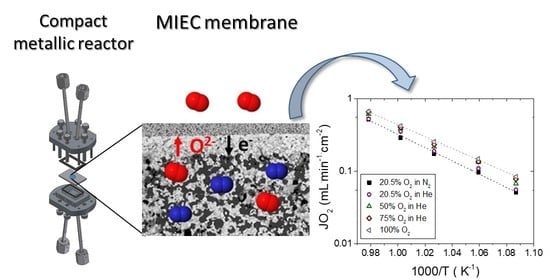

Development and Proof of Concept of a Compact Metallic Reactor for MIEC Ceramic Membranes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Membrane Reactor

2.2. Membrane Manufacture

2.3. Membrane Sealing

2.4. Oxygen Permeation Measurements

3. Results

3.1. Oxygen Permeation Results

3.2. Membrane and Sealing Characterization after Permeation Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lobera, M.P.; Escolástico, S.; Serra, J.M. High ethylene production through oxidative dehydrogenation of ethane membrane reactors based on fast oxygen-ion conductors. ChemCatChem 2011, 3, 1503–1508. [Google Scholar] [CrossRef]

- Liu, H.; Wei, Y.; Caro, J.; Wang, H. Oxidative Coupling of Methane with High C2 Yield by using Chlorinated Perovskite Ba0.5Sr0.5Fe0.2Co0.8O3−δ as Catalyst and N2O as Oxidant. ChemCatChem 2010, 2, 1539–1542. [Google Scholar] [CrossRef]

- Lobera, M.P.; Escolástico, S.; Garcia-Fayos, J.; Serra, J.M. Ethylene production by ODHE in catalytically modified Ba 0.5Sr0.5Co0.8Fe0.2O3-γ membrane reactors. ChemSusChem 2012, 5, 1587–1596. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lobera, M.P.; Valero, S.; Serra, J.M.; Escolástico, S.; Argente, E.; Botti, V. Optimization of ODHE membrane reactor based on mixed ionic electronic conductor using soft computing techniques. Chem. Eng. Sci. 2011, 66, 6308–6317. [Google Scholar] [CrossRef]

- Czuprat, O.; Schiestel, T.; Voss, H.; Caro, J. Oxidative Coupling of Methane in a BCFZ Perovskite Hollow Fiber Membrane Reactor. Ind. Eng. Chem. Res. 2010, 49, 10230–10236. [Google Scholar] [CrossRef]

- Luo, H.; Wei, Y.; Jiang, H.; Yuan, W.; Lv, Y.; Caro, J.; Wang, H. Performance of a ceramic membrane reactor with high oxygen flux Ta-containing perovskite for the partial oxidation of methane to syngas. J. Memb. Sci. 2010, 350, 154–160. [Google Scholar] [CrossRef]

- Wei, Y.; Liao, Q.; Li, Z.; Wang, H.; Feldhoff, A.; Caro, J. Partial oxidation of methane in hollow-fiber membrane reactors based on alkaline-earth metal-free CO2-tolerant oxide. AIChE J. 2014, 60, 3587–3595. [Google Scholar] [CrossRef]

- Kniep, J.; Lin, Y.S. Partial Oxidation of Methane and Oxygen Permeation in SrCoFeOx Membrane Reactor with Different Catalysts. Ind. Eng. Chem. Res. 2011, 50, 7941–7948. [Google Scholar] [CrossRef]

- Arratibel Plazaola, A.; Cruellas Labella, A.; Liu, Y.; Badiola Porras, N.; Pacheco Tanaka, D.A.; Van Sint Annaland, M.; Gallucci, F. Mixed Ionic-Electronic Conducting Membranes (MIEC) for Their Application in Membrane Reactors: A Review. Processes 2019, 7, 128. [Google Scholar] [CrossRef] [Green Version]

- Sunarso, J.; Baumann, S.; Serra, J.M.; Meulenberg, W.A.; Liu, S.; Lin, Y.S.; Diniz da Costa, J.C. Mixed ionic–electronic conducting (MIEC) ceramic-based membranes for oxygen separation. J. Memb. Sci. 2008, 320, 13–41. [Google Scholar] [CrossRef]

- Balaguer, M.; Solís, C.; Serra, J.M. Structural–Transport Properties Relationships on Ce1–xLnxO2−δ System (Ln = Gd, La, Tb, Pr, Eu, Er, Yb, Nd) and Effect of Cobalt Addition. J. Phys. Chem. C 2012, 116, 7975–7982. [Google Scholar] [CrossRef]

- Balaguer, M.; Escolástico, S.; Serra, J.M. Oxygen permeation and stability of CaTi0.73Fe0.18Mg0.09O3−δ oxygen-transport membrane. J. Memb. Sci. 2017, 524, 56–63. [Google Scholar] [CrossRef]

- Cheng, H.; Yao, W.; Lu, X.; Zhou, Z.; Li, C.; Liu, J. Structural stability and oxygen permeability of BaCo0.7Fe0.2M0.1O3−δ (M=Ta, Nb, Zr) ceramic membranes for producing hydrogen from coke oven gas. Fuel Process. Technol. 2015, 131, 36–44. [Google Scholar] [CrossRef]

- Yao, W.; Cheng, H.; Zhao, H.; Lu, X.; Zou, X.; Li, S.; Li, C. Synthesis, oxygen permeability, and structural stability of BaCo0.7Fe0.3−xZrxO3−δ ceramic membranes. J. Memb. Sci. 2016, 504, 251–262. [Google Scholar] [CrossRef]

- Serra, J.M.; Garcia-Fayos, J.; Baumann, S.; Schulze-Küppers, F.; Meulenberg, W.A. Oxygen permeation through tape-cast asymmetric all-La0.6Sr0.4Co0.2Fe0.8O3−δ membranes. J. Memb. Sci. 2013, 447, 297–305. [Google Scholar] [CrossRef]

- Baumann, S.; Serra, J.M.; Lobera, M.P.; Escolástico, S.; Schulze-Küppers, F.; Meulenberg, W.A. Ultrahigh oxygen permeation flux through supported Ba0.5Sr0.5Co0.8Fe0.2O3–δ membranes. J. Memb. Sci. 2011, 377, 198–205. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Fayos, J.; Serra, J.M.; Luiten-Olieman, M.W.J.; Meulenberg, W.A. 8-Gas separation ceramic membranes. In Elsevier Series on Advanced Ceramic Materials; Guillon, O., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 321–385. ISBN 978-0-08-102726-4. [Google Scholar]

- Gaudillere, C.; Garcia-Fayos, J.; Balaguer, M.; Serra, J.M. Enhanced Oxygen Separation through Robust Freeze-Cast Bilayered Dual-Phase Membranes. ChemSusChem 2014, 7, 2554–2561. [Google Scholar] [CrossRef]

- Gaudillere, C.; Garcia-Fayos, J.; Serra, J.M. Enhancing oxygen permeation through hierarchically-structured perovskite membranes elaborated by freeze-casting. J. Mater. Chem. A 2014, 2, 3828–3833. [Google Scholar] [CrossRef]

- Schulze-Küppers, F.; Unije, U.V.; Blank, H.; Balaguer, M.; Baumann, S.; Mücke, R.; Meulenberg, W.A. Comparison of freeze-dried and tape-cast support microstructure on high-flux oxygen transport membrane performance. J. Memb. Sci. 2018, 564, 218–226. [Google Scholar] [CrossRef]

- Teraoka, Y.; Honbe, Y.; Ishii, J.; Furukawa, H.; Moriguchi, I. Catalytic effects in oxygen permeation through mixed-conductive LSCF perovskite membranes. Solid State Ionics 2002, 152–153, 681–687. [Google Scholar] [CrossRef]

- Boeltken, T.; Belimov, M.; Pfeifer, P.; Peters, T.A.; Bredesen, R.; Dittmeyer, R. Fabrication and testing of a planar microstructured concept module with integrated palladium membranes. Chem. Eng. Process. Process. Intensif. 2013, 67, 136–147. [Google Scholar] [CrossRef]

- Boeltken, T.; Wunsch, A.; Gietzelt, T.; Pfeifer, P.; Dittmeyer, R. Ultra-compact microstructured methane steam reformer with integrated Palladium membrane for on-site production of pure hydrogen: Experimental demonstration. Int. J. Hydrog. Energy 2014, 39, 18058–18068. [Google Scholar] [CrossRef]

- Wunsch, A.; Kant, P.; Mohr, M.; Haas-Santo, K.; Pfeifer, P.; Dittmeyer, R. Recent Developments in Compact Membrane Reactors with Hydrogen Separation. Membranes 2018, 8, 107. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pfaff, E.M.; Kaletsch, A.; Broeckmann, C. Design of a Mixed Ionic/Electronic Conducting Oxygen Transport Membrane Pilot Module. Chem. Eng. Technol. 2012, 35, 455–463. [Google Scholar] [CrossRef]

- Raju, K.; Kim, S.; Song, K.; Yu, J.H.; Yoon, D.-H. Joining of metal-ceramic using reactive air brazing for oxygen transport membrane applications. Mater. Des. 2016, 109, 233–241. [Google Scholar] [CrossRef]

- Kiebach, R.; Engelbrecht, K.; Kwok, K.; Molin, S.; Søgaard, M.; Niehoff, P.; Schulze-Küppers, F.; Kriegel, R.; Kluge, J.; Hendriksen, P.V. Joining of ceramic Ba0.5Sr0.5Co0.8Fe0.2O3 membranes for oxygen production to high temperature alloys. J. Memb. Sci. 2016, 506, 11–21. [Google Scholar] [CrossRef]

- Gallucci, F.; Basile, A. Co-current and counter-current modes for methanol steam reforming membrane reactor. Int. J. Hydrog. Energy 2006, 31, 2243–2249. [Google Scholar] [CrossRef]

- Piemonte, V.; De Falco, M.; Favetta, B.; Basile, A. Counter-current membrane reactor for WGS process: Membrane design. Int. J. Hydrog. Energy 2010, 35, 12609–12617. [Google Scholar] [CrossRef]

- Xing, Y.; Baumann, S.; Sebold, D.; Rüttinger, M.; Venskutonis, A.; Meulenberg, W.A.; Stöver, D. Chemical Compatibility Investigation of Thin-Film Oxygen Transport Membranes on Metallic Substrates. J. Am. Ceram. Soc. 2011, 94, 861–866. [Google Scholar] [CrossRef]

- VDM® Alloy 625. Available online: https://www.vdm-metals.com/fileadmin/user_upload/Downloads/Data_Sheets/Data_Sheet_VDM_Alloy_625.pdf (accessed on 1 June 2021).

- Schulze-Küppers, F.; Niehoff, P.; Guillon, O.; Baumann, S.; Meulenberg, W.A.; Kiebach, R.; Sogaard, M.; Hendriksen, P.V.; Kiesel, L.; Ritter, K.; et al. Joining and sealing technologies for asymmetric Ba0.5Sr0.5(Co0.2Fe0.8)0.97Zr0.03 O3–δ (BSCF-Zr) membranes for Oxy Combustion processes. In Proceedings of the Euromembrane 2015, Aachen, Germany, 6–10 September 2015. [Google Scholar]

- Gryaznov, D.; Baumann, S.; Kotomin, E.A.; Merkle, R. Comparison of Permeation Measurements and Hybrid Density-Functional Calculations on Oxygen Vacancy Transport in Complex Perovskite Oxides. J. Phys. Chem. C 2014, 118, 29542–29553. [Google Scholar] [CrossRef]

- García-Fayos, J.; Ruhl, R.; Navarrete, L.; Bouwmeester, H.J.M.; Serra, J.M. Enhancing oxygen permeation through Fe2NiO4-Ce0.8Tb0.2O2-δ composite membranes using porous layers activated with Pr6O11 nanoparticles. J. Mater. Chem. A 2018, 6, 1201–1209. [Google Scholar] [CrossRef]

- Pirou, S.; García-Fayos, J.; Balaguer, M.; Kiebach, R.; Serra, J.M. Improving the performance of oxygen transport membranes in simulated oxy-fuel power plant conditions by catalytic surface enhancement. J. Memb. Sci. 2019, 580, 307–315. [Google Scholar] [CrossRef]

- Othman, N.H.; Wu, Z.; Li, K. An oxygen permeable membrane microreactor with an in-situ deposited Bi1.5Y0.3Sm0.2O3−δ catalyst for oxidative coupling of methane. J. Memb. Sci. 2015, 488, 182–193. [Google Scholar] [CrossRef]

- Garcia-Fayos, J.; Lobera, M.P.; Balaguer, M.; Serra, J.M. Catalyst Screening for Oxidative Coupling of Methane Integrated in Membrane Reactors. Front. Mater. 2018, 5, 31. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, H.; Werth, S.; Schiestel, T.; Caro, J. Simultaneous Production of Hydrogen and Synthesis Gas by Combining Water Splitting with Partial Oxidation of Methane in a Hollow-Fiber Membrane Reactor. Angew. Chem. Int. Ed. 2008, 47, 9341–9344. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Escolástico, S.; Schulze-Küppers, F.; Baumann, S.; Haas-Santo, K.; Dittmeyer, R. Development and Proof of Concept of a Compact Metallic Reactor for MIEC Ceramic Membranes. Membranes 2021, 11, 541. https://0-doi-org.brum.beds.ac.uk/10.3390/membranes11070541

Escolástico S, Schulze-Küppers F, Baumann S, Haas-Santo K, Dittmeyer R. Development and Proof of Concept of a Compact Metallic Reactor for MIEC Ceramic Membranes. Membranes. 2021; 11(7):541. https://0-doi-org.brum.beds.ac.uk/10.3390/membranes11070541

Chicago/Turabian StyleEscolástico, Sonia, Falk Schulze-Küppers, Stefan Baumann, Katja Haas-Santo, and Roland Dittmeyer. 2021. "Development and Proof of Concept of a Compact Metallic Reactor for MIEC Ceramic Membranes" Membranes 11, no. 7: 541. https://0-doi-org.brum.beds.ac.uk/10.3390/membranes11070541