Dining Lampblack Treatment Processes in China

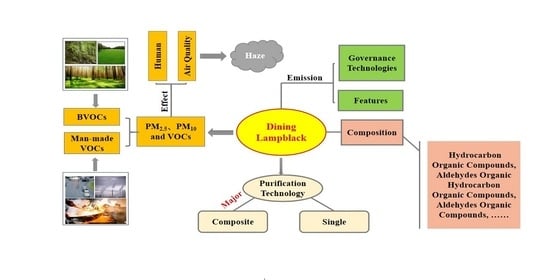

Abstract

:1. Introduction

1.1. Features and Hazards of Dining Lampblack

1.2. Hazards of Dining Lampblack

2. Control Policies and Treatment Status of Dining Lampblack

2.1. Control Policies

2.2. Treatment Status

3. Purification Processes and Prospects

3.1. Lampblack Purification Processes

3.2. VOCs Treatment Processes

3.3. Technical Outlook

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, F.G.; Wang, T.; Chen, H.Q.; Liu, Q.; Li, P.S.; Bo, Y.J.; Xu, L.W. Characteristics of cooking fume emission. In Proceedings of the 2002 Annual Meeting of the Chinese Granulation Society and the Cross-Strait Symposium on Granulation Technology, Guilin, China, 28 November–4 December 2002; p. 5. [Google Scholar]

- Penuelas, J.; Staudt, M. BVOCs and global change. Trends Plant Sci. 2010, 15, 133–144. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.Y.; Li, X.; Chen, J.M. Study on transformation mechanism of SOA from biogenic VOC under UV-B Condition. Environ. Sci. 2011, 32, 3588–3592. [Google Scholar]

- Yao, H.Y.; Shi, L.Y. Meta-analysis of risk factors for lung cancer morbidity in Chinese population. Chin. J. Epidemiol. 2003, 1, 51–55. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment of the People’s Republic of China. Emission Standard of Cooking Fume (Trial); GB 18483-2001; Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2001.

- Li, Q.Q.; Wu, A.H.; Gong, D.C.; Wang, B.G.; Luan, S.J. Research Progress on Pollution Characteristics of PM2.5 Emissions from Catering Sources. Environ. Sci. Technol. 2018, 41, 41–50. [Google Scholar] [CrossRef]

- Deng, Z.X. Analysis on The Formation, Endanger and Purification Technology of The Restaurant Industry Soot. Arid Environ. Monit. 2008, 22, 246–248. [Google Scholar] [CrossRef]

- Chung, T.Y.; Eiserich, J.P.; Shibamoto, T. Volatile compounds identified in headspace samples of peanut oil heated under temperatures ranging from 50 to 200 °C. J. Agric. Food Chem. 1993, 41, 1467–1470. [Google Scholar] [CrossRef]

- Wang, Y.X.; Li, S.G.; Zhang, H.; Yin, L.H.; Pu, Y.P. Analysis of chemical components of refined edible oil and its heating products. China J. Mod. Med. 1999, 6, 364–366. [Google Scholar] [CrossRef]

- Li, L.X.; Cheng, Y.; Du, X.; Dai, Q.L.; Wu, J.H.; Bi, X.H.; Feng, Y.C. Chemical composition spectra of PM2.5 emitted from six food and beverage sources. Res. Environ. Sci. 2021, 34, 71–78. [Google Scholar] [CrossRef]

- Cui, T.; Cheng, J.C.; He, W.Q.; Ren, P.F.; Nie, L.; Xu, D.Y.; Pan, T. Study on VOCs Emission Characteristics of Typical Catering Enterprises in Beijing. Environ. Sci. 2015, 36, 1523–1529. [Google Scholar] [CrossRef]

- Xu, H.; Ta, W.; Yang, L.; Feng, R.; He, K.; Shen, Z.; Meng, Z.; Zhang, N.; Li, Y.; Zhang, Y.; et al. Characterizations of PM2.5-bound organic compounds and associated potential cancer risks on cooking emissions from dominated types of commercial restaurants in northwestern China. Chemosphere 2020, 261, 127758. [Google Scholar] [CrossRef]

- Pei, B.; Cui, H.; Liu, H.; Yan, N. Chemical characteristics of fine particulate matter emitted from commercial cooking. Front. Environ. Sci. Eng. 2016, 10, 559–568. [Google Scholar] [CrossRef]

- Dou, X.Y.; Zhao, X.Y.; Xu, X.; Gao, H.P.; Li, T.; Ding, M.M.; Liu, Y.; Han, B.; Bai, Z.P. Application of Chemical Mass Balance Model to Source Apportionment of PM2.5 in Xining. Environ. Monit. China 2016, 32, 7–14. [Google Scholar] [CrossRef]

- Torkmahalleh, M.A.; Goldasteh, I.; Zhao, Y.; Udochu, N.M.; Rossner, A.; Hopke, P.K.; Ferro, A.R. PM2.5 and ultrafine particles emitted during heating of commercial cooking oils. Indoor Air 2012, 22, 483–491. [Google Scholar] [CrossRef]

- Zhang, T.; Peng, L.; Li, Y.H.; Liu, H.L.; Wang, Y.X.; Wang, Y. Chemical characteristics of PM2.5 emitted from cooking fumes. Res. Environ. Sci. 2016, 29, 183–191. [Google Scholar] [CrossRef]

- Zhou, J.W.; Zhao, L.; Chen, J. Effects of cooking oil fume on serum lipid peroxides and blood lipids in dietetic workers. Ningxia Med. J. 2010, 32, 539–540. [Google Scholar] [CrossRef]

- Lin, Q.H.; Xu, Y.Q.; Chen, G.X.; You, K.L.; Zheng, N.X. Effect of cooking oil fume on reproductive health of female workers. Occup. Health 2012, 28, 303–305. [Google Scholar] [CrossRef]

- Peng, C.Y.; Lan, C.H.; Lin, P.C.; Kuo, Y.C. Effects of cooking method, cooking oil, and food type on aldehyde emissions in cooking oil fumes. J. Hazard. Mater. 2017, 324, 160–167. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.L.; Chen, Z.J.; Yue, B.H. Epidemiological characteristics and risk factors of primary lung cancer in women. Mod. Pract. Med. 2018, 30, 1433–1436. [Google Scholar]

- Pope, C.A., III.; Burnett, R.T.; Thun, M.J. Lung cancer: Cardiopulmonary mortality.; and long-term exposure to fine particulate air pollution. JAMA J. Am. Med. Assoc. 2002, 9, 1132–1141. [Google Scholar] [CrossRef] [Green Version]

- Chen, T.Y.; Fang, Y.H.; Chen, H.L.; Chang, C.H.; Huang, H.; Chen, Y.S.; Liao, K.M.; Wu, H.Y.; Chang, G.C.; Tsai, Y.H.; et al. Impact of cooking oil fume exposure and fume extractor use on lung cancer risk in non-smoking Han Chinese women. Sci. Rep. 2020, 10, 6774. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fu, H.H.; Tian, N.; Shang, H.B.; Zhang, B.; Ye, S.F.; Chen, X.Q.; Wu, S.Q. Study on particle size distribution of simulated particles and polycyclic aromatic hydrocarbons from different emission sources. Environ. Sci. 2014, 35, 46–52. [Google Scholar] [CrossRef]

- Engling, G.; Gelencser, A. Atmospheric Brown Clouds, From Local Air Pollution to Climate Change. Elements 2010, 6, 223–228. [Google Scholar] [CrossRef]

- Zhong, S.; Zhang, L.S.; Jiang, X.Y.; Gao, P. Comparison of chemical composition and airborne bacterial community structure in PM2.5 during haze and non-haze days in the winter in Guilin, China. Sci. Total Environ. 2019, 655, 202–210. [Google Scholar] [CrossRef] [PubMed]

- Stolarski, R.S.; Douglass, A.R.; Oman, L.D.; Waugh, D.W. Impact of future nitrous oxide and carbon dioxide emissions on the stratospheric ozone layer. Environ. Res. Lett. 2015, 10, 6. [Google Scholar] [CrossRef]

- Wang, S.B.; Su, W.H.; Wei, D.W. The relationship between the biologically effective radiation of the sun’s ultraviolet rays and the reduction of atmospheric ozone content. Acta Sci. Circumstantian 1993, 1, 114–120. [Google Scholar] [CrossRef]

- Ye, F.; Huang, P. Effects of Intensive Ultraviolet Radiation on Asphalt Performance. J. Tongji Univ. (Nat. Sci.) 2005, 7, 909–913. [Google Scholar] [CrossRef]

- Liu, D.Q.; Tan, X.J. Pollution and treatment of cooking fume in catering industry. Fujian Environ. 2002, 05, 40–42. [Google Scholar]

- Lu, Y. Influence of cooking oil fume on air pollution and its countermeasures. Resour. Conserv. Environ. Prot. 2019, 7, 2. [Google Scholar] [CrossRef]

- Yu, J.H.; Wang, Y.P.; Bian, D.W.; Bian, S.C. Comparison and discussion on emission standards of cooking fume pollution in catering industry. Environ. Prot. Circ. Econ. 2016, 36, 56–60. [Google Scholar] [CrossRef]

- Hu, J.J.; Li, C.M.; Zheng, Y.T.; Li, X.X.; Xu, S.M. The requirements of cooking fume control and the status and analysis of emission standards in Chinese catering industry. In Proceedings of the 2018 Science and Technology Annual Meeting of the Chinese Society of Environmental Sciences, Hefei, China, 10–13 November 2018. [Google Scholar]

- Ministry of Ecology and Environment of the People’s Republic of China. Law of the People’s Republic of China on the Prevention and Control of Air Pollution; Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China, 2018.

- Yang, C.W. Study on the Transformation Design and Operation Parameter Optimization of the Cooking Fume Purification Process in University Canteen; Lanzhou University: Lanzhou, China, 2019. [Google Scholar] [CrossRef]

- Gysel, N.; Welch, W.A.; Chen, C.L.; Dixit, P.; Cocker, D.R.; Karavalakis, G. Particulate matter emissions and gaseous air toxic pollutants from commercial meat cooking operations. J. Environ. Sci. 2018, 65, 162–170. [Google Scholar] [CrossRef] [Green Version]

- Li, J.L. Preliminary Study on Catalysts for Oil Fume and Exhaust Gas Purification with Electrically Heated Active Metal Wires. J. Shaoxing Univ. Arts Sci. 2001, 1, 60–63. [Google Scholar] [CrossRef]

- Ye, C.M. Study on Catalytic Purification of Oil Fume; Zhengzhou University: Zhengzhou, China, 2002. [Google Scholar] [CrossRef]

- Feng, T.C.; Yi, H.H.; Tang, X.L.; Wang, Y.W.; Huang, Y.H.; Ma, Y.Q.; Yang, Q.; Cui, X.X. Research progress of cooking fume pollution and its purification technology. Mod. Chem. Ind. 2017, 37, 20–23. [Google Scholar] [CrossRef]

- Huang, Y.H.; Yi, H.H.; Tang, X.L.; Zhao, S.Z.; Feng, T.C. Research progress of catalytic combustion technology for purification of oil fume. Chem. Ind. Eng. Prog. 2017, 36, 1270–1277. [Google Scholar] [CrossRef]

- Xu, F.C.; Gao, H.Q.; Wu, M.G.; Cheng, X.M. Experimental study on swirl purifier for cooking fume in catering industry. Environ. Pollut. Control 2000, 2, 12–13. [Google Scholar] [CrossRef]

- Ma, J.Y.; Mo, X.M.; Wang, Z.W.; Liao, X.Q.; Ding, C.; Li, N.; Gao, X.J. Development Status of Cooking Fume Purification Industry in Catering Industry. China Environ. Prot. Ind. 2020, 9, 25–28. [Google Scholar]

- Cheng, J.C.; Cui, T.; He, W.Q.; Nie, L.; Wang, J.L.; Pan, T. Pollution characteristics of aldehydes and ketones in cooking fumes from typical catering enterprises in Beijing. Environ. Sci. 2015, 36, 2743–2749. [Google Scholar] [CrossRef]

- Shao, Z.H.; Wei, B.L.; Ye, Z.P.; He, Y.; Shi, Y. Treatment of exhaust gas from spray paint process with plasma-photocatalytic method. J. Zhejiang Univ. (Eng. Sci.) 2014, 48, 1127–1131. [Google Scholar] [CrossRef]

- Zhang, X.; Qian, Z.Q.; Zhang, D.F.; Zhu, T.; Yuan, Q.C.; Ye, Z.F. Research progress of cooking fume emission characteristics and purification technologies. Environ. Eng. 2020, 38, 37–61. [Google Scholar] [CrossRef]

- Mi, J.F.; Pei, D.M.; Du, S.N.; Dong, M.; Li, X.L. Experiments on removing fume and smell of cooking fume composite purifier. Chem. Ind. Eng. Prog. 2015, 34, 4403–4406, 4421. [Google Scholar] [CrossRef]

- Zhao, Q.C.; Chen, C.M.; Zhang, J.T.; Hu, P.J.; Zhang, X.J. Performance of cooking aerosol treatment in China catering: A review and assessment. Pol. J. Environ. Stud. 2021, 2, 1923–1933. [Google Scholar] [CrossRef]

| Pollutant Item | Emission Limit (mg/m3) | Pollutant Emission Monitoring Location |

|---|---|---|

| Dining lampblack | 1.0 | Lampblack exhaust funnel or purifying facility discharge outlet |

| Total hydrocarbon | 10 |

| Purifying Technology | Purifying Principle | Advantages | Disadvantages | Application Situation |

|---|---|---|---|---|

| Oxidative Incineration Technology | The particulate matter and VOCs in the cooking fume are oxidized with oxygen and converted into harmless substances after full combustion. | Purification efficiency is high; low emission of nitrogen oxides | A large amount of oxygen is required to be introduced; equipment cost is high; inconvenient maintenance | Large-scale fried food and beverage industry and the enterprise |

| Catalytic Oxidation Technology | The organic substances in the cooking fume are catalytically converted into carbon dioxide and water. | Purification effect is strong; can remove that peculiar smell of oil smoke | The equipment cost is high; purification effect is greatly influenced by the type and efficiency of catalyst | Small and medium-sized catering industry and family kitchen |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, W.; Ye, J.; Chen, X.; Wang, G.; Li, S.; Wang, H.; Li, H.; Zhang, H. Dining Lampblack Treatment Processes in China. Processes 2021, 9, 2241. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9122241

Hu W, Ye J, Chen X, Wang G, Li S, Wang H, Li H, Zhang H. Dining Lampblack Treatment Processes in China. Processes. 2021; 9(12):2241. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9122241

Chicago/Turabian StyleHu, Wanpeng, Jumei Ye, Xiaozhen Chen, Guoying Wang, Sen Li, Hui Wang, Hong Li, and Haiping Zhang. 2021. "Dining Lampblack Treatment Processes in China" Processes 9, no. 12: 2241. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9122241