Experimental Efficiency Analysis of a Photovoltaic System with Different Module Technologies under Temperate Climate Conditions

Abstract

:Featured Application

Abstract

1. Introduction

- a-Si, HIT, mc-Si—India [26],

- a-Si, HIT, pc-Si—India [27],

- a-Si, c-Si, CdTe—Turkey [5],

- mc-Si—Greece [2],

- mc-Si, pc-Si, a-Si, CIGS, CdTe–Italy [28],

- c-Si, a-Si, HIT—Italy [29],

- mono-Si, CIS—Turkey [30],

- a-Si, c-Si, CIGS—United Kingdom [11],

- a-Si, c-Si, CIGS, CdTe—Germany [31],

- mono-Si, poli-Si, a-Si, CIGS, CIS, CdTe—Netherlands [20].

2. Methodology

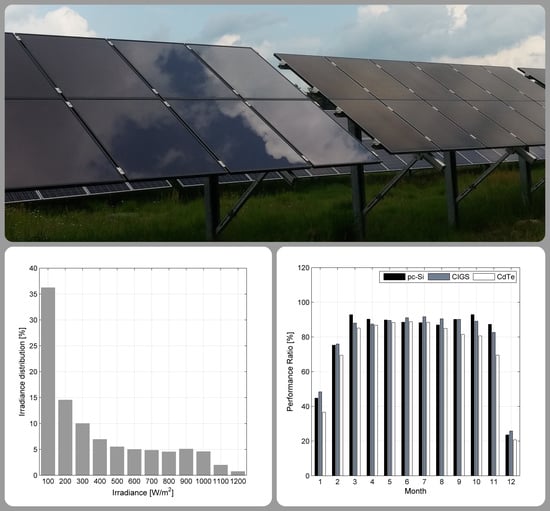

2.1. Experimental Photovoltaic Installation

2.2. Methods of Experimental Data Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Directive (EU) 2015/1513 of the European Parliament and of the Council of 9 September 2015 Amending Directive 2009/28/EC on the Promotion of the Use of Energy from Renewable Sources. Available online: http://data.europa.eu/eli/dir/2015/1513/oj (accessed on 20 December 2018).

- Gaglia, A.G.; Lykoudis, S.; Argiriou, A.A.; Balaras, C.A.; Dialynas, E. Energy efficiency of PV panels under real outdoor conditions—An experimental assessment in Athens, Greece. Renew. Energy 2017, 101, 236–243. [Google Scholar] [CrossRef]

- Dale, M. A comparative Analysis of Energy Costs of Photovoltaic, Solar Thermal, and Wind Electricity Generation Techniques. Appl. Sci. 2013, 3, 325–337. [Google Scholar] [CrossRef]

- Rehman, S.; El-Amin, I. Performance evaluation of an off-grid photovoltaic system in Saudi-Arabia. Energy 2012, 46, 451–458. [Google Scholar] [CrossRef]

- Ozden, T.; Akinoglu, B.G.; Turan, R. Long term outdoor performances of three different on-grid PV arrays in central Anatolia—An extended analysis. Renew. Energy 2017, 101, 182–195. [Google Scholar] [CrossRef]

- Raugei, M.; Frankl, P. Life cycle impacts and costs of photovoltaic systems: Current state of the art and future outlooks. Energy 2009, 34, 392–399. [Google Scholar] [CrossRef]

- Dinçer, F. The analysis on photovoltaic electricity generation status, potential and policies of the leading countries in solar energy. Renew. Sustain. Energy Rev. 2011, 15, 713–720. [Google Scholar] [CrossRef]

- Olchowik, J.M.; Dragan, P.; Gembarzewski, O.; Gulkowski, S.; Szymczuk, D.; Tomaszewski, R. The Reasons of the Delays in Introducing in Poland Law Regulations Favorable for Photovoltaics. In Proceedings of the 28th EUPVSEC, Paris, France, 30 September–4 October 2013; pp. 4676–4679. [Google Scholar]

- Olchowik, J.M.; Cieslak, K.; Gulkowski, S.; Mucha, J.; Sordyl, M.; Zabielski, K.; Szymczuk, D.; Zdyb, A. Progress of development of PV systems in South-Eastern Poland. In Proceedings of the 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010. [Google Scholar]

- Canete, C.; Carretero, J.; Sidrach-de-Cardona, M. Energy performance of different photovoltaic module technologies under outdoor conditions. Energy 2014, 65, 295–302. [Google Scholar] [CrossRef]

- Gottschalg, R.; Betts, T.R.; Eeles, A.; Williams, A.R.; Zhu, J. Influences on the energy delivery of thin film photovoltaic modules. Sol. Energy Mater. Sol. Cells 2013, 119, 169–180. [Google Scholar] [CrossRef] [Green Version]

- Kaldellis, J.K.; Kokala, A. Quantifying the decrease of the photovoltaic panels’ energy yield due to phenomena of natural air pollution disposal. Energy 2010, 35, 4862–4869. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Kapsali, M. Simulating the dust effect on the energy performance of photovoltaic generators based on experimental measurements. Energy 2011, 36, 5154–5161. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Schwingshackl, C.; Petitta, M.; Wagner, J.E.; Belluardo, G.; Moser, D.; Castelli, M.; Zebisch, M.; Tetzlaff, A. Wind effect on PV module temperature: Analysis of different techniques for an accurate estimation. Energy Procedia 2013, 40, 77–86. [Google Scholar] [CrossRef]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T. Seasonal effect of dust on the degradation of PV modules performance deployed in different climate areas. Renew. Energy 2017, 111, 105–115. [Google Scholar] [CrossRef]

- Olchowik, J.M.; Gulkowski, S.; Cieslak, K.; Banas, J.; Jozwik, I.; Szymczuk, D.; Zabielski, K.; Mucha, J.; Zdrojewska, M.; Adamczyk, J.; et al. Influence of temperature on the efficiency of monocrystalline silicon solar cells in the South-eastern Poland conditions. Mater. Sci.-Pol. 2006, 24, 1127–1132. [Google Scholar]

- Huld, T.; Gottschalg, R.; Beyer, H.G.; Topič, M. Mapping the performance of PV modules, effects of module type and data averaging. Sol. Energy 2010, 84, 324–338. [Google Scholar] [CrossRef] [Green Version]

- Makrides, G.; Zinsser, B.; Phinikarides, A.; Schubert, M.; Georghiou, G.E. Temperature and thermal annealing effects on different photovoltaic technologies. Renew. Energy 2012, 43, 407–417. [Google Scholar] [CrossRef]

- Louwen, A.; de Waal, A.C.; Schropp, R.E.I.; Faaij, A.P.C.; van Sark, W.G.J.H.M. Comprehensive characterization and analysis of PV module performance under real operating conditions. Prog. Photovolt. Res. Appl. 2017, 25, 218–232. [Google Scholar] [CrossRef]

- Fuentes, M.; Nofuentes, G.; Aguilera, J.; Talavera, D.L.; Castro, M. Application and validation of algebraic methods to predict the behaviour of crystalline silicon PV modules in Mediterranean climates. Sol. Energy 2007, 81, 1396–1408. [Google Scholar] [CrossRef]

- Sidrach-de-Cardona, M.; López, L.M. Performance analysis of a grid-connected photovoltaic system. Energy 1999, 24, 93–102. [Google Scholar] [CrossRef]

- Muñoz, J.V.; Nofuentes, G.; Fuentes, M.; de la Casa, J.; Aguilera, J. DC energy yield prediction in large monocrystalline and polycrystalline PV plants: Time-domain integration of Osterwald’s model. Energy 2016, 114, 951–960. [Google Scholar] [CrossRef]

- Grzesiak, W.; Mackow, P.; Maj, T.; Polak, A.; Klugman-Radziemska, E.; Zawora, S.; Drabczyk, K.; Gulkowski, S.; Grzesiak, P. Innovative system for Energy collection and management integrated within a photovoltaic module. Sol. Energy 2016, 132, 442–452. [Google Scholar] [CrossRef]

- Zdyb, A.; Krawczak, E. The influence of external conditions on the photovoltaic modules performance. In Environmental Engineering V, 1st ed.; Pawlowska, M., Pawlowski, L., Eds.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2017; pp. 261–266. ISBN 9781138031630. [Google Scholar]

- Bora, B.; Kumar, R.; Sastry, O.S.; Prasad, B.; Mondal, S.; Tripathi, A.K. Energy rating estimation of PV module technologies for different climatic conditions. Sol. Energy 2018, 174, 901–911. [Google Scholar] [CrossRef]

- Sharma, V.; Kumar, A.; Sastry, O.S.; Chandel, S.S. Performance assessment of different solar photovoltaic technologies under similar outdoor conditions. Energy 2013, 58, 511–518. [Google Scholar] [CrossRef]

- Belluardo, G.; Ingenhoven, P.; Sparber, W.; Wagner, J.; Weihs, P.; Moser, D. Novel method for the improvement in the evaluation of outdoor performance loss rate in different PV technologies and comparison with two other methods. Sol. Energy 2015, 117, 139–152. [Google Scholar] [CrossRef]

- Aste, N.; Del Pero, C.; Leonforte, F. PV technologies performance comparison in temperate climates. Sol. Energy 2014, 109, 1–10. [Google Scholar] [CrossRef]

- Kesler, S.; Kivrak, S.; Dincer, F.; Rustemli, S.; Karaaslan, M.; Unal, E.; Erdiven, U. The analysis of PV power potential and system installation in Manavgat, Turkey—A case study in winter season. Renew. Sustain. Energy Rev. 2014, 31, 671–680. [Google Scholar] [CrossRef]

- Dirnberger, D.; Blackburn, G.; Müler, B.; Reise, C. On the impact of solar spectral irradiance on the yield of different PV technologies. Sol. Energy Mater. Sol. Cells 2015, 132, 431–442. [Google Scholar] [CrossRef]

- IEC 61724-1. Photovoltaic System Performance Monitoring—Guidelines for Measurement, Data Exchange, and Analysis (Part 1); Technical Report 1; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2017. [Google Scholar]

- Polo, J.; Alonso-Abella, M.; Ruiz-Arias, J.A.; Balenzategui, J.L. Worldwide analysis of spectral factors for seven photovoltaic technologies. Sol. Energy 2017, 142, 194–203. [Google Scholar] [CrossRef]

- Mattei, M.; Notton, G.; Cristofari, C.; Muselli, M.; Poggi, P. Calculation of the polycrystalline PV module temperature using a simple method of energy balance. Renew. Energy 2016, 31, 553–567. [Google Scholar] [CrossRef]

- Goetzberger, A.; Hebling, C. Photovoltaic materials, past, present, future. Sol. Energy Mater. Sol. Cells 2000, 62, 1–19. [Google Scholar] [CrossRef]

- Tobias, I.; del Canizo, C.; Alonso, J. Crystalline Silicon Solar Cells and Modules. In Handbook of Photovoltaic Science and Engineering, 2nd ed.; Luque, A., Hegedus, S., Eds.; Wiley: Hoboken, NJ, USA, 2003; pp. 255–306. [Google Scholar]

- Khana, N.A.; Rahmanb, K.S.; Aris, K.A.; Ali, A.M.; Misran, H.; Akhtaruzzaman, M.; Tiong, S.K.; Amin, N. Effect of laser annealing on thermally evaporated CdTe thin films for photovoltaic absorber application. Sol. Energy 2018, 173, 1051–1057. [Google Scholar] [CrossRef]

- Olusol, O.I.; Madugu, M.L.; Dharmadas, I.M. Investigating the electronic properties of multi-junction ZnS/CdS/CdTe graded bandgap solar cells. Mater. Chem. Phys. 2017, 191, 145–150. [Google Scholar] [CrossRef] [Green Version]

- Shafarman, W.N.; Stolt, L. Cu(InGa)Se2 solar cells. In Handbook of Photovoltaic Science and Engineering, 2nd ed.; Luque, A., Hegedus, S., Eds.; Wiley: Hoboken, NJ, USA, 2011; pp. 567–616. [Google Scholar]

- Dupré, O.; Vaillon, R.; Green, M.A. Physics of the temperature coefficients of solar cells. Sol. Energy Mater. Sol. Cells 2015, 140, 92–100. [Google Scholar] [CrossRef]

- Lorenzo, E.; Moretón, R.; Luque, I. Dust effects on PV array performance: In-field observations with non-uniform patterns. Prog. Photovolt. Res. Appl. 2014, 22, 666–670. [Google Scholar] [CrossRef]

- Gulkowski, S.; Żytkowska, N.; Dragan, P. Temperature distribution analysis of different technologies of PV modules using infrared thermography. E3S Web Conf. 2018, 49, 00044. [Google Scholar] [CrossRef]

| PV Technology | Pmax [W] | Area [m2] | Temp. Coefficient of Pmax, β [%/°C] | Efficiency ηr [%] |

|---|---|---|---|---|

| Cadmium telluride (CdTe) | 75 | 0.72 | −0.25 | 10.6 |

| Copper indium gallium diselenide (CIGS) | 155 | 1.25 | −0.31 | 12.6 |

| Polycrystalline silicon (pc-Si) | 250 | 1.55 | −0.4 | 15.4 |

| Solar Radiation Sensor | Temperature Sensor |

|---|---|

| Monocrystalline silicon cell (5 × 3.3 cm) Temperature range: −20 °C to +70 °C Radiation range: 0 to max. 1400 W/m2 Tolerance of the irradiance sensor: +/−5% | Range: −40 °C–70 °C |

| Photovoltaic (PV) Technology | Temperature Coefficients Calculated According to Manufacturer Data [%/°C] | Temperature Coefficients Obtained Basing on Experimental Data [%/°C] |

|---|---|---|

| Cadmium telluride (CdTe) | 0.0265 | 0.0152 |

| Copper indium gallium diselenide (CIGS) | 0.0391 | 0.0102 |

| Polycrystalline silicon (pc-Si) | 0.0616 | 0.0728 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gulkowski, S.; Zdyb, A.; Dragan, P. Experimental Efficiency Analysis of a Photovoltaic System with Different Module Technologies under Temperate Climate Conditions. Appl. Sci. 2019, 9, 141. https://0-doi-org.brum.beds.ac.uk/10.3390/app9010141

Gulkowski S, Zdyb A, Dragan P. Experimental Efficiency Analysis of a Photovoltaic System with Different Module Technologies under Temperate Climate Conditions. Applied Sciences. 2019; 9(1):141. https://0-doi-org.brum.beds.ac.uk/10.3390/app9010141

Chicago/Turabian StyleGulkowski, Slawomir, Agata Zdyb, and Piotr Dragan. 2019. "Experimental Efficiency Analysis of a Photovoltaic System with Different Module Technologies under Temperate Climate Conditions" Applied Sciences 9, no. 1: 141. https://0-doi-org.brum.beds.ac.uk/10.3390/app9010141