Low-Velocity Impact Response of Auxetic Seamless Knits Combined with Non-Newtonian Fluids

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

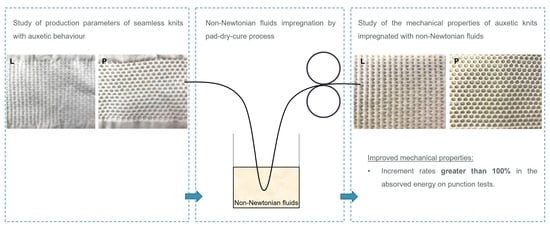

2.2. Methods

3. Results

3.1. Auxetic Behaviour

3.2. Structural and Mechanical Characterization

3.3. Combination of Auxetic Knits with STF

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Safri, S.N.A.; Sultan, M.T.H.; Yidris, N.; Mustapha, F. Low velocity and high velocity impact test on composite materials—A review. Int. J. Eng. Sci. (IJES) 2014, 3, 50–60. [Google Scholar] [CrossRef]

- Alcock, B.; Cabrera, N.O.; Barkoula, N.M.; Peijs, T. Low velocity impact performance of recyclable all-polypropylene composites. Compos. Sci. Technol. 2006, 66, 1724–1737. [Google Scholar] [CrossRef]

- Duncan, O.; Shepherd, T.; Moroney, C.; Foster, L.; Venkatraman, P.D.; Winwood, K.; Allen, T.; Alderson, A. Review of auxetic materials for sports applications: Expanding options in comfort and protection. Appl. Sci. 2018, 8, 941. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Zeng, J.; Jiang, L.; Hu, H. Low-velocity impact properties of 3D auxetic textile composite. J. Mater. Sci. 2017, 53, 3899–3914. [Google Scholar] [CrossRef]

- Chang, Y.; Ma, P.; Jiang, G. Energy absorption property of warp-knitted spacer fabrics with negative Possion’s ratio under low velocity impact. Compos. Struct. 2017, 182, 471–477. [Google Scholar] [CrossRef]

- Xu, W.; Yan, B.; Hu, D.; Ma, P. Preparation of auxetic warp-knitted spacer fabric impregnated with shear thickening fluid for low-velocity impact resistance. J. Ind. Text. 2020, 1528083720927013. [Google Scholar] [CrossRef]

- Al-Rifaie, H.; Studziński, R.; Gajewski, T.; Malendowski, M.; Sumelka, W.; Sielicki, P.W. A new blast absorbing sandwich panel with unconnected corrugated layers—numerical study. Energies 2021, 14, 214. [Google Scholar] [CrossRef]

- Sun, D.; Zhu, F.; Stylios, G.K. Investigation of composite fabric impregnated with non-Newtonian fluid for protective textiles. J. Compos. Mater. 2019, 1–9. [Google Scholar] [CrossRef]

- Santos, T.F.; Santos, C.M.; Aquino, M.S.; Oliveira, F.R.; Medeiros, J.I. Statistical study of performance properties to impact of Kevlar® woven impregnated with Non-Newtonian Fluid (NNF). J. Mater. Res. Technol. 2020, 9, 3330–3339. [Google Scholar] [CrossRef]

- de Goede, T.C.; de Bruin, K.G.; Bonn, D. High-velocity impact of solid objects on Non-Newtonian Fluids. Nature 2019, 9, 1250. [Google Scholar] [CrossRef]

- Lima, M.; Silva, L.F.; Vasconcelos, R.; Martins, J.; Hes, L. FRICTORQ, Tribómetro para Avaliação Objectiva de Superfícies Têxteis. Communication 2005, 1–11. [Google Scholar]

- Hu, H.; Zulifqar, A. Auxetic Textile Materials—A review. J. Text. Eng. Fash. Technol. 2017, 1, 00002. [Google Scholar] [CrossRef]

- Debnath, S.; Madhusoothanan, M. Thermal insulation, compression and air permeability of polyester needle-punched nonwoven. Indian J. Fibre Text. Res. 2010, 35, 38–44. [Google Scholar]

- Ogulata, R.T.; Mezarcioz, S.M. Optimization of air permeability of knitted fabrics with the Taguchi approach. J. Text. Inst. 2011, 102, 395–404. [Google Scholar] [CrossRef]

- Vilhena, L.; Ramalho, A. Friction of Human Skin against Different Fabrics for Medical Use. Lubricants 2016, 4, 1–10. [Google Scholar] [CrossRef]

- Čiukas, R.; Abramavičiūtė, J. Investigation of the Air Permeability of Socks Knitted from Yarns with Peculiar Properties. Fibres Text. East. Eur. 2010, 18, 84–88. [Google Scholar]

- Santos, T.F.; Santos, C.M.; Fonseca, R.T.; Melo, K.M.; Aquino, M.S.; Oliveira, F.R.; Medeiros, J.I. Experimental analysis of the impact protection properties for Kevlar® fabrics under different orientation layers and non-Newtonian fluid compositions. J. Compos. Mater. 2020, 54, 3515–3526. [Google Scholar] [CrossRef]

- Santos, T.F.; Santos, C.M.S.; Aquino, M.S.; Ionesi, D.; Medeiros, J.I. Influence of silane coupling agent on shear thickening fluids (STF) for personal protection. J. Mater. Res. Technol. 2019, 8, 4032–4039. [Google Scholar] [CrossRef]

- Lu, Z.; Jing, X.; Sun, B.; Gu, B. Compressive behaviors of warp-knitted spacer fabrics impregnated with shear thickening fluid. Compos. Sci. Technol. 2013, 88, 184–189. [Google Scholar] [CrossRef]

- Mohsenizadeh, M.; Gasbarri, F.; Munther, M.; Beheshti, A.; Davami, K. Additively-manufactured lightweight Metamaterials for energy absorption. Mater. Des. 2018, 139, 521–530. [Google Scholar] [CrossRef]

- Yan, R.; Wang, R.; Lou, C.W.; Lin, J.H. Low-velocity impact and static behaviors of high-resilience thermal-bonding inter/intra-ply hybrid composites. Compos. Part B Eng. 2015, 69, 58–68. [Google Scholar] [CrossRef]

| Pattern | Polyamide | Knit Stitch | Reference |

|---|---|---|---|

| L | PA 78/68×2×2 | P0 | L_PA 78/68×2_P0 |

| PA 78/68×3 | P-15 | L_PA 78/68×3_P-15 | |

| P0 | L_PA 78/68×3_P0 | ||

| P | PA 78/68×2×2 | P0 | P_PA 78/68×2_P0 |

| PA 78/68×3 | P-15 | P_PA 78/68×3_P-15 | |

| P0 | P_PA 78/68×2×2_P0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pais, V.; Silva, P.; Bessa, J.; Dias, H.; Duarte, M.H.; Cunha, F.; Fangueiro, R. Low-Velocity Impact Response of Auxetic Seamless Knits Combined with Non-Newtonian Fluids. Polymers 2022, 14, 2065. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14102065

Pais V, Silva P, Bessa J, Dias H, Duarte MH, Cunha F, Fangueiro R. Low-Velocity Impact Response of Auxetic Seamless Knits Combined with Non-Newtonian Fluids. Polymers. 2022; 14(10):2065. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14102065

Chicago/Turabian StylePais, Vânia, Pedro Silva, João Bessa, Hernâni Dias, Maria Helena Duarte, Fernando Cunha, and Raul Fangueiro. 2022. "Low-Velocity Impact Response of Auxetic Seamless Knits Combined with Non-Newtonian Fluids" Polymers 14, no. 10: 2065. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14102065