Effect of Seawater Exposure on Impact Damping Behavior of Viscoelastic Material of Pounding Tuned Mass Damper (PTMD)

Abstract

:1. Introduction

2. Specimen Preparation and Experimental Setup

3. Results and Discussion

3.1. Influence on the Pounding Stiffness

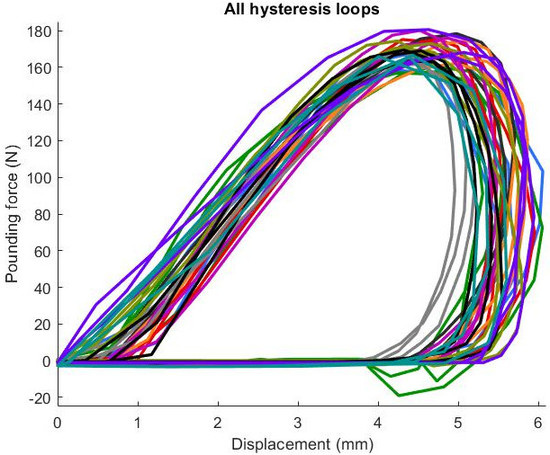

3.2. Influence on the Hysteresis Loops

- Remark 1: As illustrated from these figures, the shapes of the hysteresis loops are very similar, which indicates that the seawater has little influence on the mechanical properties of the viscoelastic material.

- Remark 2: Although all the hysteresis loops in Figure 4 are very similar, minor differences are still observed among these loops. The cause of these minute differences may be the different impact points during the impacts although these locations are very close to each other.

- Remark 3: From the subplots in Figure 4, we also notice that there is a slight decrease in the stiffness measured during the 5th year as compared to previous years. It is possible that the seawater has a “softening” effect on the viscoelastic material over a long period, which should be further studied.

3.3. Influence on the Energy Dissipation

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Song, L.; Fu, S.; Cao, J.; Ma, L.; Wu, J. An investigation into the hydrodynamics of a flexible riser undergoing vortex-induced vibration. J. Fluids Struct. 2016, 63, 325–350. [Google Scholar] [CrossRef]

- Carruth, A.L.; Cerkovnik, M.E. Jumper VIV–new issues for new frontiers, In Proceedings of the Sixteenth International Offshore and Polar Engineering Conference, Lisbon, Portugal, 1–6 July 2007; 2796–2081.

- Lu, Y.; Liang, C.; Manzano-Ruiz, J.J.; Janardhanan, K.; Perng, Y. Flow-induced vibration in subsea jumper subject to downstream slug and ocean current. J. Offshore Mech. Arct. Eng. 2016, 138, 021302–021302-10. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, J.; Xiong, Y.; Wang, M.; Peng, G. Experimental investigation of the effects of the coverage of helical strakes on the vortex-induced vibration response of a flexible riser. Appl. Ocean Res. 2016, 59, 53–64. [Google Scholar] [CrossRef]

- Zeinoddini, M.; Farhangmehr, A.; Seif, M.S.; Zandi, A.P. Cross-flow vortex induced vibrations of inclined helically straked circular cylinders: An experimental study. J. Fluids Struct. 2015, 59, 178–201. [Google Scholar] [CrossRef]

- Cicolin, M.M.; Assi, G.R.S. Experiments with flexible shrouds to reduce the vortex-induced vibration of a cylinder with low mass and damping. Appl. Ocean Res. 2017, 65, 290–301. [Google Scholar] [CrossRef]

- Kumar, N.; Kolahalam, V.K.V.; Kantharaj, M.; Manda, S. Suppression of vortex-induced vibrations using flexible shrouding—An experimental study. J. Fluids Struct. 2018, 81, 479–491. [Google Scholar] [CrossRef]

- Lou, M.; Wu, W.G.; Chen, P. Experimental study on vortex induced vibration of risers with fairing considering wake interference. Int. J. Naval Archit. Ocean Eng. 2017, 9, 127–134. [Google Scholar] [CrossRef] [Green Version]

- Liang, S.; Wang, J.; Hu, Z. VIV and galloping response of a circular cylinder with rigid detached splitter plates. Ocean Eng. 2018, 162, 176–186. [Google Scholar] [CrossRef]

- Wang, C.; Cui, Y.; Ge, S.; Sun, M.; Jia, Z. Experimental Study on Vortex-Induced Vibration of Risers Considering the Effects of Different Design Parameters. Appl. Sci. 2018, 8, 2411. [Google Scholar] [CrossRef]

- Nikoo, H.M.; Bi, K.; Hao, H. Passive vibration control of cylindrical offshore components using pipe-in-pipe (PIP) concept: An analytical study. Ocean Eng. 2017, 142, 39–50. [Google Scholar] [CrossRef]

- Nikoo, H.M.; Bi, K.; Hao, H. Effectiveness of using pipe-in-pipe (PIP) concept to reduce vortex-induced vibrations (VIV): Three-dimensional two-way FSI analysis. Ocean Eng. 2018, 148, 263–276. [Google Scholar] [CrossRef]

- Bi, K.; Hao, H.; Chen, W. Effectiveness of Using RFHDS Connected PIP System for Subsea Pipeline Vibration Control. Int. J. Struct. Stab. Dyn. 2018, 18, 1840005. [Google Scholar] [CrossRef]

- Agrawal, B.N.; Mcclelland, R.S.; Song, G. Attitude control of flexible spacecraft using pulse-width pulse-frequency modulated thrusters. Space Technol.—Kedlington 1997, 17, 15–34. [Google Scholar] [CrossRef]

- Song, G.; Cai, S.; Li, H.N. Energy dissipation and vibration control: modeling, algorithm and devices. Appl. Sci. 2018, 8, 801. [Google Scholar] [CrossRef]

- Tang, J.; Cao, D.; Ren, F.; Li, H. Design and experimental study of a VCM-based whole-spacecraft vibration isolation system. J. Aerosp. Eng. 2018, 31, 04018045. [Google Scholar] [CrossRef]

- Chen, J.; Lu, G.; Li, Y.; Wang, T.; Song, G. Experimental study on robustness of an eddy current-tuned mass damper. Appl. Sci. 2017, 7, 895. [Google Scholar] [CrossRef]

- Ma, G.; Xu, M.; Zhang, S.; Zhang, Y.; Liu, X. Active Vibration Control of an Axially Moving Cantilever Structure Using PZT Actuator. J. Aerosp. Eng. 2018, 31, 04018049. [Google Scholar] [CrossRef]

- Gu, H.; Song, G. Active vibration suppression of a flexible beam with piezoceramic patches using robust model reference control. Smart Mater. Struct. 2007, 16, 1453. [Google Scholar] [CrossRef]

- Xu, X.Z.; Wu, W.X.; Zhang, W.G. Sliding Mode Control for a Nonlinear Aeroelastic System through Backstepping. J. Aerosp. Eng. 2017, 31, 04017080. [Google Scholar] [CrossRef]

- Xu, Z.D.; Xu, F.H.; Chen, X. Intelligent vibration isolation and mitigation of a platform by using MR and VE devices. J. Aerosp. Eng. 2016, 29, 04016010. [Google Scholar] [CrossRef]

- Huo, L.; Song, G.; Nagarajaiah, S.; Li, H. Semi-active vibration suppression of a space truss structure using a fault tolerant controller. J. Vib. Control 2012, 18, 1436–1453. [Google Scholar] [CrossRef]

- Fu, W.; Zhang, C.; Sun, L.; Askari, M.; Samali, B.; Chung, K.L.; Sharafi, P. Experimental investigation of a base isolation system incorporating MR dampers with the high-order single step control algorithm. Appl. Sci. 2017, 7, 344. [Google Scholar] [CrossRef]

- Huang, Z.W.; Hua, X.G.; Chen, Z.Q.; Niu, H.W. Modeling, Testing and Validation of an Eddy Current Damper for Structural Vibration Control. J. Aerosp. Eng. 2018, 31, 04018063. [Google Scholar] [CrossRef]

- Liu, M.; Li, H.; Song, G.; Ou, J. Investigation of vibration mitigation of stay cables incorporated with superelastic shape memory alloy dampers. Smart Mater. Struct. 2007, 16, 2202. [Google Scholar] [CrossRef]

- Huang, B.; Lao, Y.; Chen, J.; Song, Y. Dynamic response analysis of a frame structure with superelastic nitinol SMA helical spring braces for vibration reduction. J. Aerosp. Eng. 2018, 31, 04018096. [Google Scholar] [CrossRef]

- Sun, W.; Wang, Z.; Liu, R.; Yan, X. Inverse identification of the frequency-dependent mechanical parameters of a viscoelastic core layer based on the vibration response. Appl. Sci. 2017, 7, 455. [Google Scholar] [CrossRef]

- Demetriou, D.; Nikitas, N. A novel hybrid semi-active mass damper configuration for structural applications. Appl. Sci. 2016, 6, 397. [Google Scholar] [CrossRef]

- Shi, W.; Wang, L.; Lu, Z.; Zhang, Q. Application of an artificial fish swarm algorithm in an optimum tuned mass damper design for a pedestrian bridge. Appl. Sci. 2018, 8, 175. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, Z.; Masri, S.F.; Lu, X. Particle impact dampers: Past, present and future. Struct. Control Health Monit. 2018, 25, e2058. [Google Scholar] [CrossRef]

- Wang, W.; Dalton, D.; Hua, X.; Wang, X.; Chen, Z.; Song, G. Experimental study on vibration control of a submerged pipeline model by eddy current tuned mass damper. Appl. Sci. 2017, 7, 987. [Google Scholar] [CrossRef]

- Wu, X.; Wang, J.; Zhou, J. Seismic performance analysis of a connected multitower structure with FPS and viscous damper. Shock Vibr. 2018. [Google Scholar] [CrossRef]

- Kim, S.Y.; Lee, C.H. Peak response of frictional tuned mass dampers optimally designed to white noise base acceleration. Mech. Syst. Sig. Process. 2019, 117, 319–332. [Google Scholar] [CrossRef]

- Collette, F.S. A combined tuned absorber and pendulum impact damper under random excitation. J. Sound Vib. 1998, 216, 199–213. [Google Scholar] [CrossRef]

- Lin, W.; Wang, Q.; Li, J.; Chen, S.; Qi, A. Shaking table test of pounding tuned mass damper (PTMD) on a frame structure under earthquake excitation. Comput. Concr. 2017, 20, 545–553. [Google Scholar]

- Lin, W.; Lin, Y.; Song, G.; Li, J. Multiple Pounding Tuned Mass Damper (MPTMD) control on benchmark tower subjected to earthquake excitations. Earthquake Struct. 2016, 11, 1123–1141. [Google Scholar] [CrossRef]

- Xue, Q.; Zhang, J.; He, J.; Zhang, C.; Zou, G. Seismic control performance for Pounding Tuned Massed Damper based on viscoelastic pounding force analytical method. J. Sound Vib. 2017, 411, 362–377. [Google Scholar] [CrossRef]

- Xue, Q.; Zhang, J.; He, J.; Li, Y.; Song, X. Reducing vibration performance of pounding TMD on high-rise steel structures subject to seismic effects. J. Haribin Eng. Univ. 2017, 38, 412–418. [Google Scholar]

- Wang, W.; Hua, X.; Wang, X.; Chen, Z.; Song, G. Numerical modeling and experimental study on a novel pounding tuned mass damper. J. Vib. Control 2018, 24, 4023–4036. [Google Scholar] [CrossRef]

- Wang, W.; Hua, X.; Wang, X.; Chen, Z.; Song, G. Optimum design of a novel pounding tuned mass damper under harmonic excitation. Smart Mater. Struct. 2017, 26, 055024. [Google Scholar] [CrossRef]

- Wang, W.; Wang, X.; Hua, X.; Song, G.; Chen, Z. Vibration control of vortex-induced vibrations of a bridge deck by a single-side pounding tuned mass damper. Eng. Struct. 2018, 173, 61–75. [Google Scholar] [CrossRef]

- Yin, X.; Liu, Y.; Song, G.; Mo, Y.L. Suppression of bridge vibration induced by moving vehicles using pounding tuned mass dampers. J. Bridge Eng. 2018, 23, 04018047. [Google Scholar] [CrossRef]

- Zhang, P.; Song, G.; Li, H.; Lin, Y. Seismic Control of Power Transmission Tower Using Pounding TMD. J. Eng. Mech. 2013, 139, 1395–1406. [Google Scholar] [CrossRef]

- Tian, L.; Gai, X. Wind-induced vibration control of power transmission tower using pounding tuned mass damper. J. Vibroeng. 2015, 17, 3693–3701. [Google Scholar]

- Xue, Q.; Zhang, J.; He, J.; Zhang, C. Control performance and robustness of pounding tuned mass damper for vibration reduction in SDOF structure. Shock Vibr. 2016. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Xue, Q.; He, J.; An, N. PTMD’s vibration reduction effect on the JZ20-2MUQ offshore jacket platform. J Vibr. Shock 2017, 36, 238–244. [Google Scholar]

- Li, L.; Song, G.; Singla, M.; Mo, Y.L. Vibration control of a traffic signal pole using a pounding tuned mass damper with viscoelastic materials (II): Experimental verification. J. Vib. Control 2015, 21, 670–675. [Google Scholar] [CrossRef]

- Zhao, N.; Lu, C.; Chen, M.; Luo, N.; Liu, C. Parametric Study of Pounding Tuned Mass Damper Based on Experiment of Vibration Control of a Traffic Signal Structure. J. Aerosp. Eng. 2018, 31, 04018108. [Google Scholar] [CrossRef]

- Song, G.; Zhang, P.; Li, L.; Singla, M.; Patil, D.; Li, H.; Mo, Y. Vibration control of a pipeline structure using pounding tuned mass damper. J. Eng. Mech. 2016, 142, 04016031. [Google Scholar] [CrossRef]

- Li, H.; Zhang, P.; Song, G.; Patil, D.; Mo, Y. Robustness study of the pounding tuned mass damper for vibration control of subsea jumpers. Smart Mater. Struct. 2015, 24, 095001. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, P.; Patil, D.; Li, H.; Song, G. Experimental studies on the effectiveness and robustness of a pounding tuned mass damper for vibration suppression of a submerged cylindrical pipe. Struct. Control Health Monit. 2017, 24, e2027. [Google Scholar] [CrossRef]

- Bordalo, S.N.; Morooka, C.K.; Tochetto, L.G.; Pavanello, R.; Song, G.; Bartos, J.C. Experimental assessment of the behaviour of a pipe vibration damper underwater. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering; Materials Technology; Petroleum Technology, San Francisco, CA, USA, 8–13 June 2014; Volume 5, p. V005T11A010. [Google Scholar]

- Zhang, P.; Li, L.; Patil, D.; Singla, M.; Li, H.; Mo, Y.L.; Song, G. Parametric study of pounding tuned mass damper for subsea jumpers. Smart Mater. Struct. 2015, 25, 015028.25. [Google Scholar] [CrossRef]

- Li, K.; Darby, A.P. An experimental investigation into the use of a buffered impact damper. J. Sound Vib. 2006, 291, 844–860. [Google Scholar] [CrossRef]

- Li, K.; Darby, A.P. Modelling a buffered impact damper system using a spring-damper model of impact. Struct. Control Health Monit. 2009, 16, 287–302. [Google Scholar] [CrossRef] [Green Version]

- Nayeri, R.D.; Masri, S.F.; Caffrey, J.P. Studies of the performance of multi-unit impact dampers under stochastic excitation. J. Vib. Acoust. 2007, 129, 239–251. [Google Scholar] [CrossRef]

- Masri, S.F. Electric-analog studies of impact dampers. Exp. Mech. 1967, 7, 49–55. [Google Scholar] [CrossRef]

- Yokomichi, I.; Araki, Y.; Jinnouchi, Y.; Inoue, J. Impact damper with granular materials for multibody system. J. Pressure Vessel Technol. 1996, 118, 95–103. [Google Scholar] [CrossRef]

- Papalou, A.; Masri, S.F. Performance of particle dampers under random excitation. J. Vib. Acoust. 1996, 118, 614–621. [Google Scholar] [CrossRef]

- Saeki, M. Analytical study of multi-particle damping. J. Sound Vib. 2005, 281, 1133–1144. [Google Scholar] [CrossRef]

- Papalou, A.; Strepelias, E.; Roubien, D.; Bousias, S.; Triantafillou, T. Seismic protection of monuments using particle dampers in multi-drum columns. Soil Dyn. Earthquake Eng. 2015, 77, 360–368. [Google Scholar] [CrossRef]

- Papalou, A. The Effect of Particle Damper’s Position on the Dynamic Response of Classical Columns. Periodica Polytechnica Civil Eng. 2018, 62, 56–63. [Google Scholar] [CrossRef]

- Lu, Z.; Lu, X.; Jiang, H.; Masri, S.F. Discrete element method simulation and experimental validation of particle damper system. Eng. Comput. 2014, 31, 810–823. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, D.; Li, P. Comparison study of vibration control effects between suspended tuned mass damper and particle damper. Shock Vibr. 2014, 2014, 1–7. [Google Scholar] [CrossRef]

- Lu, Z.; Lu, X.; Lu, W.; Masri, S.F. Experimental studies of the effects of buffered particle dampers attached to a multi-degree-of-freedom system under dynamic loads. J. Sound Vib. 2012, 331, 2007–2022. [Google Scholar] [CrossRef]

- Tucker, W.C. Degradation of graphite/polymer composites in seawater. J. Energy Res. Technol. 1991, 113, 264–267. [Google Scholar] [CrossRef]

- D’Amico, F.; Carbone, G.; Foglia, M.M.; Galietti, U. Moving cracks in viscoelastic materials: Temperature and energy-release-rate measurements. Eng. Fract. Mech. 2013, 98, 315–325. [Google Scholar] [CrossRef]

- Putignano, C.; Carbone, G.; Dini, D. Mechanics of rough contacts in elastic and viscoelastic thin layers. Int. J. Solids Struct. 2015, 69, 507–517. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P.; Huo, L.; Song, G. Impact fatigue of viscoelastic materials subjected to pounding. Appl. Sci. 2018, 8, 117. [Google Scholar] [CrossRef]

- Weitsman, Y.J.; Elahi, M. Effects of fluids on the deformation, strength and durability of polymeric composites–an overview. Mech. Time-Depend. Mater. 2000, 4, 107–126. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Z.; Keey, S.L.; Boay, C.G. Long-term viscoelastic response of e-glass/bismaleimide composite in seawater environment. Appl. Compos. Mater. 2015, 22, 693–709. [Google Scholar]

- Peng, J.; Hu, S.; Zhang, J.; Cai, C.S.; Li, L.Y. Influence of cracks on chloride diffusivity in concrete: A five-phase mesoscale model approach. Constr. Build. Mater. 2019, 197, 587–596. [Google Scholar] [CrossRef]

- Likhanova, N.V.; Nava, N.; Olivares-Xometl, O.; Domínguez-Aguilar, M.A.; Arellanes-Lozada, P.; Lijanova, I.V.; Arriola-Morales, J.; Lartundo-Rojas, L. Corrosion Evaluation of Pipeline Steel API 5L X52 in partially deaerated Produced Water with High Chloride Content. Int. J. Electrochem. Sci. 2018, 13, 7949–7967. [Google Scholar] [CrossRef]

- Huo, Z.; Mohamed, M.; Nicholas, J.R.; Anandan, S.; Chandrashekhara, K. Effect of salt water exposure on foam-cored polyurethane sandwich composites. J. Sandwich Struct. Mater. 2018. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Wei, J.; Shyha, I.; Inam, F. Biodegradation of halloysite nanotubes-polyester nanocomposites exposed to short term seawater immersion. Polymers 2017, 9, 314. [Google Scholar] [CrossRef]

- Yin, L.; Zhao, R. Moisture absorption and mechanical degradation studies of PMI foam cored fiber/epoxy resin sandwich composites. Int. J. Eng. Res. Appl. 2015, 5, 78–85. [Google Scholar]

| Thickness | Main Ingredient | Normal Tensile | Dynamic Overlap Shear | 90° Peel Adhesion |

|---|---|---|---|---|

| 1.6 mm | Acrylic foam | 620 kPa | 550 kPa | 30 N/cm |

| Initial | 1 m | 2 m | 3 m | 4 m | 5 m | 6 m | 7 m | 8 m | 9 m | 5 Year |

|---|---|---|---|---|---|---|---|---|---|---|

| 48,258 | 52,854 | 45,657 | 52,776 | 45,619 | 47,462 | 53,313 | 53,943 | 47,848 | 50,754 | 50,793 |

| 51,335 | 53,221 | 46,887 | 52,493 | 50,100 | 53,910 | 46,269 | 49,303 | 46,506 | 53,625 | 51,562 |

| 53,417 | 46,997 | 50,629 | 47,807 | 51,063 | 51,356 | 51,846 | 49,369 | 46,316 | 47,525 | 48,739 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Patil, D.; Ho, S.C.M. Effect of Seawater Exposure on Impact Damping Behavior of Viscoelastic Material of Pounding Tuned Mass Damper (PTMD). Appl. Sci. 2019, 9, 632. https://0-doi-org.brum.beds.ac.uk/10.3390/app9040632

Zhang P, Patil D, Ho SCM. Effect of Seawater Exposure on Impact Damping Behavior of Viscoelastic Material of Pounding Tuned Mass Damper (PTMD). Applied Sciences. 2019; 9(4):632. https://0-doi-org.brum.beds.ac.uk/10.3390/app9040632

Chicago/Turabian StyleZhang, Peng, Devendra Patil, and Siu Chun M. Ho. 2019. "Effect of Seawater Exposure on Impact Damping Behavior of Viscoelastic Material of Pounding Tuned Mass Damper (PTMD)" Applied Sciences 9, no. 4: 632. https://0-doi-org.brum.beds.ac.uk/10.3390/app9040632