Production of Ethanol from Livestock, Agricultural, and Forest Residuals: An Economic Feasibility Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Feedstocks and Logistics

2.2. Proximate and Ultimate Analyses of Feedstock

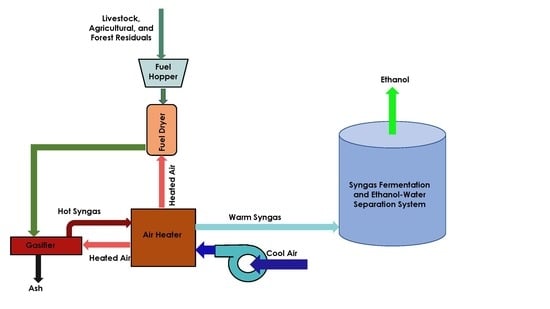

2.3. Syngas Production Using a Commercial Gasification System

2.4. Theoretical Ethanol Yields from Syngas Fermentation and Ethanol Production Rates

2.5. Cash Flow Analyses

3. Results and Discussion

3.1. Feedstock Characteristics

3.2. Syngas Yields and Production Rates

3.3. Cost Analyses

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Langholtz, M.; Stokes, B.J.; Eaton, L. 2016 Billion-Ton report: Advanding Domestic Resources for a Thriving Bioeconomy, Volume 1: Economic Availability of Feedstock; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2016; p. 448. [Google Scholar]

- Dean, J.E.; Weil, R.R. Brassica cover crops for nitrogen retention in the Mid-Atlantic Coastal Plain. J. Envion. Qual. 2009, 38, 520–528. [Google Scholar] [CrossRef] [PubMed]

- SARE. Managing Cover Crops Profitably: Sustainable Agriculture Research and Eduction (SARE) Handbook Series 9, 3rd ed.; DIANE Publishing: Collingdale, PA, USA, 2012. [Google Scholar]

- Cantrell, K.B.; Ducey, T.F.; Ro, K.S.; Hunt, P.G. Livestock waste-to-bioenergy generation opportunities. Bioresour. Technol. 2008, 99, 7941–7953. [Google Scholar] [CrossRef] [PubMed]

- Ro, K.S.; Libra, J.A.; Bae, S.; Berge, N.D.; Flora, J.R.V.; Pecenka, R. Combustion behavior of animal-manure-based hydrochar and pyrochar. ACS Sustain. Chem. Eng. 2019, 7, 470–478. [Google Scholar] [CrossRef]

- Ro, K.S.; Hunt, P.G.; Jackson, M.A.; Compton, D.L.; Yates, S.R.; Cantrell, K.; Chang, S.C. Co-pyrolysis of swine manure with agricultural plastic waste: Laboratory-scale study. Waste Manag. 2014, 34, 1520–1528. [Google Scholar] [CrossRef] [PubMed]

- Cantrell, K.; Ro, K.S.; Szogi, A.A.; Vanotti, M.B.; Smith, M.C.; Hunt, P.G. Green farming systems for the Southeast USA using manure-to-energy conversion platforms. J. Renew. Sustain. Energy 2012, 4, 041401. [Google Scholar] [CrossRef]

- Hwang, O.; Lee, S.-R.; Cho, S.; Ro, K.S.; Spiechs, M.; Woodbury, B.L.; Silva, P.J.; Han, D.-W.; Choi, H.; Kim, K.-Y.; et al. Efficacy of different biochars in removing odorous volatile organic compounds (VOCs) emitted from swine manure. ACS Sustain. Chem. Eng. 2018, 6, 14239–14247. [Google Scholar] [CrossRef]

- Ro, K.S.; Lima, I.M.; Reddy, G.B.; Jackson, M.A.; Gao, B. Removing gaseous NH3 using biochar as an adsorbent. Agriculture 2015, 5, 991–1002. [Google Scholar] [CrossRef]

- Lima, I.M.; Ro, K.S.; Reddy, G.B.; Boykin, D.L.; Klasson, K.T. Efficacy of chicken litter and wood biochars and their activated counterparts in heavy metal cleanup from wastewater. Agriculture 2015, 5, 806–825. [Google Scholar] [CrossRef]

- Novak, J.M.; Spokas, K.A.; Cantrell, K.; Ro, K.S.; Watts, D.W.; Glaz, B.; Busscher, W.J.; Hunt, P.G. Effects of biochars and hydrochars produced from lignocellulosic and animal manure on fertility of a Mollisol and Entisol. Soil Use Manag. 2014, 30, 175–181. [Google Scholar] [CrossRef]

- Ro, K.S.; Novak, J.M.; Johnson, M.G.; Szogi, A.A.; Libra, J.A.; Spokas, K.A.; Bae, S. Leachate water quality of soils amended with different swine manure-based amendements. Chemosphere 2016, 142, 92–99. [Google Scholar] [CrossRef]

- Cantrell, K.; Ro, K.; Mahajan, D.; Anjom, M.; Hunt, P.G. Role of thermochemical conversion in livestock waste-to-energy treatments: Obstacles and opportunities. Ind. Eng. Chem. Res. 2007, 46, 8918–8927. [Google Scholar] [CrossRef]

- INEOS. Available online: https://www.ineos.com/news/ineos-group/ineos-bio-produces-cellulosic-ethanol-at-commercial-scale/ (accessed on 31 July 2013).

- LanzaTech. Available online: https://www.lanzatech.com/ (accessed on 2 July 2019).

- Kirsanovs, V.; Zandeckis, A.; Blumberga, D.; Veidenbergs, I. Influence of process temperature, equivalence ratio and fuel moisture content on gasification process, a review. In Proceedings of the 27th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems—ECOS, Turku, Finland, June 2014. [Google Scholar]

- Ince, P.; Bilek, E.; Dietenberger, M. Modeling integrated biomass gasification business concepts. 2011. [Google Scholar] [CrossRef]

- Dietenberger, M.; Anderson, M. Vision of the U.S. biofuel future: A case for hydrogen-enriched biomass gasification. Ind. Eng. Chem. Res. 2007, 46, 8863–8874. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, W.; Blasiak, W. Energy and exergy analysis of high temperature agent gasification of biomass. Energies 2014, 7, 2107–2122. [Google Scholar] [CrossRef]

- Pian, C.C.P.; Yoshikawa, K. Development of a high-temperature air-blown gasification system. Bioresour. Technol. 2001, 79, 231–241. [Google Scholar] [CrossRef]

- Young, L.; Pian, C.C.P. High-temperature, air-blown gasification of dairy-farm wastes for energy product. Energy 2003, 28, 655–672. [Google Scholar] [CrossRef]

- Kopke, M.; Mihalcea, C.; Bromley, J.C.; Simpson, S.D. Fermentative production of ethanol from carbon monooxide. Curr. Opin. Biotechnol. 2011, 22, 320–325. [Google Scholar] [CrossRef]

- Phillips, J.; Huhnke, R.; Atiyeh, H. Syngas Fermentation: A Microbial Conversion Process of Gaseous Substrates to Various Products. Fermentation 2017, 3, 28. [Google Scholar] [CrossRef]

- Abubackar, H.N.; Veiga, M.C.; Kennes, C. Carbon monoxide fermentation to ethanol by Clostridium autoethanogenum in a bioreactor with no accumulation of acetic acid. Bioresour. Technol. 2015, 186, 122–127. [Google Scholar] [CrossRef] [Green Version]

- Devarapalli, M.; Atiyeh, H.K.; Phillips, J.R.; Lewis, R.S.; Huhnke, R.L. Ethanol production during semi-continuous syngas fermentation in a trickle bed reactor using Clostridium ragsdalei. Bioresour. Technol. 2016, 209, 56–65. [Google Scholar] [CrossRef] [Green Version]

- Huhnke, R.L.; Lewis, R.S.; Tanner, R.S. Isolation and characterization of novel clostridial species. U.S. Patent 7,704,723, 27 April 2010. [Google Scholar]

- Liu, K.; Atiyeh, H.K.; Tanner, R.S.; Wilkins, M.R.; Huhnke, R.L. Fermentative production of ethanol from syngas using novel moderately alkaliphilic strains of Alkalibaculum bacchi. Bioresour. Technol. 2012, 104, 336–341. [Google Scholar] [CrossRef]

- Phillips, J.R.; Atiyeh, H.K.; Tanner, R.S.; Torres, J.R.; Saxena, J.; Wilkins, M.R.; Huhnke, R.L. Butanol and hexanol production in Clostridium carboxidivorans syngas fermentation: Medium development and culture techniques. Bioresour. Technol. 2015, 190, 114–121. [Google Scholar] [CrossRef]

- Phillips, J.R.; Klasson, K.T.; Clausen, E.C.; Gaddy, J.L. Biological production of ethanol from coal synthesis gas. Appl. Biochem. Biotechnol. 1993, 39, 559–571. [Google Scholar] [CrossRef]

- Sun, X.; Atiyeh, H.K.; Zhang, H.; Tanner, R.S.; Huhnke, R.L. Enhanced ethanol production from syngas by Clostridium ragsdalei in continuous stirred tank reactor using medium with poultry litter biochar. Appl. Energy 2019, 236, 1269–1279. [Google Scholar] [CrossRef]

- Diender, M.; Stams, A.J.M.; Sousa, D.Z. Production of medium-chain fatty acids and higher alcohols by a synthetic co-culture grown on carbon monoxide or syngas. Biotechnol. Biofuels 2016, 9, 82. [Google Scholar] [CrossRef]

- He, P.; Han, W.; Shao, L.; Lü, F. One-step production of C6–C8 carboxylates by mixed culture solely grown on CO. Biotechnol. Biofuels 2018, 11, 4. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Atiyeh, H.K.; Stevenson, B.S.; Tanner, R.S.; Wilkins, M.R.; Huhnke, R.L. Mixed culture syngas fermentation and conversion of carboxylic acids into alcohols. Bioresour. Technol. 2014, 152, 337–346. [Google Scholar] [CrossRef]

- Richter, H.; Molitor, B.; Diender, M.; Sousa, D.Z.; Angenent, L.T. A Narrow pH Range Supports Butanol, Hexanol, and Octanol Production from Syngas in a Continuous Co-culture of Clostridium ljungdahlii and Clostridium kluyveri with In-Line Product Extraction. Front. Microbiol. 2016, 7, 1773. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.-Q.; Zhang, F.; Zhang, W.; Dai, K.; Wang, H.-J.; Li, X.; Zeng, R.J. Hydrogen and carbon dioxide mixed culture fermentation in a hollow-fiber membrane biofilm reactor at 25 °C. Bioresour. Technol. 2018, 249, 659–665. [Google Scholar] [CrossRef]

- Xu, S.; Fu, B.; Zhang, L.; Liu, H. Bioconversion of H2/CO2 by acetogen enriched cultures for acetate and ethanol production: The impact of pH. World J. Microbiol. Biotechnol. 2015, 31, 941–950. [Google Scholar] [CrossRef]

- Werpy, T.; Petersen, G. Top Value Added Chemicals from Biomass: Volume 1—Results of Screening for Potential Candidates from Sugars and Synthesis Gas, 1st ed.; National Renewable Energy Laboratory: Golden, CO, USA, 2004. [Google Scholar]

- Pfltzgraff, L.A.; De bruyn, M.; Cooper, E.C.; Budarin, V.; Clark, J.H. Food waste biomass: A resource for high-value chemicals. Green Chem. 2013, 15, 307–314. [Google Scholar] [CrossRef]

- Molino, A.; Larocca, V.; Chianese, S.; Musmarra, D. Biofuels production by biomass gasification: A review. Energies 2018, 11, 811. [Google Scholar] [CrossRef]

- Bergman, R.; Berry, M.; Bilek, E.M.T.; Bower, T.; Eastin, I.; Ganguly, I.; Han, H.-S.; Hirth, K.; Jacobson, A.; Karp, S.; et al. Waste to Wisdom: Utilizing forest residues for the production of bioenergy and biobased products. Appl. Eng. Agric. 2018, 34, 5–10. [Google Scholar]

- Sahoo, K.; Bilek, E.; Bergman, R.; Mani, S. Techno-economic analysis of producing solid biofuels and biochar from forest residues using portable systems. Appl. Energy 2019, 235, 578–590. [Google Scholar] [CrossRef]

- Sahoo, K.; Mani, S. Engineering Economics of Cotton Stalk Supply Logistics Systems for Bioenergy Applications. Trans. ASABE 2016, 59, 737–747. [Google Scholar]

- Sahoo, K.; Mani, S. Techno-economic assessment of biomass bales storage systems for a large-scale biorefinery. Biofuels Bioprod. Biorefin. 2017, 11, 417–429. [Google Scholar] [CrossRef]

- Sahoo, K.; Bilek, E.M.; Mani, S. Techno-economic and environmental assessments of storing woodchips and pellets for bioenergy applications. Renew. Sustain. Energy Rev. 2018, 98, 27–39. [Google Scholar] [CrossRef]

- Sahoo, K.; Bilek, E.M.; Bergman, R.D.; Kizha, A.R.; Mani, S. Economic analysis of forest residues supply chain options to produce enhanced quality feedstocks. Biofuels Bioprod. Biorefin. 2018, 13, 514–534. [Google Scholar] [CrossRef]

- USDA Oil crops yearbook. Available online: https://www.ers.usda.gov/data-products/oil-crops-yearbook/ (accessed on 15 June 2019).

- Sahoo, K. Sustainable Design and Simulation of Multi-Feedstock Bioenergy Supply Chain. Doctroal Thesis, University of Georgia, Athens, Greece, 2017; 436p. [Google Scholar]

- Eriksson, G.; Hedman, H.; Bostrom, D.; Pettersson, E.; Backman, R.; Ohman, M. Combustion characterization of rapeseed meal and possible combustion applications. Energy Fuels 2009, 23, 3930–3939. [Google Scholar] [CrossRef]

- Ro, K.S.; Cantrell, K.B.; Hunt, P.G. High-temperature pyrolysis of blended animal manures for producing renewable energy and value-added biochar. Ind. Eng. Chem. Res. 2010, 49, 10125–10131. [Google Scholar] [CrossRef]

- Ljungdhal, L. The autotrophic pathway of acetate synthesis in acetogenic bacteria. Annu. Rev. Microbiol. 1986, 40, 415–450. [Google Scholar] [CrossRef]

- Köpke, M.; Mihalcea, C.; Liew, F.; Tizard, J.H.; Ali, M.S.; Conolly, J.J.; Al-Sinawi, B.; Simpson, S.D. 2,3-Butanediol Production by Acetogenic Bacteria, an Alternative Route to Chemical Synthesis, Using Industrial Waste Gas. Appl. Environ. Microbiol. 2011, 77, 5467–5475. [Google Scholar] [CrossRef] [Green Version]

- Fernández-Naveira, Á.; Veiga, M.C.; Kennes, C. H-B-E (hexanol-butanol-ethanol) fermentation for the production of higher alcohols from syngas/waste gas. J. Chem. Technol. Biotechnol. 2017, 92, 712–731. [Google Scholar] [CrossRef]

- Xu, D.; Tree, D.R.; Lewis, R.S. The effects of syngas impurities on syngas fermentation to liquid fuels. Biomass Bioenergy 2011, 35, 2690–2696. [Google Scholar] [CrossRef]

- UFOP. UFOP Report on Global Market Supply 2017/2018. Available online: https://www.ufop.de/files/3515/1515/2657/UFOP_Report_on_Global_Market_Supply_2017-2018.pdf (accessed on 16 August 2019).

| Biomass Type | Stumpage Cost a ($/Dry Tonne) [1] | Harvesting Cost ($/Dry Tonne) [1] | Transportation Cost ($/Dry Tonne) | Storage Cost d ($/Dry Tonne) [43,44] | Grinding ($/Dry Tonne) e [42] | Average Total Feedstock Cost f ($/Dry Tonne) | |||

|---|---|---|---|---|---|---|---|---|---|

| 20 b km | 60 c km | 20 a km | 60 c km | ||||||

| Logging residues | Wood chips | 1−5 | 15−20 | 6 | 12 | 8 | - | 34.5 | 40.5 |

| Wheat Straw | Rectangular bale | 9−28 | 44−49 | 4 | 10 | 6.0 | 10.5 | 85.5 | 91.5 |

| Corn Stover | Rectangular bale | 5−15 | 14−16 | 4 | 10 | 6.0 | 10.5 | 45.5 | 51.5 |

| Swine Manure | 70 | 0 | 3.5 | 8.0 | - | - | 73.5 | 78.0 | |

| Oilseed rape (OSR) meal | 342 | - | 4 | 10 | - | - | 346.0 | 352.0 | |

| Wheat Straw (50%) + Swine manure (50%) | - | - | - | - | - | - | 79.5 | 84.8 | |

| Base a | Case 1 b | Case 2 c | |

|---|---|---|---|

| Nameplate Ethanol (MGY) | 8 | 50 | 1 to 2 |

| Construction Cost (M$) | 130 | Varied d | Varied d |

| Assumed Yield (gal/tonne) | 100 | Varied e | Varied f |

| Feedstock Cost (per tonne) | $70 | Varied g | Varied g |

| Feedstock Requirement (M tonne,yr) | 0.080 | Varied e | Varied f |

| Operations Employees | 69 | Varied h | 8 |

| Payroll Burden per Employee/year | $60,000 | $60,000 | $60,000 |

| Payout Period (years) | 10 | 10 | 10 |

| Interest for Capital Return (%) | 5% | 5% | 5% |

| Operating costs (% of Capital Cost/yr) | 10% | 10% | 10% |

| Parameters | Wood Chips | Wheat Straw (WS) | 1:1 Blend of WS and SM [49] | OSR Meal (OSRM) [48] | Corn Stover |

|---|---|---|---|---|---|

| Proximate—dry basis (db) | |||||

| Feed MC (%db) | 40 | 40 | 40 | 8 | 10 |

| Dried MC (%db) | 10 | 10 | 10 | 2 | 2.5 |

| Ash (%db) | 1 | 3.4 | 12.3 | 7.3 | 4.9 |

| Ultimate—dry and ash free basis (dafb) | |||||

| C (%dafb) | 48.0 | 48.4 | 53.7 | 50.7 | 49.5 |

| H (%dafb) | 6.2 | 6.4 | 6.9 | 6.8 | 6.1 |

| O (%dafb) | 45.8 | 44.1 | 35.7 | 34.7 | 43.7 |

| N (%dafb) | 0 | 1.0 | 3.2 | 6.9 | 0.68 |

| S (%dafb) | 0 | 0.1 | 0.5 | 0.9 | 0.02 |

| Gasification Parameters | Wood Chips | Wheat Straw | 50 Wheat Straw/50 Manure | OSR Meal | Corn Stover | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 649 °C | 850 °C | 649 °C | 850 °C | 649 °C | 850 °C | 649 °C | 850 °C | 649 °C | 850 °C | |

| Feed Flow (g/s) | 56 | 49.1 | 45.3 | 40.8 | 38.4 | 35.3 | 29.8 | 27.5 | 36.6 | 33.4 |

| Dried Feed Flow (g/s) | 44 | 38.6 | 35.6 | 32.1 | 30.2 | 27.7 | 28.2 | 26.0 | 34.1 | 31.1 |

| Pumped Air Flow (g/s) | 182 | 121.2 | 193.4 | 132 | 119.7 | 94.1 | 80.8 | 72.6 | 118.9 | 90.7 |

| Dryer Air Flow (g/s) | 145.6 | 79.4 | 147.9 | 83.1 | 66.5 | 38.8 | 26.9 | 16.8 | 71.4 | 40.3 |

| Gasifier Air Flow (g/s) | 36.4 | 41.8 | 45.5 | 48.9 | 53.2 | 55.4 | 53.9 | 55.8 | 47.6 | 50.4 |

| Ash Flow (g/s) | 0.4 | 0.4 | 1.1 | 1.0 | 3.4 | 3.1 | 2.0 | 1.9 | 1.6 | 1.5 |

| Syngas/dried feed (g/g) | 1.8 | 2.1 | 2.2 | 2.5 | 2.6 | 2.9 | 2.8 | 3.1 | 2.3 | 2.6 |

| Syngas Temperature (°C) | 649 | 850 | 649 | 850 | 649 | 850 | 649 | 850 | 649 | 850 |

| Heated Air Temperature (°C) | 443 | 612 | 445 | 615 | 485 | 665 | 460 | 626 | 450 | 621 |

| Cooled Syngas Temperature (°C) | 521 | 637 | 477 | 585 | 416 | 509 | 423 | 524 | 460 | 565 |

| CO (% mass) | 43.42 | 40.87 | 30.76 | 30.42 | 26.46 | 26.45 | 28.93 | 28.29 | 35.51 | 34.14 |

| H2 (% mass) | 2.93 | 2.63 | 2.27 | 1.98 | 1.92 | 1.68 | 1.84 | 1.65 | 2.06 | 1.84 |

| CO2 (% mass) | 14.47 | 11.65 | 18.15 | 14.39 | 15.48 | 12.57 | 11.97 | 10.15 | 13.46 | 11.45 |

| H2O (% mass) | 2.69 | 4.64 | 3.7 | 5.8 | 3.09 | 4.95 | 2.01 | 3.67 | 2.15 | 3.83 |

| CH4 (% mass) | 1.58 | 0.15 | 1.02 | 0.09 | 0.73 | 0.07 | 0.69 | 0.07 | 0.84 | 0.08 |

| N2 (% mass) | 34.89 | 40.06 | 44.03 | 47.26 | 51.97 | 53.96 | 53.84 | 55.59 | 45.88 | 48.58 |

| SO2 (% mass) | 0 | 0 | 0.06 | 0.06 | 0.35 | 0.32 | 0.63 | 0.58 | 0.09 | 0.08 |

| CO (% moles) | 32.11 | 30.89 | 24.52 | 24.63 | 21.84 | 22.1 | 23.96 | 23.7 | 28.78 | 28.05 |

| H2 (% moles) | 30.14 | 27.58 | 25.17 | 22.27 | 22.01 | 19.52 | 21.21 | 19.23 | 23.17 | 21.03 |

| CO2 (% moles) | 6.81 | 5.61 | 9.21 | 7.41 | 8.13 | 6.68 | 6.31 | 5.42 | 6.95 | 5.99 |

| H2O (% moles) | 3.1 | 5.45 | 4.58 | 7.3 | 3.97 | 6.43 | 2.71 | 4.78 | 2.71 | 4.89 |

| CH4 (% moles) | 2.05 | 0.2 | 1.42 | 0.13 | 1.06 | 0.1 | 1 | 0.1 | 1.19 | 0.12 |

| N2 (% moles) | 25.79 | 30.27 | 35.08 | 38.24 | 42.87 | 45.05 | 44.58 | 46.56 | 37.17 | 39.9 |

| SO2 (% moles) | 0 | 0 | 0.02 | 0.02 | 0.12 | 0.12 | 0.23 | 0.21 | 0.03 | 0.03 |

| Feedstocks Parameters | Wood Chips | Wheat Straw | 50 Wheat Straw/50 Manure | OSR Meal | Corn Stover | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 649 °C | 850 °C | 649 °C | 850 °C | 649 °C | 850 °C | 649 °C | 850 °C | 649 °C | 850 °C | |

| Syngas yield, kg/kg feedstock (db) | 2.0 | 2.2 | 2.4 | 2.6 | 2.9 | 3.1 | 2.8 | 3.0 | 2.4 | 2.5 |

| Syngas input (kg/s) | 30.4 | 31.9 | 39.8 | 41.8 | 47.9 | 50.0 | 45.8 | 48.1 | 40.2 | 40.9 |

| Feedstock feed, tonne (db)/d a,b | 1311.3 | 1252.2 | 1433.1 | 1390.0 | 1425.7 | 1394.7 | 1412.4 | 1386.6 | 1445.5 | 1414.8 |

| Annual demand, thousand tonne (db)/y a,b | 393.39 | 375.66 | 429.92 | 417.01 | 427.72 | 418.41 | 423.73 | 415.97 | 433.65 | 424.45 |

| Theoretical ethanol yield, gal/tonne (db) a | 156.9 | 164.4 | 143.6 | 148.0 | 144.3 | 147.5 | 145.6 | 148.4 | 142.3 | 145.4 |

| Ethanol selling price, $/gal a | 1.98 | 1.92 | 2.47 | 2.41 | 2.42 | 2.38 | 4.23 | 4.16 | 2.21 | 2.17 |

| Ethanol selling price, $/gal b | 2.02 | 1.95 | 2.51 | 2.45 | 2.46 | 2.41 | 4.27 | 4.20 | 2.25 | 2.21 |

| Ethanol yield, gal/tonne (db) c | 127.1 | 133.1 | 116.3 | 119.9 | 116.9 | 119.5 | 118.0 | 120.2 | 115.3 | 117.8 |

| Construction cost, $ million a,b,c,d | 396.42 | 383.83 | 421.85 | 412.94 | 420.33 | 413.91 | 417.58 | 412.22 | 424.40 | 418.08 |

| Operating cost, $ million a,b,c,d | 50.67 | 49.08 | 53.87 | 52.75 | 53.68 | 52.87 | 53.33 | 52.66 | 54.19 | 53.39 |

| Minimum ethanol selling price (MESP), $/gal a,c | 2.31 | 2.24 | 2.91 | 2.84 | 2.84 | 2.79 | 5.08 | 5.00 | 2.58 | 2.54 |

| Minimum ethanol selling price (MESP), $/gal b,c | 2.36 | 2.28 | 2.96 | 2.89 | 2.89 | 2.84 | 5.13 | 5.05 | 2.63 | 2.59 |

| Feedstocks Parameters | Wood Chips | Wheat Straw | 50 Wheat Straw/50 Manure | OSR Meal | Corn Stover | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 649 °C | 850 °C | 649 °C | 850 °C | 649 °C | 850 °C | 649 °C | 850 °C | 649 °C | 850 °C | |

| Feedstock feed, tonne (db)/d | 43.20 | 37.88 | 34.95 | 31.47 | 29.62 | 27.23 | 29.80 | 27.50 | 35.93 | 32.79 |

| Annual demand, thousand tonne (db)/y a | 12.96 | 11.36 | 10.48 | 9.44 | 8.87 | 8.17 | 8.94 | 8.25 | 10.78 | 9.34 |

| Ethanol production, million gal/y a | 1.647 | 1.513 | 1.220 | 1.132 | 1.039 | 0.976 | 1.055 | 0.992 | 1.243 | 1.159 |

| Ethanol yield, gal/tonne (db) a,b | 127.1 | 133.1 | 116.3 | 119.9 | 116.9 | 119.5 | 118.0 | 120.2 | 115.3 | 117.8 |

| Construction cost, $million | 36.35 | 33.17 | 31.36 | 29.13 | 27.92 | 26.32 | 28.04 | 26.51 | 31.96 | 29.98 |

| Operating cost, $million c | 4.12 | 3.80 | 3.62 | 3.39 | 3.27 | 3.11 | 3.28 | 3.13 | 3.68 | 3.48 |

| Minimum ethanol selling price (MESP), $/gal a,b,d | 5.63 | 5.61 | 7.03 | 7.04 | 7.31 | 7.35 | 9.49 | 9.49 | 6.68 | 6.74 |

| Minimum ethanol selling price (MESP), $/gal a,b,e | 5.68 | 5.65 | 7.08 | 7.09 | 7.35 | 7.39 | 9.54 | 9.54 | 6.73 | 6.79 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ro, K.S.; Dietenberger, M.A.; Libra, J.A.; Proeschel, R.; Atiyeh, H.K.; Sahoo, K.; Park, W.J. Production of Ethanol from Livestock, Agricultural, and Forest Residuals: An Economic Feasibility Study. Environments 2019, 6, 97. https://0-doi-org.brum.beds.ac.uk/10.3390/environments6080097

Ro KS, Dietenberger MA, Libra JA, Proeschel R, Atiyeh HK, Sahoo K, Park WJ. Production of Ethanol from Livestock, Agricultural, and Forest Residuals: An Economic Feasibility Study. Environments. 2019; 6(8):97. https://0-doi-org.brum.beds.ac.uk/10.3390/environments6080097

Chicago/Turabian StyleRo, Kyoung S, Mark A Dietenberger, Judy A Libra, Richard Proeschel, Hasan K. Atiyeh, Kamalakanta Sahoo, and Wonkeun J Park. 2019. "Production of Ethanol from Livestock, Agricultural, and Forest Residuals: An Economic Feasibility Study" Environments 6, no. 8: 97. https://0-doi-org.brum.beds.ac.uk/10.3390/environments6080097