black to silica ratio increased and peaked at 40 phr carbon black content before decreased slightly. Abrasion Resistance and Modulus The composite with the highest carbon black content (50 phr) exhibited the highest abrasion resistant index (ARI) and modulus. The ARI and modulus increased proportionally to the carbon black content. | [13] |

| Carbon black | - | Type of carbon black (HAF and ECF) | Curing Characteristic The cure rate index (CRI) for rubber composite added with both type of carbon black showed significant lower value than rubber composite without reinforcement. Tensile Strength Both types of carbon black filler (HAF and ECF) decreased the tensile strength of natural rubber composite. | [14] |

| Carbon black | N-tert-butyl-2-benzothiazole sulfenamide (TBBS) | TTBS concentration (1.0, 1.4, 1.8, 2.2, 2.6 phr) | Curing Characteristic The cure rate index (CRI) was similar between carbon black (40 phr) and silica (3.2 phr) filled rubber composite. The CRI decreased with increasing TTBS concentration. Tensile Strength and Modulus Tensile strength and modulus of carbon black filled rubber composite (40 phr) showed higher tensile strength than silica reinforced rubber composite (3.2 phr) for all TTBS concentration. The tensile strength for carbon black filled rubber composite peaked at 2.0 phr TTBS concentration then decreased with higher concentration, while the modulus value continued to increase with increasing concentration. | [15] |

| Nanocellulose | Surface Modification | Nanocomposite | Findings | References |

|---|---|---|---|---|

| Nanocrystalline cellulose (NCC) from commercial microcrystalline cellulose (MCC) | Silylation—3-aminopropyl-triethoxysilane | Natural rubber (NR)/NCC/silica nanocomposite at different ratios of NCC and silica (0:30, 5:25, 10:20, 15:15, 20:10 and 25:5) |

| [52] |

| Cellulose nanocrystals (CNC) from kenaf bast fiber | Silylation—0.5 wt% silane | CNC reinforced unsaturated polyester resins (UPR) toughened with liquid natural rubber (LNR) at 2, 4 and 6 wt% CNC content |

| [53] |

| Crystalline nanocellulose (CNC) from ramie fiber | Silylation—Different organosilanes: (3-Aminopropyl)triethoxysilane (APTES), 3-aminopropyl-triethoxysilane, bis[3-(triethoxysilyl)propyl] tetrasulfide (TESPT), (3-mercaptopropyl) trimethoxysilane (MPTMS) | Natural rubber (NR)/CNC nanocomposite at 2.5 and 5 wt% CNC content |

| [54] |

| Cellulose nanofibrils (CNF) from Napier grass stem | Silylation—Bis-(triethoxysilyl-propyl) tetrasulfide (TESPT) | Natural rubber (NR)/CNF nanocomposite at 0.5, 1, 3, 5 and 10 wt% filler loading |

| [55] |

| Nanocrystalline cellulose (NCC) and nanofiber cellulose (NFC) from lower part of empty fruit bunches | TEMPO-mediated oxidation—2,2,6,6-tetramethyl-1-piperidinyloxyl | Polypropylene (PP)/cyclic natural rubber (CNR)/NCC or NFC nanocomposite with 1, 2 and 3 wt% NCC content |

| [56] |

| Commercial cellulose nanofibers (CNF) | TEMPO-mediated oxidation—2,2,6,6-tegramethylpyperidine-1-oxyl | TEMPO-CNF/ nitrile-butadiene rubber (NBR) and sheets and carboxy group-containing nitrile-butadiene rubber (XNBR) composite |

| [57] |

| Nanofibrillated cellulose (NFC) from bleached softwood bisulfite pulp | TEMPO-mediated oxidation—2,2,6,6-tetramethylpiperidine-1-oxyl | NFC reinforced latex nanocomposite at 1, 2, 3, 4 and 5 wt% NFC content |

| [58] |

| Cellulose Nanocrystals (CNC) from cotton cellulose | Esterification of thiols—mercaptoundecanoic acid mixed with acetic anhydride, glacial acetic acid, and concentrated sulfuric acid | Natural rubber/CNC nanocomposite at 2, 5 and 10 wt% CNC content |

| [34] |

| Cellulose nanofibers (CNF) from never-dried bleached softwood kraft pulp | Esterification—unsaturated fatty acids (oleic acid and stearic acid) | sulfur-vulcanized natural rubber reinforced with CNF at 1, 3 and 5 wt% |

| [59] |

| Nanocrystalline cellulose (NCC) from softwood pulp | Non-covalent surface modification—cationic surfactant, cetyltrimethyl ammonium bromide (CTMAB) | Natural rubber (NR) composite reinforced with NCC at 5, 10, 15 and 20 wt% |

| [60] |

| Bacterial cellulose (BC) from modified Hestrin Shran liquid culture medium | Admicelar polymerization of styrene at the surface of the BC nanofibers | Natural-rubber based nanocomposites reinforced with bacterial cellulose (BC) and bacterial cellulose coated with polystyrene (BCPS) at 1, 2.5, 5 and 10 wt% |

| [61] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hakimi, N.M.F.; Lee, S.H.; Lum, W.C.; Mohamad, S.F.; Osman Al Edrus, S.S.; Park, B.-D.; Azmi, A. Surface Modified Nanocellulose and Its Reinforcement in Natural Rubber Matrix Nanocomposites: A Review. Polymers 2021, 13, 3241. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13193241

Hakimi NMF, Lee SH, Lum WC, Mohamad SF, Osman Al Edrus SS, Park B-D, Azmi A. Surface Modified Nanocellulose and Its Reinforcement in Natural Rubber Matrix Nanocomposites: A Review. Polymers. 2021; 13(19):3241. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13193241

Chicago/Turabian StyleHakimi, Nik Muhammad Faris, Seng Hua Lee, Wei Chen Lum, Siti Fatahiyah Mohamad, Syeed SaifulAzry Osman Al Edrus, Byung-Dae Park, and Anis Azmi. 2021. "Surface Modified Nanocellulose and Its Reinforcement in Natural Rubber Matrix Nanocomposites: A Review" Polymers 13, no. 19: 3241. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13193241