Pneumatic Rotary Actuator Position Servo System Based on ADE-PD Control

Abstract

:1. Introduction

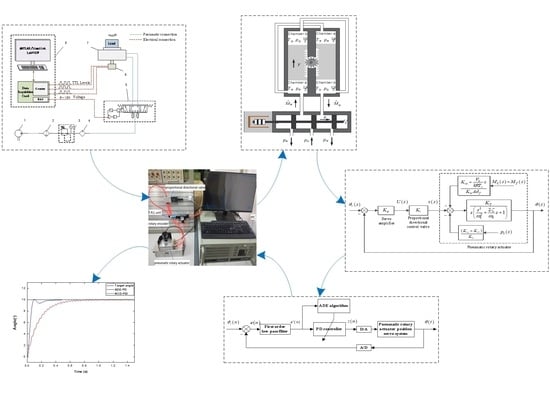

2. Experimental Set-Up

3. Modeling the System

3.1. Mass Flow Throttling Equation

3.2. Mass Flow Continuity Equation

3.3. Mechanical Equation of the Pneumatic Rotary Actuator

3.4. Block Diagram and Transfer Function of the Pneumatic Rotary Actuator

- (1)

- After setting load moment , friction moment , and to zero, we obtain the transfer function from the displacement x of proportional valve spool to the output angle θ of pneumatic rotary actuator, which can be simplified as:where: gainnatural frequencyand damping ratio

- (2)

- After setting displacement x of proportional valve spool and to zero, we obtain the transfer function from to the output angle θ of pneumatic rotary actuator, which can be predigested as:

- (3)

- After setting displacement x of proportional valve spool, load moment and friction moment to zero, we obtain the transfer function from the friction to the output angle θ of pneumatic rotary actuator, which can be simplified as

- (4)

- Total output of the pneumatic rotary actuator system is

3.5. Transfer Function of Proportional Directional Control Valve and Servo Amplifier

3.6. Transfer Function of the System

4. Adaptive Differential Evolution (ADE) Algorithm

4.1. Generating the Initial Population

4.2. Mutation Operation

4.3. Crossover Operation

4.4. Selection Operation

5. ADE-PD Controller Design

6. Experiment and Analysis

6.1. Parameters Selection and Comparison with DE Algorithms

6.2. Comparison with NCD-PID Control

6.3. Discussion on Increasing Inertia Load

7. Conclusions

- (a)

- Different values of and can change the stability of the control. Rotation position controlled by ADE-PD has smaller overshoot and fluctuation than others controlled by DE-PD when = 1.5, = 1.0, = 0.9, = 0.6.

- (b)

- The control precision of the system becomes worse with the increase of the frequency of sinusoidal wave. And there are persistent fluctuations in steady state because of stickiness in the actuator when changing the direction of motion. The system based on ADE-PD control can reduce the occurrence of stickiness, and has greater position precision and faster response than NCD-PID control.

- (c)

- Increasing the moment of inertia will reduce natural frequency and damping ratio, and make the error increase and even deviate from center. Even so, the system has relatively stable trajectories and tiny errors, which shows great robustness.

- (d)

- Although a resonance is expected by the compressibility and the friction could cause a small displacement instability, a reasonable control can be obtained.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| effective area of the piston of actuator [m2] | |

| two D-dimensional initial vectors | |

| viscosity damping coefficient [N·s/m] | |

| critical pressure ratio = 0.21 | |

| flow coefficient of orifice of proportional valve = 0.68 | |

| crossover probability | |

| pitch diameter of the pinion [m] | |

| the number of dimensions of vectors | |

| input and output of the filter at the n-th sampling | |

| function of mass flow passing through the port of proportional valve | |

| target function | |

| scaling factor | |

| the number of evolutionary iterations | |

| the maximum generation | |

| optimal index; cost function value | |

| moment of inertia of pinion [kg·m2] | |

| adiabatic index of ideal gas = 1.4 | |

| differential coefficient | |

| proportional coefficient | |

| gain of servo amplifier [V/rad] | |

| flow-pressure coefficients | |

| sum of flow-pressure coefficient and flow gain | |

| flow gains flowing through a port and b port of proportional valve | |

| gain of pneumatic rotary actuator [rad/m] | |

| gain of proportional directional control valve [m/V] | |

| mass of one piston in the actuator [kg] | |

| mass of gas in chamber a or b [kg] | |

| friction moment [N·m] | |

| load moment [N·m] | |

| mass flow flowing into chamber a or flowing out from chamber b [kg/s] | |

| sampling times | |

| the number of D-dimensional vectors | |

| pressure of chamber a or b [Pa] | |

| pai,bi | pressure of chamber a or b in working position i [Pa] |

| pe | atmospheric pressure [Pa] |

| difference between and [Pa] | |

| supply pressure [Pa] | |

| random number generated in the interval [0,1] | |

| gas constant = 287 [J/(kg·K)] | |

| time [s] | |

| initial temperature [K] | |

| gas temperature in chamber a or b [K] | |

| temperature of chamber a or b in working position i [K] | |

| differential time constant | |

| sampling period [ms] | |

| ambient temperature = 293 [K] | |

| test vector; j-th parameter of i-th test vector | |

| Laplace transform of the output voltage of servo amplifier | |

| vi,g; vj,i,g | mutant vector; j-th parameter of i-th mutant vector |

| value of the volume of gas [m3] | |

| volume of gas in chamber a or b [m3] | |

| volume of gas of chamber a or b in working position i [m3] | |

| weights | |

| geometric cross-sectional area gradient of orifice in proportional valve [m] | |

| displacement of proportional valve spool [m] | |

| the gap between valve spool and inwall of the valve [m] | |

| displacement of proportional valve spool in working position i [m] | |

| the i-th vector of the g-th generation;j-th parameter of i-th vector | |

| displacement of the actuator piston [m] | |

| output of the controller | |

| total points of sampling | |

| filter coefficient | |

| damping ratio | |

| rotation angle of the actuator [rad] | |

| Laplace transform of rotation angle of the actuator when input is , + and | |

| Laplace transform of the system input angle | |

| density of gas in chamber a or b [kg/m3] | |

| time constant | |

| natural frequency [Hz] |

References

- Zhang, Y.; Cai, M. Whole life-cycle costing analysis of pneumatic actuators. J. Beijing Univ. Aeronaut. Astronaut. 2011, 37, 1006–1010. [Google Scholar]

- Yang, F.; Tadano, K.; Li, G.; Kagawa, T. Analysis of the energy efficiency of a pneumatic booster regulator with energy recovery. Appl. Sci. 2017, 7, 816. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Cai, M.L. Overall life cycle comprehensive assessment of pneumatic and electric actuator. Chin. J. Mech. Eng. (Engl. Ed.) 2014, 27, 584–594. [Google Scholar] [CrossRef]

- Zang, X.; Liu, Y.; Li, W.; Lin, Z.; Zhao, J. Design and experimental development of a pneumatic stiffness adjustable foot system for biped robots adaptable to bumps on the ground. Appl. Sci. 2017, 7, 1005. [Google Scholar] [CrossRef]

- Jiang, G.; Luo, M.; Bai, K.; Chen, S. A precise positioning method for a puncture robot based on a PSO-optimized BP neural network algorithm. Appl. Sci. 2017, 7, 969. [Google Scholar] [CrossRef]

- Sheng, Z.; Li, Y. Hybrid robust control law with disturbance observer for high-frequency response electro-hydraulic servo loading system. Appl. Sci. 2016, 6, 98. [Google Scholar] [CrossRef]

- Pujana-Arrese, A.; Mendizabal, A.; Arenas, J.; Prestamero, R.; Landaluze, J. Modelling in modelica and position control of a 1-DoF set-up powered by pneumatic muscles. Mechatronics 2010, 20, 535–552. [Google Scholar] [CrossRef]

- Niu, J.; Shi, Y.; Cao, Z.; Cai, M.; Chen, W.; Zhu, J.; Xu, W. Study on air flow dynamic characteristic of mechanical ventilation of a lung simulator. Sci. China Technol. Sci. 2017, 60, 243–250. [Google Scholar] [CrossRef]

- Ren, S.; Shi, Y.; Cai, M.; Xu, W. Influence of secretion on airflow dynamics of mechanical ventilated respiratory system. IEEE/ACM Trans. Comput. Biol. Bioinform. 2017, 99, 1. [Google Scholar] [CrossRef] [PubMed]

- Ren, S.; Shi, Y.; Cai, M.; Xu, W.; Zhang, X.D. Influence of bronchial diameter change on the airflow dynamics based on a pressure-controlled ventilation system. Int. J. Numer. Method Biomed. Eng. 2017. [Google Scholar] [CrossRef] [PubMed]

- Saravanakumar, D.; Mohan, B.; Muthuramalingam, T. A review on recent research trends in servo pneumatic positioning systems. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2017, 49, 481–492. [Google Scholar] [CrossRef]

- Rad, C.-R.; Hancu, O. An improved nonlinear modelling and identification methodology of a servo-pneumatic actuating system with complex internal design for high-accuracy motion control applications. Simul. Model. Pract. Theory 2017, 75, 29–47. [Google Scholar] [CrossRef]

- Ren, H.; Fan, J. Adaptive backstepping slide mode control of pneumatic position servo system. Chin. J. Mech. Eng. (Engl. Ed.) 2016, 29, 1003–1009. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Y.; Cai, M.; Zhang, B.; Zhu, J. An aviation oxygen supply system based on a mechanical ventilation model. Chin. J. Aeronaut. 2017, 31, 197–204. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, B.; Cai, M.; Xu, W. Coupling effect of double lungs on a VCV ventilator with automatic secretion clearance function. IEEE/ACM Trans. Comput. Biol. Bioinform. 2017, 99, 1. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Wu, T.; Cai, M.; Wang, Y.; Xu, W. Energy conversion characteristics of a hydropneumatic transformer in a sustainable-energy vehicle. Appl. Energy 2016, 171, 77–85. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Y.; Liang, H.; Cai, M. Power characteristics of a new kind of air-powered vehicle. Int. J. Energy Res. 2016, 40, 1112–1121. [Google Scholar] [CrossRef]

- Bai, Y.H. Research on Pneumatic Rotation Position Servo Control Technology. Ph.D. Thesis, Nanjing University of Science and Technology, Nanjing, China, 2006. [Google Scholar]

- Thanh, T.U.D.C.; Ahn, K.K. Nonlinear PID control to improve the control performance of 2 axes pneumatic artificial muscle manipulator using neural network. Mechatronics 2006, 16, 577–587. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, M.; Kong, D. Overall energy efficiency of lubricant-injected rotary screw compressors and aftercoolers. In Proceedings of the IEEE Computer Society 2009 Asia-Pacific Power and Energy Engineering Conference (APPEEC 2009), Wuhan, China, 27–31 March 2009; Chinese Society for Electrical Engineering; IEEE Power and Energy Society; Scientific Research Publishing; Wuhan University: Wuhan, China, 2009. [Google Scholar]

- Lin, T.; Chen, Q.; Ren, H.; Zhao, Y.; Miao, C.; Fu, S.; Chen, Q. Energy regeneration hydraulic system via a relief valve with energy regeneration unit. Appl. Sci. 2017, 7, 613. [Google Scholar] [CrossRef]

- Kagawa, T.; Cai, M.; Kameya, H. Overall efficiency consideration of pneumatic systems including compressor, dryer, pipe and actuator. In Proceedings of the JFPS International Symposium on Fluid Power 2002, Nara, Japan, 12–15 November 2002; pp. 383–388. [Google Scholar]

- Shi, Y.; Zhang, B.; Cai, M.; Zhang, X.D. Numerical simulation of volume-controlled mechanical ventilated respiratory system with 2 different lungs. Int. J. Numer. Method Biomed. Eng. 2016, 33, 2852. [Google Scholar] [CrossRef] [PubMed]

- Gai, Y.; Cai, M.; Shi, Y. Analytical and experimental study on complex compressed air pipe network. Chin. J. Mech. Eng. (Engl. Ed.) 2015, 28, 1023–1029. [Google Scholar] [CrossRef]

- Kaitwanidvilai, S.; Parnichkun, M. Position control of a pneumatic servo system by genetic algorithm based fixed-structure robust h, loop shaping control. In Proceedings of the IECON 2004—30th Annual Conference of IEEE Industrial Electronics Society, Busan, Korea, 2–6 November 2004; IEEE Computer Society: Busan, Korea, 2004; pp. 2246–2251. [Google Scholar]

- Li, J.P. Pneumatic Transmission System Dynamics; South China University of Technology Press: Guangzhou, China, 1991; pp. 32–35. ISBN 7562302677. [Google Scholar]

- Yin, Y.B. High Speed Pneumatic Theory and Technology; Shanghai Science and Technology Press: Shanghai, China, 2014; pp. 165–171. ISBN 978-7-5478-2068-1. [Google Scholar]

- Ning, F.; Shi, Y.; Cai, M.; Wang, Y.; Xu, W. Research progress of related technologies of electric-pneumatic pressure proportional valves. Appl. Sci. 2017, 7, 1074. [Google Scholar] [CrossRef]

- Shi, Y.; Ren, S.; Cai, M.; Xu, W.; Deng, Q. Pressure dynamic characteristics of pressure controlled ventilation system of a lung simulator. Comput. Math. Methods Med. 2014, 761712–761722. [Google Scholar] [CrossRef] [PubMed]

- Shearer, J.L. Study of pneumatic processes in the continuous control of motion with compressed air-I. Trans. ASME 1956, 2, 233–242. [Google Scholar]

- Wu, Z.S. Pneumatic Transmission and Control, 2nd ed.; Harbin Institute of Technology Press: Harbin, China, 2009; pp. 197–199. ISBN 7-5603-0989-5. [Google Scholar]

- Cai, M.; Wang, Y.; Shi, Y.; Liang, H. Output dynamic control of a late model sustainable energy automobile system with nonlinearity. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef]

- Yang, Z.R.; Hua, K.Q.; Xu, Y. Electro-Hydraulic Ratio and Servo Control; Metallurgical Industry Press: Beijing, China, 2015; pp. 108–120. ISBN 978-7-5024-4622-2. [Google Scholar]

- Storn, R.; Price, K. Differential evolution—A simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Y.; Zhou, S.; Tan, W. Design of PID controller with incomplete derivation based on differential evolution algorithm. J. Syst. Eng. Electron. 2008, 19, 578–583. [Google Scholar]

- Zhang, X.; Zhang, X. Shift based adaptive differential evolution for PID controller designs using swarm intelligence algorithm. Clust. Comput. 2017, 20, 291–299. [Google Scholar] [CrossRef]

- Liu, J.K. Advanced Pid Control Matlab Simulation, 4th ed.; Publishing House of Electronics Industry: Beijing, China, 2016; pp. 331–332. ISBN 978-7-121-28846-3. [Google Scholar]

- Cheng, L.; Chen, J.; Chen, M.; Xu, J.; Wang, W.; Wang, T.; Guo, J. Adaptive differential evolution algorithm identification of photoelectric tracking servo system. Hongwai Yu Jiguang Gongcheng Infrared Laser Eng. 2016, 45. [Google Scholar] [CrossRef]

- Andromeda, T.; Yahya, A.; Samion, S.; Baharom, A.; Hashim, N.L. Differential evolution for optimization of PID gain in electrical discharge machining control system. Trans. Can. Soc. Mech. Eng. 2013, 37, 293–301. [Google Scholar]

- Niu, J.; Shi, Y.; Cai, M.; Cao, Z.; Wang, D.; Zhang, Z.; Zhang, X.D. Detection of sputum by interpreting the time-frequency distribution of respiratory sound signal using image processing techniques. Bioinformatics 2018, 34, 820–827. [Google Scholar] [CrossRef] [PubMed]

| Component | Model | Parameters |

|---|---|---|

| Pneumatic rotary actuator | SMC MSQA30A | bore: 30 mm, maximum angle: 190° |

| Proportional directional control valve | FESTO MPYE-5-M5-010-B | control voltage: 0~10 V, rated flow:100 L/min |

| Data acquisition card | NI PCI-6229 | 32 bit counter, output voltage: −10~10 V |

| Rotary encoder | OMRON E6B2-CWZ3E | resolution: 1800 P/R |

| IPC | IPC-610H | standard configuration |

| F.R.L Unit | AirTAC AC2000 | maximum pressure: 1 MPa |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| A | 3.4636 × 10−4 [m2] | m | 0.21 [kg] |

| B | 228 [N·s/m] | pe | 1.013 × 105 [Pa] |

| C | 0.68 | R | 287 [J/(kg·K)] |

| c0 | 0.21 | Ts | 293 [K] |

| df | 0.014 [m] | V0 | 1.6767 × 10−5 [m3] |

| J | 1.678 × 10−4 [kg·m2] | W | 3.1415 × 10−2 [m] |

| k | 1.4 | x0 | 5 × 10−6 [m] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, K.; Wei, S.; Wang, G. Pneumatic Rotary Actuator Position Servo System Based on ADE-PD Control. Appl. Sci. 2018, 8, 406. https://0-doi-org.brum.beds.ac.uk/10.3390/app8030406

Zhang Y, Li K, Wei S, Wang G. Pneumatic Rotary Actuator Position Servo System Based on ADE-PD Control. Applied Sciences. 2018; 8(3):406. https://0-doi-org.brum.beds.ac.uk/10.3390/app8030406

Chicago/Turabian StyleZhang, Yeming, Ke Li, Shaoliang Wei, and Geng Wang. 2018. "Pneumatic Rotary Actuator Position Servo System Based on ADE-PD Control" Applied Sciences 8, no. 3: 406. https://0-doi-org.brum.beds.ac.uk/10.3390/app8030406