The Brewing Industry and the Opportunities for Real-Time Quality Analysis Using Infrared Spectroscopy

Abstract

:1. Introduction

1.1. Background on Infrared (Near and Mid)

1.2. Cereal Breeding

1.2.1. Protein

1.2.2. Starch

1.2.3. Non-Starch Polysaccharides—Beta-Glucan and Arabinoxylan

1.2.4. Minor Constituents

1.3. Hops

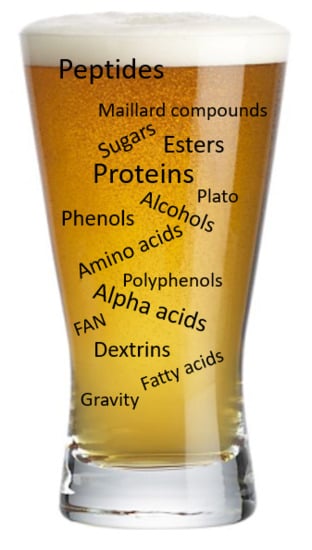

1.4. Production of Wort then Beer

1.4.1. Mashing

1.4.2. Fermentation

1.4.3. Post-Production

2. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Sileoni, V.; Marconi, O.; Perretti, G. Near-infrared spectroscopy in the brewing industry. Crit. Rev. Food Sci. Nutr. 2015, 55, 1771–1791. [Google Scholar] [CrossRef]

- Reich, G. Mid and Near Infrared Spectroscopy. In Analytical Techniques in the Pharmaceutical Sciences; Müllertz, A., Perrie, Y., Rades, T., Eds.; Springer: New York, NY, USA, 2016; pp. 61–138. [Google Scholar]

- Fox, G.P.; Panozzo, J.F.; Li, C.D.; Lance, R.C.M.; Inkerman, P.A.; Henry, R.J. Molecular basis of barley quality. Aust. J. Agric. Res. 2003, 54, 1081–1101. [Google Scholar] [CrossRef] [Green Version]

- Welle, R.; Zahle, K.; Hildebrand, C.; Kraling, K.; Greten, W. Application of near infrared spectroscopy on-combine for canola breeding. J. Near Infrared Spectrosc. 2007, 15, 317–325. [Google Scholar] [CrossRef]

- Fox, G.P.; Bloustein, G.; Sheppard, J. “On-the-go” NIT technology to assess protein and moisture during harvest of wheat breeding trials. J. Cereal Sci. 2010, 51, 171–173. [Google Scholar] [CrossRef]

- Lu, M.Q.; O’Brien, L.; Stuart, I.M. Environmental and genetic variation for grain yield and barley malting quality attributes. Aust. J. Agric. Res. 1999, 50, 1425–1434. [Google Scholar] [CrossRef]

- Ratcliffe, M.; Panozzo, J.F. The application of near infrared spectroscopy to evaluate malting quality. J. Inst. Brew. 1999, 105, 85–88. [Google Scholar] [CrossRef]

- Jacobsen, S.; Sondergaard, I.; Moller, B.; Desler, T.; Munck, L.A. Chemometric evaluation of the underlying physical and chemical patterns that support near infrared spectroscopy of barley seeds as a tool for explorative classification of endosperm, genes and gene combinations. J. Cereal Sci. 2005, 42, 281–299. [Google Scholar] [CrossRef]

- Fox, G.; Manley, M. Applications of single kernel conventional and hyperspectral imaging near infrared spectroscopy in cereals. J. Sci. Food Agric. 2014, 94, 174–179. [Google Scholar] [CrossRef]

- Fox, G.P.; Bowman, J.; Kelly, A.; Inkerman, A.; Poulsen, D.; Henry, R. Assessing for genetic and environmental effects on ruminant feed quality in barley (Hordeum vulgare). Euphytica 2008, 163, 249–257. [Google Scholar] [CrossRef]

- Osborne, B.G. Applications of near infrared spectroscopy in quality screening of early-generation material in cereal breeding programmes. J. Near Infrared Spectrosc. 2006, 14, 93–101. [Google Scholar] [CrossRef]

- Osborne, B.G. Recent developments in NIR analysis of grains and grain products. Cereal Foods World 2000, 45, 11–15. [Google Scholar]

- Munck, L.; Moller, B.; Jacobsen, S.; Sondergaard, I. Near infrared spectra indicate specific mutant endosperm genes and reveal a new mechanism for substituting starch with (1→3,1→4)-beta-glucan in barley. J. Cereal Sci. 2004, 40, 213–222. [Google Scholar] [CrossRef]

- Fox, G.; Borgognone, M.G.; Flinn, P.; Poulsen, D. Genetic and environmental analysis of NIR feed quality predictions on genotypes of barley (Hordeum vulgare L.). Field Crops Res. 2011, 120, 380–386. [Google Scholar] [CrossRef]

- Munck, L.A. New holistic exploratory approach to systems biology by near infrared spectroscopy evaluated by chemometrics and data inspection. J. Chemomet. 2007, 21, 406–426. [Google Scholar] [CrossRef]

- Fox, G.P.; Osborne, B.; Bowman, J.; Kelly, A.; Cakir, M.; Poulsen, D.; Inkerman, A.; Henry, R. Measurement of genetic and environmental variation in barley (Hordeum vulgare) grain hardness. J. Cereal Sci. 2007, 46, 82–92. [Google Scholar] [CrossRef]

- Cozzolino, D.; Roumeliotis, S.; Eglinton, J. Feasibility study on the use of attenuated total reflectance infrared spectroscopy as high throughput screening tool to phenotype single barley seeds (Hordeum vulgare L.). Biosyst. Eng. 2013, 116, 379–384. [Google Scholar] [CrossRef]

- Rajala, A.; Peltonen-Sainio, P.; Kauppila, R.; Wilhelmson, A.; Reinikainen, P.; Kleemola, J. Within-field variation in grain yield, yield components and quality traits of two-row barley. J. Agric. Sci. 2007, 145, 445–454. [Google Scholar] [CrossRef]

- Henry, R.J. Evaluation of barley and malt quality using near-infrared reflectance techniques. J. Inst. Brew. 1985, 91, 393–396. [Google Scholar] [CrossRef]

- Gordon, R.; Chapman, J.; Power, A.; Chandra, S.; Roberts, J.; Cozzolino, D. Unfrazzled by fizziness: Identification of beers using attenuated total reflectance mid-infrared spectroscopy and multivariate analysis. Food Anal. Meth. 2018, 11, 2360–2367. [Google Scholar] [CrossRef]

- Angelino, S.; Van Laarhoven, H.P.M.; Van Westerop, J.J.M.; Broekhuijse, B.M.; Mocking, H.C.M. Total nitrogen content in single kernel malting barley samples. J. Inst. Brew. 1997, 103, 41–46. [Google Scholar] [CrossRef]

- Home, S.; Wilhelmson, A.; Tammisola, J.; Husman, J. Natural variation among barley kernels. J. Am. Soc. Brew. Chem. 1997, 55, 47–51. [Google Scholar] [CrossRef]

- Fox, G.P.; Kelly, A.; Sweeney, N.; Hocroft, D.M. Development of a single kernel NIR barley protein calibration and assessment of variation in protein on grain quality. J. Inst. Brew. 2011, 117, 582–586. [Google Scholar] [CrossRef]

- Bak-Jensen, K.S.; Laugesen, S.; Roepstorff, P.; Svensson, B. Two-dimensional gel electrophoresis pattern (pH 6–11) and identification of water-soluble barley seed and malt proteins by mass spectrometry. Proteomics 2004, 4, 728–742. [Google Scholar] [CrossRef] [PubMed]

- Finnie, C.; Svensson, B. Barley seed proteomics from spots to structures. J. Proteomics 2009, 72, 315–324. [Google Scholar] [CrossRef] [PubMed]

- Iimure, T.; Nankaku, N.; Kihara, M.; Yamada, S.; Sato, K. Proteome analysis of the wort boiling process. Food Res. Int. 2012, 45, 262–271. [Google Scholar] [CrossRef]

- Kerr, E.D.; Caboche, C.H.; Schulz, B.L. Posttranslational modifications drive protein stability to control the dynamic beer brewing proteome. Mol. Cell. Proteom. 2019, 18, 1721–1731. [Google Scholar] [CrossRef]

- Schulz, B.L.; Phung, T.K.; Bruschi, M.; Janusz, A.; Stewart, J.; Mehan, J.; Healy, P.; Nouwens, A.S.; Fox, G.P.; Vickers, C.E. Process proteomics of beer reveals a dynamic proteome with extensive modifications. J. Proteome Res. 2018, 17, 1647–1653. [Google Scholar] [CrossRef]

- Evans, D.E.; Fox, G.P. Comparison of diastatic power enzyme release and persistence during modified Institute of Brewing 65 degrees C and Congress Programmed mashes. J. Am. Soc. Brew. Chem. 2017, 75, 302–311. [Google Scholar]

- Bamforth, C.W. Scientific Principles of Malting and Brewing; American Society of Brewing Chemists: Saint Paul, MN, USA, 2006. [Google Scholar]

- Wiley, P.R.; Tanner, G.J.; Chandler, P.M.; Anderssen, R.S. Molecular classification of barley (Hordeum vulgare L.) mutants using derivative NIR spectroscopy. J. Agric. Food Chem. 2009, 57, 4042–4050. [Google Scholar] [CrossRef]

- Fox, G.P.; Onley-Watson, K.; Osman, A. Multiple linear regression calibrations for barley and malt protein based on the spectra of hordein. J. Inst. Brew. 2002, 108, 155–159. [Google Scholar] [CrossRef]

- Wrobel, R.; Jones, B.L. Electrophoretic study of substrate and pH-dependence of endoproteolytic enzymes in green malt. J. Inst. Brew. 1992, 98, 471–478. [Google Scholar] [CrossRef]

- Jones, B.L. Endoproteases of barley and malt. J. Cereal Sci. 2005, 42, 139–156. [Google Scholar] [CrossRef]

- Daldegan, F.; Rocher, A.; Cameronmills, V.; Von Wettstein, D. The expression of serine carboxypeptidases during maturation and germination of the barley grain. Proc. Natl. Acad. Sci. USA 1994, 91, 8209–8213. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sogaard, M.; Olsen, F.L.; Svensson, B. C-Terminal processing of barley alpha-amylase-1 in malt, aleurone protoplasts, and yeast. Proc. Natl. Acad. Sci. USA 1991, 88, 8140–8144. [Google Scholar] [CrossRef] [Green Version]

- Gorinstein, S.; Zemser, M.; Vargas-Albores, F.; Ochoa, J.L.; Paredes-Lopez, O.; Scheler, C.; Salnikow, J.; Martin-Belloso, O.; Trakhtenberg, S. Proteins and amino acids in beers, their contents and relationships with other analytical data. Food Chem. 1999, 67, 71–78. [Google Scholar] [CrossRef]

- Fox, G.P. Chemical composition in barley grains and malt 1uality. In Quality, Genetics and Improvement of Malt Barley; Zhang, G.P., Li, C.D., Eds.; Zhejing University Press: Hangzhou, China, 2009; pp. 63–98. [Google Scholar]

- Yu, W.W.; Tan, X.L.; Zou, W.; Hu, Z.X.; Fox, G.P.; Gidley, M.J.; Gilbert, R.G. Relationships between protein content, starch molecular structure and grain size in barley. Carbohydr. Polym. 2017, 155, 271–279. [Google Scholar] [CrossRef]

- Czuchajowska, Z.; Szczodrak, J.; Pomeranz, Y. Characterization and estimation of barley polysaccharides by near-iInfrared spectroscopy 1. Barleys, starches, and beta-deuterium-glucans. Cereal Chem. 1992, 69, 413–418. [Google Scholar]

- Cozzolino, D.; Roumeliotis, S.; Eglinton, J. Prediction of starch pasting properties in barley flour using ATR-MIR spectroscopy. Carbohydr. Polym. 2013, 95, 509–514. [Google Scholar] [CrossRef]

- Cozzolino, D.; Roumeliotis, S.; Eglinton, J. Exploring the use of near infrared (NIR) reflectance spectroscopy to predict starch pasting properties in whole grain barley. Food Biophys. 2013, 8, 256–261. [Google Scholar] [CrossRef]

- Munck, L.; Mller, B. Principal component analysis of near infrared spectra as a tool of endosperm mutant characterization and in barley breeding for quality. Czech J. Gen. Plant Breed. 2005, 41, 89–95. [Google Scholar] [CrossRef] [Green Version]

- Munck, L. Conceptual validation of self-organisation studied by spectroscopy in an endosperm gene model as a data-driven logistic strategy in chemometrics. Chemomet. Intell. Lab. Syst. 2006, 84, 26–32. [Google Scholar] [CrossRef]

- Garden, S.W.; Freeman, P.L. Applications of near-infrared spectroscopy in malting.Calibrations for analysis of green malt. J. Am. Soc. Brew. Chem. 1998, 56, 159–163. [Google Scholar]

- Contreras-Jimenez, B.; del Real, A.; Millan-Malo, B.M.; Gaytan-Martinez, M.; Morales-Sanchez, E.; Rodriguez-Garcia, M.E. Physicochemical changes in barley starch during malting. J. Inst. Brew. 2019, 125, 10–17. [Google Scholar] [CrossRef]

- Han, J.Y.; Schwarz, P.B. Arabinoxylan composition in barley, malt, and beer. J. Am. Soc. Brew. Chem. 1996, 54, 216–220. [Google Scholar] [CrossRef]

- Sadosky, P.; Schwarz, P.B.; Horsley, R.D. Effect of arabinoxylans, beta-glucans, and dextrins on the viscosity and membrane filterability of a beer model solution. J. Am. Soc. Brew. Chem. 2002, 60, 153–162. [Google Scholar]

- Stewart, D.; Freeman, G.; Evans, E. Development and assessment of a small-scale Wort filtration test for the prediction of beer filtration efficiency. J. Inst. Brew. 2000, 106, 361–366. [Google Scholar] [CrossRef]

- Cozzolino, D.; Roumeliotis, S.; Eglinton, J. Evaluation of the use of attenuated total reflectance mid infrared spectroscopy to determine fatty acids in intact seeds of barley (Hordeum vulgare). LWT Food Sci. Technol. 2014, 56, 478–483. [Google Scholar] [CrossRef]

- Correia, I.; Nunes, A.; Barros, A.S.; Delgadillo, I. Protein profile and malt activity during sorghum germination. J. Sci. Food Agric. 2008, 88, 2598–2605. [Google Scholar] [CrossRef]

- Marte, L.; Belloni, P.; Genorini, E.; Sileoni, V.; Perretti, G.; Montanari, L.; Marconi, O. Near-Infrared reflectance models for the rapid prediction of quality of brewing raw materials. J. Agric. Food Chem. 2009, 57, 326–333. [Google Scholar] [CrossRef]

- Sileoni, V.; Perretti, G.; Marte, L.; Marconi, O.; Fantozzi, P. Near-infrared spectroscopy for proficient quality evaluation of the malt and maize used for beer production. J. Inst. Brew. 2010, 116, 134–140. [Google Scholar] [CrossRef]

- Verardo, V.; Cevoli, C.; Pasini, F.; Gomez-Caravaca, A.M.; Marconi, E.; Fabbri, A.; Caboni, M.F. Analysis of oligomer proanthocyanidins in different barley genotypes using high-performance liquid chromatography-fluorescence detection-mass spectrometry and near-infrared methodologies. J. Agric. Food Chem. 2015, 63, 4130–4137. [Google Scholar] [CrossRef] [PubMed]

- Bamforth, C.W. Brewing and Brewing research: Past, present and future. J. Sci. Food Agric. 2000, 80, 1371–1378. [Google Scholar] [CrossRef]

- Garden, S.W.; Pruneda, T.; Irby, S.; Hysert, D.W. Development of near-infrared calibrations for hop analysis. J. Am. Soc. Brew. Chem. 2000, 58, 73–82. [Google Scholar] [CrossRef] [Green Version]

- Lachenmeier, D.W. Rapid quality control of spirit drinks and beer using multivariate data analysis of Fourier transform infrared spectra. Food Chem. 2007, 101, 825–832. [Google Scholar] [CrossRef]

- Machado, J.C.; Faria, M.A.; Ferreira, I.; Pascoa, R.; Lopes, J.A. Varietal discrimination of hop pellets by near and mid infrared spectroscopy. Talanta 2018, 180, 69–75. [Google Scholar] [CrossRef]

- Gous, P.W.; Fox, G.P. Review: Amylopectin synthesis and hydrolysis-Understanding isoamylase and limit dextrinase and their impact on starch structure on barley (Hordeum vulgare) quality. Trends Food Sci. Technol. 2017, 62, 23–32. [Google Scholar] [CrossRef] [Green Version]

- Baxter, E.D.; McGill, W. Near infra-red spectroscopy for identifying malting quality. HGCA Proj. Rep. 1991, 28, 48. [Google Scholar]

- Titze, J.; Ilberg, V.; Friess, A.; Jacob, F.; Parlar, H. Efficient and quantitative measurement of malt and wort parameters using FTIR spectroscopy. J. Am. Soc. Brew. Chem. 2009, 67, 193–199. [Google Scholar] [CrossRef]

- Cozzolino, D.; Degner, S.; Eglinton, J. A novel approach to monitor the hydrolysis of barley (Hordeum vulgare L.) malt.A chemometrics approach. J. Agric. Food Chem. 2014, 62, 11730–11736. [Google Scholar] [CrossRef]

- Halsey, S.A. The application of transmission near-infrared spectrscopy to the analysis of worts. J. Inst. Brew. 1986, 92, 387–393. [Google Scholar] [CrossRef]

- Cejka, P.; Kellner, V.; Culik, J.; Jurkova, M.; Horak, T.; Polednikova, M. Determining the original gravity using near-infrared spectrometry and cryoscopy. Monat. Brauwissen. 2000, 53, 223–228. [Google Scholar]

- Grassi, S.; Amigo, J.M.; Lyndgaard, C.B.; Foschino, R.; Casiraghi, E. Beer fermentation.Monitoring of process parameters by FT-NIR and multivariate data analysis. Food Chem. 2014, 155, 279–286. [Google Scholar] [CrossRef] [PubMed]

- Cernuda, C.; Lughofer, E.; Klein, H.; Forster, C.; Pawliczek, M.; Brandstetter, M. Improved quantification of important beer quality parameters based on nonlinear calibration methods applied to FT-MIR spectra. Anal. Bioanal. Chem. 2017, 409, 841–857. [Google Scholar] [CrossRef] [PubMed]

- Fox, G. Infrared spectral analysis of sugar profiles of worts from varying grist to liquor ratios using infusion and ramping mash styles. J. Inst. Brew. 2016, 122, 437–445. [Google Scholar] [CrossRef]

- Holtz, C.; Krause, D.; Hussein, M.; Gastl, M.; Becker, T. Lautering performance prediction from malt by combining whole near-infrared spectral information with lautering process evaluation as reference values. J. Am. Soc. Brew. Chem. 2014, 72, 214–219. [Google Scholar] [CrossRef]

- Tenhunen, J.; Sjoholm, K.; Pietila, K.; Home, S. Determination of fermentable sugars and nitrogenous compounds in wort by near infrared and mid infrared spectroscopy. J. Inst. Brew. 1994, 100, 11–15. [Google Scholar] [CrossRef]

- Grassi, S.; Amigo, J.M.; Lyndgaard, C.B.; Foschino, R.; Casiraghi, E. Assessment of the sugars and ethanol development in beer fermentation with FT-IR and multivariate curve resolution models. Food Res. Int. 2014, 62, 602–608. [Google Scholar] [CrossRef]

- Cozzolino, D.; Schultz, D.; Allder, K.; Eglinton, J.; Roumeliotis, S. Feasibility study on the use of attenuated total reflectance mid-infrared spectroscopy for the analysis of malt quality parameters in wort. J. Inst. Brew. 2014, 120, 385–389. [Google Scholar] [CrossRef]

- Lachenmeier, D.W.; Godelmann, R.; Steiner, M.; Ansay, B.; Weigel, J.; Krieg, G. Rapid and mobile determination of alcoholic strength in wine, beer and spirits using a flow-through infrared sensor. Chem. Cent. J. 2010, 4, 5. [Google Scholar] [CrossRef] [Green Version]

- Vann, L.; Layfield, J.B.; Sheppard, J.D. The application of near-infrared spectroscopy in beer fermentation for online monitoring of critical process parameters and their integration into a novel feedforward control strategy. J. Inst. Brew. 2017, 123, 347–360. [Google Scholar] [CrossRef] [Green Version]

- Fritsch, A.; Shellhammer, T.H. The bitter qualities of reduced and nonreduced iso-alpha-acids. J. Am. Soc. Brew. Chem. 2009, 67, 8–13. [Google Scholar]

- Parkin, E.; Shellhammer, T. Toward understanding the bitterness of dry-hopped beer. J. Am. Soc. Brew. Chem. 2017, 75, 363–368. [Google Scholar] [CrossRef]

- Hahn, C.D.; Lafontaine, S.R.; Pereira, C.B.; Shellhammer, T.H. Evaluation of nonvolatile chemistry affecting sensory bitterness intensity of highly hopped beers. J. Agric. Food Chem. 2018, 66, 3505–3513. [Google Scholar] [CrossRef] [PubMed]

- Samp, E.J.; Sedin, D.; Foster, A. Enhanced NIR calibration for wort fermentability using orthogonal signal correction. J. Inst. Brew. 2003, 109, 16–26. [Google Scholar] [CrossRef]

- Sjoholm, K.; Tenhunen, J.; Tammisola, J.; Pietila, K.; Home, S. Determination of the fermentability and extract content of industrial worts by NIR. J. Am. Soc. Brew. Chem. 1996, 54, 135–140. [Google Scholar] [CrossRef]

- Noack, D.; Knodl, C.; Lachenmeier, D.W. Evaluation of fluorescence-marked gene probes and Fourier transform infrared spectroscopy as novel methods to detect beer spoilage bacteria. Dtsch. Lebensm. Rundsch. 2008, 104, 65–69. [Google Scholar]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fox, G. The Brewing Industry and the Opportunities for Real-Time Quality Analysis Using Infrared Spectroscopy. Appl. Sci. 2020, 10, 616. https://0-doi-org.brum.beds.ac.uk/10.3390/app10020616

Fox G. The Brewing Industry and the Opportunities for Real-Time Quality Analysis Using Infrared Spectroscopy. Applied Sciences. 2020; 10(2):616. https://0-doi-org.brum.beds.ac.uk/10.3390/app10020616

Chicago/Turabian StyleFox, Glen. 2020. "The Brewing Industry and the Opportunities for Real-Time Quality Analysis Using Infrared Spectroscopy" Applied Sciences 10, no. 2: 616. https://0-doi-org.brum.beds.ac.uk/10.3390/app10020616