4.1. Temperature Distribution

The parameter chosen as input for the simulation is the average heat source at the wall equal to 5990 W/m

2 previously calculated. The results are presented in

Figure 10 and show AISI 310 and Inconel 625 and their temperature profile at a constant time value of 28 min. A fixed time value was chosen to evaluate which material can guarantee a higher temperature on the internal side of the pipe. The value settled for both simulations with AISI 310 and Inconel 625 is 28 min.

Figure 11 shows the difference in the temperature profile between the two materials at the same fixed time value. This was decided to choose the most suitable material for the exchanger. The higher the reached temperature, the higher will be the production of thermal energy. This is why it is important to verify which material reaches the highest exchange temperature with the fluid.

The results presented above easily demonstrate how AISI 310 allows to reach a temperature of about 876 °C, whereas, in the same amount of time, 28 min, Inconel 625’s temperature profile enables the system to reach a temperature equal to 856 °C. Therefore, AISI 310 was chosen as the design material for the heat exchanger. By imposing the same time on the two different simulations, it is clear that the most suitable material for this application is AISI 310 because it allows the system to reach a higher interface temperature than Inconel 625. These two materials are used by Genoastirling as materials for the exchanger section.

The third and final simulation sets itself the objective to simulate the fluid flow inside the pipe for the evaluation of the temperature reached by air, the heat carrier for the engine, inside the hot side of the heat exchanger. This step has to be preceded by the fluid regime evaluation. It is very important to evaluate the fluid flow also to set the final simulation on COMSOL Multiphysics 5.3. In addition, by calculating the Reynolds and Prandtl number, it will also be possible to calculate the Nusselt number. The Nusselt number is useful to calculate the heat transfer coefficient, a value that has to be implemented in the simulation to calculate the final temperature achieved by the fluid inside the pipe.

Through Aspen Plus V9, the main physical properties of the system have been calculated at an average temperature of 500 °C and at the indicated average pressure of the cycle equal to 15 bar.

Table 5 reports the main parameters for the calculation of the Reynolds and Prandtl number.

The results shown in

Table 5 provide the following values for Reynolds and Prandtl numbers:

where:

is the fluid density, kg/m3;

is the average velocity of the fluid, m/s;

Dh is the hydraulic diameter, m;

is the dynamic viscosity of the fluid, Pa·s;

Cp is the specific heat at constant pressure of the fluid, J/kg/K;

k is the thermal conductivity of the fluid, W/m/K.

The Reynolds number calculated confirms that the flow of the fluid inside the pipe is turbulent and it is possible to calculate the Nusselt number by using the Dittus–Boelter correlation. The Nusselt number is in turn used to calculate the heat transfer coefficient.

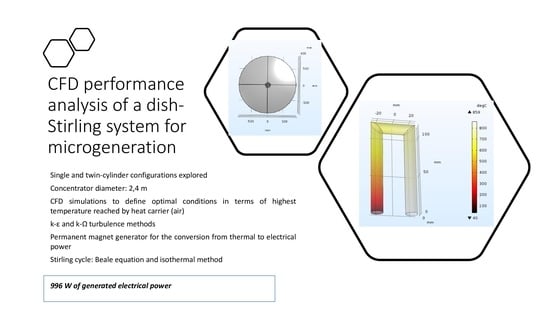

The multiphysics simulation can now be implemented to study the temperature profile of the fluid inside the heat exchanger. The two physics chosen for the simulation are: “heat transfer in fluids” and “turbulent flow”. As far as the latter is concerned, two methods for turbulent flow study have been compared: k-ε and k-Ω, with an internal pressure at the inlet of the pipe equal to 15 bar with a constant fluid velocity of 15 m/s. The former, instead, can simulate the external conditions of 890 °C of external temperature and can also be used to insert the convective heat transfer coefficient previously calculated. The inlet temperature of the gas is equal to 40 °C for the Stirling cycle. The results are shown in

Figure 11.

The results shown in

Figure 11 provide an equal final temperature with both turbulent methods: 859 °C. This value guarantees a value of pressure equal to 21 bar, comparable with the literature results [

25].

This temperature value is high enough to start the Stirling cycle (700 °C) for the Genoastirling engine. This value of temperature can be used to simulate the Stirling cycle for the energy output of this system.

4.2. Real Stirling Cycle Analysis

The results obtained in the previous paragraphs are extremely useful to analyze a real Stirling cycle. The approach used in this section follows a two-step methodology: the first method used to calculate the thermal power output is the empirical Beale equation, a first-order method that provides an initial value for the power generated. This value has to be compared to a more accurate method: the second-order Schmidt analysis, which can provide a more detailed model for the value of thermal power [

26].

The first-order empirical analysis is based on the Beale equation:

where

P is the thermal power, expressed in kW;

p is the average pressure in the cycle, bar;

f is the frequency of the cycle, Hz;

V0 is the displacement of the power piston, expressed in cm3;

Be is the “Beale Number”, a dimensionless parameter.

The information required to perform this calculation is reported in

Table 6.

The Beale equation provides an empirical simplified estimation of thermal power. This method could be used to verify the validity of this equation and add more effectiveness to the simulation.

The second-order method is known as the “Schmidt analysis” and uses as simplification the isothermal transformation of both the expansion and the compression side. The temperature profile of the regenerator is constant as well and calculated as the logarithmic mean of the first two. The three sections of the engine are simplified as shown in

Figure 12 [

27,

28].

This method is a simplified method as well and for an even more thorough analysis, the adiabatic model must be implemented. Therefore, discrepancies are expected between the calculated values with this method and the values measured experimentally.

Since the α-Stirling engine is a two-piston configuration, the model can be simplified using the equation presented by G. Walker in the 1980 “Stirling engines” manual [

29], whose equation is presented as follows:

The output of the equation, in this case, is the work per cycle of the Stirling cycle. This equation is also a function of three parameters:

These parameters have been calculated starting from the geometric and operative parameters of the engine. In

Table 7, the list of parameters and their respective values used for the calculation are reported. The results of such calculation can be highlighted in the bottom part of the table.

The result obtained through the Walker equation is comparable to the value obtained with the Beale equation. The two results are comparable: 1.18 kW for the Beale equation and 1.12 kW for the Walker equation.

As previously stated, these two methods provide estimated values of thermal output, but since the two values are very close, it is possible to confirm that the expected experimental values measured with this system will not have significant discrepancies with the calculated ones.

The cycle efficiency has been set at 30%. This value comes directly from Walker’s Stirling Engine Design Manual. In this work, the worst-case scenario presented by Walker has been evaluated and therefore the most pessimistic value.

This claim is supported by data found in literature which prove that efficiencies in Stirling engines range between high-20’s up to 42% [

30].

By using these two methods, we can conclude that the value of thermal power that the system is able to produce in these conditions is 1.12 kW.

The last section of the analysis is the coupling of the system with a permanent magnet generator to verify the electrical output of the dish-Stirling. For a complete system, the Mecc Alte Eogen [

31] generator can be coupled for the generation of electrical energy. The efficiency of generation for the chosen generator is 88%. In conclusion, the result of the entire analysis is presented in

Table 8.

As shown in

Table 8, an irradiance value of 800 W/m

2 allows the system to produce 996 W of electrical power.

The result of the simulation shows that a single-cylinder configuration of the engine with AISI 310 as coating material can allow the heat carrier fluid to reach a temperature of 859 °C.

This value can be used for the thermal energy production analysis, with an approximate resulting thermal power produced of 1.12 kW. Being the efficiency of the permanent magnet generator for this specific case equal to 88%, the resulting production of electrical energy is equal to 996 W. The result is in line with the expected results gained from the literature [

32,

33].

Furthermore, the specifics of the Genoastirling ML1000 single-cylinder Stirling engine set the maximum electrical power produced by the engine at 1.1 kW. This experimental value is close to the result obtained under similar conditions [

34]. Therefore, it is possible to surmise that the electrical power produced by this technology, taking into consideration all the losses caused by the many components present in the system, is around 1 kW for a solar parabolic concentrator with a diameter of 2.4 m.

This result was compared with a much bigger CSP system with a production of 25 kW of electrical power simulated in similar conditions [

35]. Obviously, since the diameter of the concentrator taken as comparison is much bigger (12.5 m

2 of diameter), the value taken for comparison is the power to area ratio to verify the effectiveness of the simulation. The modularity of the CSP technology should allow to obtain similar data from different sizes of concentrators.

In fact, the comparison from the simulation from literature allows to obtain a power-to-surface ratio equal to 0.204 kW/m

2. The current study simulated from Politecnico di Torino instead enables to reach a power-to-surface ratio equal to 0.205 kW/m

2. The results based on G. Walker’s analysis [

29] showed that a CSP system is useful for micro-generation purposes. The simulation is in line with both data from similar size concentrators and with scaled concentrators with bigger sizes.

Table 9 [

36] compares the real efficiency of the Stirling engine mounted in various cities. This shows that the efficiency of the engine for small-scale microgeneration applications is stable between the high 20′s and 40%, with fluctuations during the different months of the year. The solar irradiance has also been compared to the same microgeneration systems to verify the validity of the simulation.

Figure 13 shows irradiance values, which are coherent with the value recorded from this article.