Effects of Solid Die Types in Complex and Large-Scale Aluminum Profile Extrusion

Abstract

:1. Introduction

2. Die Design

- The bearing area further away from the center will have a smaller length value.

- Bearing lengths for regions with complex geometries (such as grooves for assembling, branches with changing directions) will be shorter than that for adjacent areas (multiplied by a coefficient from 0.75 to 0.9).

- The bearing length at the tip of the product profile is calculated to be approximately 0.6 times smaller than the adjacent bearing.

3. Finite Element Modelling

4. Results and Discussion

4.1. Extrusion Velocity of the Product

4.2. Extrusion Force

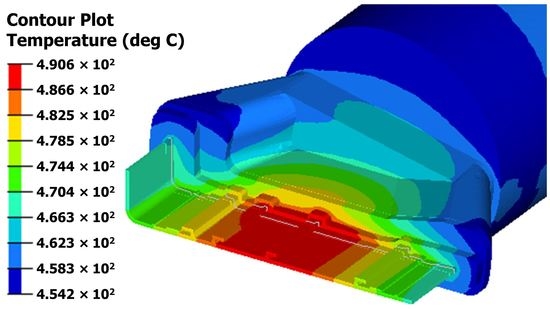

4.3. Extrudate Temperature

4.4. Extrusion Die Deformation

4.5. The Transverse Weld of the Pocket Die and the Spread Die

5. Conclusions

- Using the traditional flat die has the advantage of achieving a more uniform temperature distribution in the extruded product when compared to other solid dies. The extrusion force of this die is about 5% smaller than that of the pocket die. This type of die has a simple structure and is easy to fabricate. However, the needed bearing length is longer than other solid die types, which is undesirable in extrusion practice. Moreover, the deformation of the flat-face die is the largest, the maximum die deflection at a speed ram of 1 mm/s up to 0.17 mm; This may exceed the permissible tolerance of the product. Deformation reduction solutions for this die need to be considered further. When using the flat-face die, a low ram speed can be used to reduce die deformation. Finally, using the traditional flat die is not suitable for extruding complex profiles.

- Using the pocket extrusion die has many advantages compared to other types of solid dies, the velocity is more balanced; the deformation is minimal; transverse welding length is half shorter when compared to the spread die. Moreover, when the ram speed increases, the value of VRD changes little and the die deformation is maintained stably, and the welding line length does not increase significantly (about 221 mm when increasing the ram speed from 1 to 9 mm/s). This die type is the best choice to ensure quality and productivity in extruding aluminum products. However, the pocket and flat-face dies have the disadvantage of being unable to extrude products with sizes larger than the container diameter of the extruder.

- Using the spread die has the advantage that the required extrusion force is the smallest when compared to other solid dies, which is about 40% of the extrusion force required for pocket extruders with the same product profile. It is an extremely effective solution when it is necessary to reduce a large amount of extrusion force or extruding products on small machines with product sizes larger than the extruder diameter. This die type has been growing rapidly in recent years because it can increase the flexibility of production. However, this die type is difficult to design to be able to uniformly distribute the flow in extruded products. Hence, using a pocket and variable bearing lengths is necessary to balance the metal flow for extruding complex product profiles. The more complicated die structure makes the fabrication cost bigger than other types of solid dies. The difference in temperature distribution in the extrusion product of this die is much larger than in other cases, which can be overcome by the increase in temperature for the die plates. The spread extrusion forming the transverse horizontal welding length is twice as long as the pocket die, and the charge weld length is increased rapidly with increasing ram speed (about 3243 mm when increasing the ram speed from 1 to 9 mm/s).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Qamar, S.Z.; Pervez, T.; Chekotu, J.C. Die Defects and Die Corrections in Metal Extrusion. Metals 2018, 8, 380. [Google Scholar] [CrossRef] [Green Version]

- Saha, P.K. Aluminum Extrusion Technology; ASM International: Materials Park, Cleveland, OH, USA, 2000. [Google Scholar]

- Zhang, C.S.; Zhao, G.Q.; Chen, H.; Wang, H. Numerical simulation and die optimal design of a complex section thin-walled aluminum profile extrusion. Adv. Mater. Res. 2011, 148, 195–199. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, G.; Chen, H.; Guan, Y.; Li, H. Optimization of an aluminum profile extrusion process based on Taguchi’s method with S/N analysis. Int. J. Adv. Manuf. Technol. 2012, 60, 589–599. [Google Scholar] [CrossRef]

- Hwang, Y.; Shen, C. Analysis of plastic flow and die design during extrusion of CPU heat sinks. J. Mater. Process. Technol. 2008, 201, 174–178. [Google Scholar] [CrossRef]

- Ji, H.; Nie, H.; Chen, W.; Ruan, X.; Pan, P.; Zhang, J. Optimization of the extrusion die and microstructure analysis for a hollow aluminum alloy profile. Int. J. Adv. Manuf. Technol. 2017, 93, 3461–3471. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, G.; Zhang, C.; Guan, Y.; Liu, H.; Kou, F. Numerical simulation of extrusion process and die structure optimization for a complex aluminum multicavity wallboard of high-speed train. Mater. Manuf. Process. 2011, 26, 1530–1538. [Google Scholar] [CrossRef]

- Valberg, H. Extrusion welding in aluminium extrusion. Int. J. Mater. Product Technol. 2002, 17, 497–556. [Google Scholar] [CrossRef]

- Mahmoodkhani, Y.; Wells, M.; Parson, N.; Jowett, C.; Poole, W. Modeling the formation of transverse weld during billet-on-billet extrusion. Materials 2014, 7, 3470–3480. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Zhao, G.; Chen, Z.; Chen, H.; Kou, F. Effect of extrusion stem speed on extrusion process for a hollow aluminum profile. Mater. Sci. Eng. B 2012, 177, 1691–1697. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, C.; Wang, C.; Zhao, G.; Chen, L.; Sun, W. Application and analysis of spread die and flat container in the extrusion of a large-size, hollow, and flat-wide aluminum alloy profile. Int. J. Adv. Manuf. Technol. 2018, 94, 4247–4263. [Google Scholar] [CrossRef]

- Liu, Z.; Li, L.; Li, S.; Yi, J.; Wang, G. Simulation analysis of porthole die extrusion process and die structure modifications for an aluminum profile with high length–width ratio and small cavity. Materials 2018, 11, 1517. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miles, N.; Evans, G.; Middleditch, A. Bearing lengths for extrusion dies: Rationale, current practice and requirements for automation. J. Mater. Process. Technol. 1997, 72, 162–176. [Google Scholar] [CrossRef]

- Sauer, G.; Ames, A. Extrusion tooling. Extrusion, 2nd ed.; ASM International: Cleveland, OH, USA, 2006. [Google Scholar]

- Lee, G.-A.; Im, Y.-T. Analysis and die design of flat-die hot extrusion process 2. Numerical design of bearing lengths. Int. J. Mech. Sci. 2002, 44, 935–946. [Google Scholar] [CrossRef]

- Van Ouwerkerk, G. CAD Implementation of Design Rules for Aluminium Extrusion Dies. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2009. [Google Scholar]

- Ammu, V.V.; Mahendiran, P.; Agnihotri, A.; Ambade, S.; Dungore, P. A simplified approach for generation of bearing curve by velocity distribution and press validation for aluminum extruded profile. Int. J. Adv. Manuf. Technol. 2018, 98, 1733–1744. [Google Scholar] [CrossRef]

- Liu, P.; Xie, S.; Cheng, L. Die structure optimization for a large, multi-cavity aluminum profile using numerical simulation and experiments. Mater. Des. 2012, 36, 152–160. [Google Scholar] [CrossRef]

- Velay, X. Prediction and control of subgrain size in the hot extrusion of aluminium alloys with feeder plates. J. Mater. Process. Technol. 2009, 209, 3610–3620. [Google Scholar] [CrossRef]

- Fang, G.; Zhou, J.; Duszczyk, J. Extrusion of 7075 aluminium alloy through double-pocket dies to manufacture a complex profile. J. Mater. Process. Technol. 2009, 209, 3050–3059. [Google Scholar] [CrossRef]

- Fang, G.; Zhou, J.; Duszczyk, J. FEM simulation of aluminium extrusion through two-hole multi-step pocket dies. J. Mater. Process. Technol. 2009, 209, 1891–1900. [Google Scholar] [CrossRef]

- Li, Q.; Smith, C.; Harris, C.; Jolly, M. Finite element investigations upon the influence of pocket die designs on metal flow in aluminium extrusion: Part, I. Effect of pocket angle and volume on metal flow. J. Mater. Process. Technol. 2003, 135, 189–196. [Google Scholar] [CrossRef]

- Li, Q.; Smith, C.; Harris, C.; Jolly, M. Finite element modelling investigations upon the influence of pocket die designs on metal flow in aluminium extrusion: Part II. Effect of pocket geometry configurations on metal flow. J. Mater. Process. Technol. 2003, 135, 197–203. [Google Scholar] [CrossRef]

- Lee, S.; Yang, D. Shape Optimization of Flow Guide in Three-dimensional Profile of an H-section Extrusion. AIP Conf. Proc. 2004, 712, 2085–2090. [Google Scholar]

- Zhang, C.; Yang, S.; Zhang, Q.; Zhao, G.; Lu, P.; Sun, W. Automatic optimization design of a feeder extrusion die with response surface methodology and mesh deformation technique. Int. J. Adv. Manuf. Technol. 2017, 91, 3181–3193. [Google Scholar] [CrossRef]

- Kim, K.; Lee, S.; Yang, D. Optimization of the shape of a lip die in extrusion of a plate wider than the diameter of a round billet using a lip die. AIP Conf. Proc. 2004, 712, 2091–2096. [Google Scholar]

- Liu, Z.; Li, L.; Yi, J.; Wang, G. Entrance shape design of spread extrusion die for large-scale aluminum panel. Int. J. Adv. Manuf. Technol. 2019, 101, 1725–1740. [Google Scholar] [CrossRef]

- Imamura, Y.; Takatsuji, N.; Matsuki, K.; Tokizawa, M.; Murotani, K.; Maruyama, H. Metal flow behaviour of wide flat bar in the spreading extrusion process. Mater. Sci. Technol. 1999, 15, 1186–1190. [Google Scholar] [CrossRef]

- Stenger, H.; Laue, K. Extrusion: Processes, Machinery, Tooling; Society for Metals: Metals Parks, OH, USA, 1981. [Google Scholar]

- Chen, L.; Zhao, G.; Yu, J.; Zhang, W. Evaluation of a pyramid die extrusion for a hollow aluminum profile using FE simulation. J. Mech. Sci. Technol. 2015, 29, 2195–2203. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, G.; Guan, Y.; Gao, A.; Wang, L.; Li, P. Virtual tryout and optimization of the extrusion die for an aluminum profile with complex cross-sections. Int. J. Adv. Manuf. Technol. 2015, 78, 927–937. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, G.; Chen, H.; Guan, Y.; Kou, F. Numerical simulation and metal flow analysis of hot extrusion process for a complex hollow aluminum profile. Int. J. Adv. Manuf. Technol. 2012, 60, 101–110. [Google Scholar] [CrossRef]

- Zhao, G.; Chen, H.; Zhang, C.; Guan, Y.; Anjiang, G.; Peng, L. Die optimization design and experimental study of a large wallboard aluminum alloy profile used for high-speed train. Int. J. Adv. Manuf. Technol. 2014, 74, 539–549. [Google Scholar] [CrossRef]

- Hsu, Q.-C.; Do, A.T. Formation ability welding seams and mechanical properties of high strength alloy AA7075 when extrusion hollow square tube. Int. J. Precis. Eng. Manuf. 2015, 16, 557–566. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, G.; Yu, J. Effects of ram velocity on pyramid die extrusion of hollow aluminum profile. Int. J. Adv. Manuf. Technol. 2015, 79, 2117–2125. [Google Scholar] [CrossRef]

- Nilsen, K.E. Numerical Modelling of the Aluminium Extrusion Process and Comparison with Results Obtained from Industrially Extruded Complex Sections. Ph.D. Thesis, Bournemouth University, Poole, UK, 2014. [Google Scholar]

- Reggiani, B.; Segatori, A.; Donati, L.; Tomesani, L. Prediction of charge welds in hollow profiles extrusion by FEM simulations and experimental validation. Int. J. Adv. Manuf. Technol. 2013, 69, 1855–1872. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, G.; Chen, L. Investigation of interface evolution, microstructure and mechanical properties of solid-state bonding seams in hot extrusion process of aluminum alloy profiles. J. Mater. Process. Technol. 2016, 230, 153–166. [Google Scholar] [CrossRef]

| Bearing Lengths with Kw | Bearing Region | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6,14 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 15 | 16 | 17 | 18 | |

| (Kw = 2.5) | 3.1 | 5.2 | 5.9 | 3 | 5.3 | 6.9 | 7.9 | 3.9 | 6.5 | 3.6 | 5.8 | 5.7 | 3.4 | 5.5 | 3.9 | 3.4 | 2 |

| A (s−1) | N | Q (J · mol−1) | R (J mol−1 · K−1) | |

|---|---|---|---|---|

| 0.04 | 5.90152 × 109 | 5.385 | 1.4155 × 105 | 8.314 |

| Material | Density (Kg/m3) | Young Modulus (GPa) | Poisson’s Ratio | Thermal Conductivity (W/m.K) | Heat Capacity (J/(kg °C)) |

|---|---|---|---|---|---|

| AA6063 | 2700 | 40 | 0.35 | 198 | 900 |

| SKD61 | 7870 | 210 | 0.35 | 24.3 | 460 |

| Extrusion Parameters | Traditional Flat Die | Pocket Die | Spread Die |

|---|---|---|---|

| Container diameter (mm) | 310 | 310 | 186 |

| Billet length (mm) | 200 | 200 | 200 |

| Extrusion ratio | 72.5 | 72.5 | 26.1 |

| Billet temperature (°C) | 480 | 480 | 480 |

| Container temperature (°C) | 450 | 450 | 450 |

| Die temperature (°C) | 450 | 450 | 450 |

| Ram speed (mm/s) | 1, 3, 5, 7, 9 | 1, 3, 5, 7, 9 | 1, 3, 5, 7, 9 |

| Bearing Lengths with Kw | Bearing Region | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6,14 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 15 | 16 | 17 | 18 | |

| (Kw =3.5) | 5.2 | 8.6 | 9 | 4.4 | 7.3 | 10 | 11 | 5.5 | 9.1 | 4.8 | 8 | 7.9 | 4.7 | 8.5 | 6.2 | 5.4 | 3.2 |

| (Kw =4.5) | 7.1 | 11.8 | 12.2 | 5.8 | 9.6 | 13.2 | 14.2 | 7 | 11.7 | 6.3 | 10.5 | 10.4 | 6.2 | 11.5 | 8.5 | 7.4 | 4 |

| Max. Deflection of Dies (mm)(Mag) | Ram Speed (mm/s) | ||

|---|---|---|---|

| 1 | 5 | 9 | |

| Flat-face die | 0.17 | 0.18 | 0.19 |

| Pocket die | 0.12 | 0.12 | 0.12 |

| Spread die | 0.11 | 0.13 | 0.13 |

| Ram Speed (mm/s) | Length of Transverse Weld | |

|---|---|---|

| The Pocket Die (mm) | The Spread Die (mm) | |

| 1 | 3497 | 5742 |

| 5 | 3624 | 7385 |

| 9 | 3718 | 8985 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Truong, T.-T.; Hsu, Q.-C.; Tong, V.-C. Effects of Solid Die Types in Complex and Large-Scale Aluminum Profile Extrusion. Appl. Sci. 2020, 10, 263. https://0-doi-org.brum.beds.ac.uk/10.3390/app10010263

Truong T-T, Hsu Q-C, Tong V-C. Effects of Solid Die Types in Complex and Large-Scale Aluminum Profile Extrusion. Applied Sciences. 2020; 10(1):263. https://0-doi-org.brum.beds.ac.uk/10.3390/app10010263

Chicago/Turabian StyleTruong, Tat-Tai, Quang-Cherng Hsu, and Van-Canh Tong. 2020. "Effects of Solid Die Types in Complex and Large-Scale Aluminum Profile Extrusion" Applied Sciences 10, no. 1: 263. https://0-doi-org.brum.beds.ac.uk/10.3390/app10010263