Development of Radiator with Thermoplastic Polymer and Insert-Molded Aluminum Alloy Parts for Light-Emitting Diode Headlights

Abstract

:1. Introduction

2. Materials and Methods

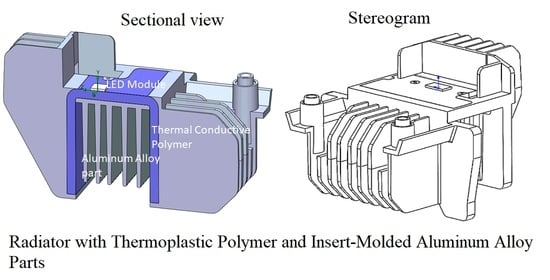

2.1. Structure of Composite Radiator

2.2. Thermal Analysis and Optimization Simulation Design

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Katzin, D.; Marcelis, L.F.M.; van Mourik, S. Energy savings in greenhouses by transition from high-pressure sodium to LED lighting. Appl. Energy 2020, 281, 116019. [Google Scholar] [CrossRef]

- Wisniewski, A. Calculations of energy savings using lighting control systems. Power Syst. Power Electron. 2020, 68, 809–817. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, D.F.; Wei, Y.W.; Wang, H. Asymmetric Double Freeform Surface Lens for Integrated LED Automobile Headlamp. Micromachines 2021, 12, 663. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Chiang, Y.; Lin, C.; Lu, M.; Lee, M.K.; Feng, S.; Kuo, C. All-reflective RGB LED flashlight design for effective color mixing. Opt. Express 2016, 24, 4411. [Google Scholar] [CrossRef] [PubMed]

- Lua, Z.; Bai, P.; Huanga, B.; Henzen, A.; Coehoorn, R.; Liaoe, H.; Zhoua, G. Experimental investigation on the thermal performance of threedimensional vapor chamber for LED automotive headlamps. Appl. Therm. Eng. 2019, 157, 113478. [Google Scholar] [CrossRef]

- Huang, Y.-R.; Chiu, Y.-C.; Huang, K.-C.; Ting, S.-Y.; Chiang, P.-J.; Lai, C.-M.; Jen, C.-P.; Tseng, S.H.; Wang, H.-C. Light extraction efficiency enhancement of flip-chip blue light-emitting diodes by anodic aluminum oxide. Beilstein J. Nanotechnol. 2018, 9, 1602–1612. [Google Scholar] [CrossRef]

- Padmasali, A.N.; Kini, S.G. Accelerated degradation test investigation for life-time performance analysis of LED luminaires. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 551–558. [Google Scholar] [CrossRef]

- Ye, Z.T.; Chen, C.L.; Chen, L.; Tien, C.H.; Nguyen, H.T.; Wang, H. Hollow light guide module involving mini light-emitting diodes for asymmetric luminous planar illuminators. Energies 2019, 12, 2755. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.Y.; Kim, M.S.; Lee, K.H.; Kang, K.M.; Oh, J.T.; Jeong, H.H.; Seong, T.Y. Optimization of InGaN-based LED package structure for automotive adaptive driving beam headlamp. ECS J. Solid State Sci. Technol. 2020, 9, 055017. [Google Scholar] [CrossRef]

- Ye, Z.T.; Ruan, M.; Kuo, H.C. CSP-LEDs Combined with Light Guide without Reflective Matrix for Antiglare Design. IEEE Access 2020, 8, 156718–156726. [Google Scholar] [CrossRef]

- Ye, Z.; Chang, C.; Juan, M.; Chen, K. Luminous Intensity Field Optimization for Antiglare LED Desk Lamp without Second Optical Element. Appl. Sci. 2020, 10, 2607. [Google Scholar] [CrossRef] [Green Version]

- Qu, X.; Liu, Q.; Blaabjerg, F. System-level lifetime prediction for LED lighting applications considering thermal coupling between LED sources and drivers. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1860–1870. [Google Scholar] [CrossRef]

- Liu, H.; Yu, D.; Niu, P.; Zhang, Z.; Guo, K.; Wang, D.; Zhang, J.; Ma, X.; Jia, C.; Wu, C. Lifetime prediction of a multi-chip high-power LED light source based on artificial neural networks. Results Phys. 2018, 12, 361–367. [Google Scholar] [CrossRef]

- Qu, X.; Wang, H.; Zhan, X.; Blaabjerg, F.; Chung, H. A lifetime prediction method for LEDs considering real mission. IEEE Trans. Power Electron. 2017, 32, 8718–8727. [Google Scholar] [CrossRef] [Green Version]

- Dumbrava, V.; Pagodinas, D.; Knyva, V.; Kupciunas, I.; Cincikas, G.; Noreika, A.; Siaudinyte, L. Simplified and accelerated method of LED lamp useful life estimation. MAPAN 2019, 34, 169–178. [Google Scholar] [CrossRef]

- Wang, X.; Jing, L.; Wang, Y.; Gao, Q.; Sun, Q. The influence of junction temperature variation of LED on the lifetime estimation during accelerated aging test. IEEE Access 2019, 7, 4773–4781. [Google Scholar] [CrossRef]

- Adhikari, R.; Beyragh, D.; Pahlevani, M.; Wood, D. A numerical and experimental study of a novel heat sink design for natural convection cooling of LED grow lights. Energies 2020, 13, 4046. [Google Scholar] [CrossRef]

- Kilic, M.; Aktas, M.; Sevilgen, G. Thermal assessment of laminar flow liquid cooling blocks for LED circuit boards used in automotive headlight assemblies. Energies 2020, 13, 1202. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Wu, J.; Yang, X.; Liu, Y.; Ma, K.; Zhu, H.; Zhou, H.; Sun, H. Analysis of mini-LED light-off phenomenon based on FEM simulation. Chin. J. Liq. Cryst. Disp. 2020, 35, 53–61. [Google Scholar] [CrossRef]

- Huang, Y.; Shen, S.; Li, H.; Gu, Y. Numerical analysis on the thermal performances of different types of fin heat sink for high-power LED lamp cooling. Therm. Sci. 2019, 23, 625–636. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, H.E. Optimization of thermal design of ribbed flat-plate fin heat sink. Appl. Therm. Eng. 2016, 102, 1422–1432. [Google Scholar] [CrossRef]

- Abdelmlek, K.B.; Araoud, Z.; Charrada, K.; Zissis, G. Optimization of the thermal distribution of multi-chip LED package. Appl. Therm. Eng. 2017, 126, 653–660. [Google Scholar] [CrossRef]

- Cenci, M.P.; Berto, F.C.D.; Schneider, E.L.; Veit, H.M. Assessment of LED lamps components and materials for a recycling perspective. Waste Manag. 2020, 107, 285–293. [Google Scholar] [CrossRef] [PubMed]

- Dzombak, R.; Padon, J.; Salsbury, J.; Dillon, H. Assessment of end-of-life design in solid-state lighting. Environ. Res. Lett. 2017, 12, 084013. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Luo, Y.; Du, P.; Wang, H.; Ma, H.; Qin, Y.; Bai, P.; Zhou, G. Experimental investigation on active heat sink with heat pipe assistance for high-power automotive LED headlights. Case Stud. Therm. Eng. 2021, 28, 101503. [Google Scholar] [CrossRef]

- Sevilgen, G.; Kiliç, M.; Aktaş, M. Dual-separated cooling channel performance evaluation for high-power led Pcb in automotive headlight. Case Stud. Therm. Eng. 2021, 25, 100985. [Google Scholar] [CrossRef]

- Mraz, K.; Bartuli, E.; Kroulikova, T.; Astrouski, I.; Resl, O.; Vancura, J.; Kudelova, T. Case study of liquid cooling of automotive headlights with hollow fiber heat exchanger. Case Stud. Therm. Eng. 2021, 28, 101689. [Google Scholar] [CrossRef]

- Huang, Y.; Luo, W.; Wang, H.; Feng, S.; Kuo, C.; Lu, C. How smart LEDs lighting benefit color temperature and luminosity transformation. Energies 2017, 10, 518. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.; Lim, M.; Kim, C.; Bae, S.J. Reliability Analysis of Accelerated Destructive Degradation Testing Data for Bi-Functional DC Motor Systems. Appl. Sci. 2021, 11, 2537. [Google Scholar] [CrossRef]

- Huang, D.-S.; Chen, T.-C.; Tsai, L.-T.; Lin, M.-T. Design of fins with a grooved heat pipe for dissipation of heat from high-powered automotive LED headlight. Energy Convers. Manag. 2019, 180, 550–558. [Google Scholar] [CrossRef]

- Mashkov, P.; Gyoch, B.; Ivanovj, R. Investigation of Characteristics and thermal loading of LED bulbs for automatics headlights. Transp. Probl. 2018, 13, 85–95. [Google Scholar] [CrossRef] [Green Version]

- Ying, S.P.; Chen, B.M.; Fu, H.K.; Yeh, C.Y. Single Headlamp with Low- and High-Beam Light. Photonics 2021, 8, 32. [Google Scholar] [CrossRef]

- Zhu, Z.; Wei, S.; Liu, R.; Hong, Z.; Zheng, Z.; Fan, Z.; Ma, D. Freeform surface design for high-efficient LED low-beam headlamp lens. Opt. Commun. 2020, 477, 126269. [Google Scholar] [CrossRef]

- Chu, S.-C.; Chen, P.-Y.; Huang, C.-Y.; Chang, K.-C. Design of a high-efficiency LED low-beam headlamp using Oliker’s compound ellipsoidal reflector. Appl. Opt. 2020, 59, 4872–4879. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.-H.; Lee, C.-H.; Yang, C.-H. Achromatic LED-based projection lens design for automobile headlamp. Optik 2019, 191, 89–99. [Google Scholar] [CrossRef]

- Cavallo, V.; Espie, S.; Dang, N.T. Improving motorcycle motion perception by using innovative motorcycle headlight configurations: Evidence from simulator and test-track experiments. Accid. Anal. Prev. 2021, 157, 106118. [Google Scholar] [CrossRef]

- You, Z.; Yang, D.; Zhou, P.; Hai, Y.; Liu, D.; Hou, F. Heat transfer analysis of vapor chamber heat pipe for high power LED package. In Proceedings of the 2010 11th International Conference on Electronic Packaging Technology & High Density Packaging, Xi’an, China, 16–19 August 2010. [Google Scholar] [CrossRef]

- Yu, G.-Y.; Zhu, Z.-P.; Hu, S.-H.; Hao, W.-W.; Guo, T.-T. Thermal simulation and optimization design on a high-power LED spot lamp. Optoelectron. Lett. 2011, 7, 117–121. [Google Scholar] [CrossRef]

- Tang, Y.; Liu, D.; Yang, H.; Yang, P. Thermal effects on LED lamp with different thermal interface materials. IEEE Trans. Electron Devices 2016, 63, 4819–4824. [Google Scholar] [CrossRef]

- Park, D.H.; Lee, D.B.; Seo, E.R.; Park, Y.J. A parametric study on heat dissipation from a LED-lamp. Appl. Therm. Eng. 2016, 108, 1261–1267. [Google Scholar] [CrossRef]

| Material | Thermoplastic Polymer Insert Molding Aluminum Alloy | Pure Aluminum Alloy |

|---|---|---|

| Aluminum Alloy Part | 56 g | 244 g |

| Thermoplastic Polymer Part | 131 g | - |

| Gross Weight | 187 g | 244 g |

| Weight percentage (%) | 76.63% | 100% |

| Point/Coordinate (x,y,z) | Composite Radiator Temperature (°C) | Pure Aluminum Alloy Temperature (°C) |

|---|---|---|

| P1 (0,0,0) | 60.82 | 60.77 |

| P2 (0,−2.5,−29.39) | 53.45 | 55.87 |

| P3 (0,−26.25,−64.35) | 49.96 | 54.28 |

| Tj | 66.74 | 66.69 |

| Measured Point | Simulation (°C) | Measured (°C) |

|---|---|---|

| The pad temperature of the LED module (P1) | 60.82 | 60.8 |

| The temperature of the nearly aluminum alloy body (P2) | 53.45 | 52.8 |

| The temperature on the composite radiator surface (P3) | 49.96 | 50.5 |

| Tj | 66.74 | 66.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Chang, J.; Huang, C.; Chiu, C.; Lai, W.; Ye, Z.; Han, P. Development of Radiator with Thermoplastic Polymer and Insert-Molded Aluminum Alloy Parts for Light-Emitting Diode Headlights. Appl. Sci. 2022, 12, 5385. https://0-doi-org.brum.beds.ac.uk/10.3390/app12115385

Chen Y, Chang J, Huang C, Chiu C, Lai W, Ye Z, Han P. Development of Radiator with Thermoplastic Polymer and Insert-Molded Aluminum Alloy Parts for Light-Emitting Diode Headlights. Applied Sciences. 2022; 12(11):5385. https://0-doi-org.brum.beds.ac.uk/10.3390/app12115385

Chicago/Turabian StyleChen, Yenlung, Juikun Chang, Chun Huang, Changche Chiu, Wei Lai, Zhiting Ye, and Pin Han. 2022. "Development of Radiator with Thermoplastic Polymer and Insert-Molded Aluminum Alloy Parts for Light-Emitting Diode Headlights" Applied Sciences 12, no. 11: 5385. https://0-doi-org.brum.beds.ac.uk/10.3390/app12115385