2.1. Analytical Theory: Strong-Stretching Approximation

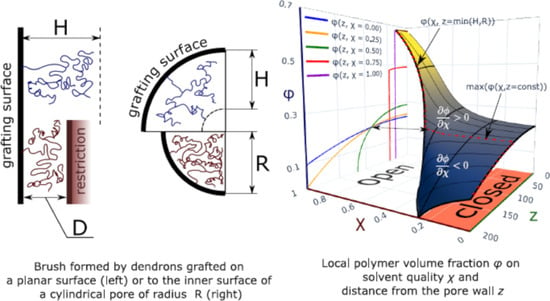

We consider a brush formed by long flexible polymer chains with degree of polymerisation (DP)

N and arbitrary linear or tree-like (dendron) architecture, grafted by one end to the inner surface of a cylindrical pore of radius

R and immersed in a solvent (

Figure 1). Here and below, we assume the brush forming chains (or any linear segment of the them) to be intrinsically flexible. Each monomer unit is assumed to have a length

a and a volume

, and in the following, all dimensions are normalised by the monomer unit length (approximately equal to the statistical segment length). The pore is assumed to be long so that edge effects on the conformation of the brush forming macromolecules are disregarded. For comparison, we also consider the case of a slit-like pore of thickness

.

The grafting density

is related to the area per chain

s or number of chains

per unit length of the pore,

Obviously, the pore can accomodate a polymer brush if , where .

The solvent quality is characterised by the Flory–Huggins parameter

. In our recent paper [

23], we considered the collapse of a brush formed by linear or branched macromolecules in the case when the pore radius exceeds the brush thickness

H, i.e,

, and there is a hollow channel around the pore axis. Here, we focus primarily on the case when, under good solvent conditions, the brush filles the pore, that is, the polymer density is nonzero at

, where

z is the distance from the wall towards the pore axis. The transition from

(filled pore) to

(open pore) triggered by variations of the solvent strength (i.e., in parameter

) or of the pore radius

R are analysed.

An analytical strong-stretching self-consistent field (SS-SCF) approach formulated initially for brushes of linear chains [

21,

25] and later extended to brushes of branched polymers [

26,

27,

28,

29] presumes linear (Gaussian) entropic elasticity of any linear segment of the brush forming macromolecules and operates with the chain trajectories

that specify the most probable position

z of the monomer unit with ranking number

m with respect to the grafting surface.

Within the strong-stretching self-consistent field approximation monomer units in the brush are subjected to the self-consistent molecular potential that exhibits a parabolic dependence on the distance

z from the grafting surface [

29]

where

is the volume fraction of monomer units in the brush,

is the free energy of interactions in the brush per unit volume,

is a coefficient dependent on the DP and topology of the brush forming chains, and the parameter

is specified below. For linear chains,

, whereas for tree-like or cycle-containing polymers,

where

is the so-called topological ratio that can be calculated for particular macromolecular architectures (tree-like or cycled) following earlier developed routines [

29,

30]. The topological ratio quantifies relative increases in the conformational entropy losses in brushes formed by branched (or cycled) polymers compared with those in brushes of linear chains with the same DP.

Equation (

2) presumes Gaussian (linear) conformational elasticity of the brush-forming chains on all the length scales and absence of “dead zones” depleted of the chain ends proximal to the grafting surface. Remarkably, Equation (

2) is applicable irrespective of the specific type of interactions (functional form of

) in the brush.

Here, we apply the mean field Flory–Huggins approximation

which (in contrast with the virial expansion used in Reference [

23]) is applicable at arbitrarily large polymer volume fractions up to

.

Combining Equations (

2) and (

4), we obtain an implicit dependence of the polymer volume fraction

in the brush on

z as

The osmotic pressure inside the brush is given by the following equation:

The normalisation condition

allows us to find

in the case of “closed” pores or the brush thickness

H if there is a hollow channel in the pore center,

.

In the case of an “open pore”,

, the polymer volume fraction at the edge of the brush,

, can be found from the condition of vanishing osmotic pressure,

, which leads to an equation for

as a function of

By substituting

into Equation (

5), we find parameter

in an open pore as

As follows from Equation (

8),

and, consequently,

in an open pore at

(i.e., under good or theta-solvent conditions). Under poor solvent conditions,

, in the open pore

and

. Under poor solvent conditions,

defined by Equation (

8) coincides with the polymer volume fraction in a polymer globule. Remarkably, under poor solvent conditions,

is independent of the pore radius

R.

A hollow channel in the center of the pore appears upon a decrease in the solvent strength or upon an increase in

R at

, where

is calculated for an open pore,

. This is equivalent to the condition

, i.e.,

, where the polymer concentration

depends on

R through

calculated from Equation (

7).

Under good or theta-solvent conditions, , the condition of the channel opening can be found directly from the condition , that is

An analytical solution can be found under good solvent conditions, when

with

. In this case,

and from Equation (

7), we find

so that

where

is average polymer concentration in the pore. As follows from Equation (

12), upon a decrease in the solvent strength (decrease in

v, brush contraction), the local polymer concentration decreases at

but increases at

. This applies as long as binary repulsive interactions remain dominant (good solvent conditions).

The condition of the channel opening,

or

, leads to

At

, there is a hollow channel in the pore center. As follows from Equation (

13),

is proportional to

N and increases upon an increase in

and

v and decreases upon replacement of linear brush forming chains by branched ones (increase in

).

At

, the brush thickness (calculated from Equations (

7) and (

12)) can be found from the equation

which in the limit

reduces to

which coincides with the result obtained in [

23].

Remarkably, as follows from Equations (

13) and (

15), the ratio

is independent of topological ratio

and grafting density

.

Under poor solvent conditions,

, the unconfined brush (

) is collapsed and

, which can be found from Equation (

8). The critical pore radius

can be estimated from simple packing conditions,

, which increases as a function of

and decreases with decreasing solvent strength (an increasing

) but, remarkably, is independent of the topology of the bruh forming chains. At

, polymer distribution in the closed pore is fairly uniform with the polymer volume fraction

.

2.2. Brush Thickness and Pore Opening/Closing Threshold

In

Figure 2, we present the reduced thickness of the brush,

, as a function of normalised

N pore radius,

, for selected values of the

-parameter and for three architectures of the brush forming chains: linear and dendrons of the second generation (

) with branching functionality

and

. The unconfined and confined brush regimes correspond, obviously, to

and

, respectively. Horizontal dashed lines correspond to the thickness of the brush (with the same

and

) grafted onto a planar surface (the limit of

). As one can see from the figure, the thickness

of a unconfined brush in the pore is systematically larger that of the brush grafted to a planar surface and monotonously increases upon a decrease in the pore radius

R. At

, the hollow channel in the pore center vanishes (the closing/opening point), and at smaller

R, the brush fills the pore. For a given pore radius

R and solvent strength

, the thickness

of an unconfined brush of linear chains is larger than that of a dendron brush, whereas for a given

R and selected topology of the chains, the brush thickness

monotonously decreases as a function of

(decreasing solvent strength).

These trends are also illustrated in

Figure 3 where we present the dependence of

(left) and polymer volume fractions at the grafting surface,

, and at the edge of the brush,

, (right) on

parameter for a set of selected values of the reduced pore radius,

, and for three polymer topologies: linear chains (upper row), and dendrons of the second generation with branching functionality

(middle row) and

(lower row). Black solid lines in the left column correspond to the reduced thickness,

of the unconfined brush grafted to a planar surface, whereas dotted black line corresponds to the pore opening threshold,

. The smaller the pore radius,

, the larger the brush thickness at any given

. Therefore, the dotted line (

at pore opening) lies systematically above the solid line (the planar brush thickness).

As one can see from

Figure 3, irrespective of the confinement, the polymer volume fraction close to the grafting surface,

, is an increasing function, whereas the polymer volume fraction at the edge of the brush,

, is a decreasing function of

. These trends and the difference between both values become less pronounced (density distribution thoughout the brush becomes more uniform) as confinement becomes stronger or/and degree of branching of the brush forming chains increases (dendron compared to the linear chain brush). For dendron brushes (middle and lower rows in

Figure 3), the brush thickness is systematically smaller and the

-range corresponding to the open pore,

, is more extended than for the brushes of linear chains.

The dependences of

corresponding to the pore opening/closing threshold on the pore radius,

R, (or the slit half-width,

D) for linear chain and dendron brushes (with the same

N and

) are presented in

Figure 4. As follows from the figure, at given pore radius

R, the pore opening occurs at better solvent strength conditions (i.e., at smaller

) for dendron brushes than for linear chain brushes. For example, the pore opening may occur only under poor solvent conditions for the linear chains brush whereas in the pore decorated by dendrons with the same

N and

the central channel emerges already under good solvent conditions. This trend is clearly explained by the weaker swelling of dendron brushes under good or theta-solvent conditions. As expected, the difference between brushes of linear chain and dendron brushes vanishes under poor solvent conditions or confinement (pore filling).

2.3. Polymer Density Distribution in the Pore

The evolution of the polymer volume fraction distribution across the cylindrical pore upon variations in

-parameter (solvent strength) is illustrated by

Figure 5. The upper row corresponds to the case when the brush is unconfined,

, at any solvent strength. In the middle row, closing/opening of the hollow channel in the center of the pore,

, occurs upon a decrease in the solvent strength at

; the lower row depicts the situation when the closing/opening occurs at

(close to theta-solvent conditions).

In the left column in

Figure 5. we present 3D profiles of the polymer volume fraction

as a function of solvent quality,

, and distance

z from the pore wall. At any value of

, the polymer density profile is a decreasing function of

z in the range of

. In accordance with Equation (

8), under good and theta-solvent conditions,

, the polymer volume fraction in a unconfined brush,

, vanishes continuously at the brush edge,

, whereas under poor solvent conditions,

, the polymer volume fraction exhibits a finite jump from

to zero at the brush edge. The polymer volume fraction at

in a confined brush is nonzero at any solvent strength and decreases upon an increase in

. If the channel opening occurs under good or theta-solvent conditions,

, then the polymer volume fraction at the edge of the brush,

, vanishes continuously in the range of

. Otherwise, if

, the nonzero polymer volume fraction is found at the edge of the brush,

, in both confined and non-confined regimes.

The dependence of the polymer volume fraction

on

exhibits qualitatively different patterns depending on the selected distance

z from the pore wall. In the right column of

Figure 5, the volume fraction

is plotted as a function of

for a few selected values of

z; the black solid lines correspond to the polymer volume fraction at the edge of the brush,

. In the middle column of

Figure 5, the contour plots of the derivative

are presented. As one can see from these plots, the polymer volume fraction

monotonously increases as a function of

and asymptotically approches unity at

for

, where

is the thickness of fully collapsed,

brush and

is the minimal radius of the pore accomodating the brush with given

N and

. At larger distances from the surface,

, where

is the brush thickness in the theta-point, the polymer volume fraction increases as a function of

as long as

, where the value

is found from the condition

, and then drops down to zero. At even larger distance from the grafting surface,

, the polymer volume fraction

exhibits more complex behaviours as a function of

, i.e., it either monotonously decreases upon an increase in

if

z is close to the periphery of the brush or passes though a maximum and then continously vanishes.

2.4. Numerical Self-Consistent Field Theory: Beyond Analytical Strong-Stretching Approximation

We note that the analytical SS-SCF approach employed above for calculating the polymer volume fraction and the brush thickness in the open pore, , does not account for Gaussian fluctuations of the non-stretched terminal segments of the brush forming chains. These fluctuations give rise to the decaying “tail” in polymer density distribution protruding beyond the brush edge, i.e., to non-vanishing polymer concentration at . Due to these density fluctuations, the effective radius of the hollow chanel is slightly smaller than predicted by SS-SCF theory.

The width of the tail is expected to vary non-monotonously as a function of solvent strength (

): in the regimes of good and theta solvent,

, it increases upon a decrease in the brush thickness

H caused by decreasing solvent strength as [

31]

because of the decreasing overall stretching of the chains in the brush. Below the theta point, i.e., at

, polymer density fluctuations and extension of the tail in the polymer density distribution are controlled by the thermal correlation length [

32], which scales as

close to the theta-point and further decreases upon an increase in

. Therefore, the relative width of the fluctuating tail scales as

under good and theta-solvent conditions and as

under poor solvent conditions.

In order to obtain a more detailed description of the polymer density distribution near the edge of the brush, we used a numerical modelling approach based on the self-consistent field Scheutjens–Fleer method [

33,

34]. The latter method does not involve any approximations concerning the degree of stretching of the brush forming chains and accounts for the Gaussian fluctuations of the non-stretched terminal segments of the chains. The polymer volume fraction profiles calculated for a planar (

brush under varied solvent strength conditions analytically (SS-SCF approximation) and numerically using the SF-SCF scheme and their difference,

are presented in

Figure 6. As one can see from

Figure 6,

vanishes far from the edge of the brush but is maximal at

. The shape of the

curves changes with the variation in the solvent strength: they are fairly symmetric under good or poor solvent conditions and asymmetric close to the theta point. In agreement with presented above analytical estimations, the magnitude and the width of

increase when the solvent strength decrease from good to theta-solvent conditions, reach maxima in the theta-point, and decrease upon further increase in

in the range of poor solvent. This is illustrated in

Figure 7, where the width of the

curves is plotted as a function of

(with the same values of

). As seen from

Figure 7, The width of

curve for a dendron brush is expected [

13] to be smaller than that for the brush of linear chains at any

. This observation brings us to the conclusion that the “tail” in the polymer volume fraction profile is most extended around the theta-point and is more pronounced for the brushes of linear chains rather than for dendron brushes.

Ending this section, we have to point out a certain peculiarity in the pore closing/opening transition when it occurs under poor solvent conditions. According to the SS-SCF approximation, under poor solvent conditions,

, the polymer density in the open pore,

, exhibits a discontinuity at the edge of the brush, at

. The polymer volume fraction at the edge of the brush,

, obeys Equation (

8) and coincides with the equilibrium volume fraction in a polymer globule [

32]. The unfavourable contacts between monomer units and poor solvent at the interface between the collapsed brush and the surrounding solution give rise to excess free energy

per unit area of the interface. In the vicinity of the theta point,

, the surface tension

scales as [

32]

, whereas far from the theta-point, at

, the linear grouth,

, is predicted with a smooth crossover between these two asymptotics in the

range [

35]. In the case of the open cylindrical pore, this excess interfacial free energy produces a negative Laplace pressure

. In order to eliminate this unfavourable interface by closing the pore and thus to vanish the excess interfacial free energy, the brush may undergo additional swelling with respect to its equilibrium thickness calculated according to the SS-SCF scheme. Consequently, the closing of the pore is expected to occur, when the channel radius is

, as a jump-like (first order) transition. This transition occurs when the free energy corresponding to the equilibrium thickness of the brush calculated above within SS-SCF scheme and complemented by the excess free energy of the brush-solvent interface (per chain),

, becomes equal to the free energy, corresponding to the filling the pore overstretched brush. Mathematically, in the “pore closing” transition range, the free energy exhibits a local minimum corresponding to the open pore and an edge minimum corresponding to the close pore, and the minima are separated by the free energy barrier.

Assuming that

and

, where the collapsed polymer volume fraction

is given by Equation (

8), we find that the minimal equilibrium radius of the open channel scales as

The derivation of Equation (

19) and expression for

are presented in the

Appendix A. Following from Equation (

19),

Hence, for sufficiently long chains, , and wide pores, the relative minimal width of the hollow channel at which jump-wise closing of the pore occurs is negligible compared with the pore radius.

Obviously, since the contribution of conformational entropy to the overall free energy of the collapsed brush under poor solvent conditions is negligible, the above estimate of the jump-wise opening/closing transition point is fairly insensitive to the topology (linear or dendritic) of the brush forming chains.

The evidence for the jupm-wise pore opening/closing transition is provided by mumerical SF-SCF calculations. In

Figure 8, the polymer volume fraction profiles

calculated analytically and numerically under poor solvent conditions (

and 0.8) are plotted for variable pore radius

close to the predicted by analytical theory pore opening/closing threshold,

. As follows from the

Figure 8, at

, the pore is filled with polymer (no hollow channel) and the numerically calculated profile perfectly matches the analytical one. If the pore radius

and there is a hollow channel in the pore center with

, the numerically caclulated profile is slightly more extended than the analytical one due to Gaussian fluctuations of the terminal chain segments, as discussed above. However, close to the analytically caclulated transition point,

, numerical calculations show that the pore is still closed with relatively high polymer concentration in the pore center, at

, whereas according to analytical theory they should be a hollow channel in the pore center. Moreover, according to numerical calculations, the shape of the polymer density profiles abruptly changes (the pore opsning/closing transition) within a very narrow range of variation of

R around

, where

evaluated from numerical calculations numerically is larger than

calculated analytically.

The same trend is illustrated by

Figure 9, where the polymer volume fraction in the pore center,

, is plotted as a function of the pore radius

R for a few selected values of the

-parameter. As expected, the polymer volume fraction in the pore center monotonously decreases upon an increase in the pore radius

R. Under good and theta-solvent conditions,

, the polymer volume fraction in the pore center smoothly vanishes above the pore openning threshold, at

. The numerical calculations predict slightly larger pore radius corrersponding to the opening transition than the analytical theory due to Gaussian fluctuations of the terminal chain segments. Under poor solvent conditions, analytical theory predicts a drop in the polymer density at the edge of the brush upon the pore opening, which is in agreement with numerical results. However, numerical results indicate that this drop in the polymer density (the pore opening) emergies at significantly larger pore radius

, than predicted by analytical theory.

In

Figure 10, the ratio between the brush thickness

H (calculated analytically or numerically) and the pore radius

R normalised by

is plotted for a set of the

-values corresponding to theta and poor solvent conditions. The brush thickness is a decreasing function of

R (at given

) or a decreasing function of

at given

. The analytical curves cross at

since, by definition,

. The numerically calculated dependences behave differently: the arrows in

Figure 10 indicate jump-wise closing-opening of the pore under poor solvent conditions upon continuous variation in the pore radius

R, the magnitude of the jump increases upon an increase in

.