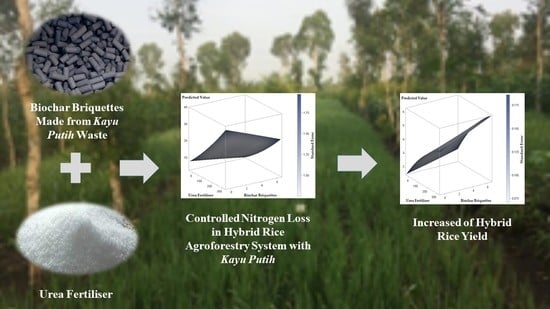

Short-Term Effect of In Situ Biochar Briquettes on Nitrogen Loss in Hybrid Rice Grown in an Agroforestry System for Three Years

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site

2.2. Experimental Design

2.3. Biochar Briquettes Preparation

2.4. Field Layout and Treatments Application

2.5. Data Collection

2.6. Statistical Approach

3. Results

3.1. Interaction between Biochar Briquettes, Nitrogen Fertiliser, and the Experimental Time Period

3.2. Comparison of Response Variables between Experimental Years

3.3. Fitted Models and Estimated Outcome of Response Variables

3.4. Relationship between Soil Properties, Physiological Characteristics, and Hybrid Rice Yield

3.5. Determining the Optimum Scenarios

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. World Food and Agriculture Statistical Pocketbook 2019; The Food and Agriculture Organization (FAO): Rome, Italy, 2013; Available online: http://www.fao.org/3/ca6463en/ca6463en.pdf (accessed on 15 September 2021).

- Statistics Indonesia. The Harvested Area and Rice Production in Indonesia. 2019. Available online: http://www.bps.go.id/pressrelease/2020/02/04/1752/luas-panen-dan-produksi-padi-pada-tahun-2019-mengalami-penurunan-dibandingkan-tahun-2018-masing-masing-sebesar-6-15-dan-7-76-persen.html (accessed on 15 September 2021).

- Mulyani, A.; Nursyamsi, D.; Syakir, M. Strategi pemanfaatan sumberdaya lahan untuk pencapaian swasembada beras berkelanjutan. J. Sumberd. Lahan 2017, 11, 11–22. [Google Scholar] [CrossRef]

- Alam, T.; Kurniasih, B.; Suryanto, P.; Basunanda, P.; Supriyanta; Ambarwati, E.; Widyawan, M.H.; Handayani, S.; Taryono. Stability analysis for soybean in agroforestry system with kayu putih. SABRAO J. Breed Genet. 2019, 51, 405–418. [Google Scholar]

- Suryanto, P.; Putra, E.T.S.; Alam, T. Minimum soil quality determinant for rice and ‘kayu putih’ yield under hilly areas. J. Agron. 2017, 16, 115–123. [Google Scholar] [CrossRef]

- Suryanto, P.; Kurniasih, B.; Faridah, E.; Nurjanto, H.H.; Rogomulyo, R.; Handayani, S.; Kastono, D.; Muttaqin, A.S.; Alam, T. Influence of furrow with organic material and Chromolaena odorata compost on upland rice productivity in an agroforestry system with Melaleuca cajuputi. Biodiversitas 2020, 21, 780–791. [Google Scholar]

- Suryanto, P.; Taryono, T.; Supriyanta, S.; Kastono, D.; Putra, E.T.S.; Widyawan, M.H.; Alam, T. Assessment of soil quality parameters and yield of rice cultivars in Melaleuca cajuputi agroforestry system. Biodiversitas 2020, 21, 3463–3470. [Google Scholar] [CrossRef]

- Huang, M.; Jiang, L.; Xia, B.; Zou, Y.; Jiang, P.; Ao, H. Yield gap analysis of super hybrid rice between two subtropical environments. Aust. J. Crop. Sci. 2013, 7, 600–608. [Google Scholar]

- Xu, L.; Yuan, S.; Wang, X.; Yu, X.; Peng, S. High yields of hybrid rice do not require more nitrogen fertilizer than inbred rice: A meta–analysis. Food Energy Secur. 2021, 10, 341–350. [Google Scholar] [CrossRef]

- Dawson, I.K.; Place, F.; Torquebiau, E.; Malézieux, E.; Iiyama, E.; Sileshi, G.W.; Kehlenbeck, K.; Masters, E.; McMullin, S.; Jamnadass, R. Agroforestry, Food and Nutritional Security; The Food and Agriculture Organization (FAO): Rome, Italy, 2013; Available online: http://www.fao.org/forestry/37082–04957fe26afbc90d1e9c0356c48185295.pdf (accessed on 15 September 2021).

- Suryanto, P.; Sadono, R.; Yohanifa, A.; Widyawan, M.H.; Alam, T. Semi–natural regeneration and conservation in agroforestry system models on small–scale farmers. Biodiversitas 2021, 22, 858–865. [Google Scholar] [CrossRef]

- Kartikawati, N.K.; Rimbawanto, A.; Susanto, M.; Baskorowati, L.; Prastyono. Budidaya dan Prospek Pengembangan Kayu Putih (Melaleuca cajuputi); IPB Press: Bogor, Indonesia, 2014; pp. 1–3. [Google Scholar]

- Alam, T.; Suryanto, P.; Handayani, S.; Kastono, D.; Kurniasih, B. Optimizing application of biochar, compost and nitrogen fertilizer in soybean intercropping with kayu putih (Melaleuca cajuputi). Rev. Bras. Cienc. Solo 2020, 44, e0200003. [Google Scholar] [CrossRef]

- Faridah, E.; Suryanto, P.; Nurjanto, H.H.; Putra, E.T.S.; Falah, M.D.; Widyawan, M.H.; Alam, T. Optimizing application of biochar amendment for nitrogen use efficiency in upland rice under Melaleuca cajuputi stands. Indian J. Agric. Res. 2021, 55, 105–109. [Google Scholar] [CrossRef]

- Marschner, H. Marschner’s Mineral Nutrition of Higher Plants, 3rd ed.; Academic Press: Cambridge, MA, USA, 2011; pp. 135–150. [Google Scholar]

- Liu, T.; Huang, J.; Chai, K.; Cao, C.; Li, C. Effects of N fertilizer sources and tillage practices on NH3 volatilization, grain yield, and N use efficiency of rice fields in Central China. Front. Plant Sci. 2018, 9, 385. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, Y.; Zou, X.; Li, F.; Zhang, J.; Kang, Z.; Li, X.; Yin, C.; Lin, Y. Nitrogen deficiency-induced decrease in cytokinins content promotes rice seminal root growth by promoting root meristem cell proliferation and cell elongation. Cells 2020, 9, 916. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Darras, K.F.A.; Corre, M.D.; Formaglio, G.; Tjoa, A.; Potapov, A.; Brambach, F.; Sibhatu, K.T.; Grass, I.; Rubiano, A.A.; Buchori, D. Reducing fertilizer and avoiding herbicides in oil palm plantations–Ecological and economic valuations. Front. Glob. Chang. 2019, 2, 65. [Google Scholar] [CrossRef] [Green Version]

- Pardon, L.; Bessou, C.; Nelson, P.N.; Dubos, B.; Ollivier, J.; Marichal, R.; Caliman, J.P.; Gabrielle, B.B. Key unknowns in nitrogen budget for oil palm plantations: A review. Agron. Sustain. Dev. 2016, 36, 20. [Google Scholar] [CrossRef] [Green Version]

- Yadegari, M.; Shamshiri, R.R.; Shariff, A.R.M.; Balasundram, S.K.; Mahns, B. Using SPOT–7 for Nitrogen fertilizer management in oil palm. Agriculture 2020, 10, 133. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.; Yang, Z.; Du, J.; He, A.; Yang, H.; Xue, G.; Yu, C.; Zhang, Y. Adding NBPT to urea increases N use efficiency of maize and decreases the abundance of N–cycling soil microbes under reduced fertilizer–N rate on the North China Plain. PLoS ONE 2020, 15, e0240925. [Google Scholar] [CrossRef]

- Lu, J.; Wang, D.; Liu, K.; Chu, G.; Huang, L.; Tian, X.; Zhang, Y. Inbred varieties outperformed hybrid rice varieties under dense planting with reducing nitrogen. Sci. Rep. 2020, 10, 8769. [Google Scholar] [CrossRef]

- Guo, L.; Bornø, M.L.; Niu, W.; Liu, F. Biochar amendment improves shoot biomass of tomato seedlings and sustains water relations and leaf gas exchange rates under different irrigation and nitrogen regimes. Agric. Wat. Manag. 2021, 245, 106580. [Google Scholar] [CrossRef]

- Ghorbani, M.; Amirahmadi, E.; Zamanian, K. In–situ biochar production in paddies: Direct involvement of farmers in greenhouse gases reduction policies besides increasing nutrients availability and rice production. Land Degrad. Dev. 2021, 32, 3893–3904. [Google Scholar] [CrossRef]

- Kang, S.W.; Yun, J.J.; Park, J.H.; Cho, J.S. Exploring suitable biochar application rates with compost to improve upland field environment. Agronomy 2021, 11, 1136. [Google Scholar] [CrossRef]

- Lehmann, J.; Joseph, S. Biochar for Environmental Management: Science, 1st ed.; Earthscan: London, UK, 2009; pp. 2–5. [Google Scholar]

- Medeiros, D.C.C.S.; Nzediegwu, C.; Benally, C.; Messele, S.A.; Kwak, J.-H.; Naeth, M.A.; Ok, Y.S.; Chang, S.X.; El-Din, M.G. Pristine and engineered biochar for the removal of contaminants co-existing in several types of industrial wastewaters: A critical review. Sci. Tot. Environ. 2022, 809, 151120. [Google Scholar] [CrossRef] [PubMed]

- Abdel–Fattah, T.M.; Mahmoud, M.E.; Ahmed, S.B.; Huff, M.D.; Lee, J.W.; Kumar, S. Biochar from woody biomass for removing metal contaminants and carbon sequestration. J. Ind. Eng. Chem. 2015, 22, 103–109. [Google Scholar] [CrossRef]

- Coumaravel, K.; Santhi, R.; Maragatham, S. Effect of biochar on yield and nutrient uptake by hybrid maize and on soil fertility. Indian J. Agric. Res. 2015, 49, 185–188. [Google Scholar] [CrossRef]

- Selvarajh, G.; Ch’ng, H.Y.; Md Zain, N.; Sannasi, P.; Azmin, S.N.H.M. Improving soil nitrogen availability and rice growth performance on a tropical acid soil via mixture of rice husk and rice straw biochars. Appl. Sci. 2021, 11, 108. [Google Scholar] [CrossRef]

- Alkharabsheh, H.M.; Seleiman, M.F.; Battaglia, M.L.; Shami, A.; Jalal, R.S.; Alhammad, B.A.; Almutairi, K.F.; Al–Saif, A.M. Biochar and its broad impacts in soil quality and fertility, nutrient leaching and crop productivity: A Review. Agronomy 2021, 11, 993. [Google Scholar] [CrossRef]

- Blanco-Canqui, H. Biochar and soil physical properties. Soil Sci. Soc. Am. J. 2017, 81, 687. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.-Z.; Dijkstra, F.A.; Liu, X.-R.; Wang, Y.-D.; Huang, J.; Lu, N. Effects of biochar on soil microbial biomass after four years of consecutive application in the North China Plain. PLoS ONE 2014, 9, e102062. [Google Scholar] [CrossRef] [Green Version]

- Cahayaningrum, F. The Effect of Biochar and Urea for Growth and Yield of Maize (Zea mays L.) under Kayu Putih Stands in Dry Season. Bachelor’s Thesis, Faculty of Agriculture, Universitas Gadjah Mada, Yogyakarta, Indonesia, 2021. [Google Scholar]

- Sianturi, S.R.N. The Effect of Biochar Types and Urea for Growth and Yield of Maize (Zea mays L.) under Kayu Putih Stands in Wet Season. Bachelor’s Thesis, Faculty of Agriculture, Universitas Gadjah Mada, Yogyakarta, Indonesia, 2021. [Google Scholar]

- Torane, H.B.; Kasture, M.C.; Kokare, V.G.; Sanap, P.B. Effect of bio–degradable coated fertilizer briquettes and their application time on growth, yield, and nutrient content on soil properties of cucumber in lateritic soil of Konkan Maharashtra. Int. J. Chem. Stud. 2017, 5, 27–32. [Google Scholar]

- Alam, T.; Suryanto, P.; Kastono, D.; Putra, E.T.S.; Handayani, S.; Widyawan, M.H.; Muttaqin, A.S.; Kurniasih, B. Evaluation of interactions between biochar briquette with ammonium sulfate fertilizer for controlled nitrogen loss in soybean intercopping with Melaleuca cajuputi. Legume Res. 2021, 4, 339–343. [Google Scholar]

- Boettinger, J.; Chiaretti, J.; Ditzler, C.; Galbraith, J.; Kerschen, K.; Loerch, C.; McDanie, P.; McVey, S.; Monger, C.; Owens, P. Illustrated Guide to Soil Taxonomy, Version 2; United States Department of Agriculture, Natural Resources Conservation Service: Washington, DC, USA, 2015; pp. 1–12. [Google Scholar]

- Djaenudin, D.; Marwan, H.; Subagjo, H.; Hidayat, A. Technical Instructions Land Evaluation for Agricultural Commodities; Indonesian Agency for Agricultural Research and Development, Ministry of Agriculture: Bogor, Indonesia, 2011; p. 38. [Google Scholar]

- Emrich, W. Handbook of Biochar Making–The Traditional and Industrial Methods; Springer: Dordrecht, The Netherlands, 1985; pp. 19–106. [Google Scholar]

- Klute, A. Water capacity. In Methods of Soil Analysis: Part 1 Physical and Mineralogical Properties, Including Statistics of Measurement and Sampling, 9.1; Black, C.A., Ed.; American Society of Agronomy, Inc.: Madison, WI, USA, 1965; pp. 273–278. [Google Scholar]

- Vomocil, J.A. Porosity. In Methods of Soil Analysis: Part 1 Physical and Mineralogical Properties, Including Statistics of Measurement and Sampling, 9.1; Black, C.A., Ed.; American Society of Agronomy, Inc.: Madison, WI, USA, 1965; pp. 299–314. [Google Scholar]

- Nelson, D.W.; Sommers, L.E. Total carbon, organic carbon, and organic matter. In Methods of Soil Analysis: Part 2 Chemical and Microbiological Properties, 9.2.2, 2nd ed.; Page, A.L., Ed.; American Society of Agronomy, Inc., Soil Science Society of America, Inc.: Madison, WI, USA, 1982; pp. 539–579. [Google Scholar]

- Stenholm, A.; Holmstrom, S.; Ragnarsson, A. Total nitrogen in waste water analysis: Comparison of devarda’s alloy method and high temperature oxidation followed by chemiluminescence detection. J. Anal. Chem. 2009, 64, 1047–1053. [Google Scholar] [CrossRef]

- David, A.B.; Davidson, C.E. Estimation method for serial dilution experiments. J. Microbiol. Methods 2014, 107, 214–221. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Krywult, M.; Bielec, D. Method of measurement of nitrate reductase activity in field conditions. J. Eco. Eng. 2013, 14, 7–11. [Google Scholar]

- Gross, J. Pigmentin Vegetable, Chlorophyll and Caretinoids; Springer: Washington, DC, USA, 2012; pp. 8–16. [Google Scholar]

- Li–Cor Bioscience Inc. Using the Li–6400: Portable Photosynthesis System.; Li–Cor Inc.: Lincoln, OR, USA, 2001; pp. 1–60. [Google Scholar]

- Fageria, N.K. Nitrogen Management in Crop Production; CRC Press: Boca Raton, FL, USA, 2014; pp. 217–233. [Google Scholar]

- Rathke, G.W.; Behrens, T.; Diepenbrock, W. Integrated nitrogen management strategies to improve seed yield, oil content and nitrogen efficiency of winter oilseed rape (Brassica napus L.): A review. Agric. Ecosyst. Environ. 2006, 117, 80–108. [Google Scholar] [CrossRef]

- IRRI. Steps to Successful Rice Production; International Rice Research Institute: Los Baños, Philippines, 2015; pp. 20–25. [Google Scholar]

- Welham, S.J.; Gezan, S.A.; Clark, S.J.; Mead, A. Statistical Methods in Biology: Design and Analysis of Experiments and Regression; CRC Press: Boca Raton, FL, USA, 2015; pp. 24–27. [Google Scholar]

- Koocheki, A.; Mahallati, M.N.; Moradi, R.; Mansoori, H. Optimizing water, nitrogen and crop density in canola cultivation using response surface methodology and central composite design. Soil Sci. Plant Nutr. 2014, 60, 286–298. [Google Scholar] [CrossRef]

- Myers, R.H.; Montgomery, D.C.; Cook, C.M.A. Response Surface Methodology: Process and Product Optimization using Designed Experiments; John Wiley and Sons: Hoboken, NJ, USA, 2009; pp. 13–61. [Google Scholar]

- Marquardt, D.W.; Snee, R.D. Ridge regression in practice. Am. Stat. 1975, 29, 3–20. [Google Scholar]

- SAS Institute Inc. Step-by-Step Programming with Base SAS® 9.4, 2nd ed.; SAS Institute Inc.: Cary, NC, USA, 2013. [Google Scholar]

- Smith, J.L.; Halvorson, J.J.; Papendick, R.I. Using multiplevariable indicator kriging for evaluating soil quality. Soil Sci. Soc. Am. J. 1993, 57, 743–749. [Google Scholar] [CrossRef]

- Zhao, H.; Li, X.; Jiang, Y. Response of nitrogen losses to excessive nitrogen fertilizer application in intensive greenhouse vegetable production. Sustainability 2019, 11, 115. [Google Scholar] [CrossRef] [Green Version]

- IFDC. Fertilizer Deep Placement–IFDC; International Fertilizer Development Center (IFDC): Alabama, USA, 2013; Available online: https://ifdc.org/2013/09/23/fertilizer-deep-placement/ (accessed on 15 September 2021).

- Alling, V.; Hale, S.E.; Martinsen, V.; Mulder, J.; Smebye, A.; Breedveld, G.D.; Cornelissen, G. The role of biochar in retaining nutrients in amended tropical soils. J. Plant Nutr. Soil. Sci. 2014, 177, 671–680. [Google Scholar] [CrossRef]

- Angst, T.E.; Sohi, S.P. Establishing release dynamics for plant nutrients from biochar. GCB Bioenergy 2013, 5, 221–226. [Google Scholar] [CrossRef]

- Oladele, S.; Adeyemo, A.; Awodun, M. Influence of rice husk biochar and inorganic fertilizer on soil nutrients availability and rain–fed rice yield in two contrasting soils. Geoderma 2019, 336, 1–11. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, Y.; Liu, S.; Huang, X.; Li, Z.; Tan, X.; Zeng, G.; Zhou, L. Potential benefits of biochar in agricultural soils: A Review. Pedosphere 2017, 27, 645–661. [Google Scholar] [CrossRef]

- Omondi, M.O.; Xia, X.; Nahayo, A.; Liu, X.; Korai, P.K.; Pan, G. Quantification of biochar effects on soil hydrological properties using meta–analysis of literature data. Geoderma 2016, 274, 28–34. [Google Scholar] [CrossRef]

- Cao, T.; Meng, J.; Liang, H.; Yang, X.; Chen, W. Can biochar provide ammonium and nitrate to poor soils? Soil column incubation. J. Soil Sci. Plant Nutr. 2017, 17, 253–265. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Durenkamp, M.; Nobili, M.; Lin, Q.; Devonshire, B.J.; Brookes, P.C. Microbial biomass growth, following incorporation of biochars produced at 350 °C or 700 °C, in a silty–clay loam soil of high and low pH. Soil Biol. Biochem. 2013, 57, 513–523. [Google Scholar] [CrossRef]

- Khadem, A.; Raiesi, F. Responses of microbial performance and community to corn biochar in calcareous sandy and clayey soils. Appl. Soil Ecol. 2017, 114, 16–27. [Google Scholar] [CrossRef]

- Singh, G.; Mavi, M.S. Impact of addition of different rates of rice–residue biochar on C and N dynamics in texturally diverse soils. Arch. Agron. Soil Sci. 2018, 64, 1419–1431. [Google Scholar] [CrossRef]

- Diniz, L.T.; Ramos, M.L.G.; Junior, W.Q.R.; Cruz, A.F.; de Franca, L.V.; Diniz, B.T.; Amabile, R.F. Effect of nitrogen fertilization on soil microbial biomass in an Oxisol cultivated with irrigated barley in the Brazilian Cerrado. Acta Agron. 2016, 65, 137–143. [Google Scholar] [CrossRef]

- Haider, G.; Steffens, D.; Müller, C.; Kammann, C.I. Standard extraction methods may underestimate nitrate stocks captured by field aged biochar. J. Environ. Qual. 2016, 45, 1196–1204. [Google Scholar] [CrossRef]

- Loussaert, D.; Clapp, J.; Mongar, N.; O’Neill, D.P.; Shen, B. Nitrate assimilation limits nitrogen use efficiency (NUE) in maize (Zea mays L.). Agronomy 2018, 8, 110. [Google Scholar] [CrossRef] [Green Version]

- Croft, H.; Chen, J.M.; Luo, X.; Bartlett, P.; Chen, B.; Staebler, R.M. Leaf chlorophyll content as a proxy for leaf photosynthetic capacity. Glob. Chang. Biol. 2017, 23, 3513–3524. [Google Scholar] [CrossRef]

- Ngulube, M.; Mweetwa, A.M.; Phiri, E.; Njoroge, S.C.M.; Chalwe, H.; Shitumbanuma, V.; Brandenburg, R.L. Effects of biochar and gypsum soil amendments on groundnut (Arachis hypogaea L.) dry matter yield and selected soil properties under water stress. Afr. J. Agric. Res. 2018, 13, 1080–1090. [Google Scholar]

- Lyu, S.; Du, G.; Liu, L.; Zhao, L.; Lyu, D. Effects of biochar on photosystem function and activities of protective enzymes in Pyrus ussuriensis Maxim. under drought stress. Acta Physiol Plant 2016, 38, 220. [Google Scholar] [CrossRef]

- Lai, L.; Ismail, M.R.; Muharam, F.M.; Yusof, M.M.; Ismail, R.; Jaafar, N.M. Effects of rice straw biochar and nitrogen fertilizer on rice growth and yield. Asian J. Crop Sci. 2017, 9, 159–166. [Google Scholar] [CrossRef] [Green Version]

- Xie, X.; Li, B.; Shen, S. Impact of high temperature stress on photosynthetic characteristic and yield of rice (Oryza sativa) at heading. Indian J. Agric. Sci. 2012, 82, 516–522. [Google Scholar]

- Bruun, E.W.; Petersen, C.T.; Hansen, E.; Holm, J.K.; Hauggaard–Nielsen, H. Biochar amendment to coarse sandy subsoil improves root growth and increases water retention. Soil Use Manag. 2014, 30, 109–118. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, G.; Bian, X.; Zhao, Q. Effects of root interaction and nitrogen fertilization on the chlorophyll content root activity, photosynthetic characteristics of intercropped soybean and microbial quantity in the rhizosphere. Plant Soil Environ. 2013, 59, 80–88. [Google Scholar] [CrossRef]

- Nurmalasari, A.I.; Suryanto, P.; Alam, T. Effectiveness of Melaleuca cajuputi biochar as a leaching loss for nitrogen fertilizer and intercropping in maize. Indian J. Agric. Res. 2020, 54, 506–510. [Google Scholar]

- Rubin, R.L.; Anderson, T.R.; Ballantine, K.A. Biochar simultaneously reduces nutrient leaching and greenhouse gas emissions in restored wetland soils. Wetlands 2020, 40, 1981–1991. [Google Scholar] [CrossRef]

- Wang, X.Q.; Zhao, Y.; Wang, H.; Zhao, X.Y.; Cui, H.Y.; Wei, Z.M. Reducing nitrogen loss and phytotoxicity during beer vinasse composting with biochar addition. Was. Manag. 2017, 61, 150–156. [Google Scholar] [CrossRef]

- Montemurro, F.; Diacono, M. Towards a better understanding of agronomic efficiency of nitrogen: Assessment and improvement strategies. Agronomy 2016, 6, 31. [Google Scholar] [CrossRef]

- Sarfraz, R.; Shakoor, A.; Abdullah, M.; Arooj, A.; Hussain, A.; Xing, S. Impact of integrated application of biochar and nitrogen fertilizers on maize growth and nitrogen recovery in alkaline calcareous soil. Soil Sci. Plant Nutr. 2017, 63, 488–498. [Google Scholar] [CrossRef]

- Abebe, Z.; Feyisa, H. Effects of nitrogen rates and time of application on yield of maize: Rainfall variability influenced time of N application. Int. J. Agron. 2017, 2017, 1545280. [Google Scholar] [CrossRef] [Green Version]

- Pan, S.; Huang, S.; Zhai, J.; Wang, J.; Cao, C.; Cai, M.; Zhan, M.; Tang, X. Effects of N management on yield and n uptake of rice in Central China. J. Integr. Agric. 2012, 11, 1993–2000. [Google Scholar] [CrossRef]

| Chemistry Characteristics 1 | Molar Ratio 1 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| pH | C | H | O | N | S | H/C | O/C | (O + N)/C | (O + N + S)/C |

| (1:10 H2O) | (%) | ||||||||

| 8.05 | 73.9 | 2.32 | 22.6 | 0.80 | 0.37 | 0.37 | 0.23 | 0.24 | 0.24 |

| Factors 2 | Soil Properties 1 | |||||

|---|---|---|---|---|---|---|

| WHC | TP | SOC | TN | TF | TB | |

| B | 321.58 ** | 963.55 ** | 6.98 ** | 0.01 ** | 5.87 × 108 ** | 8.06 × 106 ** |

| U | 0.001 ns | 42.08 ns | 0.03 ns | 0.67 ** | 4.06 × 104 ns | 2.99 × 104 ns |

| Y | 555.55 ** | 87.03 ** | 0.19 ** | 0.0008 ** | 1.23 × 109 ** | 4.21 × 106 ** |

| B × U | 0.01 ns | 54.09 ns | 0.03 ns | 0.0008 ** | 2.76 × 104 ns | 8.99 × 102 ns |

| B × Y | 62.25 ns | 97.37 ns | 0.08 ns | 0.000002 ns | 1.45 × 108 ns | 7.24 × 105 ns |

| U × Y | 0.0001 ns | 45.80 ns | 0.0004 ns | 0.001 ns | 2.04 × 105 ns | 6.71 × 102 ns |

| B × U × Y | 0.0001 ns | 46.15 ns | 0.0004 ns | 0.000003 ns | 1.68 × 104 ns | 1.86 × 102 ns |

| Factors | Physiological Characteristics and Yield of Hybrid Rice 1 | |||||

|---|---|---|---|---|---|---|

| NRA | TC | LPR | NL | NUE | YHR | |

| B | 0.93 ** | 0.014 ** | 5742.37 ** | 243.77 ** | 7.73 ** | 5.24 ** |

| U | 4.33 ** | 0.14 ** | 37,816.55 ** | 2087.78 ** | 46.56 ** | 37.47 ** |

| Y | 0.55 ** | 0.12 ** | 14,914.79 ** | 344.58 ** | 27.31 ** | 9.66 ** |

| B × U | 0.11 ** | 0.0007 ** | 194.36 ** | 45.89 ** | 0.24 ** | 0.35 ** |

| B × Y | 0.02 ns | 0.0003 ns | 67.41 ns | 4.93 ns | 0.17 ns | 0.12 ns |

| U × Y | 0.02 ns | 0.002 ns | 95.43 ns | 72.04 ns | 0.34 ns | 1.02 ns |

| B × U × Y | 0.01 ns | 0.0002 ns | 57.94 ns | 1.22 ns | 0.21 ns | 0.02 ns |

| Response Variables 2 | Years 1 | ||

|---|---|---|---|

| 2019 | 2020 | 2021 | |

| WHC | 40.60 c | 46.72 b | 48.56 a |

| TP | 39.87 c | 43.41 b | 42.96 a |

| SOC | 1.59 c | 1.71 b | 1.74 a |

| TN | 0.28 c | 0.29 b | 0.29 c |

| TF | 1.27 × 103 c | 1.12 × 104 b | 1.27 × 104 a |

| TB | 1.31 × 103 b | 1.85 × 103 a | 2.00 × 103 a |

| NRA | 3.09 c | 3.21 b | 3.35 a |

| TC | 0.58 c | 0.65 b | 0.70 a |

| LPR | 359.33 c | 381.22 b | 402.51 a |

| NL | 21.63 a | 15.89 b | 16.00 b |

| NUE | 3.23 c | 4.45 b | 5.04 a |

| YHR | 3.42 c | 4.01 b | 4.52 a |

| Variables 2 | Response of Independent Variables 1 | R2 | RMSE | Lack of Fit | |||||

|---|---|---|---|---|---|---|---|---|---|

| β0 | β1x1 | β2x2 | β11x12 | β12x1x2 | β22x22 | ||||

| WHC | 40.11 ** | 3.60 ** | 0.0003 ns | –0.41 ns | –0.00003 ns | –0.0000004 ns | 0.935 | 0.904 | 0.136 |

| TP | 33.29 ** | 4.31 ** | –0.02 ns | –0.28 ns | –0.002 ns | –0.00007 ns | 0.830 | 2.776 | 0.467 |

| SOC | 1.08 ** | 0.25 ** | –0.0007 ns | –0.008 ns | –0.00005 ns | –0.000002 ns | 0.982 | 0.071 | 0.101 |

| TN | 0.07 ** | 0.007 ** | 0.001 ** | –0.00002 ns | 0.00002 ** | –0.0000004 ns | 0.992 | 0.015 | 0.572 |

| TF | 1337.38 ** | 4646.69 * | 0.84 ns | –496.90 ns | 0.01 ns | –0.002 ns | 0.972 | 79.614 | 0.885 |

| TB | 928.73 ** | 444.59 ** | 0.01 ns | –39.53 ** | 0.03 ns | –0.00006 ns | 0.986 | 66.211 | 0.890 |

| NRA | 2.36 ** | 0.12 * | 0.006 ** | –0.004 ns | –0.0001 ** | –0.000007 * | 0.904 | 0.146 | 0.301 |

| TC | 0.50 ** | 0.01 * | 0.001 ** | –0.00004 ns | –0.00002 ** | –0.000001 ** | 0.943 | 0.019 | 0.990 |

| LPR | 311.17 ** | 7.09 * | 0.49 ** | –0.22 ns | 0.001 ** | –0.0006 ** | 0.927 | 11.479 | 0.945 |

| NL | 11.62 ** | –1.82 ** | 0.06 ** | 0.10 ns | –0.001 ** | 0.00005 ns | 0.959 | 1.969 | 0.547 |

| NUE | 4.68 ** | 0.22 * | 0.02 ** | 0.009 ns | 0.0004 ** | –0.00003 ** | 0.899 | 0.503 | 0.801 |

| YHR | 2.01 ** | 0.12 * | 0.01 ** | 0.002 ns | 0.0003 ** | 0.00002 ** | 0.969 | 0.231 | 0.990 |

| Runs | Dependent Variables 1 | Estimates Response of Independent Variables 2 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | WHC | TP | SOC | TN | TF | TB | NRA | TC | LPR | NL | NUE | YHR | |

| 1 | 0 | 0 | 39.81 | 36.54 | 1.08 | 0.08 | 1.07 × 103 | 9.13 × 102 | 2.21 | 0.51 | 312.95 | 9.29 | 5.27 | 2.26 |

| 2 | 2 | 0 | 46.61 | 41.65 | 1.59 | 0.08 | 9.45 × 103 | 1.73 × 103 | 2.53 | 0.53 | 326.26 | 8.02 | 5.20 | 2.29 |

| 3 | 4 | 0 | 47.18 | 44.85 | 1.91 | 0.10 | 1.11 × 104 | 1.99 × 103 | 2.84 | 0.56 | 337.32 | 5.79 | 5.78 | 2.53 |

| 4 | 6 | 0 | 47.53 | 48.05 | 2.23 | 0.10 | 1.12 × 104 | 2.20 × 103 | 3.02 | 0.58 | 342.27 | 5.62 | 5.95 | 2.65 |

| 5 | 0 | 100 | 39.83 | 24.69 | 1.05 | 0.19 | 1.07 × 103 | 8.96 × 102 | 3.13 | 0.60 | 348.59 | 21.62 | 5.32 | 2.82 |

| 6 | 2 | 100 | 46.60 | 41.65 | 1.49 | 0.20 | 9.74 × 103 | 1.74 × 103 | 3.16 | 0.61 | 364.70 | 18.37 | 6.29 | 3.29 |

| 7 | 4 | 100 | 47.20 | 43.78 | 1.91 | 0.22 | 1.11 × 104 | 2.01 × 103 | 3.17 | 0.63 | 375.79 | 10.46 | 7.00 | 3.66 |

| 8 | 6 | 100 | 47.56 | 49.12 | 2.33 | 0.25 | 1.12 × 104 | 2.22× 103 | 3.25 | 0.67 | 395.77 | 9.47 | 8.61 | 4.42 |

| 9 | 0 | 200 | 39.86 | 35.88 | 0.90 | 0.32 | 1.08 × 103 | 9.03 × 102 | 3.23 | 0.66 | 388.58 | 24.65 | 7.29 | 4.14 |

| 10 | 2 | 200 | 46.60 | 40.58 | 1.49 | 0.36 | 9.73 × 103 | 1.75 × 103 | 3.28 | 0.68 | 399.39 | 19.78 | 8.07 | 4.57 |

| 11 | 4 | 200 | 47.19 | 44.85 | 1.80 | 0.38 | 1.11 × 104 | 2.03 × 103 | 3.48 | 0.70 | 406.92 | 17.87 | 8.52 | 4.86 |

| 12 | 6 | 200 | 47.55 | 48.05 | 2.33 | 0.40 | 1.17 × 104 | 2.23 × 103 | 3.62 | 0.71 | 419.33 | 16.56 | 9.41 | 5.31 |

| 13 | 0 | 300 | 39.82 | 35.88 | 1.00 | 0.45 | 1.07 × 103 | 9.07 × 102 | 3.37 | 0.70 | 400.82 | 33.60 | 7.20 | 4.62 |

| 14 | 2 | 300 | 46.68 | 40.58 | 1.59 | 0.47 | 9.68 × 104 | 1.75 × 103 | 3.55 | 0.71 | 407.73 | 30.39 | 7.70 | 4.89 |

| 15 | 4 | 300 | 47.16 | 44.85 | 1.91 | 0.48 | 1.11 × 104 | 2.04 × 103 | 3.86 | 0.72 | 437.12 | 28.81 | 8.95 | 5.70 |

| 16 | 6 | 300 | 47.52 | 46.98 | 2.23 | 0.50 | 1.18 × 104 | 2.24 × 103 | 3.79 | 0.72 | 432.78 | 25.13 | 9.03 | 5.69 |

| Variables and Treatments 1 | Scenarios | |||

|---|---|---|---|---|

| Economic | Environmental | Eco–Environmental | ||

| Response Variables | WHC | 47.98 | 47.11 | 47.48 |

| TP | 34.20 | 37.30 | 37.65 | |

| SOC | 1.68 | 1.54 | 1.89 | |

| TN | 0.37 | 0.25 | 0.34 | |

| TF | 1.23 × 104 | 1.07 × 104 | 1.19 × 104 | |

| TB | 2.19 × 103 | 1.90 × 103 | 2.22 × 103 | |

| NRA | 3.82 | 3.42 | 3.78 | |

| TC | 0.72 | 0.66 | 0.71 | |

| LPR | 430.05 | 394.51 | 425.96 | |

| NL | 24.01 | 17.91 | 19.75 | |

| NUE | 9.66 | 8.05 | 9.71 | |

| YHR | 7.29 | 4.69 | 6.49 | |

| Independent Variables 2 | X1 | 4.73 | 2.89 | 5.54 |

| X2 | 272.40 | 163.98 | 230.08 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suryanto, P.; Faridah, E.; Nurjanto, H.H.; Putra, E.T.S.; Kastono, D.; Handayani, S.; Boy, R.; Widyawan, M.H.; Alam, T. Short-Term Effect of In Situ Biochar Briquettes on Nitrogen Loss in Hybrid Rice Grown in an Agroforestry System for Three Years. Agronomy 2022, 12, 564. https://0-doi-org.brum.beds.ac.uk/10.3390/agronomy12030564

Suryanto P, Faridah E, Nurjanto HH, Putra ETS, Kastono D, Handayani S, Boy R, Widyawan MH, Alam T. Short-Term Effect of In Situ Biochar Briquettes on Nitrogen Loss in Hybrid Rice Grown in an Agroforestry System for Three Years. Agronomy. 2022; 12(3):564. https://0-doi-org.brum.beds.ac.uk/10.3390/agronomy12030564

Chicago/Turabian StyleSuryanto, Priyono, Eny Faridah, Handojo Hadi Nurjanto, Eka Tarwaca Susila Putra, Dody Kastono, Suci Handayani, Ruslan Boy, Muhammad Habib Widyawan, and Taufan Alam. 2022. "Short-Term Effect of In Situ Biochar Briquettes on Nitrogen Loss in Hybrid Rice Grown in an Agroforestry System for Three Years" Agronomy 12, no. 3: 564. https://0-doi-org.brum.beds.ac.uk/10.3390/agronomy12030564