Reusable Water Bottles: Release of Inorganic Elements, Phthalates, and Bisphenol A in a “Real Use” Simulation Experiment

Abstract

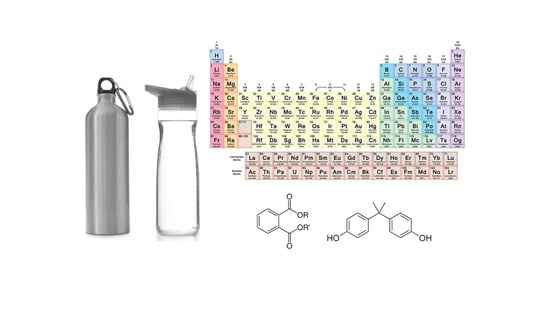

:1. Introduction

2. Materials and Methods

2.1. Selection of Reusable Water Bottles and Experimental Planning

2.2. Instrument

2.3. Materials, Reagents, and Standard Solutions

2.4. Elemental Analysis

2.5. PAEs and BP-A Analysis

2.6. Data Elaboration

3. Results and Discussion

3.1. Main Results of the Experimental Tests

3.2. Possible Consumers’ Health Risks from Reusable Water Bottles Use

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Directive (EU) 2019/904 of the European Parliament and of the Council on the Reduction of the Impact of Certain Plastic Products on the Environment. 2019. Available online: https://eur-lex.europa.eu/eli/dir/2019/904/oj (accessed on 20 August 2021).

- Tamburini, E.; Costa, S.; Summa, D.; Battistella, L.; Fano, E.A.; Castaldelli, G. Plastic (PET) vs bioplastic (PLA) or refillable aluminium bottles—What is the most sustainable choice for drinking water? A life-cycle (LCA) analysis. Environ. Res. 2021, 196, 110974. [Google Scholar] [CrossRef]

- Marazzi, L.; Loiselle, S.; Anderson, L.G.; Rocliffe, S.; Winton, D.J. Consumer-based actions to reduce plastic pollution in rivers: A multi-criteria decision analysis approach. PLoS ONE 2020, 15, e0236410. [Google Scholar] [CrossRef]

- Graydon, R.C.; Gonzalez, P.A.; Laureano-Rosario, A.E.; Pradieu, G.R. Bottled water versus tap water: Risk perceptions and drinking water choices at the University of South Florida. Int. J. Sustain. High. Educ. 2019, 20, 654–674. [Google Scholar] [CrossRef]

- Levêque, J.G.; Burns, R.C. Drinking water in West Virginia (USA): Tap water or bottled water—What is the right choice for college students? J. Water Health 2018, 16, 827–838. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Commission Regulation (EC), No.1935/2004 of the European Parliament and of the Council on Materials and Articles Intended to Come into Contact with FOOD and Repealing Directives 80/590/EEC and 89/109/EEC. 2004. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2004:338:0004:0017:en:PDF (accessed on 20 August 2021).

- Commission Regulation (EC), No. 2023/2006 on Good Manufacturing Practice for Materials and Articles Intended to Come into Contact with Food. 2006. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2006:384:0075:0078:EN:PDF (accessed on 20 August 2021).

- Legal Information Institute. The United States Code, Title 21—Food and Drugs. Available online: https://www.law.cornell.edu/uscode/text/21 (accessed on 3 August 2021).

- Food Standards Australia New Zealand. Food Standards Code. Available online: https://www.foodstandards.gov.au/code/Pages/default.aspx (accessed on 3 August 2021).

- The Japanese Food Sanitation Act. 1947. Available online: http://extwprlegs1.fao.org/docs/pdf/jap52285.pdf (accessed on 3 August 2021).

- Silveira, M.B.; Scudese, E.; Weber Senna, G.; Ferreira, A.P.; Dantas, E.H.M.; Pereira Ribero, L.C. Microbial contamination in shaker bottles among members of fitness centers. J. Exerc. Physiol. 2018, 21, 134. [Google Scholar]

- Sun, X.; Kim, J.; Behnke, C.; Almanza, B.; Greene, C.; Miller, J.; Schindler, B. The cleanliness of reusable water bottles: How contamination levels are affected by bottle usage and cleaning behaviors of bottle owners. Food Prot. Trends 2017, 37, 392–402. [Google Scholar]

- Hubbard, A.T.M.; Newire, E.; Botelho, J.; Reiné, J.; Wright, E.; Murphy, E.A.; Hutton, W.; Roberts, A.P. Isolation of an antimicrobial-resistant, biofilm-forming, Klebsiella grimontii isolate from a reusable water bottle. Microbiologyopen 2020, 9, e1023. [Google Scholar] [CrossRef] [Green Version]

- Mills, K.; Golden, J.; Bilinski, A.; Beckman, A.L.; McDaniel, K.; Harding, A.S.; France, A.; Napa Tobar, H.; Vecitis, C. Bacterial contamination of reusable bottled drinking water in Ecuador. J. Water Sanit. Hyg. Dev. 2018, 8, 81–89. [Google Scholar] [CrossRef]

- Cheng, X.; Shi, H.; Adams, C.D.; Ma, Y. Assessment of metal contaminations leaching out from recycling plastic bottles upon treatments. Environ. Sci. Pollut. Res. 2010, 17, 1323–1330. [Google Scholar] [CrossRef]

- Farid, S.M.; Enani, M.A.; Wajid, S.A. Determination of trace elements in cow’s milk in Saudi Arabia. J. Zhejiang Univ. Eng. Sci. 2004, 15, 131–140. [Google Scholar] [CrossRef]

- De la Guardia, M.; Garrigues, S. Handbook of Mineral Elements in Food; Wiley-Blackwell: Hoboken, NJ, USA, 2015; p. 792. [Google Scholar]

- Barros Paiva, R.; Neves, A.; Sequeira, V.; Cardoso, C.; Bandarra, N.; Serrano Gordo, L.; Nunes, M.L. Risks and benefits’ consumption of birdbeak dogfish Deania calcea. Br. Food J. 2012, 114, 826–839. [Google Scholar] [CrossRef]

- Wilkes, C.E.; Daniels, C.A.; Summers, J.W. PVC Handbook; Hanser Fachbuchverlag: Munchen, Deutschland, 2008; p. 701. [Google Scholar]

- Al-Shukri, S.; Mahmood, A.; Al-Hanbali, O.A. Thermal properties, adhesive strength, and optical transparency of cyclolinear poly(aryloxycyclotriphosphazenes). J. Appl. Polym. Sci. 2011, 122, 1058–1065. [Google Scholar] [CrossRef]

- Notardonato, I.; Protano, C.; Vitali, M.; Bhattacharya, B.; Avino, P. Phthalates and Bisphenol-A determination and release from different beverage plastic containers by dispersive liquid-liquid microextraction and GC-IT/MS analysis. Food Anal. Methods 2019, 12, 2562–2571. [Google Scholar] [CrossRef]

- Heudorf, U.; Mersch-Sundermann, V.; Angerer, J. Phthalates: Toxicology and exposure. Int. J. Hyg. Env. Health 2007, 210, 623–634. [Google Scholar] [CrossRef]

- Rudel, R.; Perovich, L. Endocrine disrupting chemicals in indoor and outdoor air. Atmos. Environ. 2008, 43, 170–181. [Google Scholar] [CrossRef] [Green Version]

- Zamkowska, D.; Karwacka, A.; Jurewicz, J.; Radwan, M. Environmental exposure to non-persistent endocrine disrupting chemicals and semen quality: An overview of the current epidemiological evidence. Int. J. Occup. Med. Environ. Health 2018, 31, 377–414. [Google Scholar] [CrossRef]

- Carlstedt, F.; Jönsson, B.G.; Bornehag, C.G. PVC flooring is related to human uptake of phthalates in infants. Indoor Air 2013, 23, 32–39. [Google Scholar] [CrossRef]

- Braun, J.M. Early-life exposure to EDCs: Role in childhood obesity and neurodevelopment. Nat. Rev. Endocrinol. 2017, 13, 161–173. [Google Scholar] [CrossRef] [Green Version]

- World Health Organization (WHO). Sustainable Development and Healthy Environments Cluster. Nutrients in Drinking Water. 2005. Available online: https://apps.who.int/iris/handle/10665/43403 (accessed on 3 August 2021).

- Li, N.; Ying, G.G.; Hong, H.; Po Keung Tsang, E.; Deng, W.J. Plasticizer contamination in the urine and hair of preschool children, airborne particles in kindergartens, and drinking water in Hong Kong. Environ. Pollut. 2021, 271, 116394. [Google Scholar] [CrossRef]

- Bach, C.; Rosin, C.; Munoz, J.F.; Dauchy, X. National screening study investigating nine phthalates and one adipate in raw and treated tap water in France. Environ. Sci. Pollut. Res. Int. 2020, 27, 36476–36486. [Google Scholar] [CrossRef]

- Yang, X.; Wang, C.; Shao, H.; Zheng, Q. Non-targeted screening and analysis of volatile organic compounds in drinking water by DLLME with GC–MS. Sci. Total Environ. 2019, 694, 133494. [Google Scholar] [CrossRef]

- Cantoni, B.; Penserini, L.; Vries, D.; Dingemans, M.M.L.; Bokkers, B.G.H.; Turolla, A.; Smeets, P.W.M.H.; Antonelli, M. Development of a quantitative chemical risk assessment (QCRA) procedure for contaminants of emerging concern in drinking water supply. Water Res. 2021, 194, 116911. [Google Scholar] [CrossRef]

- Yee Wee, S.; Zaharin Aris, A.; Md Yusoff, F.; Mangala Praveena, S. Tap water contamination: Multiclass endocrine disrupting compounds in different housing types in an urban settlement. Chemosphere 2021, 264, 128488. [Google Scholar] [CrossRef] [PubMed]

- Astolfi, M.L.; Protano, C.; Schiavi, E.; Marconi, E.; Capobianco, D.; Massimi, L.; Ristorini, M.; Baldassarre, M.E.; Laforgia, N.; Vitali, M.; et al. A prophylactic multi-strain probiotic treatment to reduce the absorption of toxic elements: In-vitro study and biomonitoring of breast milk and infant stools. Env. Int. 2019, 130, 104818. [Google Scholar] [CrossRef] [PubMed]

- Astolfi, M.L.; Marconi, E.; Protano, C.; Canepari, S. Comparative elemental analysis of dairy milk and plant-based milk alternatives. Food Control. 2020, 116, 107327. [Google Scholar] [CrossRef]

- Astolfi, M.L.; Protano, C.; Marconi, E.; Massimi, L.; Brunori, M.; Piamonti, D.; Migliara, G.; Vitali, M.; Canepari, S. A new treatment of human hair for elemental determination by inductively coupled mass spectrometry. Anal. Methods 2020, 12, 1906–1918. [Google Scholar] [CrossRef]

- Astolfi, M.L.; Di Filippo, P.; Gentili, A.; Canepari, S. Semiautomatic sequential extraction of polycyclic aromatic hydrocarbons and elemental bio-accessible fraction by accelerated solvent extraction on a single particulate matter sample. Talanta 2017, 174, 838–844. [Google Scholar] [CrossRef]

- Astolfi, M.L.; Conti, M.E.; Marconi, E.; Massimi, L.; Canepari, S. Effectiveness of different sample treatments for the elemental characterization of bees and beehive products. Molecules 2020, 25, 4263. [Google Scholar] [CrossRef]

- Lucentini, L.; Patriarca, M. Analytical reference methods for water intended for human consumption according to Legislative Decree 31/2001. Chemical methods. Rapp. ISTISAN Ist. Super. Sanità. 2019, 19, 1–187. [Google Scholar]

- Cooper, J.E.; Kendig, E.L.; Belcher, S.M. Assessment of bisphenol A released from reusable plastic, aluminium and stainless steel water bottles. Chemosphere 2011, 85, 943–947. [Google Scholar] [CrossRef] [Green Version]

- Kubwabo, C.; Kosarac, I.; Stewart, B.; Gauthier, B.R.; Lalonde, K.; Lalonde, P.J. Migration of bisphenol A from plastic baby bottles, baby bottle liners and reusable polycarbonate drinking bottles. Food Addit. Contam. Part A 2009, 26, 928–937. [Google Scholar] [CrossRef] [PubMed]

- Catarina Luís, C.; Algarra, M.; Câmara, J.S.; Perestrelo, R. Comprehensive insight from phthalates occurrence: From health outcomes to emerging analytical approaches. Toxics 2021, 9, 157. [Google Scholar] [CrossRef] [PubMed]

- Meeker, J.D.; Sathyanarayana, S.; Shanna, H.S. Phthalates and other additives in plastics: Human exposure and associated health outcomes. Phil. Trans. R. Soc. B 2009, 364, 2097–2113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Directive (EU) 2020/2184 of the European Parliament and of the Council of on the Quality of Water Intended for Human Consumption. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32020L2184 (accessed on 20 August 2021).

- World Health Organization (WHO). Barium in Drinking-Water: Background Document for Development of WHO Guide-Lines for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2016; Available online: https://www.who.int/water_sanitation_health/water-quality/guidelines/chemicals/barium-background-jan17.pdf (accessed on 3 August 2021).

- World Health Organization (WHO). Beryllium in Drinking-Water: Background DOCUMENT for development of WHO Guide-Lines for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2009; Available online: https://apps.who.int/iris/handle/10665/70172 (accessed on 3 August 2021).

- World Health Organization (WHO). Molybdenum in Drinking-Water: Background Document for Development of WHO Guidelines for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2011; Available online: https://apps.who.int/iris/handle/10665/75372 (accessed on 3 August 2021).

- Government of Canada. Guidelines for Canadian Drinking Water Quality: Guideline Technical Document–Strontium; Health Canada: Ottawa, ON, Canada, 2019; p. 58. Available online: https://www.canada.ca/en/health-canada/services/publications/healthy-living/guidelines-canadian-drinking-water-quality-guideline-technical-document-strontium.html (accessed on 3 August 2021).

- United States Environmental Protection Agency (US-EPA). 2018 Edition of the Drinking Water Standards and Health Advisories; US-EPA: Washington, DC, USA, 2018. Available online: https://www.epa.gov/sites/default/files/2018-03/documents/dwtable2018.pdf (accessed on 3 August 2021).

- Ministero della Salute. Decreto 22 dicembre 2011. Attuazione della direttiva 98/83/CE, relativa alla qualita’ delle acque destinate al consumo umano. Modifica del valore parametrico per il Vanadio. Available online: https://www.gazzettaufficiale.it/eli/id/2012/01/05/11A16893/sg (accessed on 3 August 2021).

| Code | Consumers’ Age Group | Material (as Declared on the Packaging) | Made in | Capacity (mL) |

|---|---|---|---|---|

| 01A–01B | adults | aluminum | not indicated | 500 |

| 02A–02B | adults | aluminum | not indicated | 600 |

| 03A–03B | children | aluminum | not indicated | 500 |

| 04A–04B | children | aluminum | not indicated | 500 |

| 05A–05B | children | aluminum | China | 750 |

| 06A–06B | adults | aluminum | not indicated | 600 |

| 07A–07B | adults | stainless steel | not indicated | 350 |

| 08A–08B | adults | aluminum | not indicated | 1000 |

| 09A–09B | adults | aluminum | not indicated | 750 |

| 10A–10B | adults | aluminum | China | 800 |

| 11A–11B | adults | aluminum | not indicated | 750 |

| 12A–12B | adults | aluminum | not indicated | 500 |

| 13A–13B | adults | aluminum | not indicated | 750 |

| 14A–14B | adults | BP-A-free plastic | not indicated | 500 |

| 15A–15B | adults | plastic | Austria | 500 |

| 16A–16B | adults | plastic | not indicated | 800 |

| 17A–17B | adults | plastic | Italy | 550 |

| 18A–18B | children | plastic | Turkey | 500 |

| 19A–19B | children | plastic | China | 400 |

| 20A–20B | adults | silicone | China | 500 |

| Day | Rinsing and Filling (hour) | Sample Taking Time Starting from Filling (hour) | Emptying (hour) | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 0.5 | 1 | 5 | 8 | 12 | 24 | 24 |

| 2 | +24 | - | - | 5 | - | - | - | +29 |

| 3 | +48 | - | - | 5 | - | - | - | +53 |

| 4 | +72 | - | - | 5 | - | - | - | +77 |

| 5 | +96 | - | - | 5 | - | - | - | +101 |

| 6 | +120 | - | - | 5 | - | - | - | +125 |

| 7 | +144 | - | - | 5 | - | - | - | +149 |

| 8–13 | every morning at 8:00 | every evening at 20:00 | ||||||

| 14 | +312 | - | - | 5 | - | - | - | +317 |

| 15–20 | every morning at 8:00 | every evening at 20:00 | ||||||

| 21 | +480 | - | - | 5 | - | - | - | +485 |

| 22–27 | every morning at 8:00 | every evening at 20:00 | ||||||

| 28 | +648 | - | - | 5 | - | - | - | +653 |

| Compounds | LOD | Metallic Water Bottles | Non-Metallic Water Bottles |

|---|---|---|---|

| % < LOD | % < LOD | ||

| Al | 0.7 | 9 | 42 |

| As | 1 | 90 | 90 |

| B | 0.7 | 86 | 89 |

| Ba | 3 | 60 | 65 |

| Be | 0.0005 | 62 | 62 |

| Bi | 0.004 | 70 | 76 |

| Ca | 70 | 56 | 64 |

| Cd | 0.01 | 95 | 99 |

| Ce | 0.004 | 57 | 73 |

| Co | 0.02 | 75 | 94 |

| Cr | 0.07 | 31 | 35 |

| Cs | 0.008 | 100 | 100 |

| Cu | 0.5 | 43 | 72 |

| Fe | 2 | 56 | 77 |

| Ga | 0.004 | 52 | 91 |

| K | 70 | 61 | 63 |

| La | 0.002 | 34 | 50 |

| Li | 0.01 | 48 | 73 |

| Mg | 4 | 43 | 58 |

| Mn | 0.4 | 57 | 71 |

| Mo | 0.01 | 23 | 42 |

| Na | 10 | 38 | 68 |

| Nb | 0.005 | 100 | 100 |

| Ni | 0.9 | 86 | 88 |

| P | 70 | 56 | 52 |

| Pb | 0.04 | 39 | 59 |

| Rb | 0.02 | 34 | 61 |

| Sb | 0.009 | 53 | 76 |

| Se | 1 | 92 | 96 |

| Si | 20 | 56 | 61 |

| Sn | 0.01 | 96 | 95 |

| Sr | 0.07 | 20 | 35 |

| Te | 0.1 | 100 | 100 |

| Ti | 0.2 | 64 | 67 |

| Tl | 0.002 | 95 | 98 |

| U | 0.002 | 92 | 96 |

| V | 0.2 | 81 | 80 |

| W | 0.01 | 53 | 75 |

| Zn | 1 | 47 | 55 |

| Zr | 0.005 | 93 | 97 |

| BP-A | 1.1 | 100 | 100 |

| DMP | 0.7 | 100 | 100 |

| DEP | 0.1 | 100 | 100 |

| DiBP | 0.8 | 100 | 100 |

| DBP | 0.4 | 100 | 100 |

| DEHP | 0.6 | 100 | 100 |

| DOP | 1.2 | 100 | 100 |

| Elements | Metallic Water Bottles | Non-Metallic Water Bottles | ||

|---|---|---|---|---|

| Max Value (µg L−1) | Max Value (µg cm−2) | Max Value (µg L−1) | Max Value (µg cm−2) | |

| Al | 211 | 0.74 | 30.7 | 0.12 |

| As | 6 | 0.0199 | 5 | 0.0151 |

| B | 2.61 | 0.0085 | 9.1 | 0.0201 |

| Ba | 79 | 0.268 | 51 | 0.171 |

| Be | 0.0352 | 0.000119 | 0.0648 | 0.000200 |

| Bi | 0.049 | 0.000181 | 0.038 | 0.000125 |

| Ca | 3400 | 12.5 | 1800 | 5.7 |

| Cd | 0.15 | 0.000542 | 0.13 | 0.000462 |

| Ce | 0.044 | 0.000141 | 0.022 | 0.000067 |

| Co | 0.51 | 0.00141 | 0.03 | 0.00010 |

| Cr | 1.46 | 0.00538 | 1.24 | 0.00384 |

| Cu | 10.5 | 0.0389 | 3.1 | 0.0098 |

| Fe | 23 | 0.085 | 18 | 0.055 |

| Ga | 0.188 | 0.00069 | 0.006 | 0.00002 |

| K | 664 | 2.45 | 587 | 1.95 |

| La | 0.026 | 0.000095 | 0.017 | 0.000058 |

| Li | 0.45 | 0.00145 | 0.13 | 0.00037 |

| Mg | 116 | 0.429 | 52 | 0.158 |

| Mn | 4.5 | 0.0165 | 1.5 | 0.0053 |

| Mo | 57.0 | 0.204 | 2.90 | 0.010 |

| Na | 664 | 1.96 | 111 | 0.44 |

| Ni | 14.3 | 0.0392 | 4.6 | 0.0153 |

| P | 832 | 2.976 | 1100 | 3.635 |

| Pb | 3.26 | 0.01015 | 0.46 | 0.00152 |

| Rb | 0.95 | 0.00352 | 0.17 | 0.00069 |

| Sb | 1.14 | 0.00337 | 0.041 | 0.00016 |

| Se | 4 | 0.01187 | 4 | 0.00999 |

| Si | 191 | 0.614 | 262 | 0.741 |

| Sn | 0.10 | 0.000384 | 0.15 | 0.000431 |

| Sr | 9.34 | 0.0345 | 1.98 | 0.0066 |

| Ti | 3.2 | 0.0109 | 2.0 | 0.0062 |

| Tl | 0.004 | 0.0000117 | 0.003 | 0.0000094 |

| U | 0.008 | 0.0000288 | 0.011 | 0.0000364 |

| V | 0.5 | 0.00187 | 0.5 | 0.00151 |

| W | 0.42 | 0.00149 | 0.06 | 0.00017 |

| Zn | 93 | 0.344 | 46 | 0.157 |

| Zr | 0.034 | 0.000122 | 0.038 | 0.000116 |

| Element | Maximum Level (µg L−1) | Limit (µg L−1) |

|---|---|---|

| Al | 211 | 200 [43] |

| As | 6 | 10 [43] |

| B | 9.1 | 1500 [43] |

| Ba | 79 | 1300 [44] |

| Be | 0.0648 | 12 [45] |

| Cd | 0.15 | 5.0 [43] |

| Cr | 1.46 | 25 [43] |

| Cu | 10.5 | 2000 [43] |

| Fe | 23 | 200 [43] |

| Mn | 4.5 | 50 [43] |

| Mo | 57.0 | 70 [46] |

| Na | 664 | 200,000 [43] |

| Ni | 14.3 | 20 [43] |

| Pb | 3.26 | 5.0 [43] |

| Sb | 1.14 | 10 [43] |

| Se | 4 | 20 [43] |

| Sr | 9.34 | 7000 [47] |

| Tl | 0.004 | 2 [48] |

| U | 0.011 | 30 [43] |

| V | 0.5 | 140 [49] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Astolfi, M.L.; Castellani, F.; Avino, P.; Antonucci, A.; Canepari, S.; Protano, C.; Vitali, M. Reusable Water Bottles: Release of Inorganic Elements, Phthalates, and Bisphenol A in a “Real Use” Simulation Experiment. Separations 2021, 8, 126. https://0-doi-org.brum.beds.ac.uk/10.3390/separations8080126

Astolfi ML, Castellani F, Avino P, Antonucci A, Canepari S, Protano C, Vitali M. Reusable Water Bottles: Release of Inorganic Elements, Phthalates, and Bisphenol A in a “Real Use” Simulation Experiment. Separations. 2021; 8(8):126. https://0-doi-org.brum.beds.ac.uk/10.3390/separations8080126

Chicago/Turabian StyleAstolfi, Maria Luisa, Federica Castellani, Pasquale Avino, Arianna Antonucci, Silvia Canepari, Carmela Protano, and Matteo Vitali. 2021. "Reusable Water Bottles: Release of Inorganic Elements, Phthalates, and Bisphenol A in a “Real Use” Simulation Experiment" Separations 8, no. 8: 126. https://0-doi-org.brum.beds.ac.uk/10.3390/separations8080126