The Crystallisation, Microphase Separation and Mechanical Properties of the Mixture of Ether-Based TPU with Different Ester-Based TPUs

Abstract

:1. Introduction

2. Experiment

2.1. Materials and Blend Preparation

2.2. Gel Permeation Chromatography

2.3. Differential Scanning Calorimetry (DSC)

2.4. Wide-Angle X-ray and Small-Angle X-ray Scattering

2.5. Atomic Force Microscope (AFM)

2.6. Mechanical Testing

2.7. Hardness Test

3. Results and Discussion

3.1. The Non-Isothermal Crystallization Dynamics of TPU and Their Blends

3.2. The Melting Behavior of TPU and Their Blends

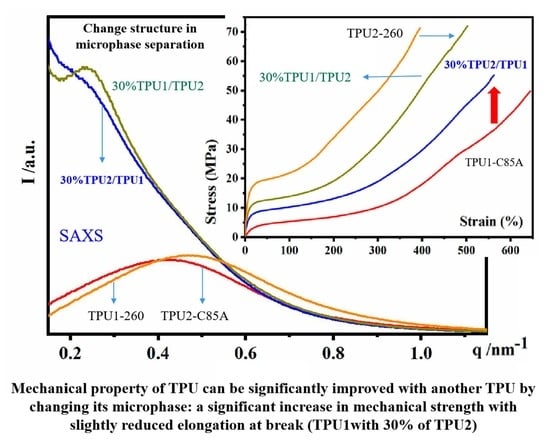

3.3. Microphase Separation Structure of TPU and Their Blends

3.4. Mechanical Properties of TPU and Their Blends

3.5. Atomic Force Microscopy (AFM) Phase Images of TPU and Their Blends

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, Q.-W.; Macosko, C.W. Comparing the Compatibility of Various Functionalized Polypropylenes with Thermoplastic Polyurethane (TPU). Polymer 2004, 45, 1981–1991. [Google Scholar] [CrossRef]

- Shi, Y.; Que, Y.-H.; Wang, Y.-X.; Liu, L.-Z. A method for adjusting the microphase separation structure and mechanical properties of TPU through physical blending. CHINESE patent application number 202110917892.1, 11 August 2021. [Google Scholar]

- Kim, Y.; Cho, W.-J.; Ha, C.-S. Dynamic Mechanical and Morphological Studies on the Compatibility of Plasticized PVC/Thermoplastic Polyurethane Blends. J. Appl. Polym. Sci. 1999, 71, 415–422. [Google Scholar] [CrossRef]

- Feng, F.; Ye, L. Morphologies and Mechanical Properties of Polylactide/Thermoplastic Polyurethane Elastomer Blends. J. Appl. Polym. Sci. 2011, 119, 2778–2783. [Google Scholar] [CrossRef]

- Kojio, K.; Furukawa, M.; Nonaka, Y.; Nakamura, S. Control of Mechanical Properties of Thermoplastic Polyurethane Elastomers by Restriction of Crystallization of Soft Segment. Materials 2010, 3, 5097–5110. [Google Scholar] [CrossRef]

- Bagdi, K.; Molnar, K.; Sajo, I.; Pukanszky, B. Specific Interactions, Structure and Properties in Segmented Polyurethane Elastomers. Express Polym. Lett. 2011, 5, 417–427. [Google Scholar] [CrossRef]

- Amirkhosravi, M.; Yue, L.; Ju, T.; Manas-Zloczower, I. Designing Thermal Annealing to Control Mechanical Performance of Thermoplastic Polyurethane Elastomers. Polymer 2021, 214, 123254. [Google Scholar] [CrossRef]

- Stribeck, A.; Pöselt, E.; Eling, B.; Jokari-Sheshdeh, F.; Hoell, A. Thermoplastic Polyurethanes with Varying Hard-Segment Components. Mechanical Performance and a Filler-Crosslink Conversion of Hard Domains as Monitored by SAXS. Eur. Polym. J. 2017, 94, 340–353. [Google Scholar] [CrossRef]

- Li, X.; Wang, H.; Xiong, B.; Pöselt, E.; Eling, B.; Men, Y. Destruction and Reorganization of Physically Cross-Linked Network of Thermoplastic Polyurethane Depending on Its Glass Transition Temperature. ACS Appl. Polym. Mater. 2019, 1, 3074–3083. [Google Scholar] [CrossRef]

- Liow, S.S.; Lipik, V.T.; Widjaja, L.K.; Venkatraman, S.S.; Abadie, M.J.M. Enhancing Mechanical Properties of Thermoplastic Polyurethane Elastomers with 1,3-Trimethylene Carbonate, Epsilon-Caprolactone and L-Lactide Copolymers via Soft Segment Crystallization. Express Polym. Lett. 2011, 5, 897–910. [Google Scholar] [CrossRef]

- Mossi Idrissa, A.K.; Wang, K.; Ahzi, S.; Patlazhan, S.; Rémond, Y. A Composite Approach for Modeling Deformation Behaviors of Thermoplastic Polyurethane Considering Soft-Hard Domains Transformation. Int. J. Mater. Form. 2018, 11, 381–388. [Google Scholar] [CrossRef]

- Yuan, X.; Sang, Z.; Zhao, J.; Zhang, Z.; Zhang, J.; Cheng, J. Synthesis and Properties of Non-Isocyanate Aliphatic Thermoplastic Polyurethane Elastomers with Polycaprolactone Soft Segments. J. Polym. Res. 2017, 24, 88. [Google Scholar] [CrossRef]

- Puszka, A.; Kultys, A. New Thermoplastic Polyurethane Elastomers Based on Aliphatic Diisocyanate: Synthesis and Characterization. J. Anal. Calorim. 2017, 128, 407–416. [Google Scholar] [CrossRef] [Green Version]

- Herrera, M.; Matuschek, G.; Kettrup, A. Thermal Degradation of Thermoplastic Polyurethane Elastomers (TPU) Based on MDI. Polym. Degrad. Stab. 2002, 78, 323–331. [Google Scholar] [CrossRef]

- Koerner, H.; Kelley, J.J.; Vaia, R.A. Transient Microstructure of Low Hard Segment Thermoplastic Polyurethane under Uniaxial Deformation. Macromolecules 2008, 41, 4709–4716. [Google Scholar] [CrossRef]

- Xiang, N.; Zhang, X.; Zheng, M.; Xu, R.; Yan, Y. Investigation of Tensile Behavior and Molecular Structure of the Thermoplastic Polyurethane Sheets Injection Molded at Different Mold Temperatures. J. Appl. Polym. Sci. 2021, 138, 50959. [Google Scholar] [CrossRef]

- Holt, A.; Ke, Y.; Bramhall, J.A.; Crane, G.; Grubbs, J.B.; White, E.M.; Horn, J.; Locklin, J. Blends of Poly(Butylene Glutarate) and Poly(Lactic Acid) with Enhanced Ductility and Composting Performance. ACS Appl. Polym. Mater. 2021, 3, 1652–1663. [Google Scholar] [CrossRef]

- Ignacz, G.; Fei, F.; Szekely, G. Ion-Stabilized Membranes for Demanding Environments Fabricated from Polybenzimidazole and Its Blends with Polymers of Intrinsic Microporosity. ACS Appl. Nano Mater. 2018, 1, 6349–6356. [Google Scholar] [CrossRef]

- Caradant, L.; Lepage, D.; Nicolle, P.; Prébé, A.; Aymé-Perrot, D.; Dollé, M. Effect of Li + Affinity on Ionic Conductivities in Melt-Blended Nitrile Rubber/Polyether. ACS Appl. Polym. Mater. 2020, 2, 4943–4951. [Google Scholar] [CrossRef]

- Barlow, J.W.; Paul, D.R. Polymer Blends and Alloys—A Review of Selected Considerations. Polym. Eng. Sci. 1981, 21, 985–996. [Google Scholar] [CrossRef]

- Billingham, N.C. Degradation and Stabilization of Polymers: Vol. 2: H. H. G. Jellinek (ed) Elsevier Science Publishers, Amsterdam, 1989, 720 pages, $234.25/DFI 445.00 ISBN 0-444-87402-X. Polymer 1990, 31, 2220. [Google Scholar] [CrossRef]

- Santra, R.N.; Chaki, T.K.; Roy, S.; Nando, G.B. Studies on miscibility of blends of thermoplastic polyurethane and poly(ethy1ene-co-methyl acrylate). Angew. Makromol. Chem. 1993, 213, 7–13. [Google Scholar] [CrossRef]

- Maity, M.; Das, C.K.; Pandey, K.N.; Mathur, G.N. Polyblends of Polyurethane and EVA Elastomers (Peroxide Cure). Int. J. Polym. Mater. 2000, 45, 123–133. [Google Scholar] [CrossRef]

- Bajsić, E.G.; Šmit, I.; Leskovac, M. Blends of Thermoplastic Polyurethane and Polypropylene. I. Mechanical and Phase Behavior. J. Appl. Polym. Sci. 2007, 104, 3980–3985. [Google Scholar] [CrossRef]

- Wang, X.; Luo, X. A Polymer Network Based on Thermoplastic Polyurethane and Ethylene–Propylene–Diene Elastomer via Melt Blending: Morphology, Mechanical Properties, and Rheology. Eur. Polym. J. 2004, 40, 2391–2399. [Google Scholar] [CrossRef]

- Tschke, P.P.; Wallheinke, K.A.; Fritsche, H.; Stutz, H. Morphology and Properties of Blends with Different Thermoplastic Polyurethanes and Polyolefines. J. Appl. Polym. Sci. 2015, 64, 749–762. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, H.; Zhang, H.; Mo, Z. Miscibility, Crystallization Behaviors and Toughening Mechanism of Poly(Butylene Terephthalate)/Thermoplastic Polyurethane Blends. Fibers Polym. 2018, 19, 1–10. [Google Scholar] [CrossRef]

- Poomalai, P. Siddaramaiah Studies on Poly(Methyl Methacrylate) (PMMA) and Thermoplastic Polyurethane (TPU) Blends. J. Macromol. Sci. Part A 2005, 42, 1399–1407. [Google Scholar] [CrossRef]

- Fang, W.; Fan, X.; Jiao, H.; Jin, Z.; Yuan, W.; Zhang, A.; Zhou, T. Characterization and Properties of Thermoplastic Polyether Elastomer/Polyoxymethylene Blends Prepared by Melt-Mixing Method. Polym. Sci. Ser. A 2019, 61, 890–896. [Google Scholar] [CrossRef]

- Dutta, J.; Naskar, K. Investigation of Morphology, Mechanical, Dynamic Mechanical and Thermal Behaviour of Blends Based on Ethylene Vinyl Acetate (EVA) and Thermoplastic Polyurethane (TPU). RSC Adv. 2014, 4, 60831–60841. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, G.-H. Effect of Rubber Content on Abrasion Resistance and Tensile Properties of Thermoplastic Polyurethane (TPU)/Rubber Blends. Macromol. Res. 2014, 22, 523–527. [Google Scholar] [CrossRef]

- Zhang, B.-F.; Zhang, M.; Ge, Z.-H.; Xia, Q.; Li, M. Influence of the Molecular Structure of the Thermoplastic Polyurethanes on Their Thermal Stability. Mater. Rev. 2012, 26, 277–280, China. [Google Scholar]

- Li, L.-M.; Li, W.-G.; Huang, X.-G. Heat treatment on the properties and microphase separation of thermoplastic polyhelium ester. Polyurethane Ind. 2004, 19, 9–11. [Google Scholar]

- Yoon, P.J.; Han, C.D. Effect of Thermal History on the Rheological Behavior of Thermoplastic Polyurethanes. Macromolecules 2000, 33, 2171–2183. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Bai, J.; Chua, C.K.; Wei, J.; Zhou, K. 3D Soft Auxetic Lattice Structures Fabricated by Selective Laser Sintering: TPU Powder Evaluation and Process Optimization. Mater. Des. 2017, 120, 317–327. [Google Scholar] [CrossRef]

- Shahrousvand, M.; Sadeghi, G.M.M.; Shahrousvand, E.; Ghollasi, M.; Salimi, A. Superficial Physicochemical Properties of Polyurethane Biomaterials as Osteogenic Regulators in Human Mesenchymal Stem Cells Fates. Colloids Surf. B Biointerfaces 2017, 156, 292–304. [Google Scholar] [CrossRef]

| Sample | Diisocyanate | Diols | HSC (wt.%) | Shore Hardness | Mw (×105 g·mol−1) | Mw/Mn | Melt Flow Rate (g·10 min−1) * |

|---|---|---|---|---|---|---|---|

| ES260 | TDI | PBT | 33 | 60D | 1.57 | 3.12 | 29.8 |

| ESC85A | MDI | PBS | 33 | 87A | 2.57 | 3.32 | 33.3 |

| ET1180A | MDI | PTHF | 25 | 80A | 1.83 | 2.17 | 22.4 |

| ESC85A/ES260 Blends (wt.%) | ET1180A/ES260 Blends (wt.%) | Moulding Temperature (°C) |

|---|---|---|

| 100/0 | 100/0 | 210 |

| 70/30 | 70/30 | 210 |

| 50/50 | 50/50 | 215 |

| 30/70 | 30/70 | 220 |

| 0/100 | 0/100 | 220 |

| Scheme | Yield Strength (MPa) | Elongation at Break (%) | Shore D Hardness |

|---|---|---|---|

| ES C85A | 3.5 ± 0.7 | 644.7 ± 30.1 | 29.5 ± 0.2 |

| ET 1180A | 3.6 ± 0.3 | 638.7 ± 27.5 | 27.2 ± 0.5 |

| ES 260 | 18.2 ± 0.1 | 395.6 ± 25.6 | 52.7 ± 0.9 |

| ES C85A/ES 260 = 7:3 | 8.5 ± 0.3 | 562.1 ± 30.5 | 38.5 ± 0.7 |

| ES C85A/ES 260 = 5:5 | 11.8 ± 0.2 | 520.4 ± 28.4 | 47.0 ± 0.2 |

| ES C85A/ES 260 = 3:7 | 11.9 ± 0.4 | 502.9 ± 29.3 | 50.0 ± 0.4 |

| ET 1180A/ES 260 = 7:3 | 5.4 ± 0.6 | 525.6 ± 29.7 | 31.5 ± 0.3 |

| ET 1180A/ES 260 = 5:5 | 7.3 ± 0.3 | 423.8 ± 26.4 | 38.8 ± 0.4 |

| ET 1180A/ES 260 = 3:7 | 14.3 ± 0.5 | 469.2 ± 27.3 | 46.3 ± 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Que, Y.-H.; Shi, Y.; Liu, L.-Z.; Wang, Y.-X.; Wang, C.-C.; Zhang, H.-C.; Han, X.-Y. The Crystallisation, Microphase Separation and Mechanical Properties of the Mixture of Ether-Based TPU with Different Ester-Based TPUs. Polymers 2021, 13, 3475. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13203475

Que Y-H, Shi Y, Liu L-Z, Wang Y-X, Wang C-C, Zhang H-C, Han X-Y. The Crystallisation, Microphase Separation and Mechanical Properties of the Mixture of Ether-Based TPU with Different Ester-Based TPUs. Polymers. 2021; 13(20):3475. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13203475

Chicago/Turabian StyleQue, Yu-Hui, Ying Shi, Li-Zhi Liu, Yuan-Xia Wang, Chen-Chen Wang, Hai-Chao Zhang, and Xu-Yang Han. 2021. "The Crystallisation, Microphase Separation and Mechanical Properties of the Mixture of Ether-Based TPU with Different Ester-Based TPUs" Polymers 13, no. 20: 3475. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13203475