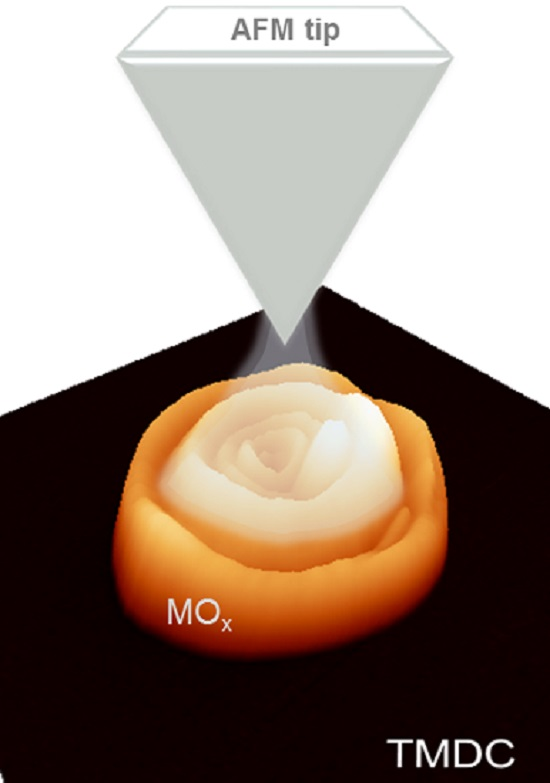

Local Oxidation Nanolithography on Metallic Transition Metal Dichalcogenides Surfaces

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. AFM LON on TaS2 Surfaces

3.1.1. Dynamic-Tip LON

3.1.2. Static-Tip LON

3.2. Characterization of LON Motifs Patterned on 2H-TaS2

3.2.1. Etching Experiments

3.2.2. Electrical Properties of the Ultrathin TaS2 Layers

3.3. LON on Other TMDCs

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Garcia, R.; Knoll, A.W.; Riedo, E. Advanced scanning probe lithography. Nat. Nanotechnol. 2014, 9, 577–587. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.N.; Chung, H.J.; Sow, C.H.; Wee, A.T.S. Nanoscale materials patterning and engineering by atomic force microscopy nanolithography. Mat. Sci. Eng. 2006, 54, 1–48. [Google Scholar] [CrossRef]

- Dagata, J.A.; Schneir, J.; Harary, H.H.; Evans, C.J.; Postek, M.T.; Bennett, J. Modification of hydrogen-passivated silicon by a scanning tunneling microscope operating in air. Appl. Phys. Lett. 1990, 56, 2001–2003. [Google Scholar] [CrossRef]

- Wendel, M.; Irmer, B.; Cortes, J.; Kaiser, R.; Lorenz, H.; Kotthaus, J.P.; Lorke, A.; Williams, E. Nanolithography with an atomic force microscope. Superlattices Microst. 1996, 20, 349–356. [Google Scholar] [CrossRef]

- Garcia, R.; Calleja, M.; Perez-Murano, F. Local oxidation of silicon surfaces by dynamic force microscopy: Nanofabrication and water bridge formation. Appl. Phys. Lett. 1998, 72, 2295–2297. [Google Scholar] [CrossRef] [Green Version]

- Suez, I.; Backer, S.A.; Fréchet, J.M.J. Generating an etch resistant “resist” layer from common solvents using scanning probe lithography in a fluid cell. Nano Lett. 2005, 5, 321–324. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, M.; Dutta, S.; Aikawa, S.; Nakaharai, S.; Wakabayashi, K.; Fuhrer, M.S.; Ueno, K.; Tsukagoshi, K. Self-limiting layer-by-layer oxidation of atomically thin WSe2. Nano Lett. 2015, 15, 2067–2073. [Google Scholar] [CrossRef] [PubMed]

- Böhmisch, M.; Burmeister, F.; Boneberg, J.; Leiderer, P. Nanostructuring on WSe2 with the atomic force microscope by a potential controlled electrochemical reaction. Appl. Phys. Lett. 1996, 69, 1882–1884. [Google Scholar] [CrossRef]

- Tsai, J.T.H.; Hsu, C.-Y.; Hsu, C.-H.; Yang, C.-S.; Lin, T.-Y. Fabrication of resistive random access memory by atomic force microscope local anodic oxidation. NANO Brief Rep. Rev. 2015, 10, 1550028–1550036. [Google Scholar] [CrossRef]

- Weng, L.; Zhang, L.; Chen, Y.; Rokhinson, L. Atomic force microscope local oxidation nanolithography of graphene. Appl. Phys. Lett. 2008, 93. [Google Scholar] [CrossRef]

- Masubuchi, S.; Ono, M.; Yoshida, K.; Hirakawa, K.; Machida, T. Fabrication of graphene nanoribbon by local anodic oxidation lithography using atomic force microscope. Appl. Phys. Lett. 2009, 94. [Google Scholar] [CrossRef]

- Choudhary, N.; Islam, M.R.; Kang, N.; Tetard, L.; Jung, Y.; Khondaker, S. Two-dimensional lateral heterojunction through bandgap engineering of MoS2 via oxygen plasma. J. Phys. Condens. Matter. 2016, 28. [Google Scholar] [CrossRef] [PubMed]

- Cartamil-Bueno, S.J.; Steeneken, P.G.; Tichelaar, F.D.; Navarro-Moratalla, E.; Venstra, W.J.; Van Leeuwen, R.; Coronado, E.; Van Der Zant, H.S.J.; Steele, G.A.; Castellanos-Gomez, A. High-quality-factor tantalum oxide nanomechanical resonators by laser oxidation of TaSe2. Nano Res. 2015, 8, 2842–2849. [Google Scholar] [CrossRef]

- Tan, C.; Liu, Y.; Chou, H.; Kim, J.-S.; Wu, D.; Akinwande, D.; Lai, K. Laser-assisted oxidation of multi-layer tungsten diselenide nanosheets. Appl. Phys. Lett. 2016, 108. [Google Scholar] [CrossRef]

- Coronado, E.; Forment-Aliaga, A.; Navarro-Moratalla, E.; Pinilla-Cienfuegos, E.; Castellanos Gomez, A. Nanofabrication of TaS2 conducting layers nanopatterned with Ta2O5 insulating regions via AFM. J. Mater. Chem. C 2013, 1, 7692–7694. [Google Scholar] [CrossRef]

- Espinosa, F.M.; Ryu, Y.K.; Marinov, K.; Dumcenco, D.; Kis, A.; Garcia, R. Direct fabrication of thin layer MoS2 field-effect nanoscale transistors by oxidation scanning probe lithography. Appl. Phys. Lett. 2015, 106. [Google Scholar] [CrossRef]

- Li, H.; Shi, Y.; Chiu, M.-H.; Li, L.-J. Emerging energy applications of two-dimensional layered transition metal dichalcogenides. Nano Energy 2015, 18, 293–305. [Google Scholar] [CrossRef]

- Duan, X.; Wang, C.; Pan, A.; Yu, R.; Duan, X. Two-dimensional transition metal dichalcogenides as atomically thin semiconductors: opportunities and challenges. Chem. Soc. Rev. 2015, 44, 8859–8876. [Google Scholar] [CrossRef] [PubMed]

- Berdiyorov, G.R.; Milošević, M.V.; Peeters, F.M. Vortex configurations and critical parameters in superconducting thin films containing antidot arrays: Nonlinear Ginzburg-Landau theory. Phys. Rev. B 2006, 74, 174512–174514. [Google Scholar] [CrossRef]

- Villegas, J.E.; Savelev, S.; Nori, F.; González, E.M.; Anguita, J.V.; García, R.; Vicent, J.L. A superconducting reversible rectifier that controls the motion of magnetic flux quanta. Science 2003, 302, 1188–1191. [Google Scholar] [CrossRef] [PubMed]

- Horcas, I.; Fernandez, R.; Gómez-Rodríguez, J.M.; Colchero, J.; Gómez-Herrero, J.; Baro, A.M. WSXM: Software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 2007, 78. [Google Scholar] [CrossRef] [PubMed]

- Houzè, F.; Meyer, R.; Schneegans, O.; Boyer, L. Imaging the local electrical properties of metal surfaces by atomic force microscopy with conducting probes. Appl. Phys. Lett. 1996, 69. [Google Scholar] [CrossRef]

- Navarro-Moratalla, E.; Pinilla-Cienfuegos, E.; Coronado, E. Metodo y Sistema de Exfoliaci6n Micromecanica por via Seca de Materiales Laminares Bidimensionales. Spanish Patent ES20130000252, 7 March 2013. [Google Scholar]

- Jang, J.; Schatz, G.C.; Ratner, M.A. Liquid meniscus condensation in dip-pen nanolithography. J. Chem. Phys. 2002, 116, 3875–3886. [Google Scholar] [CrossRef]

- Calleja, M.; Tello, M.; Garcia, R. Size determination of field-induced water menisci in noncontact atomic force microscopy. J. Appl. Phys. 2002, 92, 5539–5542. [Google Scholar] [CrossRef] [Green Version]

- Lyuksyutov, S.F.; Paramonov, P.B.; Ralich, R.M.; Dolog, I. Peculiarities of an anomalous electronic current during atomic force microscopy assisted nanolithography on n-type silicon. Nanotechnology 2003, 14. [Google Scholar] [CrossRef]

- Park, J.B.; Jaeckel, B.; Parkinson, B.A. Fabrication and investigation of nanostructures on transition metal dichalcogenide surfaces using a scanning tunneling microscope. Langmuir 2006, 22, 5334–5340. [Google Scholar] [CrossRef] [PubMed]

- Tello, M.; García, F.; Garcia, R. Linewidth determination in local oxidation nanolithography of silicon surfaces. J. Appl. Phys. 2002, 92, 4075–4079. [Google Scholar] [CrossRef]

- Garcia, R.; Martinez, R.V. Nano-chemistry and scanning probe nanolithographies. Chem. Soc. Rev. 2006, 35, 29–38. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.N.; Chung, H.J.; Sow, C.H.; Adamiak, K.; Wee, A.T.S. Electrical discharge in a nanometer-sized air/water gap observed by atomic force microscopy. J. Am. Chem. Soc. 2005, 127, 15562–15567. [Google Scholar] [CrossRef] [PubMed]

- Donarelli, M.; Perrozzi, F.; Bisti, F.; Paparella, F.; Feyer, V.; Ponzoni, A.; Gonchigsuren, M.; Ottaviano, L. Few layered MoS2 lithography with an AFM tip: Description of the technique and nanospectroscopy investigations. Nanoscale 2015, 7, 11453–11459. [Google Scholar] [CrossRef] [PubMed]

- Jaeckel, B.; Gassenbauer, Y.; Jaegermann, W.; Tomm, Y. AFM tip induced formation of nanometer scale structures on WSe2 under defined conditions. Surf. Sci. 2005, 597, 65–79. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pinilla-Cienfuegos, E.; Mañas-Valero, S.; Navarro-Moratalla, E.; Tatay, S.; Forment-Aliaga, A.; Coronado, E. Local Oxidation Nanolithography on Metallic Transition Metal Dichalcogenides Surfaces. Appl. Sci. 2016, 6, 250. https://0-doi-org.brum.beds.ac.uk/10.3390/app6090250

Pinilla-Cienfuegos E, Mañas-Valero S, Navarro-Moratalla E, Tatay S, Forment-Aliaga A, Coronado E. Local Oxidation Nanolithography on Metallic Transition Metal Dichalcogenides Surfaces. Applied Sciences. 2016; 6(9):250. https://0-doi-org.brum.beds.ac.uk/10.3390/app6090250

Chicago/Turabian StylePinilla-Cienfuegos, Elena, Samuel Mañas-Valero, Efrén Navarro-Moratalla, Sergio Tatay, Alicia Forment-Aliaga, and Eugenio Coronado. 2016. "Local Oxidation Nanolithography on Metallic Transition Metal Dichalcogenides Surfaces" Applied Sciences 6, no. 9: 250. https://0-doi-org.brum.beds.ac.uk/10.3390/app6090250