Reusable TiN Substrate for Surface Plasmon Resonance Heterodyne Phase Interrogation Sensor

Abstract

:1. Introduction

2. Experimental Setup

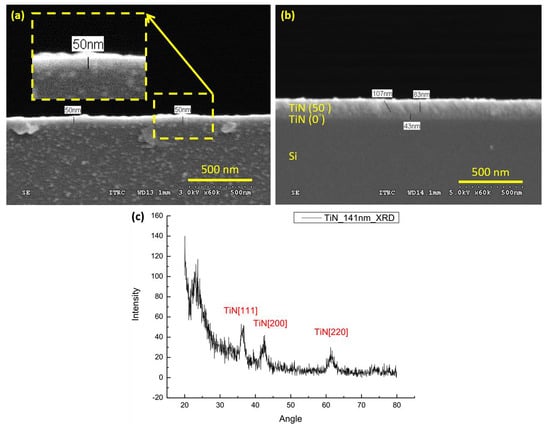

2.1. Sample Preparation

2.2. Experimental Setup

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, B.H.; Chang, I.S.; Gil, G.C.; Park, H.S.; Kim, H.J. Novel BOD (biological oxygen demand) sensor using mediator-less microbial fuel cell. Biotechnol. Lett. 2003, 25, 541–545. [Google Scholar] [CrossRef] [PubMed]

- Preininger, C.; Klimant, I.; Wolfbeis, O.S. Optical fiber sensor for biological oxygen demand. Anal. Chem. 1994, 66, 1841–1846. [Google Scholar] [CrossRef]

- Grönroos, A.; Kyllönen, H.; Korpijärvi, K.; Pirkonen, P.; Paavola, T.; Jokela, J.; Rintala, J. Ultrasound assisted method to increase soluble chemical oxygen demand (SCOD) of sewage sludge for digestion. Ultrason. Sonochem. 2005, 12, 115–120. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Zhou, B.; Bai, J.; Li, L.; Jin, Z.; Zhang, J.; Li, J.; Liu, Y.; Cai, W.; Zhu, X. Self-organized TiO2 nanotube array sensor for the determination of chemical oxygen demand. Adv. Mater. 2008, 20, 1044–1049. [Google Scholar] [CrossRef]

- Sun, K.; Xia, N.; Zhao, L.; Liu, K.; Hou, W.; Liu, L. Aptasensors for the selective detection of alpha-synuclein oligomer by colorimetry, surface plasmon resonance and electrochemical impedance spectroscopy. Sens. Actuators B Chem. 2017, 245, 87–94. [Google Scholar] [CrossRef]

- Fischer, M.; Scholz-Böttcher, B.M. Microplastics analysis in environmental samples-recent pyrolysis-gas chromatography-mass spectrometry method improvements to increase the reliability of mass-related data. Anal. Methods 2019, 11, 2489–2497. [Google Scholar] [CrossRef]

- Nie, S.; Emory, S.R. Probing single molecules and single nanoparticles by surface-enhanced Raman scattering. Science 1997, 275, 1102–1106. [Google Scholar] [CrossRef]

- Kneipp, K.; Lemma, T.; Antunes, P.A.; Aroca, R. Single molecule detection using surface-enhanced Raman scattering (SERS). Phys. Rev. Lett. 1997, 78, 1667–1670. [Google Scholar] [CrossRef] [Green Version]

- Tseng, M.; Chang, C.M.; Cheng, B.H.; Wu, P.H.; Chung, K.S.; Hsiao, M.-K.; Huang, H.W.; Huang, D.-W.; Chiang, H.-P.; Leung, P.T.; et al. Multi-level surface enhanced Raman scattering using AgOx thin film. Opt. Express 2013, 21, 24460–24467. [Google Scholar] [CrossRef] [Green Version]

- Lin, W.-C.; Jen, H.-C.; Chen, C.-L.; Hwang, D.-F.; Chang, R.; Hwang, J.-S.; Chiang, H.-P. SERS study of tetrodotoxin (TTX) by using silver nanoparticle arrays. Plasmonics 2016, 4, 187–192. [Google Scholar] [CrossRef]

- Rodgers, P.J.; Amemiya, S. Cyclic voltammetry at micropipetelectrodes for the study of ion-transfer kinetics at liquid/liquid interfaces. Anal. Chem. 2007, 79, 9276–9285. [Google Scholar] [CrossRef] [PubMed]

- Yuhu, S.H.; Wang, Y.; Wang, X.; Xu, L.; Xiang, J.; Sun, W. Electrochemical detection of hydroquinone with a gold nanoparticle and graphene modified carbon ionic liquid electrode. Sens. Actuators B Chem. 2012, 168, 27–33. [Google Scholar]

- Roberts, J.G.; Sombers, L.A. Fast scan cyclic voltammetry: Chemical sensing in the brain and beyond. Anal. Chem. 2018, 90, 490–504. [Google Scholar] [CrossRef] [PubMed]

- Saiki, R.; Scharf, S.; Faloona, F.; Mullis, K.; Horn, G.; Erlich, H.; Arnheim, N. Enzymatic amplification of beta-globin genomic sequences and restriction site analysis for diagnosis of sickle cell anemia. Science 1985, 230, 1350–1354. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Jiang, H.R. A review on continuous-flow microfluidic PCR in droplets: Advances, challenges and future. Anal. Chim. Acta 2016, 914, 7–16. [Google Scholar] [CrossRef] [Green Version]

- Cavanaugh, S.E.; Bathrick, A.S. Direct PCR amplification of forensic touch and other challenging DNA samples: A review. Forensic Sci. Int. Genet. 2018, 32, 40–49. [Google Scholar] [CrossRef]

- Gerislioglu, B.; Dong, L.; Ahmadivand, A.; Hu, H.; Nordlander, P.; Halas, N.J. Monolithic metal dimer-on-film structure: New plasmonic properties introduced by the underlying metal. Nano Lett. 2020, 20, 2087–2093. [Google Scholar] [CrossRef]

- Gerislioglu, B.; Ahuja, R.; Mishra, Y.K. Terahertz plasmonics: The rise of toroidal metadevices towards immune biosensing. Mater. Today 2020, 32, 108–130. [Google Scholar]

- Ahmadivand, A.; Gerislioglu, B.; Ramezani, Z.; Ghoreishi, S.A. Attomolar detection of low-molecular weight antibiotics using midinfrared-resonant toroidal plasmonic metachip technology. Phys. Rev. Appl. 2019, 12, 034018. [Google Scholar] [CrossRef]

- Chung, H.; Chen, C.-C.; Wu, P.C.; Tseng, M.L.; Lin, W.-C.; Chen, C.-W.; Chiang, H.-P. Enhanced sensitivity of surface plasmon resonance phase-interrogation biosensor by using oblique deposited silver nanorods. Nanoscale Res. Lett. 2014, 9, 476. [Google Scholar] [CrossRef] [Green Version]

- Peng, T.C.; Lin, W.C.; Chen, C.W.; Tsai, D.P.; Chiang, H.P. Enhanced sensitivity of surface plasmon resonance phase-interrogation biosensor by using silver nanoparticles. Plasmonics 2011, 6, 29–34. [Google Scholar] [CrossRef]

- Raether, H. Surface Plasmons on Smooth and Rough Surfaces and on Gratings; Springer: New York, NY, USA, 1988. [Google Scholar]

- Gryga, M.; Vala, D.; Kolejak, P.; Gembalova, L.; Ciprian, D.; Hlubina, P. One-dimensional photonic crystal for Bloch surface waves and radiation modes-based sensing. Opt. Mater. Express 2019, 9, 4009–4022. [Google Scholar] [CrossRef]

- Hlubina, P.; Lunackova, M.; Ciprian, D. Phase sensitive measurement of the wavelength dependence of the complex permittivity of a thin gold film using surface plasmon resonance. Opt. Mater. Express 2019, 9, 992–1001. [Google Scholar] [CrossRef] [Green Version]

- Luo, W.; Wang, R.; Li, H.; Kou, J.; Zeng, X.; Huang, H.; Hu, X.; Huang, W. Simultaneous measurement of refractive index and temperature for prism-based surface plasmon resonance sensors. Opt. Express 2019, 27, 576–589. [Google Scholar] [CrossRef] [PubMed]

- Abdulhalim, I.; Lakhtakia, A.; Lahav, A.; Zhang, F.; Xu, J. Porosity effect on surface plasmon resonance from metallic sculptured thin films. SPIE Opt. Photonics 2008, 7041, 70410C. [Google Scholar]

- Homola, J. Present and future of surface plasmon resonance biosensors. Anal. Bioanal. Chem. 2003, 377, 528–539. [Google Scholar] [CrossRef] [PubMed]

- Nelson, S.G.; Johnston, K.S.; Yee, S.S. High sensitivity surface plasmon resonace sensor based on phase detection. Sens. Actuators B Chem. 1996, 35, 187–191. [Google Scholar] [CrossRef]

- Naraoka, R.; Kajikawa, K. Phase detection of surface plasmon resonance using rotating analyzer method. Sens. Actuators B Chem. 2005, 107, 952–956. [Google Scholar] [CrossRef]

- Chiang, H.-P.; Yeh, H.-T.; Chen, C.-M.; Wu, J.-C.; Su, S.-Y.; Chang, R.; Wu, Y.-J.; Tsai, D.P.; Jen, S.U.; Leung, P.T. Surface plasmon resonance monitoring of temperature via phase measurement. Opt. Commun. 2004, 241, 409–418. [Google Scholar] [CrossRef]

- Chiang, H.-P.; Lin, J.-L.; Chang, R.; Su, S.-Y.; Leung, P.T. High-resolution angular measurement using surface-plasmon-resonance via phase interrogation at optimal incident wavelengths. Opt. Lett. 2005, 30, 2727–2729. [Google Scholar] [CrossRef] [Green Version]

- Barchiesi, D.; Lidgi-Guigui, N.; Chapelle, M.L.D.L. Functionalization layer influence on the sensitivity of surface plasmon resonance (SPR) biosensor. Opt. Commun. 2012, 285, 1619–1623. [Google Scholar] [CrossRef]

- Szunerits, S.; Shalabney, A.; Boukherroub, R.; Abdulhalim, I. Dielectric coated plasmonic interfaces: Their interest for sensitive sensing of analyte-ligand interactions. Rev. Anal. Chem. 2012, 31, 15–28. [Google Scholar] [CrossRef]

- Shalabney, A.; Abdulhalim, I. Figure of merit enhancement of surface plasmon resonance sensors in the spectral interrogation. Opt. Lett. 2012, 37, 1175. [Google Scholar] [CrossRef] [PubMed]

- Lahav, A.; Shalabney, A.; Abdulhalim, I. Surface plasmon resonance sensor with enhanced sensitivity using top nano dielectric layer. J. Nanophotonics 2009, 3, 031501. [Google Scholar] [CrossRef]

- Lahav, A.; Auslender, M.; Abdulhalim, I. Sensitivity enhancement of guided wave surface plasmon resonance sensors. Opt. Lett. 2008, 33, 2539–2541. [Google Scholar] [CrossRef]

- Faryad, M.; Lakhtakia, A. Surface plasmon–polariton wave propagation guided by a metal slab in a sculptured nematic thin film. J. Opt. A 2010, 12, 085102. [Google Scholar] [CrossRef] [Green Version]

- Shalabney, A.; Lakhtakia, A.; Abdulhalim, I.; Lahav, A.; Patzig, C.; Hazek, I.; Karabchevsky, A.; Rauschenbach, B.; Zhang, F.; Xub, J. Surface plasmon resonance from metallic columnar thin films. Photon. Nanostruct. Fundam. Appl. 2009, 7, 176–185. [Google Scholar] [CrossRef]

- Shalabney, A.; Abdulhalim, I. Electromagnetic fields distribution in multilayer thin film structures and the origin of sensitivity enhancement in surface plasmon resonance sensors. Sens. Actuators A Phys. 2010, 159, 24–32. [Google Scholar] [CrossRef]

- Shalabney, A.; Abdulhalim, I. Sensitivity enhancement methods for surface plasmon sensors. Laser Photonics Rev. 2011, 5, 571–606. [Google Scholar] [CrossRef]

- Shalabney, A.; Khare, C.; Rauschenbach, B.; Abdulhalim, I. Sensitivity of surface plasmon resonance sensors based on metallic columnar thin films in the spectral and angular interrogations. Sens. Actuators B Chem. 2011, 159, 201–212. [Google Scholar] [CrossRef]

- Abdulhalim, I. Plasmonic sensing using metallic nano-sculptured thin films. Small 2014, 10, 3499–3514. [Google Scholar] [CrossRef] [PubMed]

- Abdulhalim, I. Coupling configurations between extended surface electromagnetic waves and localized surface plasmons for ultrahigh field enhancement. Nanophotonics 2018, 7, 1891–1916. [Google Scholar] [CrossRef]

- Chiang, H.P.; Lin, J.L.; Chen, Z.W. High sensitivity surface plasmon resonance sensor based on phase interrogation at optimal incident wavelengths. Appl. Phys. Lett. 2006, 88, 141105. [Google Scholar] [CrossRef]

- Homola, J.; Yee, S.S.; Gauglitz, G. Surface plasmon resonance sensors: Review. Sens. Actuators B Chem. 1999, 54, 3–15. [Google Scholar] [CrossRef]

- Zhang, W.; Li, Q.; Qiu, M. A plasmon ruler based on nanoscale photothermal effect. Opt. Express 2013, 21, 172–181. [Google Scholar] [CrossRef]

- Lu, J.Y.; Nam, S.H.; Wilke, K.; Raza, A.; Lee, Y.E.; AlGhaferi, A.; Fang, N.X.; Zhang, T. Localized surface plasmon-enhanced ultrathin film broadband nanoporous absorbers. Adv. Opt. Mater. 2016, 4, 1255–1264. [Google Scholar] [CrossRef]

- Kumara, N.T.R.N.; Chou Chau, Y.-F.; Huang, J.-W.; Huang, H.J.; Lin, C.-T.; Chiang, H.-P. Plasmonic spectrum on 1D and 2D periodic arrays of rod-shape metal nanoparticle pairs with different core patterns for biosensor and solar cell applications. J. Opt. 2016, 18, 115003. [Google Scholar] [CrossRef]

- Chou Chau, Y.-F.; Chou Chao, C.-T.; Lim, C.M.; Huang, H.J.; Chiang, H.-P. Deploying tunable metal-shell/dielectric core nanorod arrays as the virtually perfect absorber in the near-infrared regime. ACS Omega 2018, 3, 7508–7516. [Google Scholar] [CrossRef] [Green Version]

- Elshorbagy, M.H.; Cuadrado, A.; Gonzalez, G.; Gonzalez, F.J.; Alda, J. Performance improvement of refractometric sensors through hybrid plasmonic-Fano resonances. J. Lightwave Technol. 2019, 37, 2905–2913. [Google Scholar] [CrossRef] [Green Version]

- Lin, W.-C.; Huang, S.-H.; Chen, C.-L.; Chen, C.-C.; Tsai, D.P.; Chiang, H.-P. Controlling SERS intensity by tuning the size and height of a silver nanoparticle array. Appl. Phys. A 2010, 101, 185–189. [Google Scholar] [CrossRef]

- Chang, R.; Chiang, H.-P.; Leung, P.T.; Tsai, D.P.; Tse, W.S. Nonlocal effects in the optical response of composite materials with metallic nanoparticles. Solid State Commun. 2005, 133, 315–320. [Google Scholar] [CrossRef]

- Chou Chau, Y.-F.; Wang, C.-K.; Shen, L.; Lim, C.M.; Chiang, H.-P.; Chou Chao, C.-T.; Huang, H.J.; Lin, C.-T.; Kumara, N.T.R.N.; Voo, N.Y. Simultaneous realization of high sensing sensitivity and tunability in plasmonic nanostructures arrays. Sci. Rep. 2017, 7, 16817. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chou Chau, Y.-F.; Chou Chao, C.-T.; Huang, H.J.; Lim, R.C.; Chiang, H.-P. Tunable plasmonic effects arising from metal–dielectric nanorods. Appl. Opt. 2019, 58, 2530–2539. [Google Scholar] [CrossRef]

- Chou Chau, Y.-F.; Chou Chao, C.-T.; Huang, H.J.; Wang, Y.-C.; Chiang, H.-P.; Idris, M.N.S.M.; Masri, Z.; Lim, C.M. Strong and tunable plasmonic field coupling and enhancement generating from the protruded metal nanorods and dielectric cores. Results Phys. 2019, 13, 102290. [Google Scholar] [CrossRef]

- Chou Chau, Y.-F.; Chou Chao, C.-T.; Huang, H.J.; Anwar, U.; Lim, C.M.; Voo, N.Y.; Mahadi, A.H.; Kumara, N.T.R.N.; Chiang, H.-P. Plasmonic perfect absorber based on metal nanorod arrays connected with veins. Results Phys. 2019, 15, 102567. [Google Scholar] [CrossRef]

- Chou Chau, Y.-F.; Chen, K.-H.; Chiang, H.-P.; Lim, C.M.; Huang, H.J.; Lai, C.-H.; Kumara, N.T.R.N. Fabrication and characterization of a metallic–dielectric nanorod array by nanosphere lithography for plasmonic sensing application. Nanomaterials 2019, 9, 1691. [Google Scholar] [CrossRef] [Green Version]

- Chou Chau, Y.-F.; Chou Chao, C.-T.; Huang, H.J.; Kooh, M.R.R.; Kumara, N.T.R.N.; Lim, C.M.; Chiang, H.-P. Perfect dual-band absorber based on plasmonic effect with the cross-hair/nanorod combination. Nanomaterials 2020, 10, 493. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chou Chau, Y.-F.; Chou Chao, C.-T.; Huang, H.J.; Kumara, N.T.R.N.; Lim, C.M.; Chiang, H.-P. Ultra-high refractive index sensing structure based on a metal-insulator-metal waveguide-coupled T-shape cavity with metal nanorod defects. Nanomaterials 2019, 9, 1433. [Google Scholar] [CrossRef] [Green Version]

- Chou Chau, Y.-F.; Syu, J.-Y.; Chou Chao, C.-T.; Chiang, H.-P.; Lim, C.M. Design of crossing metallic metasurface arrays based on high sensitivity of gap enhancement and transmittance shift for plasmonic sensing applications. J. Phys. D Appl. Phys. 2017, 50, 045105. [Google Scholar] [CrossRef]

- Wang, T.-J.; Hsu, K.-C.; Liu, Y.-C.; Lai, C.-H.; Chiang, H.-P. Nanostructured SERS substrates produced by nanosphere lithography and plastic deformation through direct peel-off on soft matter. J. Opt. 2016, 18, 055006. [Google Scholar] [CrossRef]

- Chou Chau, Y.-F.; Lim, C.M.; Lee, C.; Huang, H.J.; Lin, C.-T.; Kumara, N.T.R.N.; Yoong, V.N.; Chiang, H.-P. Tailoring surface plasmon resonance and dipole cavity plasmon modes of scattering cross section spectra on the single solid-gold/gold-shell nanorod. J. Appl. Phys. 2016, 120, 093110. [Google Scholar] [CrossRef]

- Naik, G.V.; Schroeder, J.L.; Ni, X.; Kildishev, A.V.; Sands, T.D.; Boltasseva, A. Titanium nitride as a plasmonic material for visible and near-infrared wavelengths. Opt. Mater. Express 2012, 2, 478–489. [Google Scholar] [CrossRef] [Green Version]

- Naik, G.V.; Kim, J.; Boltasseva, A. Oxides and nitrides as alternative plasmonic materials in the optical range. Opt. Mater. Express 2011, 1, 1090–1099. [Google Scholar] [CrossRef] [Green Version]

- Chen, N.C.; Lien, W.C.; Liu, C.R.; Huang, Y.L.; Lin, Y.R.; Chou, C.; Chang, S.Y.; Ho, C.W. Excitation of surface plasma wave at TiN/air interface in the Kretschmann geometry. J. Appl. Phys. 2011, 109, 043104. [Google Scholar] [CrossRef]

- Kumar, K.K.; Raole, P.M.; Rayjada, P.A.; Chauhan, N.L.; Mukherjee, S. Study of structure development of titanium nitride on inclined substrates. Surf. Coat. Technol. 2011, 205, S187–S191. [Google Scholar] [CrossRef]

- Wei, B.; Liang, H.; Qi, Z.; Zhang, D.; Shen, H.; Hu, W.; Wang, Z. Construction of 3D Si@Ti@TiN thin film arrays for aqueous symmetric supercapacitors. Chem. Commun. 2019, 55, 1402–1405. [Google Scholar] [CrossRef] [PubMed]

- Fang, S.; Shen, L.; Li, S.; Dou, H.; Zhang, X. Self-supported TiN nanorod array/carbon textile as a lithium host that induces dendrite-free lithium plating with high rates and long cycle life. J. Mater. Chem. A 2020, 8, 3293–3299. [Google Scholar] [CrossRef]

- Yu, L.; Liang, F.; Wang, L.; Chang, L.; Wang, F.; Li, N. Significantly improved cycling stability for electrochemical hydrogen storage in Ti1.4V0.6Ni alloy with TiN. Mater. Res. Bull. 2019, 118, 110509. [Google Scholar] [CrossRef]

- Viarbitskaya, S.J.; Arocas, J.; Heintz, O.; Colas-Des-Francs, G.; Rusakov, D.; Koch, U.; Leuthold, J.; Markey, L.; Dereux, A.; Weeber, J.-C. Correlation between electrical direct current resistivity and plasmonic properties of CMOS compatible titanium nitride thin films. Opt. Express 2018, 26, 9813–9821. [Google Scholar] [CrossRef] [PubMed]

- Zakomirnyi, V.I.; Rasskazov, I.L.; Gerasimov, V.S.; Ershov, A.E.; Polyutov, S.P.; Karpov, S.V.; Ågren, H. Titanium nitride nanoparticles as an alternative platform for plasmonic waveguides in the visible and telecommunication wavelength ranges. Photon. Nanostruct. Fundam. Appl. 2018, 30, 50–56. [Google Scholar] [CrossRef]

- Patskovsky, S.; Vallieres, M.; Maisonneuve, M.; Song, I.-H.; Meunier, M.; Kabashin, A.V. Designing efficient zero calibration point for phase sensitive surface plasmon resonance biosensing. Opt. Express 2009, 17, 2255. [Google Scholar] [CrossRef] [PubMed]

- Watad, I.; Abdulhalim, I. Spectropolarimetric surface plasmon resonance sensor and the selection of the best polarimetric function. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 4600609. [Google Scholar] [CrossRef]

- Watad, I.; Abdulhalim, I. Comparative study between polarimetric and intensity based surface plasmon resonance sensors in the spectral mode. Appl. Opt. 2017, 56, 7549–7558. [Google Scholar] [CrossRef] [PubMed]

- Watad, I.; Abdulhalim, I. Phase-shifted polarimetric surface plasmon resonance sensor using a liquid crystal retarder and a diverging beam. Opt. Lett. 2019, 44, 1607–1610. [Google Scholar] [CrossRef] [PubMed]

- Watad, I.; Abuleil, M.; Abdulhalim, I. Spectro-ellipsometric surface plasmon resonance sensor using a liquid crystal achromatic waveplate. IEEE Photonics Technol. Lett. 2020, 32, 550–553. [Google Scholar] [CrossRef]

- Chen, C.; Wang, Z.; Wu, K.; Chong, H.; Xu, Z.; Ye, H. ITO–TiN–ITO sandwiches for near-infrared plasmonic materials. ACS Appl. Mater. Interfaces 2018, 10, 14886–14893. [Google Scholar] [CrossRef]

| Bulk Carrier Density (1/cm3) | Sheet Carrier Density (1/cm2) | |

|---|---|---|

| Glass/TiN (46 nm) | 1.91 × 1022 | 8.77 × 1016 |

| Glass/TiN (50 nm) | 1.45 × 1021 | 7.22 × 1015 |

| Glass/TiN (54.5 nm) | 3.32 × 1021 | 1.81 × 1016 |

| Glass/TiN (46 nm)/Inc. TiN (1.4 nm) | 1.28 × 1022 | 5.87 × 1016 |

| Glass/TiN (46 nm)/Inc. TiN (4.1 nm) | 2.10 × 1021 | 9.64 × 1015 |

| Glass/TiN (46 nm)/Inc. TiN (6.9 nm) | 1.12 × 1021 | 5.13 × 1015 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, R.-J.; Huang, H.J.; Hsiao, C.-N.; Lin, Y.-W.; Liao, B.-H.; Chou Chau, Y.-F.; Chiang, H.-P. Reusable TiN Substrate for Surface Plasmon Resonance Heterodyne Phase Interrogation Sensor. Nanomaterials 2020, 10, 1325. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10071325

Sun R-J, Huang HJ, Hsiao C-N, Lin Y-W, Liao B-H, Chou Chau Y-F, Chiang H-P. Reusable TiN Substrate for Surface Plasmon Resonance Heterodyne Phase Interrogation Sensor. Nanomaterials. 2020; 10(7):1325. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10071325

Chicago/Turabian StyleSun, Ru-Jing, Hung Ji Huang, Chien-Nan Hsiao, Yu-Wei Lin, Bo-Huei Liao, Yuan-Fong Chou Chau, and Hai-Pang Chiang. 2020. "Reusable TiN Substrate for Surface Plasmon Resonance Heterodyne Phase Interrogation Sensor" Nanomaterials 10, no. 7: 1325. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10071325