Rheological Properties of Aqueous Dispersions of Bacterial Cellulose

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

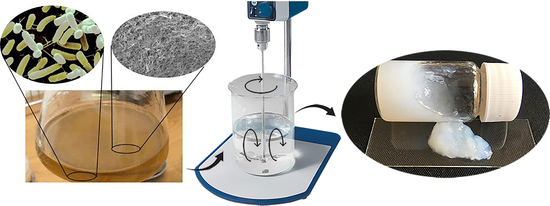

2.2. Preparation of Aqueous Dispersions

2.3. Characterization Methods

2.3.1. Morphology

2.3.2. Rheology

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Azeredo, H.M.C.; Barud, H.; Farinas, C.S.; Vasconcellos, V.M.; Claro, A.M. Bacterial Cellulose as a Raw Material for Food and Food Packaging Applications. Front. Sustain. Food Syst. 2019, 3, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Keshk, S.M.A.S. Bacterial Cellulose Production and its Industrial Applications. J. Bioprocess. Biotech. 2014, 4, 1–10. [Google Scholar] [CrossRef]

- Ross, P.; Mayer, R.; Benziman, M. Cellulose Biosynthesis and Function in Bacteria. J. Microb. Rev. 1991, 55, 35–58. [Google Scholar] [CrossRef] [Green Version]

- Sani, A.; Dahman, Y. Improvements in The Production of Bacterial Synthesized BiocelluloseNanofibres Using Different Culture Methods. J. Chem. Technol. Biotechnol. 2010, 85, 151–164. [Google Scholar]

- Moosavi-Nasab, M.; Yousefi, M. Biotechnological Production of Cellulose by Gluconacetobacter Xylinus from Agricultural Waste. Iran. J. Biotechnol. 2011, 9, 94–101. [Google Scholar]

- Morgan, J.L.; Strumillo, J.; Zimmer, J. Crystallographic snapshot of cellulose synthesis and membrane translocation. Nature 2013, 493, 181–186. [Google Scholar] [CrossRef] [Green Version]

- Brown, R.M. Cellulose structure and biosynthesis: What is in store for the 21st century? J. Polym. Sci. Polym. Chem. 2004, 42, 487–495. [Google Scholar] [CrossRef]

- Esa, F.; Tasirin, S.M.; Rahman, N.A. Overview of Bacterial Cellulose Production and Application. Agric. Agric. Sci. Procedia 2014, 2, 113–119. [Google Scholar] [CrossRef] [Green Version]

- Karim, Z.; Afrin, S. Bacterial cellulose: Preparation and characterization. In Cellulose-Reinforced Nanofibre Composites; Woodhead Publishing: Cambridge, UK, 2017; pp. 327–340. [Google Scholar]

- Mitrofanov, R.Y.; Budaeva, V.V.; Sakovich, G.V. Preparation and Properties of Bacterial Cellulose Gel Films. Chem. Sustain. Dev. 2010, 18, 503–508. [Google Scholar]

- Chawla, P.R.; Bajaj, I.B.; Survase, S.A.; Singhal, R.S. Fermentative Production of Microbial Cellulose. Food Technol. Biotechnol. 2009, 47, 107–124. [Google Scholar]

- Li, Y.; Tian, C.; Tian, H.; Zhang, J.; He, X.; Ping, W.; Lei, H. Improvement of bacterial cellulose production by manipulating the metabolic pathways in which ethanol and sodium citrate involved. Appl. Microbiol. Biotechnol. 2012, 96, 1479–1487. [Google Scholar] [CrossRef] [PubMed]

- Czaja, W.; Romanovicz, D.; Brown, R.M. Structural investigations of microbial cellulose produced in stationary and agitated culture. Cellulose 2004, 11, 403–411. [Google Scholar] [CrossRef]

- Watanabe, K.; Tabuchi, M.; Morinaga, Y.; Yoshinaga, F. Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose 1998, 5, 187–200. [Google Scholar] [CrossRef]

- Prashnt, C.; Ishwar, B.; Shrikant, S.; Singhal, R.S. Microbial Cellulose: Fermentative Production and Applications. Food Technol. Biotechnol. J. 2009, 47, 107–124. [Google Scholar]

- Vitta, S.; Thiruvengadam, V. Multifunctional bacterial cellulose and nanoparticle-embedded composites. Curr. Sci. 2012, 102, 1398–1405. [Google Scholar]

- Hestrin, S.; Schramm, M. Synthesis of cellulose by Acetobacterxylinum. II. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem. J. 1954, 58, 345–352. [Google Scholar] [CrossRef] [Green Version]

- Kleem, D.; Schumann, D.; Udhardt, U.; Marsch, S. Bacterial synthesized cellulose - Artificial blood vessels for microsurgery. Prog. Polym. Sci. 2001, 26, 1561–1603. [Google Scholar] [CrossRef]

- Rangaswamy, B.E.; Vanitha, K.P.; Hungund, B.S. Microbial Cellulose Production from Bacteria Isolated from Rotten Fruit. Int. J. Polym. Sci. 2015, 2015, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Niyazbekova, Z.T.; Nagmetova, Z.H.; Kurmanbayev, A.A. An Overview of Bacterial Cellulose Applications. Natl. Cent. Biotechnol. 2018, 2, 1–17. [Google Scholar] [CrossRef]

- Radotic, K.; Micic, M. Methods for Extraction and Purification of Lignin and Cellulose from Plant Tissues. In Sample Preparation Techniques for Soil, Plant, and Animal Samples; Springer Protocols Handbooks; Micic, M., Ed.; Humana Press: New York, NY, USA, 2016; pp. 365–376. [Google Scholar] [CrossRef]

- Park, S.U.; Lee, B.K.; Kim, M.S.; Park, K.K.; Sung, W.J.; Kim, H.Y.; Han, D.G.; Shim, J.S.; Lee, Y.J.; Kim, S.H.; et al. The possibility of microbial cellulose for dressing and scaffold materials. Int. Wound J. 2014, 11, 35–43. [Google Scholar] [CrossRef] [PubMed]

- Costa, A.F.S.; Almeida, F.C.G.; Vinhas, G.M.; Sarubbo, L.A. Production of Bacterial Cellulose by Gluconacetobacterhansenii Using Corn Steep Liquor As Nutrient Sources. Front. Microbiol. 2017, 8, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Mohite, B.V.; Koli, S.; Patil, S.V. Bacterial Cellulose-Based Hydrogels: Synthesis, Properties, and Applications. In Cellulose-Based Superabsorbent Hydrogels. Polymers and Polymeric Composites: A Reference Series; Mondal, M., Ed.; Springer: Cham, Germany, 2018; pp. 1255–1276. [Google Scholar] [CrossRef]

- Wu, D.; Li, X.; Shen, C.; Lu, J.; Chen, J.; Xie, G. Decreased ethyl carbamate generation during Chinese rice wine fermentation by disruption of CAR1 in an industrial yeast strain. Int. J. Food Microbiol. 2014, 180, 19–23. [Google Scholar] [CrossRef] [PubMed]

- Czaja, W.K.; Young, D.J.; Kawecki, M.J.R. The future prospects of microbial cellulose in biomedical applications. Biomacromolecules 2007, 8, 1–12. [Google Scholar] [CrossRef]

- Eming, S.; Smola, H.; Kreig, T. Treatment of chronic wounds: State of the art and future concepts. Cell. Tissues Org. 2002, 172, 105–117. [Google Scholar] [CrossRef]

- Fontana, J.D.; de Sous, A.M.; Fontana, C.K.; Torriani, I.L.; Moreschi, J.C.; Gallotti, B.J.; De Souza, S.J.; Narcisco, G.P.; Bichara, J.A.; Farah, L.F.X. Acetobacter cellulose pellicle as a temporary skin substitute. Appl. Biochem. Biotechnol. 1990, 24, 253–264. [Google Scholar] [CrossRef]

- Okiyama, A.; Motoki, M.; Yamanaka, S. Bacterial cellulose IV. Application to processed foods. Food Hydrocoll. 1993, 6, 503–511. [Google Scholar] [CrossRef]

- Tsalagkas, D.; Dimic-Misic, K.; Gane, P. Rheological behaviour of sonochemically prepared bacterial cellulose aqueous dispersion. In Proceedings of the SIE 2015, Belgrade, Serbia, 24–25 September 2015. [Google Scholar]

- Bhat, A.H.; Dasan, Y.K.; Khan, I.; Soleimani, H.; Usmani, A. Application of nanocrystalline cellulose: Processing and biomedical applications. In Cellulose-Reinforced Nanofibre Composites: Production, Properties and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 215–240. [Google Scholar] [CrossRef]

- Flory, P.J. Phase equilibria in solutions of rod-like particles. Proc. R. Soc. 1956, A234, 73–88. [Google Scholar]

- Kadar, R.; Fazilati, M.; Nypelo, T. Unexpeted microphase transitions in flow towards nematic order of cellulose nanocrystals. Cellulose 2020, 27, 2003–2024. [Google Scholar] [CrossRef] [Green Version]

- Dimic-Misic, K.; Maloney, T.; Gane, P. Effect of fibril length, aspect ratio and surface charge on ultralow shear-induced structuring in micro and nanofibrillated cellulose aqueous suspensions. Cellulose 2018, 25, 117–136. [Google Scholar] [CrossRef]

- Dimic-Misic, K.; Vanhatal, K.; Dahl, O.; Gane, P. Rheological Properties Comparison of Aqueous Dispersed Nanocellulose Derived from a Novel Pathway-produced Microcrystalline Cellulose or by Conventional Methods. Appl. Rheol. 2018, 28, 1–15. [Google Scholar]

- Rudraraju, V.S.; Wyandt, C.M. Rheological characterization of Microcrystalline Cellulose/Sodiumcarboxymethyl cellulose hydrogels using a controlled stress rheometer: Part I. Int. J. Pharm. 2005, 292, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Papkov, S.P.; Kulichikhin, V.G.; Kalmykova, V.D. Rheological properties of poly-p-benzamide solutions. J. Polym. Sci. Polym. Phys. Ed. 1974, 12, 1753–1764. [Google Scholar] [CrossRef]

- Shafiei-Sabet, S.; Hamad, W.Y.; Hatzikiriakos, S.G. Rheology of Nanocrystalline Cellulose Aqueous Suspensions. Langmuir 2012, 28, 17124–17133. [Google Scholar] [CrossRef] [PubMed]

- Kulichikhin, V.G.; Malkin, A.Y.; Papkov, S.P. Rheological criteria of transition of the poly-p-benzamide solutions into LC state. Polym. Sci. 1974, 16A, 169–179. [Google Scholar]

- Bercea, M.; Navard, P. Shear Dynamics of Aqueous Suspensions of Cellulose Whiskers. Macromolecules 2000, 33, 6011–6016. [Google Scholar] [CrossRef]

- Peng, B.L.; Dhar, N.; Liu, H.L.; Tam, K.C. Chemistry and Applications of Nanocrystalline Cellulose and its Derivatives: A Nanotechnology Perspective. Can. J. Chem. Eng. 2011, 89, 1191–1206. [Google Scholar] [CrossRef]

- Phanthong, P.; Reubroycharoen, P.; Hao, X.; Xu, G.; Abudula, A.; Guana, G. Nanocellulose: Extraction and application. Carbon Resour. Convers. 2018, 1, 32–43. [Google Scholar] [CrossRef]

- Autlov, S.A.; Bazarnova, N.G.; Kushnir, E.Y. Microcrystalline cellulose: Structure, properties and applications (review). Khimija Rastitel’nogo Syr’ja. 2013, 3, 33–41. [Google Scholar] [CrossRef]

- Michael, I.; Alex, L. Structural characteristics and rheological properties of microcrystalline cellulose. Cell. Chem. Technol. 2006, 40, 699–703. [Google Scholar]

- Gromovykh, T.I.; Danilchuk, T.N.; Hanh, P.M. Gluconacetobacter Hansenii gh-1/2008 Bacterial Strain—Bacterial Cellulose Producer. Russian Patent 2464307, 20 October 2012. [Google Scholar]

- Burlawar, S.; Klingenberg, D.J.; Root, T.W.; Schlafmann, K.; Scott, C.T. Effect of temperature on the rheology of concentrated fiber suspensions. J. Rheol. 2019, 63, 677–691. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vinogradov, M.I.; Makarov, I.S.; Golova, L.K.; Gromovykh, P.S.; Kulichikhin, V.G. Rheological Properties of Aqueous Dispersions of Bacterial Cellulose. Processes 2020, 8, 423. https://0-doi-org.brum.beds.ac.uk/10.3390/pr8040423

Vinogradov MI, Makarov IS, Golova LK, Gromovykh PS, Kulichikhin VG. Rheological Properties of Aqueous Dispersions of Bacterial Cellulose. Processes. 2020; 8(4):423. https://0-doi-org.brum.beds.ac.uk/10.3390/pr8040423

Chicago/Turabian StyleVinogradov, Markel I., Igor S. Makarov, Lyudmila K. Golova, Peter S. Gromovykh, and Valery G. Kulichikhin. 2020. "Rheological Properties of Aqueous Dispersions of Bacterial Cellulose" Processes 8, no. 4: 423. https://0-doi-org.brum.beds.ac.uk/10.3390/pr8040423