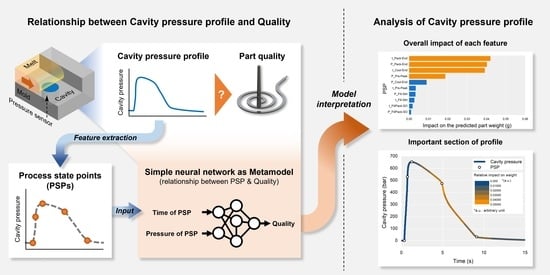

Novel Analysis Methodology of Cavity Pressure Profiles in Injection-Molding Processes Using Interpretation of Machine Learning Model

Abstract

:1. Introduction

2. Methodology

3. Experiment

3.1. Polymer Material

3.2. Injection Mold and Molding Machine

3.3. Experimental Conditions

4. Modeling and Analysis

4.1. Process State Points (PSPs)

4.2. Neural Network Model

4.3. Analysis of Neural Network Model

5. Results and Discussion

5.1. Model Quality

5.2. Interpretation of Cavity Pressure Profile

5.3. Validity Check

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kazmer, D.O. Dynamic Feed Control: A New Method for Injection Molding of High Quality Plastic Parts. Ph.D. Dissertation, Stanford University, Stanford, CA, USA, June 1995. [Google Scholar]

- Ageyeva, T.; Horváth, S.; Kovács, J.G. In-mold sensors for injection molding: On the way to industry 4.0. Sensors 2019, 19, 3551. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, P.; Zhang, J.; Dong, Z.; Huang, J.; Zhou, H.; Fu, J.; Turng, L.-S. Intelligent injection molding on sensing, optimization, and control. Adv. Polym. Technol. 2020, 2020, 7023616. [Google Scholar] [CrossRef] [Green Version]

- Gordon, G.; Kazmer, D.O.; Tang, X.-Y.; Fan, Z.-Y.; Gao, R.X. Validation of an in-mold multivariate sensor for measurement of melt temperature, pressure, velocity, and viscosity. Int. Polym. Proc. 2017, 32, 406–415. [Google Scholar] [CrossRef]

- Gim, J.; Tae, J.; Jeon, J.; Han, E.; Kim, B.; Rhee, B. The real-time determination algorithm of mold temperature stabilization. In Proceedings of the Society of Plastics Engineers’ Annual Technical Conference (SPE ANTEC), Orlando, FL, USA, 23–25 March 2015. [Google Scholar]

- Gao, R.X.; Tang, X.; Gordon, G.; Kazmer, D.O. Online product qualiy monitoring through in-process measurement. CIRP Ann. Manuf. Technol. 2014, 63, 493–496. [Google Scholar] [CrossRef]

- Han, E.; Gim, J.; Kim, B.; Rhee, B. Examination of the melt temperature stability of the mold-type slit rheometer affected by plasticizing conditions and the shear heating in the nozzle and sprue. Korea Aust. Rheol. J. 2021, 32, 151–162. [Google Scholar] [CrossRef]

- Friesenbichler, W.; Duretek, I.; Rajganesh, J.; Kumar, S.R. Measuring the pressure dependent viscosity at high shear rates using a new rheological injection mould. Polymery 2011, 56, 58–62. [Google Scholar] [CrossRef]

- Menges, G.; Michaeli, W.; Mohren, P. How to Make Injection Molds, 3rd ed.; Hanser Gardner Publications, Inc.: Cincinnati, OH, USA, 2000; pp. 543–551. [Google Scholar]

- Collins, C. Monitoring cavity pressure perfects injection molding. Assem. Autom. 1999, 19, 197–202. [Google Scholar] [CrossRef]

- Gao, F.; Yang, Y. Injection molding control. In Injection Molding Technology and Fundamentals; Kamal, M.R., Isayev, A.I., Liu, S.-J., White, J.L., Eds.; Hanser Publications, Inc.: Cincinnati, OH, USA, 2009; pp. 439–510. [Google Scholar]

- Kim, B.; Gim, J.; Han, E.; Rhee, B. Development of the vent clogging monitoring method for injection molding. CIRP J. Manuf. Sci. Technol. 2021, 32, 277–286. [Google Scholar] [CrossRef]

- Gim, J.-S.; Tae, J.-S.; Jeon, J.-H.; Choi, J.-H.; Rhee, B.-O. Detection method of filling imbalance in a multi-cavity mold for small lens. Int. J. Precis. Eng. Manuf. 2015, 16, 531–535. [Google Scholar] [CrossRef]

- Chen, Z.; Turng, L.-S.; Wang, K.-K. Adaptive online quality control for injection-molding by monitoring and controlling mold separation. Polym. Eng. Sci. 2006, 46, 569–580. [Google Scholar] [CrossRef]

- Debey, D.; Bluhm, R.; Habets, N.; Kurz, H. Fabrication of planar thermocouples for real-time measurements of temperature profiles in polymer melts. Sens. Actuators A 1997, 58, 179–184. [Google Scholar] [CrossRef]

- Peng, Y.; Li, H.; Turng, L.-S. Development of a rheo-dielectric sensor for online shear stress measurement during the injection molding process. Polym. Eng. Sci. 2010, 50, 61–68. [Google Scholar] [CrossRef]

- Chen, X.; Gao, F. Profiling of injection velocity for uniform mold filling. Adv. Polym. Technol. 2006, 25, 1321. [Google Scholar] [CrossRef]

- Chen, W.-C.; Liou, P.-H.; Chou, S.-C. An integrated parameter optimization system for MIMO plastic injection molding using soft computing. Int. J. Adv. Manuf. Technol. 2014, 73, 1465–1474. [Google Scholar] [CrossRef]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. modeling and optimization of the injection-molding process: A review. Adv. Polym. Technol. 2018, 37, 21683. [Google Scholar] [CrossRef]

- Mehat, N.M.; Kamaruddin, S. Investigating the effects of injection molding parameters on the mechanical properties of recycled plastic parts using the taguchi method. Mater. Manuf. Processes. 2011, 26, 202–209. [Google Scholar] [CrossRef]

- Altan, M. Reducing shrinkage in injection moldings via the taguchi, ANOVA and neural network methods. Mater. Des. 2010, 31, 599–604. [Google Scholar] [CrossRef]

- Ozcelik, B.; Erzurumlu, T. Comparison of the warpage optimization in the plastic injection molding using ANOVA, neural network model and genetic algorithm. J. Mater. Process. Techol. 2006, 171, 437–445. [Google Scholar] [CrossRef]

- Oliaei, E.; Heidari, B.S.; Davachi, S.M.; Bahrami, M.; Davoodi, S.; Hejazi, I.; Seyfi, J. Warpage and shrinkage optimization of injection-molded plastic spoon parts for biodegradable polymers using taguchi, ANOVA and artificial neural network method. J. Mater. Sci. Technol. 2016, 32, 710–720. [Google Scholar] [CrossRef]

- Abdul, R.; Guo, G.; Chen, J.C.; Yoo, J.J.-W. Shrinkage prediction of injection molded high density polyethylene parts with Taguchi/artificial neural network hybrid experimental design. Int. J. Interact. Des. Manuf. 2019, 14, 345–357. [Google Scholar] [CrossRef]

- Li, K.; Yan, S.; Pan, W.; Zhao, G. Warpage optimization of fiber-reinforced composite injection molding by combining back propagation neural network and genetic algorithm. Int. J. Adv. Manuf. Technol. 2017, 90, 963–970. [Google Scholar] [CrossRef]

- Guo, F.; Zhou, X.; Liu, J.; Zhang, Y.; Li, D.; Zhou, H. A reinforcement learning decision model for online process parameters optimization from offline data in injection molding. Appl. Soft. Comput. 2019, 85, 105828. [Google Scholar] [CrossRef]

- Shi, H.; Xie, S.; Wang, X. A warpage optimization method for injection molding using artificial neural network with parameteric sampling evaluation strategy. Int. J. Adv. Manuf. Technol. 2013, 65, 343–353. [Google Scholar] [CrossRef]

- Tercan, H.; Guajardo, A.; Heinisch, J.; Thiele, T.; Hopmann, C.; Meisen, T. Transfer-learning: Bridging the gap between real and simulation data for machine leaning in injection molding. Procedia CIRP 2018, 72, 185–190. [Google Scholar] [CrossRef]

- Lee, C.; Na, J.; Park, K.; Yu, H.; Kim, J.; Choi, K.; Park, D.; Park, S.; Rho, J.; Lee, S. Development of artifical neural network system to recommend process conitions of injection molding for various geometries. Adv. Intell. Syst. 2020, 2, 2000037. [Google Scholar] [CrossRef]

- Tsai, K.-M.; Luo, H.-J. Comparison of injection molding process windows for plastic lens established by artificial neural network and response surface methodology. Int. J. Adv. Manuf. Techol. 2015, 77, 1599–1611. [Google Scholar] [CrossRef]

- Changyu, S.; Lixia, W.; Qian, L. Optimization of injection molding process parameters using combination of artificial neural network and genetic algorithm method. J. Mater. Process Technol. 2007, 183, 412–418. [Google Scholar] [CrossRef]

- Gim, J.; Rhee, B. Generation mechanism of gloss defect for high-glossy injection-molded surface. Korea Aust. Rheol. J. 2020, 32, 183–194. [Google Scholar] [CrossRef]

- Chen, Z.; Turng, L.-S. Injection molding quality control by integrating weight feedback into a cascade closed-loop control system. Polym. Eng. Sci. 2007, 47, 852–862. [Google Scholar] [CrossRef]

- Gim, J.; Han, E.; Rhee, B.; Friesenbichler, W.; Gruber, D.P. Causes of the gloss transition defect on high-gloss injection-molded surfaces. Polymers 2020, 12, 2100. [Google Scholar] [CrossRef]

- Kazmer, D.O.; Velusamy, S.; Westerdale, S.; Johnston, S.; Gao, R.X. A comparison of seven filling to packing switchover methods for injection molding. Polym. Eng. Sci. 2010, 50, 2031–2043. [Google Scholar] [CrossRef]

- Zhao, C.; Gao, F. Melt temperature profile prediction for thermoplastic injection molding. Polym. Eng. Sci. 1999, 39, 1787–1801. [Google Scholar] [CrossRef]

- Chung, F.-L.; Fu, T.-C.; Ng, V.; Luk, R.W.P. An evolutionary approach to pattern-based time series segmentation. IEEE Trans. Evol. Comput. 2004, 8, 471–489. [Google Scholar] [CrossRef]

- Lockner, Y.; Hopmann, C. Induced network-based transfer learning in injection molding for process modelling and optimization with artificial neural networks. Int. J. Adv. Manuf. Technol. 2021, 112, 3501–3513. [Google Scholar] [CrossRef]

- Nair, V.; Hinton, G.E. Rectified linear units improve restricted boltzmann machines. In Proceedings of the 27th International Conference on Machine Learning (ICML), Haifa, Israel, 21–24 June 2010. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Delving deep rectifiers: Surpassing human-level performance on ImageNet classification. In Proceedings of the 2015 IEEE International Conference on Computer Vision (ICCV 2015), Santiago, Chile, 11–18 December 2015. [Google Scholar] [CrossRef] [Green Version]

- Kingma, D.P.; Ba, J.L. Adam: A method for stochastic optimization. In Proceedings of the 3rd International Conference on Learning Representations (ICLR), San Diego, CA, USA, 7–9 May 2015. [Google Scholar]

- Ribeiro, M.T.; Singh, S.; Guestrin, C. Model-agnostic interpretability of machine learning. In Proceedings of the 2016 ICML Workshop on Human Interpretability in Machine Learning (WHI 2016), New York, NY, USA, 23 June 2016. [Google Scholar]

- Kashyap, S.; Datta, D. Process parameter optimization of plastic injection molding: A review. Int. J. Plast. Technol. 2015, 19, 1–18. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, Y.; Mao, T.; Ruan, Y.; Gao, H.; Zhou, H. Feature extraction and physical interpretation of melt pressure during injection molding process. J. Mater. Process Technol. 2018, 261, 50–60. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Erion, G.; Chen, H.; DeGrave, A.; Prutkin, J.M.; Nair, B.; Katz, R.; Himmelfarb, J.; Bansal, N.; Lee, S.-I. From local explanations to global understanding with explainable AI for trees. Nat. Mach. Intell. 2020, 2, 56–67. [Google Scholar] [CrossRef]

- Covert, I.C.; Lundberg, S.; Lee, S.-I. Feature removal is a unifying principle for model explanation methods. In Proceedings of the Machine Learning Retrospectives, Surveys & Meta-Analyses (ML-RSA) Workshop at NeurIPS 2020, Online, 11 December 2020. [Google Scholar]

- Chen, X.; Gao, F. A study of packing profile on injection molded part quality. Mater. Sci. Eng. A 2003, 358, 205–213. [Google Scholar] [CrossRef]

- Tsai, K.-M.; Luo, H.-J. An inverse model for injection molding of optical lens using artificial neural network coupled with genetic algorithm. J. Intell. Manuf. 2017, 28, 473–487. [Google Scholar] [CrossRef]

- Xie, P.C.; Wang, X.H.; Wu, T.; Ding, Y.M.; Yang, W.M. Study on packing phase control based on the cavity pressure-temperature during injection molding. Int. Polym. Proc. 2014, 29, 184–190. [Google Scholar] [CrossRef]

| Process Parameter | Levels | Values |

|---|---|---|

| Injection speed (mm/s) | 5 | 30, 40, 50, 60, 70 |

| Packing pressure (bar) | 5 | 800, 900, 1000, 1100, 1200 |

| Packing time (s) | 4 | 2, 3, 4, 5 |

| Name | Meaning |

|---|---|

| Fill-Strt | Start point of filling stage |

| FillPack-SO | Switchover point from filling to packing stage |

| Prs-Peak | Maximum point of cavity pressure |

| Pack-End | Endpoint of packing stage |

| Cool-End | End of cooling stage |

| Parameter | Value or Setting | Note |

|---|---|---|

| Number of layers | 3 | Single hidden layer |

| Input layer neurons | 10 | Time and pressure values of the extracted PSPs |

| Hidden layer neurons | 8 | Single digit number of neurons |

| Hidden layer activation | ReLU | [39] |

| Hidden layer initialization | He_Normal | [40] |

| Optimizer | Adamax | [41] |

| Loss for training | Mean square error | |

| Maximal training iteration | 10,000 epochs |

| Design Parameters | Degree of Freedom | Sum of Squares | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| Injection speed | 4 | 0.027084 | 0.006771 | 133.20 | 0.000 |

| Packing pressure | 4 | 0.147199 | 0.036800 | 723.93 | 0.000 |

| Packing time | 3 | 0.834256 | 0.278085 | 5470.53 | 0.000 |

| Error | 200 | 0.010167 | 0.000051 | ||

| Total | 299 | 1.044250 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gim, J.; Rhee, B. Novel Analysis Methodology of Cavity Pressure Profiles in Injection-Molding Processes Using Interpretation of Machine Learning Model. Polymers 2021, 13, 3297. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13193297

Gim J, Rhee B. Novel Analysis Methodology of Cavity Pressure Profiles in Injection-Molding Processes Using Interpretation of Machine Learning Model. Polymers. 2021; 13(19):3297. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13193297

Chicago/Turabian StyleGim, Jinsu, and Byungohk Rhee. 2021. "Novel Analysis Methodology of Cavity Pressure Profiles in Injection-Molding Processes Using Interpretation of Machine Learning Model" Polymers 13, no. 19: 3297. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13193297