Comparative Analysis of Viscoelastic Properties of Open Graded Friction Course under Dynamic and Static Loads

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

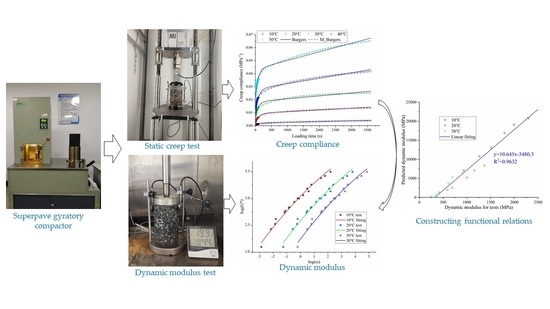

2.2. Experimental Methods

2.2.1. Uniaxial Compression Creep Test

2.2.2. Dynamic Modulus Test

2.2.3. Interconversion between Relaxation Modulus and Creep Compliance

2.2.4. Interconversion between Dynamic Modulus and Relaxation Modulus

3. Results and Discussion

3.1. Creep Characteristic Analysis of OGFC

3.1.1. Creep Test Results of OGFC

3.1.2. Creep Characteristic Analysis Based on the Burgers Model and the Modified Burgers Model

Instantaneous Elastic Deformation.

Irreversible Permanent Deformation

Viscoelastic Deformation

3.2. Relaxation Characteristic Analysis of OGFC

3.2.1. Relaxation Modulus Calculation Results of OGFC

3.2.2. Relaxation Characteristic Analysis Based on Second-Order Extensive Maxwell Model and Scott-Blair model

3.3. Dynamic Modulus Analysis of OGFC

3.3.1. Dynamic Modulus Test Results of OGFC

3.3.2. Dynamic Modulus Analysis Based on the Modified Sigmoid Model

3.4. Comparative Analysis of Dynamic Modulus of OGFC under Dynamic and Static Loads

4. Conclusions

- (1)

- With the increase in test temperature, the creep compliance of OGFC increases significantly, and the corresponding anti-instantaneous elastic deformation ability ( and ), anti-irrecoverable permanent deformation ability ( and ) and anti-viscoelastic deformation ability () show negative exponential decline.

- (2)

- With the increase in loading time, the relaxation modulus of OGFC decreased rapidly at first and then slowly; with the increase in test temperature, the relaxation modulus of OGFC decreased significantly. The Scott-Blair model can better describe the change in OGFC relaxation modulus with loading time than the second-order extensive Maxwell model, and the fractional order of the Scott-Blair model can adequately characterize the transition of OGFC from solid to fluid with the increase in temperature.

- (3)

- With the increase in loading frequency, the dynamic modulus of OGFC increases and the phase angle decreases. The increase in test temperature will have an adverse effect on the dynamic modulus of OGFC. The fitting analysis results show that the dynamic modulus of OGFC at different temperatures almost converges to the same value at very high or very low loading frequency, converges to the glassy modulus around 105 MPa at high frequency, and converges to the static modulus around 2 MPa at low frequency.

- (4)

- The dynamic modulus derived from static creep compliance has a good linear correlation with that obtained by dynamic modulus tests, but the correlation of the phase angle is poor. The actual dynamic modulus of OGFC can be calculated and obtained by the linear function modified the dynamic modulus derived from creep compliance, which can provide a new way to obtain the parameters needed for the structural design of asphalt pavement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, J.; Yin, X.; Wang, H.; Ding, Y. Evaluation of durability and functional performance of porous polyurethane mixture in porous pavement. J. Clean. Prod. 2018, 188, 12–19. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.; Wang, H.; Huang, W.; Sun, W.; Xu, T. Preparation and effectiveness of composite phase change material for performance improvement of Open Graded Friction Course. J. Clean. Prod. 2019, 214, 259–269. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, W.; Hao, G.; Yan, C.; Lv, Q.; Cai, Q. Evaluation of open-grade friction course (OGFC) mixtures with high content SBS polymer modified asphalt. Constr. Build. Mater. 2021, 270, 121374. [Google Scholar] [CrossRef]

- Naik, A.K.; Biligiri, K.P. Predictive Models to Estimate Phase Angle of Asphalt Mixtures. J. Mater. Civil Eng. 2015, 27, 04014235. [Google Scholar] [CrossRef]

- Asmael, N.M.; Chailleux, E. Investigate engineering properties of modified open-graded asphalt mixtures. Cogent Eng. 2019, 6, 1678555. [Google Scholar] [CrossRef]

- Sarkar, A.; Hojjati, F. The effect of nano-silica material and alkali resistant glass fibre on the OGFC asphalt mixture. Int. J. Pavement Eng. 2019, 1–13. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, W.; Zhang, Y.; Lv, Q.; Yan, C. Evaluating four typical fibers used for OGFC mixture modification regarding drainage, raveling, rutting and fatigue resistance. Constr. Build. Mater. 2020, 253, 119131. [Google Scholar] [CrossRef]

- Gupta, A.; Castro-Fresno, D.; Lastra-Gonzalez, P.; Rodriguez-Hernandez, J. Selection of fibers to improve porous asphalt mixtures using multi-criteria analysis. Constr. Build. Mater. 2021, 266, 121198. [Google Scholar] [CrossRef]

- Biligiri, K.P.; Kaloush, K.E. Effect of specimen geometries on asphalt mixtures’ phase angle characteristics. Constr. Build. Mater. 2014, 67, 249–257. [Google Scholar] [CrossRef]

- Wu, H.; Yu, J.; Song, W.; Zou, J.; Song, Q.; Zhou, L. A critical state-of-the-art review of durability and functionality of open-graded friction course mixtures. Constr. Build. Mater. 2020, 237, 117759. [Google Scholar] [CrossRef]

- Pattanaik, M.L.; Choudhary, R.; Kumar, B.; Kumar, A. Mechanical properties of open graded friction course mixtures with different contents of electric arc furnace steel slag as an alternative aggregate from steel industries. Road Mater. Pavement 2021, 22, 268–292. [Google Scholar] [CrossRef]

- Yi, J.; Shen, S.; Muhunthan, B.; Feng, D. Viscoelastic–plastic damage model for porous asphalt mixtures: Application to uniaxial compression and freeze–thaw damage. Mech. Mater. 2014, 70, 67–75. [Google Scholar] [CrossRef]

- Hafeez, I. Investigating the creep response of asphalt mixtures under waveform loading. Road Mater. Pavement 2017, 19, 819–836. [Google Scholar] [CrossRef]

- Venudharan, V.; Biligiri, K.P. Estimation of phase angles of asphalt mixtures using resilient modulus test. Constr. Build. Mater. 2015, 82, 274–286. [Google Scholar] [CrossRef]

- Zhang, H.; Anupam, K.; Scarpas, A.; Kasbergen, C. Comparison of Different Micromechanical Models for Predicting the Effective Properties of Open Graded Mixes. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 404–415. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Cui, B.; Gu, X.; Dong, Q. Comparison of Relaxation Modulus Converted from Frequency- and Time-Dependent Viscoelastic Functions through Numerical Methods. Appl. Sci. 2018, 8, 2447. [Google Scholar] [CrossRef] [Green Version]

- Schapery, R.A.; Park, S.W. Methods of interconversion between linear viscoelastic material functions. Part II—An approximate analytical method. Int. J. Solids Struct. 1999, 36, 1677–1699. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, H.; Li, L.; Zhang, Y.; Wang, H.; Bai, Y. Viscoelastic Properties of Asphalt Mixtures with Different Modifiers at Different Temperatures Based on Static Creep Tests. Appl. Sci. 2019, 9, 4246. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Y.; Li, L.; Zhou, P.; Zhang, Y.; Liu, H. Multi-objective optimization design and test of compound diatomite and basalt fiber asphalt mixture. Materials 2019, 12, 1461. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Irfan, M.; Ali, Y.; Iqbal, S.; Ahmed, S.; Hafeez, I. Rutting Evaluation of Asphalt Mixtures Using Static, Dynamic, and Repeated Creep Load Tests. Arab J. Sci. Eng. 2017, 43, 5143–5155. [Google Scholar] [CrossRef]

- Ma, T.; Wang, H.; Zhang, D.; Zhang, Y. Heterogeneity effect of mechanical property on creep behavior of asphalt mixture based on micromechanical modeling and virtual creep test. Mech. Mater. 2017, 104, 49–59. [Google Scholar] [CrossRef]

- Deepa, S.; Saravanan, U.; Murali Krishnan, J. On measurement of dynamic modulus for bituminous mixtures. Int. J. Pavement Eng. 2017, 20, 1073–1089. [Google Scholar] [CrossRef]

- Lachance-Tremblay, E.; Perraton, D.; Vaillancourt, M.; Di Benedetto, H. Effect of hydrated lime on linear viscoelastic properties of asphalt mixtures with glass aggregates subjected to freeze-thaw cycles. Constr. Build. Mater. 2018, 184, 58–67. [Google Scholar] [CrossRef]

- Chen, S.Q.; Wang, D.S.; Yi, J.Y.; Feng, D.C. Implement the Laplace transform to convert viscoelastic functions of asphalt mixtures. Constr. Build. Mater. 2019, 203, 633–641. [Google Scholar] [CrossRef]

- Sorvari, J.; Malinen, M. Numerical interconversion between linear viscoelastic material functions with regularization. Int. J. Solids Struct. 2007, 44, 1291–1303. [Google Scholar] [CrossRef] [Green Version]

- Anderssen, R.S.; Davies, A.R.; de Hoog, F.R. On the Volterra integral equation relating creep and relaxation. Inverse Probl. 2008, 24, 035009. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Luo, R.; Lytton, R.L. Anisotropic Viscoelastic Properties of Undamaged Asphalt Mixtures. J. Transp. Eng. 2012, 138, 75–89. [Google Scholar] [CrossRef]

- Moon, K.H.; Cannone Falchetto, A.; Marasteanu, M.O. Rheological modelling of asphalt materials properties at low temperatures: From time domain to frequency domain. Road Mater. Pavement 2013, 14, 810–830. [Google Scholar] [CrossRef]

- Sun, Y.; Huang, B.; Chen, J.; Jia, X.; Ding, Y. Characterizing rheological behavior of asphalt binder over a complete range of pavement service loading frequency and temperature. Constr. Build. Mater. 2016, 123, 661–672. [Google Scholar] [CrossRef]

- Li, P.L.; Jiang, X.M.; Guo, K.; Xue, Y.; Dong, H. Analysis of viscoelastic response and creep deformation mechanism of asphalt mixture. Constr. Build. Mater. 2018, 171, 22–32. [Google Scholar] [CrossRef]

- Ho, C.H.; Martin Linares, C.P. Representation Functions to Predict Relaxation Modulus of Asphalt Mixtures Subject to the Action of Freeze-Thaw Cycles. J. Transp. Eng. B Pave 2018, 144, 04018013. [Google Scholar] [CrossRef]

- Hajikarimi, P.; Nejad, F.M.; Aghdam, M.M. Implementing General Power Law to Interconvert Linear Viscoelastic Functions of Modified Asphalt Binders. J. Transp. Eng. B Pave 2018, 144. [Google Scholar] [CrossRef]

- Wu, C.; Li, L.; Wang, W.; Gu, Z. Experimental Characterization of Viscoelastic Behaviors of Nano-TiO2/CaCO3 Modified Asphalt and Asphalt Mixture. Nanomaterials (Basel) 2021, 11, 106. [Google Scholar] [CrossRef]

- Park, S.W.; Schapery, R. Methods of interconversion between linear viscoelastic material functions. Part I—A numerical method based on Prony series. Int. J. Solids Struct. 1998, 36, 1653–1675. [Google Scholar] [CrossRef]

- Mainardi, F.; Spada, G. Creep, relaxation and viscosity properties for basic fractional models in rheology. Eur. Phys. J. Spec. Top. 2011, 193, 133–160. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Gu, X.; Lv, J.; Zhu, Z.; Ni, F. Mechanism and behavior of fiber-reinforced asphalt mastic at high temperature. Int. J. Pavement Eng. 2018, 19, 407–415. [Google Scholar] [CrossRef]

- Sun, Y.; Gu, B.; Gao, L.; Li, L.; Guo, R.; Yue, Q.; Wang, J. Viscoelastic Mechanical Responses of HMAP under Moving Load. Materials 2018, 11, 2490. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liang, C.; Zhang, H.; Gu, Z.; Xu, X.; Hao, J. Study on Mechanical and Viscoelastic Properties of Asphalt Mixture Modified by Diatomite and Crumb Rubber Particles. Appl. Sci. 2020, 10, 8748. [Google Scholar] [CrossRef]

- Gu, L.; Chen, L.; Zhang, W.; Ma, H.; Ma, T. Mesostructural Modeling of Dynamic Modulus and Phase Angle Master Curves of Rubber Modified Asphalt Mixture. Materials 2019, 12, 1667. [Google Scholar] [CrossRef] [Green Version]

- Di Benedetto, H.; Olard, F.; Sauzéat, C.; Delaporte, B. Linear viscoelastic behaviour of bituminous materials: From binders to mixes. Road Mater. Pavement 2004, 5, 163–202. [Google Scholar] [CrossRef]

| Properties | Standard | Results |

|---|---|---|

| Penetration (0.1 mm) at 25 °C | 60–80 | 67.9 |

| Ductility (cm) at 5 °C | ≥20 | 26.8 |

| Softening point TR&B (°C) | ≥65 | 76.4 |

| Elastic recovery (%) at 25 °C | ≥85 | 90.3 |

| After rolling thin film oven test | ||

| Mass loss (%) | ≤±0.8 | 0.26 |

| Residual penetration ratio (%) at 25 °C | ≥60 | 81.5 |

| Residual ductility (cm) at 5 °C | ≥10 | 14.4 |

| Sieve Size (mm) | 0.075 | 0.15 | 0.3 | 0.6 | 1.18 | 2.36 | 4.75 | 9.5 | 13.2 | 16 |

| Percent passing (%) | 4 | 5.5 | 7.5 | 9.5 | 12 | 16 | 21 | 70 | 95 | 100 |

| Fitting Model | Parameters | Test Temperature (°) | ||||

|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | ||

| Burgers model | Eb1 (MPa) | 2031.74 | 409.42 | 136.06 | 90.30 | 47.97 |

| ηb1 (MPa∙s) | 1.81 × 106 | 7.57 × 105 | 4.47 × 105 | 2.40 × 105 | 1.52 × 105 | |

| Eb2 (MPa) | 646.61 | 143.43 | 90.37 | 58.69 | 44.06 | |

| ηb2 (MPa∙s) | 87,432.04 | 15,779.04 | 8351.56 | 5520.72 | 3510.45 | |

| τb (s) | 135.2 | 110.0 | 92.4 | 94.1 | 79.7 | |

| R2 | 0.9943 | 0.9912 | 0.9864 | 0.9887 | 0.9867 | |

| Modified Burgers model | Em1 (MPa) | 2290.66 | 397.43 | 184.10 | 92.88 | 48.88 |

| Am | 71,157.57 | 15,954.89 | 72,040.56 | 4739.02 | 3328.47 | |

| Bm | 0.0138 | 0.0101 | 0.0011 | 0.0156 | 0.0148 | |

| Em2 (MPa) | 360.79 | 155.54 | 134.28 | 48.47 | 30.28 | |

| ηm2 (MPa∙s) | 6.84 × 105 | 3.69 × 105 | 3.25 × 103 | 9.59 × 104 | 8.10 × 104 | |

| R2 | 0.9983 | 0.9937 | 0.9963 | 0.9930 | 0.9902 | |

| Fitting Model | Parameters | Test Temperature (°C) | ||||

|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | ||

| Second-order extensive Maxwell model | G1 (MPa) | 846.14 | 160.89 | 55.29 | 37.21 | 17.96 |

| G2 (MPa) | 409.42 | 98.05 | 51.14 | 33.28 | 21.59 | |

| ρ1 (s) | 76.06 | 61.96 | 67.55 | 67.64 | 69.55 | |

| ρ2 (s) | 5076.08 | 9107.26 | 10,255.41 | 8208.08 | 7977.76 | |

| R2 | 0.9180 | 0.9229 | 0.9616 | 0.9634 | 0.9731 | |

| Scott-Blair model | η | 3483.14 | 442.90 | 164.96 | 117.90 | 63.53 |

| α | 0.3048 | 0.2113 | 0.1678 | 0.1848 | 0.1634 | |

| R2 | 0.9865 | 0.9518 | 0.9842 | 0.9901 | 0.9952 | |

| Parameters | |||||

|---|---|---|---|---|---|

| 10 | 0.353 | 5.041 | −0.746 | −0.149 | −0.585 |

| 20 | 0.297 | 5.041 | −0.518 | −0.149 | −0.574 |

| 30 | 0.330 | 5.043 | −0.356 | −0.149 | −0.582 |

| Parameters | Test Temperature (°C) | ||||

|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |

| Ge (MPa) | 23.26 | 41.88 | 30.86 | 12.03 | 7.12 |

| G1 (MPa) | 6573.63 | 6284.02 | 6284.02 | 6284.02 | 6283.98 |

| G2 (MPa) | 6573.63 | 1073.81 | 192.55 | 133.20 | 53.75 |

| G3 (MPa) | 6573.63 | 1073.81 | 192.55 | 133.20 | 53.75 |

| G4 (MPa) | 755.43 | 147.87 | 47.63 | 32.22 | 15.01 |

| G5 (MPa) | 424.01 | 67.33 | 24.56 | 16.50 | 7.87 |

| G6 (MPa) | 191.83 | 27.44 | 15.90 | 11.38 | 7.87 |

| G7 (MPa) | 191.83 | 27.44 | 4.91 | 10.24 | 7.10 |

| R2 | 0.9953 | 0.9953 | 0.9985 | 0.9985 | 0.9992 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Wu, C.; Cheng, Y.; Ai, Y.; Li, H.; Tan, X. Comparative Analysis of Viscoelastic Properties of Open Graded Friction Course under Dynamic and Static Loads. Polymers 2021, 13, 1250. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13081250

Li L, Wu C, Cheng Y, Ai Y, Li H, Tan X. Comparative Analysis of Viscoelastic Properties of Open Graded Friction Course under Dynamic and Static Loads. Polymers. 2021; 13(8):1250. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13081250

Chicago/Turabian StyleLi, Liding, Chunli Wu, Yongchun Cheng, Yongming Ai, He Li, and Xiaoshu Tan. 2021. "Comparative Analysis of Viscoelastic Properties of Open Graded Friction Course under Dynamic and Static Loads" Polymers 13, no. 8: 1250. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13081250