Investigations on Epoxy-Carbamate Foams Modified with Different Flame Retardants for High-Performance Applications

Abstract

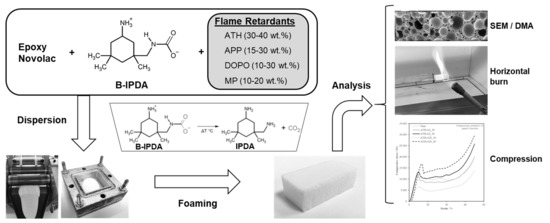

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

2.2.1. Dispersion

2.2.2. Foaming and Specimen Preparation

2.2.3. Characterization Methods

3. Results

3.1. Fill Study of ATH in Epoxy Foams

3.1.1. Morphology of ATH-Modified Epoxy Foams

3.1.2. Evaluation on the Mechanical and Thermal Properties of ATH-Modified Epoxy Foams

3.1.3. Flame Retardance of ATH-Modified Epoxy Foams

3.2. Fill Study of APP in Epoxy Foams

3.2.1. Morphology of APP-Modified Epoxy Foams

3.2.2. Mechanical and Thermal Properties of APP-Modified Epoxy Foams

3.2.3. Flame Retardance of APP-Modified Epoxy Foams

3.3. Fill Study of DOPO in Epoxy Foams

3.3.1. Morphology of DOPO-Modified Epoxy Foams

3.3.2. Mechanical and Thermal Properties of DOPO-Modified Epoxy Foams

3.3.3. Flame Retardance of DOPO-Modified Epoxy Foams

3.4. Fill Study of Melamine Phosphate in Epoxy Foams

3.4.1. Morphology of MP-Modified Epoxy Foams

3.4.2. Mechanical and Thermal Properties of MP-Modified Epoxy Foams

3.4.3. Flame Retardance of MP-Modified Epoxy Foams

4. Summary of Mechanical Properties and Flame Retardance

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fette, M.; Reiss, M.; Hentschel, M.; Stöß, N. Technologie zur Herstellung von komplexen und funktionalen SMC-Schaum-Sandwich-Strukturen für Luftfahrt- und Automobilindustrie. Lightweight Des. 2016, 3, 52–55. [Google Scholar] [CrossRef]

- Fette, M.; Reiss, M.; Stöß, N.; Hentschel, M. New Approach for the Efficient Manufacturing of Sandwich Structures Based on Sheet Moulding Compounds. Adv. Mater. Res. 2016, 1140, 264–271. [Google Scholar] [CrossRef]

- Buck, J.; Riecken, B.T.; Fette, M.; Keun, C.A.; Wulfsberg, J.P. Experimental Parameter Study on the Manufacturing of Sandwich Structures based on Sheet Molding Compounds. In Proceedings of the SAMPE Europe Conference Proceedings, Amsterdam, The Netherlands, 30 September–1 October 2020. [Google Scholar]

- Pascalut, J.P.; Williams, R.J.J. Epoxy Polymers, New Materials and Innovations, 2nd ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2010. [Google Scholar]

- Takiguchi, O.; Ishikawa, D.; Sugimoto, M. Effect of Rheological Behavior of Epoxy during Precuring on Foaming. J. Appl. Polym. Sci. 2008, 110, 657–662. [Google Scholar] [CrossRef]

- Ren, Q.; Zhu, S. One-Pack Epoxy Foaming with CO2 as Latent Blowing Agent. ACS Macro Lett. 2015, 4, 693–697. [Google Scholar] [CrossRef]

- Kurek, K.; Bledzki, A. Fatigue Behavior of Composites with Foamed Matrix. J. Reinf. Plast. Compos. 1994, 13, 1116–1134. [Google Scholar] [CrossRef]

- Kurek, K.; Bledzki, A. Mechanical Behavior of Polyurethane- and Epoxy Foams and Their Glass Fiber Composites. Mech. Compos. Mater. 1994, 30, 105–109. [Google Scholar] [CrossRef]

- Hajimichael, M.; Lewis, A.; Scholey, D. Investigation and Development of Epoxy Foams. Br. Polym. J. 1986, 18, 307–311. [Google Scholar] [CrossRef]

- Kühlkamp, A.; Mauz, O.; Göwecke, S. Process for Making Epoxy Resin Foam Plastics. U.S. Patent US3406131, 15 October 1968. [Google Scholar]

- Lyu, J.; Liu, T.; Xi, Z. Effect of pre-curing process on epoxy resin foaming using carbon dioxide as blowing agent. J. Cell. Plast. 2017, 53, 181–197. [Google Scholar] [CrossRef]

- Ren, Q.; Zhu, S. Development of Epoxy Foaming with CO2 as Latent Blowing Agent and Principle in Se-lection of Amine Curing Agent. Ind. Eng. Chem. Res. 2015, 54, 11056–11064. [Google Scholar] [CrossRef]

- Bethke, C.; Sanchez-Vanquez, S.A.; Raps, D. Effect of Resin and Blocked/Unblocked Hardener Mixture on the Production of Epoxy Foams with CO2 Blocked Hardener in Batch Foaming Process. Polymers 2019, 11, 793. [Google Scholar] [CrossRef] [Green Version]

- Bethke, C.; Kaysser, S.T.; Uy Lan, D.N.; Goller, S.M.; van der Zwan, K.P.; Senker, J.; Ruckdäschel, H.; Altstädt, V. Synthesis and characterization of dual functional carbamates as blowing and curing agents for epoxy foam. Ind. Eng. Chem. Res. 2021, 60, 7065–7080. [Google Scholar] [CrossRef]

- Kaysser, S.T.; Keun, C.A.; Bethke, C.; Altstädt, V. Tailoring Epoxy Foam Properties with an Innovative Process Approach using CO2 as Blowing Agent. In Proceedings of the SAMPE US Virtual Conference Proceedings, Seattle, WA, USA, 8−28 June 2020. [Google Scholar]

- Bethke, C.; Goller, S.M.; Ngoc, U.L.D.; Kaysser, S.T.; Altstädt, V.; Ruckdäschel, H. Tailoring Epoxy Resin Foams by Pre-Curing with Neat Amine Hardeners and Its Derived Carbamates. Polymers 2021, 13, 1348. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, C.; Gong, W.; Ji, Y.; Qin, S.; He, L. Preparation of Microcellular Epoxy Foams through a Limited-Foaming Process: A Contradiction with the Time-Temperature-Transformation Cure Diagram. Adv. Mater. 2018, 30, 1703992. [Google Scholar] [CrossRef]

- Chen, K.; Tian, C.; Lu, A.; Zhou, Q.; Jia, X.; Wang, J. Effect of SiO2 on Rheology, Morphology, Thermal, and Mechanical Properties of High Thermal Stable Epoxy Foam. J. Appl. Polym. Sci. 2014, 131, 40068. [Google Scholar]

- Asaro, R.J.; Lattimer, B.; Ramroth, W. Structural response of FRP composites during fire. Compos. Struct. 2009, 87, 382–393. [Google Scholar] [CrossRef]

- Bai, Y.; Keller, T. Time Dependence of Material Properties of FRP Composites in Fire. J. Compos. Mater. 2009, 43, 2469–2484. [Google Scholar] [CrossRef]

- Gibson, A.G. The Integrity of Polymer Composites during and after Fire. J. Compos. Mater. 2004, 38, 1283–1307. [Google Scholar] [CrossRef]

- Bourbigot, S.; Duquesne, S. Fire retardant polymers: Recent developments and opportunities. J. Mater. Chem. 2007, 17, 2283–2300. [Google Scholar] [CrossRef]

- Commission Regulation (EU) 2019/2021 of 1 October 2019 laying down ecodesign requirements for electronic displays pursuant to Directive 2009/125/EC of the European Parliament and of the Council, amending Commission Regulation (EC) No 1275/2008 and repealing Commission Regulation (EC) No 642/2009. Off. J. Eur. Union 2019, L315, 243.

- Khalili, P.; Tshai, K.Y.; Kong, I. The synergistic effect of flame retardants on flammability, thermal and mechanical properties of natural fiber reinforced epoxy composite. Key Eng. Mater. 2016, 701, 281–285. [Google Scholar] [CrossRef]

- Carja, I.D.; Serbezeanu, D.; Vlad-Bubulac, T.; Hamciuc, C.; Coroaba, A.; Lisa, G.; Lopez, C.G.; Suriano, M.F.; Perez, V.F.; Sanchez, M.D.R. A straightforward, eco-friendly and cost-effective approach towards flame retardant epoxy resins. R. Soc. Chem. 2014, 2, 16230–16241. [Google Scholar] [CrossRef]

- Weil, E.D.; Levchik, S.V. Flame retardants in Commercial Use or Development for Epoxy resins. In Flame Retardants for Plastics and Textiles; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2009. [Google Scholar]

- Xu, D.; Hongchao, L.; Huang, Q.; Deng, B.; Li, L. Flame retardant effect and mechanism of melamine phosphate on silicone thermoplastic elastomer. R. Soc. Chem. 2018, 8, 5034–5041. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Li, J.; Gao, M. Thermal degradation and flame-retardant mechanism of the rigid polyurethane foam including functionalized graphene oxide. Polymers 2019, 11, 78. [Google Scholar] [CrossRef] [Green Version]

- Xing, W.; Yuan, H.; Zhang, P.; Yang, H.; Song, L.; Hu, Y. Functionalized lignin for halogen-free flame retardant rigid polyurethane foam: Preparation, thermal stability, fire performance and mechanical properties. J. Polym. Res. 2013, 20, 234–246. [Google Scholar] [CrossRef]

- Underwriters Laboratories Inc. UL94–Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances, 6th ed.; Underwriters Laboratories Inc.: Northbrook, IL, USA, 2013. [Google Scholar]

- Product Data Sheet “Addforce FR APP Serie, Version 05.00; WTH Walter Thieme Handel GmbH: Stade, Germany, 2020.

- Product Data Sheet “Addforce FR SxxLxx–Übersicht”, Version 01.00; WTH Walter Thieme Handel GmbH: Stade, Germany, 2020.

- Product Data Sheet “Melagard MP”, Version 03.00; WTH Walter Thieme Handel GmbH: Stade, Germany, 2020.

- DIN Deutsches Institut für Normung e. V. Rigid Cellular Plastics–Determination of Compression Properties (ISO 844:2014); German Version EN ISO 844:2014; Beuth Verlag GmbH: Berlin, Germany, 2014. [Google Scholar]

- Nikolaeva, M.; Kärki, T. A Review of Fire Retardant Processes and Chemistry, with Discussion of the Case of Wood-Plastic Composites. Balt. For. 2011, 17, 314–326. [Google Scholar]

- Chen, W.; Liu, P.; Wang, Q.; Duan, W. Flame retardant and thermal degradation mechanisms of melamine polyphosphate in combination with aluminum phosphinate in glass fabric-reinforced epoxy resin. Polym. Compos. 2019, 40, 3199–3208. [Google Scholar] [CrossRef]

- Rakotomalala, M.; Wagner, S.; Dörig, M. Recent Developments in halogen free flame retardants for epoxy resins for electrical and electronic applications. Materials 2010, 3, 4300–4327. [Google Scholar] [CrossRef] [Green Version]

| Type | Trade Name | Supplier/Manufacturer | Specification | Abbreviation |

|---|---|---|---|---|

| ATH | Addforce FR S20L20 | WTH Walter Thieme Handel GmbH | 4–5 µm (D50) | ATH-A20 |

| ATH | Addforce FR S2L40 | WTH Walter Thieme Handel GmbH | 13–18 µm (D50) | ATH-A2 |

| APP | Addforce FR APP 201 | WTH Walter Thieme Handel GmbH | <15 µm | APP |

| MP | Melagard MP | WTH Walter Thieme Handel GmbH/Italmatch Chemicals S.p.A. | 4 µm (D50) 25 µm (D98) | MP |

| DOPO | NOFIA OL3001-P | WTH Walter Thieme Handel GmbH/FRX Polymers (Europe), NV | - | DOPO |

| Sample | Additive | Fd [wt.%] | Density [g/cm3] | Tg [°C] | dcell [µm] | Ec [MPa] | CS [MPa] |

|---|---|---|---|---|---|---|---|

| Neat | ⎼ | ⎼ | 0.3 ± 0.03 | 157 | 169 ± 243 | 123.3 ± 9.3 | 6.9 ± 1.1 |

| ATH-A20_30 | ATH-A20 | 30 | 0.43 ± 0.01 | 153 | 134 ± 113 | 180 ± 7 | 12.3 ± 0.04 |

| ATH-A2_30 | ATH-A2 | 30 | 0.44 ± 0.02 | 153 | 124 ± 113 | 186 ± 6.2 | 11.4 ± 0.3 |

| ATH-A20_40 | ATH-A20 | 40 | 0.51 ± 0.01 | 155 | 124 ± 84 | 190.3 ± 18.9 | 15.5 ± 1.2 |

| ATH-A2_40 | ATH-A2 | 40 | 0.51 ± 0.01 | 149 | 123 ± 94 | 184.7 ± 3.5 | 12.8 ± 0.6 |

| Sample | Additive | Fd [wt.%] | Density [g/cm3] | Tg [°C] | dcell [µm] | Ec [MPa] | CS [MPa] |

|---|---|---|---|---|---|---|---|

| Neat | ⎼ | ⎼ | 0.28 ± 0.03 | 157 | 169 ± 243 | 123.3 ± 9.3 | 6.9 ± 1.1 |

| APP_15 | APP | 15 | 0.36 ±0.01 | 159 | 148 ± 136 | 132 ± 9.54 | 8.84 ± 0.16 |

| APP_20 | APP- | 20 | 0.38 ± 0.00 | 158 | 155 ± 127 | 125 ± 17.44 | 8.77 ± 0.32 |

| APP_30 | APP | 30 | 0.44 ± 0.01 | 157 | 143 ± 122 | 135 ± 17.1 | 9.21 ± 0.45 |

| Sample | Additive | Fd [wt.%] | Density [g/cm3] | Tg [°C] | dcell [µm] | Ec [MPa] | CS [MPa] |

|---|---|---|---|---|---|---|---|

| Neat | ⎼ | ⎼ | 0.28 ± 0.03 | 157 | 169 ± 243 | 123 ± 9 | 6.9 ± 1.1 |

| DOP_10 | DOPO | 10 | 0.33 ± 0.02 | 154 | 162 ± 238 | 113 ± 10 | 4.8 ± 0.4 |

| DOP_20 | DOPO | 20 | 0.32 ± 0.01 | 153 | 158 ± 210 | 146 ± 19 | 8.3 ± 0.9 |

| DOP_30 | DOPO | 30 | 0.35 ± 0.03 | 142 | 172 ± 181 | 181 ± 21 | 11.9 ± 1.5 |

| Sample | Additive | Fd [wt.%] | Density [g/cm3] | Tg [°C] | dcell [µm] | Ec [MPa] | CS [MPa] |

|---|---|---|---|---|---|---|---|

| Neat | ⎼ | ⎼ | 0.28 ± 0.03 | 157 | 169 ± 243 | 123.3 ± 9.3 | 6.9 ± 1.1 |

| MP_10 | MP | 10 | 0.35 ± 0.01 | 157 | 165 ± 204 | 113 ± 20 | 5.1 ± 1.6 |

| MP_15 | MP | 15 | 0.36 ± 0.00 | 156 | 206 ± 264 | 115 ± 16 | 5.3 ± 1.3 |

| MP_20 | MP | 20 | 0.38 ± 0.00 | 157 | 156 ± 211 | 86 ± 6 | 3.0 ± 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaysser, S.T.; Bethke, C.; Romero, I.F.; Wei, A.W.W.; Keun, C.A.; Ruckdäschel, H.; Altstädt, V. Investigations on Epoxy-Carbamate Foams Modified with Different Flame Retardants for High-Performance Applications. Polymers 2021, 13, 3893. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13223893

Kaysser ST, Bethke C, Romero IF, Wei AWW, Keun CA, Ruckdäschel H, Altstädt V. Investigations on Epoxy-Carbamate Foams Modified with Different Flame Retardants for High-Performance Applications. Polymers. 2021; 13(22):3893. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13223893

Chicago/Turabian StyleKaysser, Simon T., Christian Bethke, Isabel Fernandez Romero, Angeline Wo Weng Wei, Christian A. Keun, Holger Ruckdäschel, and Volker Altstädt. 2021. "Investigations on Epoxy-Carbamate Foams Modified with Different Flame Retardants for High-Performance Applications" Polymers 13, no. 22: 3893. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13223893