Towards Sustainable Composite Manufacturing with Recycled Carbon Fiber Reinforced Thermoplastic Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Carbon Fibers

2.2. Matrix Materials

2.3. Fiber Surface Modification

2.4. Interfacial Shear Strength

2.5. Single Fiber Tensile Testing

2.6. Scanning Electron Microscopy

2.7. Use-Case Study

3. Results and Discussion

3.1. Fiber Characterization

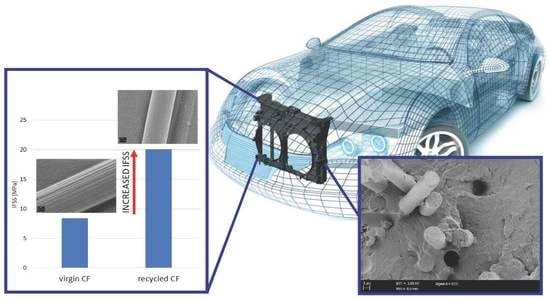

3.2. Interfacial Shear Strength

3.3. Macroscopic Testing of Use-Case Applications

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hazell, P.J.; Stennett, C.; Cooper, G. The effect of specimen thickness on the shock propagation along the in-fibre direction of an aerospace-grade CFRP laminate. Compos. Part A Appl. Sci. Manuf. 2009, 40, 204–209. [Google Scholar] [CrossRef] [Green Version]

- Deshmukh, K.A.; Chopra, S.; Khajanji, P.; Gaidhani, V.; Gopichand, U.; Gawande, A.; Turkar, S.; Khodaskar, F.; Deshmukh, A.D.; Peshwe, D.R. Augmenting the wear performance of epoxy composites by different fillers: Synthesis of highly crystalline g-C3N4 by simple pyrolysis and recycling of carbon fibres from old aircraft composites. Appl. Surf. Sci. Adv. 2021, 6, 100125. [Google Scholar] [CrossRef]

- Friedrich, K. Carbon Fiber Reinforced Thermoplastic Composites for Future Automotive Applications; AIP Publishing LLC: Melville, NY, USA; p. 020001.

- Henninger, F.; Friedrich, K. Production of textile reinforced thermoplastic profiles by roll forming. Compos. Part A Appl. Sci. Manuf. 2004, 35, 573–583. [Google Scholar] [CrossRef]

- Lu, S.; Bai, E.; Xu, J.; Chen, J. Research on electromagnetic properties and microwave deicing performance of carbon fiber modified concrete. Constr. Build. Mater. 2021, 286, 122868. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schneider, K.; Großmann, C. Mineral-impregnated carbon fiber composites as novel reinforcement for concrete construction: Material and automation perspectives. Autom. Constr. 2020, 110, 103002. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process. Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- May, D.; Goergen, C.; Friedrich, K. Multifunctionality of polymer composites based on recycled carbon fibers: A review. Adv. Ind. Eng. Polym. Res. 2021, 4, 70–81. [Google Scholar] [CrossRef]

- European Commission. Directive 2008/98/EC on Waste (Waste Framework Directive); European Commission: Luxembourg, 2018. [Google Scholar]

- Roux, M.; Eguémann, N.; Dransfeld, C.; Thiébaud, F.; Perreux, D. Thermoplastic carbon fibre-reinforced polymer recycling with electrodynamical fragmentation: From cradle to cradle. J. Thermoplast. Compos. Mater. 2017, 30, 381–403. [Google Scholar] [CrossRef]

- Park, J.M.; Kwon, D.J.; Wang, Z.J.; Gu, G.Y.; DeVries, K.L. Effect of thermal treatment temperatures on the reinforcing and interfacial properties of recycled carbon fiber–phenolic composites. Compos. Part A Appl. Sci. Manuf. 2013, 47, 156–164. [Google Scholar] [CrossRef]

- Cai, G.; Wada, M.; Ohsawa, I.; Kitaoka, S.; Takahashi, J. Influence of treatment with superheated steam on tensile properties of carbon fiber. Compos. Part A Appl. Sci. Manuf. 2018, 107, 555–560. [Google Scholar] [CrossRef]

- Ye, S.Y.; Bounaceur, A.; Soudais, Y.; Barna, R. Parameter optimization of the steam thermolysis: A process to recover carbon fibers from polymer-matrix composites. Waste Biomass Valorization 2013, 4, 73–86. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef] [Green Version]

- Morin, C.; Loppinet-Serani, A.; Cansell, F.; Aymonier, C. Near-and supercritical solvolysis of carbon fibre reinforced polymers (CFRPs) for recycling carbon fibers as a valuable resource: State of the art. J. Supercrit. Fluids 2012, 66, 232–240. [Google Scholar] [CrossRef] [Green Version]

- Piñero-Hernanz, R.; Dodds, C.; Hyde, J.; García-Serna, J.; Poliakoff, M.; Lester, E.; Cocero, M.J.; Kingman, S.; Pickering, S.; Wong, K.H. Chemical recycling of carbon fibre reinforced composites in nearcritical and supercritical water. Compos. Part A Appl. Sci. Manuf. 2008, 39, 454–461. [Google Scholar] [CrossRef]

- Pei, C.; Chen, P.Y.; Kong, S.C.; Wu, J.; Zhu, J.H.; Xing, F. Recyclable separation and recovery of carbon fibers from CFRP composites: Optimization and mechanism. Sep. Purif. Technol. 2021, 278, 119591. [Google Scholar] [CrossRef]

- Santacesaria, E.; Tesser, R.; Mallardo, S.; Vitiello, R.; Di Serio, M.; Dimiccoli, A.; Saviano, L. Thermochemical Process for Recovering Fiberglass Reinforced Plastics Waste Matter. Patent EP 3114192 (WO 2015162505A2), 29 October 2015. [Google Scholar]

- Ma, Y.; Yan, C.; Xu, H.; Liu, D.; Shi, P.; Zhu, Y.; Liu, J. Enhanced interfacial properties of carbon fiber reinforced polyamide 6 composites by grafting graphene oxide onto fiber surface. Appl. Surf. Sci. 2018, 452, 286–298. [Google Scholar] [CrossRef]

- Fernández, A.; Santangelo-Muro, M.; Fernández-Blázquez, J.P.; Lopes, C.S.; Molina-Aldareguia, J.M. Processing and properties of long recycled-carbon-fibre reinforced polypropylene. Compos. Part B Eng. 2021, 211, 108653. [Google Scholar] [CrossRef]

- Cai, G.; Wada, M.; Ohsawa, I.; Kitaoka, S.; Takahashi, J. Interfacial adhesion of recycled carbon fibers to polypropylene resin: Effect of superheated steam on the surface chemical state of carbon fiber. Compos. Part A Appl. Sci. Manuf. 2019, 120, 33–40. [Google Scholar] [CrossRef]

- Miller, B.; Muri, P.; Rebenfeld, L. A microbond method for determination of the shear strength of a fiber/resin interphase. Compos. Sci. Technol. 1987, 28, 17–32. [Google Scholar] [CrossRef]

- Laurikainen, P.; Kakkonen, M.; von Essen, M.; Tanhuanpää, O.; Kallio, P.; Sarlin, E. Identification and compensation of error sources in the microbond test utilising a reliable high-throughput device. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105988. [Google Scholar] [CrossRef]

- Watanabe, J.; Tanaka, F.; Okuda, H.; Okabe, T. Tensile strength distribution of carbon fibers at short gauge lengths. Adv. Compos. Mater. 2014, 23, 535–550. [Google Scholar] [CrossRef]

- Li, C.; Xian, G. Experimental and modeling study of the evolution of mechanical properties of PAN-based carbon fibers at elevated temperatures. Materials 2019, 12, 724. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nevare, M.R.; Tatiya, P.D.; Mahulikar, P.P.; Gite, V.V. Effect of maleated polypropylene as a compatibilizer and hyperbranched polyester as a processing aid on polypropylene-wood flour biocomposites. J. Vinyl Addit. Technol. 2018, 24, 179–184. [Google Scholar] [CrossRef]

- Palola, S.; Javanshour, F.; Kolahgar Azari, S.; Koutsos, V.; Sarlin, E. One Surface Treatment, Multiple Possibilities: Broadening the Use-Potential of Para-Aramid Fibers with Mechanical Adhesion. Polymers 2021, 13, 3114. [Google Scholar] [CrossRef]

- Vedrtnam, A.; Sharma, S.P. Study on the performance of different nano-species used for surface modification of carbon fiber for interphase strengthening. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105509. [Google Scholar] [CrossRef]

- Wang, H.; Jin, K.; Tao, J. Improving the interfacial shear strength of carbon fibre and epoxy via mechanical interlocking effect. Compos. Sci. Technol. 2020, 200, 108423. [Google Scholar] [CrossRef]

- Wada, M.; Kawai, K.; Suzuki, T.; Hira, H.; Kitaoka, S. Effect of superheated steam treatment of carbon fiber on interfacial adhesion to epoxy resin. Compos. Part A Appl. Sci. Manuf. 2016, 85, 156–162. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Zhang, C.; Zhang, B. Effects of thermal histories on interfacial properties of carbon fiber/polyamide 6 composites: Thickness, modulus, adhesion and shear strength. Compos. Part A Appl. Sci. Manuf. 2016, 85, 31–39. [Google Scholar] [CrossRef]

| Use Case | Loaded Component | Load (kN) | Deformation Limits | |

|---|---|---|---|---|

| Elastic Deformation (mm) | Plastic Deformation (mm) | |||

| Pedal bracket | Brake pedal | 2.3 | <17.0 | <5.0 |

| 3.0 | No failure | No failure | ||

| Gas pedal | 0.2 | <6.0 | <2.0 | |

| 1.0 | No failure | No failure | ||

| Stiffness (N/mm) | Strength | |||

| Front-end carrier | Bonnet latch traction | 2.3 | >420 | No failure |

| Bonnet latch compression | 1.5 | >350 | No failure | |

| Sample | IFSS (MPa) | Stdev (MPa) | Successful/Failed Fiber Samples |

|---|---|---|---|

| CF | 62.5 | 3.7 | 5/0 |

| rCFs | 66.5 | 6.0 | 5/1 |

| rCFs 1 wt% FF | 54.7 | 5.5 | 5/3 |

| rCFs 5 wt% FF | N/A | N/A | 0/5 |

| Sample | Matrix | Critical Length (mm) |

|---|---|---|

| CF | PP | 2.00 |

| PA6 | 0.51 | |

| rCFs | PP | 1.67 |

| PA6 | 0.78 | |

| rCFp | PP | 0.46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palola, S.; Laurikainen, P.; García-Arrieta, S.; Goikuria Astorkia, E.; Sarlin, E. Towards Sustainable Composite Manufacturing with Recycled Carbon Fiber Reinforced Thermoplastic Composites. Polymers 2022, 14, 1098. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14061098

Palola S, Laurikainen P, García-Arrieta S, Goikuria Astorkia E, Sarlin E. Towards Sustainable Composite Manufacturing with Recycled Carbon Fiber Reinforced Thermoplastic Composites. Polymers. 2022; 14(6):1098. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14061098

Chicago/Turabian StylePalola, Sarianna, Pekka Laurikainen, Sonia García-Arrieta, Egoitz Goikuria Astorkia, and Essi Sarlin. 2022. "Towards Sustainable Composite Manufacturing with Recycled Carbon Fiber Reinforced Thermoplastic Composites" Polymers 14, no. 6: 1098. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14061098