1. Introduction

There have been problems in urban underground pipe networks for a long time, such as insufficient performance of drainage and sewage pipes, uneven product quality, and so on. It is extremely urgent to improve the mechanical properties of underground pipelines. Nowadays, buried large-diameter double-wall bellows are also gradually being upgraded from cement or steel materials to polymer materials. HDPE has become the preferred material for most bellows manufacturers due to its excellent comprehensive mechanical properties [

1]. The introduction of bimodal HDPE further broadened the market of bellows materials. The high molecular weight part yields materials with increased mechanical properties, whereas the low molecular weight part acts as lubricant during HDPE extrusion [

2]. Improving the performance of large diameter HDPE bellows is still a difficult problem. Increasing the ring stiffness in HDPE bellows is the key to improving the quality of bellows. On the one hand, the ring stiffness can be increased by improving the mechanical properties of the materials used to prepare the bellows. On the other hand, we can optimize the waveform structure of bellows to improve their performance. In this paper, HDPE composites used for the preparation of bellows were studied, and the ring stiffnesses of bellows with different diameters were calculated using finite element analysis.

With the increasing demand for high-performance bellows and the reduction in the amount of polyethylene raw materials, many people try to add inorganic fillers to HDPE to obtain stronger mechanical properties and cut the use of polyethylene raw materials. There are a large number of studies that report improvements, with an emphasis on the mechanical properties of polyolefins, with the addition of inorganic particles [

3]. G. Savini and R. L. Orefice prepared nano-talc/HDPE composites [

4]. The results showed that the tensile strength and impact strength of the composites decreased slightly with the addition of talc powder, but the elongation at break increased significantly. M. E. Mahmoud et al. studied the effects of Al

2O

3 and BaO nano-additives on the mechanical properties of HDPE [

5]. The results indicated that when the content of BaO and Al

2O

3 nano-fillers reached 4% and 6% respectively, the increase in Young’s modulus relative to the matrix was 229% and 208% respectively. D. K. Mohan Kumar et al. used HDPE as matrix material and bagasse ash and nano-montmorillonite as reinforcement materials to prepare composites. The results showed that the composites had higher tensile strength and bending strength compared with pure HDPE [

6].

As mentioned above, many people add inorganic fillers to polyolefins to enhance the strength or toughness of the materials. However, these inorganic fillers usually come from mining, which easily damages geology and forests. Therefore, many people currently use solid waste as inorganic reinforcing fillers. For example, there are some people who use FA Cenospheres, modified FA, ultrafine FA or other mineral materials as reinforcement materials, which grant HDPE excellent strength and stiffness. FA is an aluminosilicate rich waste with light weight and high strength obtained from coal-fired power plants, whose disposal causes serious environmental pollution [

7]. High value-added utilization of FA is an urgent and long-term task [

8]. Since polymers are often hydrophobic while FA is hydrophilic, modification of the filler, the matrix, or both is helpful [

9]. M. V. Deepthi et al. used a silane coupling agent to treat the surface of FA Cenospheres and prepared FA Cenosphere/HDPE composites. The results indicated that the addition of FA hollow beads could greatly improve the mechanical properties and thermal stability of the composites, but the elongation at break would be reduced [

10]. D. Guo et al. studied the effect of ultra-fine FA (UFA) incorporation on the properties of HDPE composites. The results showed that UFA particles without surface treatment could be uniformly dispersed in polyethylene, and UFA had an obvious toughening effect upon rigid particles [

11]. However, the addition of UFA greatly reduced the elongation at break of the composite system. In addition, T. T. Wu et al. studied the effect of FA particle size on the mechanical properties of modified FA/HDPE composites [

12]. The results showed that the tensile, bending and impact strength of the materials increased at first and then decreased with increasing FA particle size. In the above papers, adding different inorganic fillers to HDPE could improve the strength or toughness of HDPE. However, it was difficult to maintain high strength and toughness at the same time in polyethylene materials. Therefore, it is important to develop a simple, effective and low-cost preparation method for HDPE composite materials.

Pipe circumferential bending stiffness refers to the ability of a pipe to resist circumferential deformation, which is referred to as ring stiffness. Ring stiffness is a very important index for bellows, indicating their ability to resist external pressure [

13]. Ring stiffness testing of bellows is generally carried out with a special instrument. Before the measurement, the pipe needs to be prepared and transported to the ring stiffness tester for measurement. This measurement method is not only time-consuming, but also often results in certain measurement errors. In a study by X. P. Wang and Q. Lian, the ring stiffness of bellows was tested using a ring stiffness tester [

14]. The results showed that the load, sample length and inner diameter would cause deviation in the measured ring stiffness results. Therefore, the finite element analysis method was used to simulate the ring stiffness testing process in this paper, and the finite element simulation results were then used to verify the potential application value of the prepared HDPE composites in bellows.

In this paper, FA was used as an inorganic filler to enhance the strength and stiffness of HDPE. However, it is usually necessary to add a large volume of filler to the polymer to obtain the desired results [

15]. Thus, FA was grafted with a silane coupling agent to obtain treated FA. Next, the reinforced masterbatch was prepared by melt blending a certain amount of FA with LDPE. The blends were then melt blended with HDPE-g-maleic anhydride (HDPE-g-MAH) as compatibilizer. The influence of FA and compatibilizer content on the tensile properties of the material was studied, and the mechanical properties, micro-morphology and thermal stability of the composite materials were analyzed. In addition, the ring stiffness of the bellows prepared by the composite was analyzed using finite element analysis. Based on the analysis and discussion of the above results, the composite material prepared in this paper was not only simple to prepare, low-cost and suitable for the preparation of large-caliber buried bellows, but also contributed to high value-added utilization of FA.

2. Materials and Methods

2.1. Materials

HDPE (CONTINUUM™ DGDA-2502NT with a melt flow index of 12.4 g/10 min, Dow Chemical Company, Midland, MI, USA);

FA (Shanxi Hujin Coal and Electricity New Materials Company, Taiyuan, China);

3-Amino propyl tri ethoxy silane (APTS) (Nanjing Chuang Shi Chemical Additives Company, Nanjing, China);

Maleic anhydride modified HDPE (HDPE-g-MAH) (FUSABOND™ E265 Functional Polymer, Dow Chemical Company, Midland, MI, USA);

LDPE (LD650 with melt flow index of 22 g/10 min, ExxonMobil, Irving, TX, USA)

Absolute ethanol and glacial acetic acid were obtained from Aladdin Biochemical Technology Co., LTD, (Shanghai, China).

The composition of FA used in this article was provided by Shanxi Hujin Coal and Electricity New Materials Co., Ltd. (Taiyuan, China). The company analyzed the mean composition of the FA using X-ray fluorescence analysis in accordance with the GB/T 14563-2008 test standard in the

Table 1.

2.2. ATPS-Modified FA

In order to improve the compatibility of the FA and HDPE, the surface of the FA was modified [

16]. Silane-modified FA refers to the grafting of APTS onto FA. First of all, anhydrous ethanol and deionized water were fully mixed to produce a mixed solvent. Silane coupling agent (ATPS) was then added and the pH value was adjusted to 5 by adding glacial acetic acid. Next, hydrolyzed ATPS was obtained at room temperature by stirring with a magnetic agitator for 30 min. The mass ratio of the components in the hydrolyzed silane coupling agent was ATPS:deionized water:anhydrous ethanol = 1:1:9. The hydrolyzed ATPS is sprayed on the surface of the FA particles, and its mass fraction is 3% of the FA particles. A high-speed mixer was used to mix the material at high speed for approximately 10 min and then discharge the material. The material was placed in a drying box and dried at 100~120 °C for 2 h to obtain the FA modified by ATPS.

2.3. Preparation of FA Masterbatch

In order to distribute FA more evenly within HDPE and prevent it from causing secondary pollution, FA was prepared as a filling masterbatch [

17]. A certain amount of LDPE (LD650) and an appropriate amount of polyethylene wax were added to the high-speed mixer and then mixed for 15 min at high speed at a temperature of 80 °C. Then, the same amount of modified FA was added to the high-speed mixer. Run the high-speed mixer first at low speed for 10 min, then at high speed for 10 min, a coarse mixture of FA masterbatch could be obtained. The coarse mixture was added to the extruder for melt extrusion and granulation to obtain the FA masterbatch. Extrusion and granulation were carried out in a micro compounder (HAAKE™ Minilab 3 Micro Compounder, Thermo Scientific, Waltham, MA, USA).

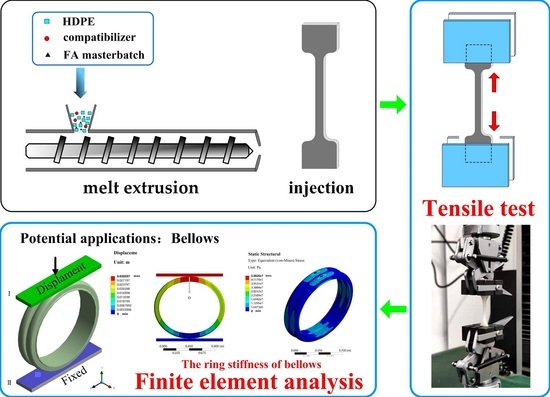

2.4. Preparation of the Composites

The particulate composites were obtained by mixing HDPE, the FA masterbatch and the HDPE-g-MAH compatibilizer in various proportions at 210~215 °C. Blending was carried out in a micro compounder (HAAKE™ Minilab 3 Micro Compounder, Thermo Scientific, Dreieich, Germany).

Dumb-bell shaped specimens were then molded as per GB/T 1040.2-2006 specifications, using injection molding (HAAKE™ Mini-Jet Pro, Thermo Scientific, Dreieich, Germany), at 210~215 °C. The amount of compatibilizer was expressed as a weight percentage of FA. The dumb-bell specimens were then subjected to tensile properties and thermal properties testing.

2.5. Characterization

Different techniques were used to test the characteristics of the silane-treated FA and HDPE composites in this study. The first technique was scanning electron microscopy (SEM, model JSM-7100F, Tokyo, Japan). For morphology observation, the sample was cryogenically fractured in liquid nitrogen. Samples were then covered with gold and examined with the scanning electron microscope at an operating voltage of 10 kV.

The second technique was thermo-gravimetric analysis (TG-209, Netzsch, Selb, Germany), working at temperatures ranging from 40 °C to 800 °C, a flow rate of 100 mL min−1 in a nitrogen atmosphere and a heating rate of 10 °C/min.

The third technique was Fourier transform infrared spectroscopy (FT–IR). FT–IR spectroscopy was performed using a Bruker Tensor 27 FTIR spectrometer (Bruker, Karlsruhe, Germany). All data were recorded at room temperature in the spectral range of 450~4000 cm−1. FT–IR spectra were used to compare untreated and treated FA.

A tensile tester (model UTM-4304X, Shenzhen Suns Technology Co., LTD, Shenzhen, China) was used to measure tensile properties. Tensile tests were performed as per GB/T 1040.2-2006. Composite specimens were mounted and subjected to strain at a rate of 5 mm/min until failure occurred. Tensile tests of the composites were carried out at room temperature. Five specimens per batch were tested and the average strength was calculated.

2.6. Finite Element Model

2.6.1. Geometry

The ring stiffness calculation model for the bellows was established using Solidworks software (Version 2021, SolidWorks, Waltham, MA, USA). As shown in

Figure 1, the waveform cross sections of different bellows were drawn first. The bellows could be obtained by rotating the corresponding section depending on the different diameter values.

In order to simulate the process of testing the stiffness of the bellows ring, two parallel steel plates were placed at the upper and lower ends of the bellows. The cuboids in

Figure 2 were treated as steel plates, which were tangential to the bellows in the x, y and z directions. The length of the cuboids was the sum of the inner diameter of the bellows and the height of the wave crest (D + h), their width was twice that of B, and their height was 50 mm.The ring stiffness of the bellows was tested by compressing the bellows and deforming them by 3%.

2.6.2. Material Parameters

Table 2 shows the material properties of the bellows and steel plates. A FA/HDPE composite material with a Young’s modulus of 1451.07 MPa was selected as the material for the bellows.

2.6.3. Mesh Parameters

In this study, the mesh model was established using Ansys Workbench software (Version 2020 R2, Ansys, Washington, PE, USA). Both the steel plates and bellows adopted the method of automatic meshing, which can be used to automatically select the mesh type for the entity and generate the mesh. Then, the mesh size of the bellows was set. The principle of setting the bellows mesh size was to select the smallest possible mesh unit size that the computer could run.

2.6.4. Boundary and Initial Conditions

The ring stiffness test is described in detail in ISO 9969-94. The basic principle is to place the bellows between two parallel plates and compress it at a constant speed to obtain the curve of the relationship between force and ring stiffness. The ring stiffness is calculated from the reaction force when the pipe produces a deformation of 0.03 times the diameter.

The static structure analysis was performed using the Mechanical APDL solver in Ansys Workbench software (Version 2020 R2). All bellows were subjected to the same boundary conditions and displacement loads. As shown in

Figure 2b, a downward displacement load was applied to the lower surface of the upper steel plate, and the displacement was 3%D. The bottom of steel plate was constrained. No load was applied to any part of the bellows.

4. Discussion

In this paper, high-strength FA was used as an inorganic filler to enhance the mechanical properties of HDPE. When the added quantity of FA masterbatch increased from 0 to 15%, the tensile strength and Young’s modulus of the composites increased at first and then decreased, and the elongation at break decreased continuously with the addition of FA masterbatch, which is consistent with the results of Y. Huang et al. [

17]. In contrast to their results, with the further addition of FA masterbatch, the tensile strength, Young’s modulus and elongation at break increased, rather than decreased further. This may be because LDPE in the FA masterbatch further uniformly distributed FA in HDPE.

It is obvious from

Figure 5 that the tensile strength of the composites increased at first and then decreased when different amounts of compatibilizers were added to the FA masterbatch/HDPE composites. The improvement in tensile strength in the composites may be attributed to the effective reaction of amino group on the modified FA with the anhydride group in the compatibility agent, which anchored the rigid FA more effectively on the HDPE. Therefore, the stress can be better transferred from the polyethylene matrix to the FA particles. The formation of interactions between filler and matrix materials plays an important role in the improvement of tensile properties [

20]. Adding too much compatibilizer reduced the tensile strength of the composites. This may be because the excessive addition of compatibilizer destroyed the highly crystalline structure of HDPE and enhanced the plasticity of the composites, thus reducing the yield strength and breaking strength of the composites. In addition, the addition of compatibilizer increased the elongation at break of the composite. This may be because the addition of the compatibilizer made the FA more evenly distributed in the HDPE matrix, which reduced the occurrence of FA agglomeration and stress concentration within the composite materials.

In a study by M. V. Deepthi et al. [

10], HDPE-g-dibutyl maleate was used as a compatibilizer, and the influence of the compatibilizer content on the mechanical properties of HDPE composites was studied. This showed that the tensile strength and Young’s modulus of the composite materials were significantly improved, and the addition of compatibilizers slightly improved the elongation at break of the composite materials. In this study, HDPE-g-MAH, which is relatively easy to buy commercially, was used as a compatibilizer. It can be seen from the above analysis that this method achieved the same effect of strengthening and toughening.

In order to verify whether the ring stiffness of HDPE composites bellows was improved, finite element analysis was used to simulate and calculate the ring stiffness of the bellows. In addition, the ring stiffness of a bellows made from a common commercially available material was also analyzed and calculated, and the ring stiffness of the two was compared. The main tested parameter of the two materials was Young’s modulus. Compared with the ring stiffness of the common material bellows, the ring stiffness of the composite bellows increased by approximately 23%. This shows that the composites are anticipated to be more useful as the preparation material for bellows. The HDPE composites prepared in this paper not only improved the strength and stiffness of the composites, but also alleviated the problem of greatly reduced toughness caused by FA added into HDPE. The utilization of FA not only reduced the preparation cost of large diameter HDPE bellows, but also achieved the reuse of solid waste materials.

At present, common polyethylene bellows usually mix plastic and steel or optimize the wave shape and increase the number of inner ribs to enhance the strength and rigidity of the pipe. The ring stiffness of this bellows was generally 8~12.5 KN/m2. The steel plates in the pipe are generally connected by welding, but quality is difficult to guarantee and water leakage is prone to occurring. Due to the complicated preparation process, its production speed is relatively slow. Pure HDPE bellows is also now common and its ring stiffness is generally 4~8 KN/m2; its strength has gradually failed to meet increasing needs. In this paper, a high-strength and high-rigidity FA/HDPE composite material was prepared. Compared with the above-mentioned types of bellows, the preparation process was simple and the cost was low. For common bellows diameters, the ring stiffness could reach 10.6~18.4 KN/m2. Combining the performance advantages of stiffness and low cost of use, FA/HDPE is a potential high-performance buried bellows material.