Kinetic Studies and Moisture Diffusivity During Cocoa Bean Roasting

Abstract

:1. Introduction

2. Materials and Methods

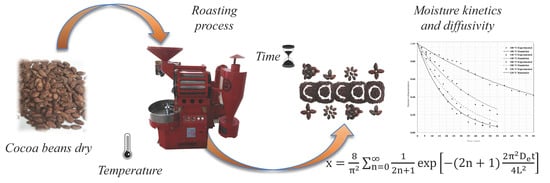

2.1. Experimental Roasting Procedure

2.2. Kinetic Model of Roasting

2.3. Diffusion Model and Activation Energy

3. Results and Discussion

3.1. Roasting Kinetics

3.2. Exponential Models

3.3. Effective Roasting Diffusivity

3.4. Activation Energy

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gutiérrez, T.J. State of the art chocolate manufacture: A review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1313–1344. [Google Scholar] [CrossRef]

- Krisiak, W. Effects of convective and microwave roasting on the physicochemical properties of cocoa beans and cocoa butter extracted from this material. Grasa y Aceites 2011, 62, 467–478. [Google Scholar] [CrossRef] [Green Version]

- Barrientos, L.D.P.; Oquendo, J.D.T.; Garzón, M.A.G.; Álvarez, O.L.M. Effect of the solar drying process on the sensory and chemical quality of cocoa (Theobroma cacao L.) cultivated in Antioquia, Colombia. Food Res. Int. 2019, 115, 259–267. [Google Scholar] [CrossRef] [PubMed]

- Jha, S.N. Mathematical simulation of roasting grain. J. Food Eng. 2005, 71, 304–310. [Google Scholar] [CrossRef]

- Zzaman, W.; Bhat, R.; Yang, T.A. Effect of Superheated Steam and Convection Roasting on Changes in Physical properties of Cocoa Bean (Theobroma cacao L.). Food Sci. Technol. Res. 2013, 19, 181–186. [Google Scholar] [CrossRef]

- Baghdadi, Y.M.; Hii, C.L. Mass transfer kinetics and effective diffusivities during cocoa roasting. J. Eng. Sci. Technol. 2017, 12, 127–137. [Google Scholar]

- Lares-Amaíz, M.D.; Gutiérrez, R.; Pérez, E.; Álvarez, C. Efecto del tostado sobre las propiedades fisicas, fisicoquimicas, composición proximal y perfil de ácidos grasos de la manetca de granos de cacao del estado Miranda, Venezuela. Rev. Cientifica UDO Agrícola 2012, 12, 439–446. [Google Scholar]

- Robbins, P.T.; Fryer, P.J. The spouted-bed roasting of barley: Development of a predictive model for moisture and temperature. J. Food Eng. 2003, 59, 199–208. [Google Scholar] [CrossRef]

- Özdemir, M.; Devres, O. Analysis of color development during roasting of hazelnuts using response surface methodology. J. Food Eng. 2000, 45, 17–24. [Google Scholar] [CrossRef]

- Feyissa, A.H.; Gernaey, K.V.; Adler-Nissen, J. Uncertainty and sensitivity analysis: Mathematical model of coupled heat and mass transfer for a contact baking process. J. Food Eng. 2012, 109, 281–290. [Google Scholar] [CrossRef]

- Kara, C.; Doymaz, I. Effective moisture diffusivity determination and mathematical modelling of drying curves of apple pomace. Heat Mass Transf. 2015, 51, 983–989. [Google Scholar] [CrossRef]

- Demirhan, E.; Özbek, B. Drying kinetics and effective moisture of purslane undergoing microwave heat treatment. Korean J. Chem. Eng. 2010, 27, 1377–1383. [Google Scholar] [CrossRef]

- Ah Hen, K.; Zambra, C.E.; Agüero, J.E.; Vega-Gálvez, A.; Lemus-Mondaca, R. Moisture diffusivity coefficient and convective drying modelling of murta (Ugni molinae Turcz): Influence of temperature and vacuum on drying kinetics. Food Bioprocess. Technol. 2013, 6, 919–930. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Lemus-Mondaca, R.; Bilbao-Saínz, C.; Yagnam, F. Mass transfer kinetics during convective drying of red pepper var. Hungarian (Capsicum anuum L.): Mathematical modeling and evaluation of kinetic parameters. J. Food Process. Eng. 2008, 31, 120–137. [Google Scholar] [CrossRef]

- Van Boekel, M. Kinetic modeling of food quality: A critical review. Compr. Rev. Food Sci. Food Saf. 2008, 7, 144–157. [Google Scholar] [CrossRef]

- Yamsaengsung, R.; Rungsee, C.; Prasertsit, K. Simulation of the heat and mass transfer processes during the vacuum frying of potato chips. Songklanakarin J. Sci. Technol. 2008, 30, 109–115. [Google Scholar]

- Zhang, Q.; Litchfield, J.B. An optimization of intermittent corn drying in a laboratory scale thin layer dryier. Dry Technol. 1991, 9, 383–395. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H.; Yapar, Z. A new model for single-layer drying. Dry Technol. 2002, 20, 1503–1513. [Google Scholar] [CrossRef]

- Ben Haj Said, L.; Najjaa, H.; Farhat, A. Thin layer convective air drying of wild edible plant (Allium roseum) leaves: Experimental kinetics, modeling and quality. J. Food Sci. Technol. 2015, 52, 3739–3749. [Google Scholar] [CrossRef]

- Pavón-Melendez, G.; Hernández, J.A.; Salgado, M.A.; García-Alvarado, M.A. Dimensionless analysis of the simultaneous heat and mass transfer in food drying. J. Food Eng. 2002, 51, 347–353. [Google Scholar] [CrossRef]

- Simal, S.; Femenia, A.; Garau, M.C.; Roselló, C. Use of exponential, Pages’s and diffusional models to simulate the drying kinetics of kiwi fruit. J. Food Eng. 2005, 66, 323–328. [Google Scholar] [CrossRef]

- Corzo, O.; Bracho, N.; Pereira, A.; Vásquez, A. Weibull distribution for modelling air drying of coroba slices. LWT Food Sci Technol. 2008, 41, 2023–2028. [Google Scholar] [CrossRef]

- Doymaz, I. Air Drying Characteristics of Tomatoes. J. Food Eng. 2007, 78, 1291–1297. [Google Scholar] [CrossRef]

- Giraldo-Zuniga, A.D.; Arévalo-Pinedo, A.; Ferreira-Silva, A.; Ferreira Silva, P.; Valdes-Serra, J.; de Menezes-Pavlak, M.C. Datos experimentales de la cinética del secado y del modelo matemático para pulpa de cupuaçu (Theobroma grandiflorum) en rodajas. Ciência e Tecnologia de Alimentos 2010, 30, 179–182. [Google Scholar] [CrossRef]

- Adiletta, G.; Russo, P.; Senadera, W.; Di Matteo, M. Drying characteristics and quality of grape under physical pretreatment. J. Food Eng. 2016, 172, 9–18. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Janius, R.B.; Nawi, N.M.; Abdan, K. Modeling the Thin-Layer Drying of Fruits and Vegetables: A Review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 599–618. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists. Official Methods of Analysis, 13th ed.; AOAC: Washington, DC, USA, 1980. [Google Scholar]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Oxford University Press: Oxford, UK, 1975. [Google Scholar]

- Sacchetti, G.; Ioannone, F.; De Gregorio, M.; Di Mattia, C.; Serafini, M.; Mastrocola, D. Non enzimatic browning during cocoa roasting as affected by processing time and temperature. J. Food Eng. 2016, 169, 44–52. [Google Scholar] [CrossRef]

- Rodriguez, J.; Mulet, A.; Bon, J. Influence of high-intensity ultrasound on drying kinetics in fixed beds of high porosity. J. Food Eng. 2014, 127, 93–102. [Google Scholar] [CrossRef]

- Liu, X.; Hou, H.; Chen, J. Applicability of moisture transfer parameters estimated by correlation between Biot number and lag factor (Bi-G correlation) for convective drying of eggplant slices. Heat Mass Transfer 2013, 49, 1595–1601. [Google Scholar] [CrossRef]

- Chayjan, R.A.; Salari, K.; Abedi, Q.; Sabziparvar, A.A. Modeling moisture diffusivity, activation energy and specific energy consumption of squash seeds in a semi fluidized and fluidized bed drying. J. Food Sci. Technol. 2013, 50, 667–677. [Google Scholar] [CrossRef]

- Arslan, D.; Musa Özcan, M. Study the effect of sun, oven and microwave drying on quality of onion slices. LWT Food Sci. Technol. 2010, 43, 1121–1127. [Google Scholar] [CrossRef]

- Nama, M.G.; Mbofung, M.F. Kinetics studies of some physic-chemical substances during roasting and preparation of beverage made by Cassia occidentalis seeds. LWT Food Sci. Technol. 2007, 40, 730–736. [Google Scholar] [CrossRef]

- Demir, A.D.; Cronin, K. The thermal kinetics of texture change and the analysis of texture variability for raw and roasted hazelnuts. Int. J. Food Sci. Technol. 2004, 39, 371–383. [Google Scholar] [CrossRef]

- Chung, H.-S.; Chung, S.-K.; Youn, J. Effects of roasting temperature and time bulk density, soluble solids, browning index and phenolic compounds of corn kernels. J. Food Process. Preserv. 2011, 35, 832–839. [Google Scholar] [CrossRef]

- Yang, J.; Bingol, G.; Pan, Z.; Brandl, M.T.; McHugh, T.H.; Wang, H. Infrared heating for dry-roasting and pasteurization of almonds. J. Food Eng. 2010, 101, 273–280. [Google Scholar] [CrossRef]

- Hernández, J.A.; Heyd, B.; Irles, C.; Valdovinos, B.; Trystram, G. Analysis of the heat and mass transfer during coffe batch roasting. J. Food Eng. 2007, 78, 1141–1148. [Google Scholar] [CrossRef]

- Udomkun, P.; Argyropoulos, D.; Nagle, M.; Mahayothee, B.; Janjai, S.; Müller, J. Single layer drying kinetics of papaya amidst vertical and horizontal airflow. LWT Food Sci. Technol. 2015, 64, 67–73. [Google Scholar] [CrossRef]

- Azzouz, S.; Guizani, A.; Jomaa, W.; Belghith, A. Moisture diffusivity and drying kinetic equation of convective drying of grapes. J. Food Eng. 2002, 55, 323–330. [Google Scholar] [CrossRef]

- Tunde-Akitunde, T.Y.; Ogunlankin, G.O. Influence of drying conditions on the effective moisture diffusivity and energy requeriments during the drying of pretreated and untreated pumpkin. Energy Convers. Manag. 2011, 52, 1107–1113. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Kianmehr, M.H.; Samimi-Akhijhani, H. Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energy Convers. Manag. 2008, 49, 2856–2871. [Google Scholar] [CrossRef]

- Páramo, D.; García-Alamilla, P.; Salgado-Cervantes, M.A.; Robles-Olvera, V.J.; Rodríguez-Jimenez, G.C. Mass transfer of water and volatile fatty acids in cocoa beans during drying. J. Food Eng. 2010, 99, 276–283. [Google Scholar] [CrossRef]

- Llave, Y.; Takemori, K.; Fukuoka, M.; Takemori, T.; Tomita, H.; Sakai, N. Mathematical modeling of shrinkage deformation in eggplant undergoing simultaneous heat and mass transfer during convection-oven roasting. J. Food Eng. 2016, 178, 124–136. [Google Scholar] [CrossRef]

- Hii, C.L.; Law, C.L.; Cloke, M. Modeling using a new thin layer drying model and product quality of cocoa. J. Food Eng. 2009, 90, 191–198. [Google Scholar] [CrossRef]

| Id. | Model | Equation | Reference |

|---|---|---|---|

| 1 | Newton | [19] | |

| 2 | Page | [19] | |

| 3 | Henderson and Pabis | [19] | |

| 4 | Logarithmic | [19] | |

| 5 | Two term model | [19] | |

| 6 | Midilli and other model | [11] | |

| 7 | Verma | [26] | |

| 8 | Aproximation of diffusion | [26] | |

| 9 | Silva and other model | [26] | |

| 10 | Peleg | [26] |

| Order | Kinetics Models | T (°C) | k | R2 | SSE |

|---|---|---|---|---|---|

| 0 | 100 | −0.0080 | 0.98 | 0.0166 | |

| 140 | −0.0158 | 0.98 | 0.0214 | ||

| 180 | −0.0204 | 0.93 | 0.1371 | ||

| 220 | −0.0223 | 0.87 | 0.3358 | ||

| 1 | 100 | 0.0108 | 0.98 | 0.0128 | |

| 140 | 0.0242 | 0.98 | 0.0221 | ||

| 180 | 0.0383 | 0.98 | 0.0587 | ||

| 220 | 0.0492 | 0.98 | 0.0292 | ||

| 2 | 100 | 0.0141 | 0.96 | 0.0364 | |

| 140 | 0.0347 | 0.94 | 5.0854 | ||

| 180 | 0.0613 | 0.93 | 5.2128 | ||

| 220 | 0.0859 | 0.94 | 5.1705 |

| Parameters | Order 0 | Order 1 | Order 2 |

|---|---|---|---|

| k0 | 0.6064 | 6.2532 | 26.9828 |

| Ea (kJ mol−1) | 13.0652 | 19.4669 | 23.2025 |

| R2 | 0.9098 | 0.9736 | 0.9843 |

| Model | T (°C) | K1 | K2 | a | b | R2 | SSE |

|---|---|---|---|---|---|---|---|

| Newton | 100 | 0.0108 | ---- | ---- | ---- | 0.98 | 0.0128 |

| 140 | 0.0242 | ---- | ---- | ---- | 0.98 | 0.0221 | |

| 180 | 0.0383 | ---- | ---- | ---- | 0.98 | 0.0587 | |

| 220 | 0.0492 | ---- | ---- | ---- | 0.98 | 0.0292 | |

| Page | 100 | 0.0072 | ---- | 1.1048 | ---- | 0.98 | 0.0099 |

| 140 | 0.0109 | ---- | 1.2338 | ---- | 0.99 | 0.0072 | |

| 180 | 0.0100 | ---- | 1.4203 | ---- | 0.99 | 0.0048 | |

| 220 | 0.0222 | ---- | 1.2615 | ---- | 0.99 | 0.0074 | |

| Henderson and Pabis | 100 | 0.0110 | ---- | 1.0080 | ---- | 0.98 | 0.0125 |

| 140 | 0.0255 | ---- | 1.0340 | ---- | 0.98 | 0.0186 | |

| 180 | 0.0428 | ---- | 1.0991 | ---- | 0.97 | 0.0348 | |

| 220 | 0.0524 | ---- | 1.0602 | ---- | 0.98 | 0.0215 | |

| Logarithmic | 100 | 0.0048 | ---- | 1.8844 | −0.8957 | 0.98 | 0.0092 |

| 140 | 0.0108 | ---- | 1.8043 | −0.8085 | 0.99 | 0.0060 | |

| 180 | 0.0303 | ---- | 1.2680 | −0.2020 | 0.98 | 0.0299 | |

| 220 | 0.0454 | ---- | 1.1103 | −0.0668 | 0.98 | 0.0173 | |

| Two terms | 100 | 0.0110 | 0.0110 | 0.4938 | 0.5142 | 0.98 | 0.0125 |

| 140 | 0.0255 | 0.0255 | 0.4494 | 0.5846 | 0.98 | 0.0186 | |

| 180 | 0.0428 | 0.0428 | 0.5525 | 0.5466 | 0.97 | 0.0186 | |

| 220 | 0.0524 | 0.0524 | 0.5337 | 0.5265 | 0.98 | 0.0186 | |

| Midilli et al. | 100 | 0.0068 | ---- | 0.9882 | −0.0023 | 0.98 | 0.0093 |

| 140 | 0.0153 | ---- | 0.9962 | −0.0044 | 0.99 | 0.0061 | |

| 180 | 0.0348 | ---- | 1.0682 | −0.0022 | 0.98 | 0.0213 | |

| 220 | 0.0484 | ---- | 1.0464 | −0.0009 | 0.98 | 0.0182 | |

| Verma et al. | 100 | 0.0186 | ---- | 14.7810 | 0.0193 | 0.98 | 0.0093 |

| 140 | 0.0443 | ---- | 8.9259 | 0.0480 | 0.99 | 0.0061 | |

| 180 | 0.0794 | ---- | 15.2588 | 0.0845 | 0.99 | 0.0034 | |

| 220 | 0.0882 | ---- | 11.2158 | 0.0944 | 0.99 | 0.0034 | |

| Aproximation difussion | 100 | 0.0263 | ---- | −0.5403 | 0.5687 | 0.98 | 0.0093 |

| 140 | 0.0499 | ---- | –3.9659 | 0.8591 | 0.99 | 0.0061 | |

| 180 | 0.0383 | ---- | −0.4388 | 1.0003 | 0.98 | 0.0587 | |

| 220 | 0.0274 | ---- | –24.6788 | 1.0239 | 0.98 | 0.0190 | |

| Silva et al. | 100 | ---- | ---- | 0.0121 | −0.0086 | 0.98 | 0.0112 |

| 140 | ---- | ---- | 0.0311 | −0.0364 | 0.98 | 0.0122 | |

| 180 | ---- | ---- | 0.0613 | −0.1080 | 0.99 | 0.0079 | |

| 220 | ---- | ---- | 0.0679 | −0.0815 | 0.99 | 0.0097 | |

| Peleg | 100 | ---- | ---- | 103.3130 | 0.3585 | 0.98 | 0.0097 |

| 140 | ---- | ---- | 50.1263 | 0.3220 | 0.99 | 0.0062 | |

| 180 | ---- | ---- | 30.7083 | 0.4565 | 0.98 | 0.0334 | |

| 220 | ---- | ---- | 20.4495 | 0.6253 | 0.98 | 0.0304 |

| Temperature (°C) | De (m2 s−1) | R2 |

|---|---|---|

| 100 | 1.26789 × 10−9 | 0.9852 |

| 140 | 3.16974 × 10−9 | 0.9816 |

| 180 | 5.07158 × 10−9 | 0.9883 |

| 220 | 5.70553 × 10−9 | 0.9825 |

| References | Product | T (°C) | Characteristic Dimension | Do | Deff (m2 s−1) | Ea (kJ mol−1) |

|---|---|---|---|---|---|---|

| This paper | Cocoa beans | 100–220 | Infinite flat plate | 0.78 × 106 | 1.26–5.70 × 10−9 | 19.52 |

| [29] | Cocoa beans | 125–145 | Spherical geometry | 4.2 × 106 | 4.4–9.3 × 10−9 | 59.6 |

| [6] | Cocoa beans | 120–160 | Infinite flat plate | 2.37 × 10−5 | 1.38–3.08 × 10−5 Nibs rewetted 2.49–4.42 × 10−5 | 28.6 |

| [45] | Cocoa beans | 60–80 | Spherical geometry | 4.08 × 106 | 1.61–3.23 × 1010 | 28.11 |

| [43] | Cocoa beans | 60–80 | Infinite flat plate | 10.23 | 1.14–4.20 × 10−9 | 63.45 |

| [44] | Eggplant | 100–200 | Cylindrical geometry | 4.95 × 1011 | 1.79 × 108–5.15 × 10−9 | 18.27 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Domínguez-Pérez, L.A.; Concepción-Brindis, I.; Lagunes-Gálvez, L.M.; Barajas-Fernández, J.; Márquez-Rocha, F.J.; García-Alamilla, P. Kinetic Studies and Moisture Diffusivity During Cocoa Bean Roasting. Processes 2019, 7, 770. https://0-doi-org.brum.beds.ac.uk/10.3390/pr7100770

Domínguez-Pérez LA, Concepción-Brindis I, Lagunes-Gálvez LM, Barajas-Fernández J, Márquez-Rocha FJ, García-Alamilla P. Kinetic Studies and Moisture Diffusivity During Cocoa Bean Roasting. Processes. 2019; 7(10):770. https://0-doi-org.brum.beds.ac.uk/10.3390/pr7100770

Chicago/Turabian StyleDomínguez-Pérez, Leydy Ariana, Ignacio Concepción-Brindis, Laura Mercedes Lagunes-Gálvez, Juan Barajas-Fernández, Facundo Joaquín Márquez-Rocha, and Pedro García-Alamilla. 2019. "Kinetic Studies and Moisture Diffusivity During Cocoa Bean Roasting" Processes 7, no. 10: 770. https://0-doi-org.brum.beds.ac.uk/10.3390/pr7100770