The Flavor Chemistry of Fortified Wines—A Comprehensive Approach

Abstract

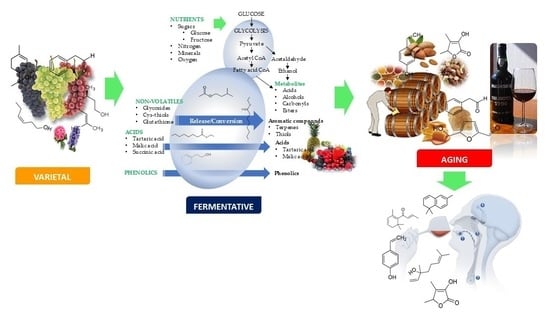

:1. A Short Introduction about Wine Flavor Chemistry

The Wine Flavor: Origin and Influencing Parameters

2. Fortified Wines

2.1. Sherry Wine

2.2. Port Wine

2.3. Madeira Wine

2.4. Marsala Wine

2.5. Moscatel de Setúbal

2.6. Vermouth Wine

2.7. Commandaria Wine

3. Volatile Composition of Fortified Wines

3.1. Sherry and Port Wines

3.2. Madeira Wine

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Perestrelo, R.; Silva, C.; Gonçalves, C.; Castillo, M.; Câmara, J.S. An Approach of the Madeira Wine Chemistry. Beverages 2020, 6, 12. [Google Scholar] [CrossRef] [Green Version]

- Mina, M.; Tsaltas, D. Contribution of Yeast in Wine Aroma and Flavour. In Yeast—Industrial Applications; IntechOpen: London, UK, 2017. [Google Scholar]

- Lin, J.; Massonnet, M.; Cantu, D. The genetic basis of grape and wine aroma. Hortic. Res. 2019, 6, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Campo, E.; Ferreira, V.; Escudero, A.; Marqués, J.C.; Cacho, J. Quantitative gas chromatography—Olfactometry and chemical quantitative study of the aroma of four Madeira wines. Anal. Chim. Acta 2006, 563, 180–187. [Google Scholar] [CrossRef]

- Lytra, G.; Tempere, S.; Le Floch, A.; De Revel, G.; Barbe, J.-C. Study of Sensory Interactions among Red Wine Fruity Esters in a Model Solution. J. Agric. Food Chem. 2013, 61, 8504–8513. [Google Scholar] [CrossRef]

- Ong, P.K.C.; Acree, T.E. Similarities in the Aroma Chemistry of Gewürztraminer Variety Wines and Lychee (Litchi chinesis Sonn.). Fruit J. Agric. Food Chem. 1999, 47, 665–670. [Google Scholar] [CrossRef]

- Díaz-Maroto, M.C.; Guchu, E.; Castro-Vázquez, L.; de Torres, C.; Pérez-Coello, M.S. Aroma-active compounds of American, French, Hungarian and Russian oak woods, studied by GC–MS and GC–O. Flavour Fragr. J. 2008, 23, 93–98. [Google Scholar] [CrossRef]

- Genovese, A.; Gambuti, A.; Piombino, P.; Moio, L. Sensory properties and aroma compounds of sweet Fiano wine. Food Chem. 2007, 103, 1228–1236. [Google Scholar] [CrossRef]

- Tarasov, A.; Giuliani, N.; Dobrydnev, A.; Schuessler, C.; Volovenko, Y.; Rauhut, R.; Jung, R. 1,1,6-Trimethyl-1,2-dihydronaphthalene (TDN) Sensory Thresholds in Riesling Wine. Foods 2020, 9, 606. [Google Scholar] [CrossRef]

- Mafata, M.; Stander, M.A.; Thomachot, B.; Buica, A. Measuring Thiols in Single Cultivar South African Red Wines Using 4,4-Dithiodipyridine (DTDP) Derivatization and Ultraperformance Convergence Chromatography-Tandem Mass Spectrometry. Foods 2018, 7, 138. [Google Scholar] [CrossRef] [Green Version]

- Gaby, J.M.; Bakke, A.J.; Baker, A.N.; Hopfer, H.; Hayes, J.E. Individual Differences in Thresholds and Consumer Preferences for Rotundone Added to Red Wine. Nutrients 2020, 12, 2522. [Google Scholar] [CrossRef]

- Perestrelo, R.; Barros, A.S.A.S.; Rocha, S.M.; Câmara, J.S. Establishment of the varietal profile of Vitis vinifera L. grape varieties from different geographical regions based on HS-SPME/GC-qMS combined with chemometric tools. Microchem. J. 2014, 116, 107–117. [Google Scholar] [CrossRef]

- Moreno-Arribas, M.V.; Polo, M.C. Winemaking Biochemistry and Microbiology: Current Knowledge and Future Trends. Crit. Rev. Food Sci. Nutr. 2005, 45, 265–286. [Google Scholar] [CrossRef]

- Lukić, I.; Horvat, I. Differentiation of Commercial PDO Wines Produced in Istria (Croatia) According to Variety and Harvest Year Based on HS-SPME-GC/MS Volatile Aroma Compound Profiling. Food Technol. Biotechnol. 2017, 55, 95–108. [Google Scholar] [CrossRef]

- Huang, X.-Y.; Jiang, Z.-T.; Tan, J.; Li, R. Geographical Origin Traceability of Red Wines Based on Chemometric Classification via Organic Acid Profiles. J. Food Qual. 2017, 2017, 2038073. [Google Scholar] [CrossRef]

- Perestrelo, R.; Silva, C.; Câmara, J.S. A useful approach for the differentiation of wines according to geographical origin based on global volatile patterns. J. Sep. Sci. 2014, 37, 1974–1981. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, J.M.; Faria, M.; Sá, F.; Barros, F.; Araújo, I.M. C6-alcohols as varietal markers for assessment of wine origin. Anal. Chim. Acta 2006, 563, 300–309. [Google Scholar] [CrossRef] [Green Version]

- González-Barreiro, C.; Rial-Otero, R.; Cancho-Grande, B.; Simal-Gándara, J. Wine aroma compounds in grapes: A critical review. Crit. Rev. Food Sci. Nutr. 2015, 55, 202–218. [Google Scholar] [CrossRef]

- Belda, I.; Ruiz, J.; Esteban-Fernández, A.; Navascués, E.; Marquina, D.; Santos, A.; Moreno-Arribas, M. Microbial contribution to wine aroma and its intended use for wine quality improvement. Molecules 2017, 22, 189. [Google Scholar] [CrossRef] [Green Version]

- Câmara, J.; Alves, A.; Marques, J. Changes in volatile composition of Madeira wines during their oxidative ageing. Anal. Chim. Acta 2006, 563, 188–197. [Google Scholar] [CrossRef] [Green Version]

- Le Menn, N.; Van Leeuwen, C.; Picard, M.; Riquier, L.; De Revel, G.; Marchand, S. Effect of Vine Water and Nitrogen Status, as Well as Temperature, on Some Aroma Compounds of Aged Red Bordeaux Wines. J. Agric. Food Chem. 2019, 67, 7098–7109. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F.; Du, B.; Li, J. Aroma Compounds in Wine. In Grape and Wine Biotechnology; Morata, A., Ed.; IntechOpen: London, UK, 2016; ISBN 9789535126935. [Google Scholar]

- Metafa, M.; Economou, A. Comparison of solid-phase extraction sorbents for the fractionation and determination of important free and glycosidically-bound varietal aroma compounds in wines by gas chromatography-mass spectrometry. Open Chem. 2013, 11, 228–247. [Google Scholar] [CrossRef]

- Ribéreau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. Handbook of Enology, The Chemistry of Wine: Stabilization and Treatments, 2nd ed.; John Wiley & Sons: Chichester, UK, 2006; Volume 2, ISBN 9780470010396. [Google Scholar]

- Sidhu, D.; Lund, J.; Kotseridis, Y.; Saucier, C. Methoxypyrazine Analysis and Influence of Viticultural and Enological Procedures on their Levels in Grapes, Musts, and Wines. Crit. Rev. Food Sci. Nutr. 2014, 55, 485–502. [Google Scholar] [CrossRef] [PubMed]

- Padilla, B.; Gil, J.V.; Manzanares, P. Past and Future of Non-Saccharomyces Yeasts: From Spoilage Microorganisms to Biotechnological Tools for Improving Wine Aroma Complexity. Front. Microbiol. 2016, 7, 411. [Google Scholar] [CrossRef] [Green Version]

- Mozzon, M.; Savini, S.; Boselli, E.; Thorngate, J.H. The herbaceous character of wines. Ital. J. Food Sci. 2016, 28, 190–207. [Google Scholar]

- Divol, B.; Strehaiano, P.; Lonvaud-Funel, A. Effectiveness of dimethyldicarbonate to stop alcoholic fermentation in wine. Food Microbiol. 2005, 22, 169–178. [Google Scholar] [CrossRef]

- Lasik-Kurdyś, M.; Majcher, M.; Nowak, J. Effects of Different Techniques of Malolactic Fermentation Induction on Diacetyl Metabolism and Biosynthesis of Selected Aromatic Esters in Cool-Climate Grape Wines. Molecules 2018, 23, 2549. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chisholm, M.G.; Guiher, L.A.; Zaczkiewicz, S.M. Aroma characteristics of aged Vidal blanc wine. Am. J. Enol. Vitic. 1995, 46, 56–62. [Google Scholar]

- Koussissi, E.; Dourtoglou, V.; Ageloussis, G.; Paraskevopoulos, Y.; Dourtoglou, T.; Paterson, A.; Chatzilazarou, A. Influence of toasting of oak chips on red wine maturation from sensory and gas chromatographic headspace analysis. Food Chem. 2009, 114, 1503–1509. [Google Scholar] [CrossRef]

- Perestrelo, R.; Barros, A.S.; Camara, J.S.; Rocha, S.M. In-Depth Search Focused on Furans, Lactones, Volatile Phenols, and Acetals as Potential Age Markers of Madeira Wines by Comprehensive Two-Dimensional Gas Chromatography with Time-of-Flight Mass Spectrometry Combined with Solid Phase Microextraction. J. Agric. Food Chem. 2011, 59, 3186–3204. [Google Scholar] [CrossRef] [Green Version]

- Echave, J.; Barral, M.; Fraga-Corral, M.; Prieto, M.; Simal-Gandara, J. Bottle Aging and Storage of Wines: A Review. Molecules 2021, 26, 713. [Google Scholar] [CrossRef]

- Pereira, A.C.; Reis, M.S.; Saraiva, P.M.; Marqués, J.C. Madeira wine ageing prediction based on different analytical techniques: UV–vis, GC-MS, HPLC-DAD. Chemom. Intell. Lab. Syst. 2011, 105, 43–55. [Google Scholar] [CrossRef]

- Perestrelo, R.; Nogueira, J.M.F.; Câmara, J.S. Potentialities of two solventless extraction approaches—Stir bar sorptive extraction and headspace solid-phase microextraction for determination of higher alcohol acetates, isoamyl esters and ethyl esters in wines. Talanta 2009, 80, 622–630. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Câmara, J.S.; Marques, J.C.; Alves, A.; Ferreira, A.C.S. 3-Hydroxy-4,5-dimethyl-2(5H)-furanone Levels in Fortified Madeira Wines: Relationship to Sugar Content. J. Agric. Food Chem. 2004, 52, 6765–6769. [Google Scholar] [CrossRef]

- Tredoux, A.; Ferreira, A.C.S. Fortified Wines: Styles, Production and Flavour Chemistry. In Alcoholic Beverages; Elsevier: Amsterdam, The Netherlands, 2012; pp. 159–179. [Google Scholar]

- Reader, H.P.; Dominguez, M. Fortified Wines Sherry, Port and Madeira. In Fermented Beverage Production; Springer: Berlin/Heidelberg, Germany, 2003; pp. 157–194. [Google Scholar]

- Pozo-Bayón, M.Á.; Moreno-Arribas, M.V. Sherry Wines: Manufacture, Composition and Analysis. In Encyclopedia of Food and Health; Elsevier: Amsterdam, The Netherlands, 2016; pp. 779–784. [Google Scholar]

- Joshi, V.K.; Sharma, S.; Thakur, A.D. Wines: White, Red, Sparkling, Fortified, and Cider. In Current Developments in Biotechnology and Bioengineering: Food and Beverages Industry; Elsevier: Amsterdam, The Netherlands, 2016; pp. 353–406. ISBN 9780444636775. [Google Scholar]

- Jackson, R. Innovations in Winemaking. In Science and Technology of Fruit Wine Production; Elsevier: Amsterdam, The Netherlands, 2017; pp. 617–662. ISBN 9780128010341. [Google Scholar]

- Jackson, R. Specific and Distinctive Wine Styles. In Wine Science; Elsevier: Amsterdam, The Netherlands, 2014; pp. 677–759. [Google Scholar]

- Bamforth, C.W.; Cook, D.J. Fortified Wines. In Food, Fermentation, and Micro-Organisms; John Wiley & Sons: Chichester, UK, 2019; pp. 111–115. [Google Scholar]

- Zea, L.; Moyano, L.; Moreno, J.; Cortes, B.; Medina, M. Discrimination of the aroma fraction of Sherry wines obtained by oxidative and biological ageing. Food Chem. 2001, 75, 79–84. [Google Scholar] [CrossRef]

- Pozo-Bayón, M.A.; Moreno-Arribas, M.V. Sherry Wines. In Advances in Food and Nutrition Research; Academic Press: Cambridge, MA, USA, 2011; Volume 63, pp. 17–40. [Google Scholar]

- Jackson, R. Post-Fermentation Treatments and Related Topics. In Wine Science; Elsevier: Amsterdam, The Netherlands, 2014; pp. 535–676. [Google Scholar]

- Bakker, J.; Clarke, R.J. Sherry, Port and Madeira. In Wine Flavour Chemistry; Wiley-Blackwell: Oxford, UK, 2011; pp. 291–339. [Google Scholar]

- Moreira, N.; Guedes de Pinho, P. Port Wine. In Advances in Food and Nutrition Research; Academic Press: Cambridge, MA, USA, 2011; Volume 63, pp. 119–146. [Google Scholar]

- Hogg, T. Port. In Sweet, Reinforced and Fortified Wines; John Wiley Sons: Oxford, UK, 2013; pp. 305–317. [Google Scholar]

- Perestrelo, R.; Albuquerque, F.; Rocha, S.; Câmara, J. Distinctive Characteristics of Madeira Wine Regarding Its Traditional Winemaking and Modern Analytical Methodologies. In Advances in Food and Nutrition Research; Elsevier: Amsterdam, The Netherlands, 2011; Volume 63, pp. 207–249. [Google Scholar]

- Perestrelo, R.; Barros, A.S.; Rocha, S.; Câmara, J. Optimisation of solid-phase microextraction combined with gas chromatography–mass spectrometry based methodology to establish the global volatile signature in pulp and skin of Vitis vinifera L. grape varieties. Talanta 2011, 85, 1483–1493. [Google Scholar] [CrossRef] [PubMed]

- Perestrelo, R.; Silva, C.; Câmara, J.S. The sui generis and notable peculiarities of fortified wines: Common characteristics and major differences. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldra, F., Eds.; Elsevier Academic Press: Amsterdam, The Netherlands, 2016; Chapter 758 Wines | Fortified Wines; pp. 534–555. ISBN 978-0-12-3839472. [Google Scholar]

- Pereira, V.; Cacho, J.; Marques, J.C. Volatile profile of Madeira wines submitted to traditional accelerated ageing. Food Chem. 2014, 162, 122–134. [Google Scholar] [CrossRef]

- Perestrelo, R.; Silva, C.L.; Silva, P.; Câmara, J.S. Impact of storage time and temperature on volatomic signature of Tinta Negra wines by LLME/GC-ITMS. Food Res. Int. 2018, 109, 99–111. [Google Scholar] [CrossRef]

- Perestrelo, R.; Fernandes, A.; Albuquerque, F.; Marques, J.; Câmara, J. Analytical characterization of the aroma of Tinta Negra Mole red wine: Identification of the main odorants compounds. Anal. Chim. Acta 2006, 563, 154–164. [Google Scholar] [CrossRef] [Green Version]

- Perestrelo, R.; Silva, C.; Câmara, J.S. Madeira wine volatile profile. A platform to establish madeira wine aroma descriptors. Molecules 2019, 24, 3028. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, I.M.; Pérez-Palacios, M.T. Anthocyanic Compounds and Antioxidant Capacity in Fortified Wines. In Processing and Impact on Antioxidants in Beverages; Elsevier: Amsterdam, The Netherlands, 2014; pp. 3–14. ISBN 9780124047389. [Google Scholar]

- Zanfi, A.; Mencarelli, S. Marsala. In Sweet, Reinforced and Fortified Wines; John Wiley & Sons: Oxford, UK, 2013; pp. 319–325. [Google Scholar]

- Feliciano, R.P.; Bravo, M.N.; Pires, M.M.; Serra, A.T.; Duarte, C.M.; Boas, L.V.; Bronze, M.R. Phenolic Content and Antioxidant Activity of Moscatel Dessert Wines from the Setúbal Region in Portugal. Food Anal. Methods 2009, 2, 149–161. [Google Scholar] [CrossRef]

- Panesar, P.S.; Joshi, V.K.; Panesar, R.; Abrol, G.S. Vermouth: Technology of production and quality characteristics. In Advances in Food and Nutrition Research; Academic Press: Cambridge, MA, USA, 2011; Volume 63, pp. 251–283. [Google Scholar]

- Mencarelli, F. Notes on Other Sweet Wines. In Sweet, Reinforced and Fortified Wines: Grape Biochemistry, Technology and Vinification; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 327–329. ISBN 9780470672242. [Google Scholar]

- Zea, L.; Serratosa, M.P.; Merida, J.; Moyano, L. Acetaldehyde as Key Compound for the Authenticity of Sherry Wines: A Study Covering 5 Decades. Compr. Rev. Food Sci. Food Saf. 2015, 14, 681–693. [Google Scholar] [CrossRef]

- Zea, L.; Moyano, L.; Moreno, J.A.; Medina, M. Aroma series as fingerprints for biological ageing in fino sherry-type wines. J. Sci. Food Agric. 2007, 87, 2319–2326. [Google Scholar] [CrossRef]

- Zea, L.; Moyano, L.; Medina, M. Changes in aroma profile of sherry wines during the oxidative ageing. Int. J. Food Sci. Technol. 2010, 45, 2425–2432. [Google Scholar] [CrossRef]

- Zea, L.; Moyano, L.; Ruiz, M.J.; Medina, M. Odor Descriptors and Aromatic Series During the Oxidative Aging of Oloroso Sherry Wines. Int. J. Food Prop. 2013, 16, 1534–1542. [Google Scholar] [CrossRef]

- Marcq, P.; Schieberle, P. Characterization of the Key Aroma Compounds in a Commercial Amontillado Sherry Wine by Means of the Sensomics Approach. J. Agric. Food Chem. 2015, 63, 4761–4770. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Bejarano, M.J.; Castro-Mejías, R.; Rodríguez-Dodero, M.D.C.; García-Barroso, C. Volatile composition of Pedro Ximénez and Muscat sweet Sherry wines from sun and chamber dried grapes: A feasible alternative to the traditional sun-drying. J. Food Sci. Technol. 2016, 53, 2519–2531. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gracia-Moreno, E.; Lopez, R.; Ferreira, V. Quantitative determination of five hydroxy acids, precursors of relevant wine aroma compounds in wine and other alcoholic beverages. Anal. Bioanal. Chem. 2015, 407, 7925–7934. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, A.C.S.; Monteiro, J.; Oliveira, C.; De Pinho, P.G.; Pedroso, J.M. Study of major aromatic compounds in port wines from carotenoid degradation. Food Chem. 2008, 110, 83–87. [Google Scholar] [CrossRef]

- Culleré, L.; Cacho, A.J.; Ferreira, V. An Assessment of the Role Played by Some Oxidation-Related Aldehydes in Wine Aroma. J. Agric. Food Chem. 2007, 55, 876–881. [Google Scholar] [CrossRef]

- Oliveira, C.M.; Santos, S.A.; Silvestre, A.J.; Barros, A.S.; Ferreira, A.C.S.; Silva, A.M. Quantification of 3-deoxyglucosone (3DG) as an aging marker in natural and forced aged wines. J. Food Compos. Anal. 2016, 50, 70–76. [Google Scholar] [CrossRef]

- Martins, R.C.; Monforte, A.R.; Ferreira, A.S. Port Wine Oxidation Management: A Multiparametric Kinetic Approach. J. Agric. Food Chem. 2013, 61, 5371–5379. [Google Scholar] [CrossRef]

- Prata-Sena, M.; Castro-Carvalho, B.M.; Nunes, S.; Amaral, B.; Silva, P. The terroir of Port wine: Two hundred and sixty years of history. Food Chem. 2018, 257, 388–398. [Google Scholar] [CrossRef] [PubMed]

- Pereira, V.; Albuquerque, F.; Cacho, J.; Marques, J.C. Polyphenols, Antioxidant Potential and Color of Fortified Wines during Accelerated Ageing: The Madeira Wine Case Study. Molecules 2013, 18, 2997–3017. [Google Scholar] [CrossRef] [Green Version]

- Miranda, A.; Pereira, V.; Pontes, M.; Albuquerque, F.; Marques, J.C. Acetic acid and ethyl acetate in Madeira wines: Evolution with ageing and assessment of the odour rejection threshold. Ciência Técnica Vitivinícola 2017, 32, 1–11. [Google Scholar] [CrossRef] [Green Version]

- López, R.; Aznar, M.; Cacho, J.; Ferreira, V. Determination of minor and trace volatile compounds in wine by solid-phase extraction and gas chromatography with mass spectrometric detection. J. Chromatogr. A 2002, 966, 167–177. [Google Scholar] [CrossRef]

- Silva, H.O.E.; De Pinho, P.G.; Machado, B.P.; Hogg, T.; Marques, J.C.; Câmara, J.S.; Albuquerque, F.; Ferreira, A.C.S. Impact of Forced-Aging Process on Madeira Wine Flavor. J. Agric. Food Chem. 2008, 56, 11989–11996. [Google Scholar] [CrossRef]

- Pereira, V.; Leça, J.M.; Gaspar, J.M.; Pereira, A.C.; Marques, J.C. Rapid Determination of Sotolon in Fortified Wines Using a Miniaturized Liquid-Liquid Extraction Followed by LC-MS/MS Analysis. J. Anal. Methods Chem. 2018, 2018, 4393040. [Google Scholar] [CrossRef] [PubMed]

- Gaspar, J.M.; Pereira, V.; Marques, A.J.C. Odor detection threshold (ODT) and odor rejection threshold (ORT) determination of sotolon in Madeira wine: A preliminary study. AIMS Agric. Food 2018, 3, 172–180. [Google Scholar] [CrossRef]

- Pereira, V.; Santos, M.; Cacho, J.; Marques, J.C. Assessment of the development of browning, antioxidant activity and volatile organic compounds in thermally processed sugar model wines. LWT 2017, 75, 719–726. [Google Scholar] [CrossRef]

| Chemical Groups | VOCs | Chemical Structure | Aroma Descriptor | OT 1 (µg/L) |

|---|---|---|---|---|

| Terpenoids | α-Terpeniol |  | Floral, linden | 250 |

| Linalool |  | Rose | 25 | |

| Geraniol |  | Citrus, floral | 20 | |

| Citronellol |  | Citrus, floral, sweet | 100 | |

| Rotundone |  | Pepper, spicy | 0.016 | |

| C13 Norisoprenoids | β-Damascenone |  | Boiled apple, sweet | 0.05 |

| 2,6,6-Trimethylcyclohex-2-ene-1,4-dione |  | Musty, citrus, sweet honey | 25 | |

| TDN 2 |  | Floral, fruit | 4 | |

| Vitispirane |  | Floral, spice, wood | 800 | |

| C6 compounds | 1-Hexanol |  | Herbaceous | 8000 |

| (Z)-3-Hexen-1-ol |  | Green, bitter | 400 | |

| 1-Hexanal |  | Green | 97 | |

| Higher alcohols | 3-Methylbutanol |  | Fusel, sour | 30,000 |

| 2-Phenylethanol |  | Rose, honey | 140,000 | |

| Benzyl alcohol |  | Blackberry | 200,000 | |

| Ethyl esters | Ethyl acetate |  | Solvent, nail polish, fruity | 12,000 |

| Ethyl hexanoate |  | Green apple | 14 | |

| Ethyl octanoate |  | Sweet, flower | 2 | |

| Ethyl decanoate |  | Brandy, grape | 200 | |

| Ethyl lactate |  | Butter | 150,000 | |

| Diethyl succinate |  | Melon | 500,000 | |

| Acetates | Isoamyl acetate |  | Banana, sweet | 160 |

| 2-Phenylethyl acetate |  | Rose, flower | 1800 | |

| Acids | Acetic acid |  | Vinegar, sour | 200,000 |

| Hexanoic acid |  | Cheese, fatty | 3000 | |

| Octanoic acid |  | Fatty, rancid | 10,000 | |

| Decanoic acid |  | Fatty, rancid | 15,000 | |

| Carbonyl compounds | 2-Phenylacetaldehyde |  | Floral | 1 |

| Diacetyl |  | Buttery | 100 | |

| Benzaldehyde |  | Almond | 2000 | |

| Furanic compounds | 2-Furfural |  | Wood, nut | 14,100 |

| 5-Methyl-2-furfural |  | Caramel | 20,000 | |

| HMF 3 |  | Almond, nut | 10,000 | |

| Volatile phenols | 4-Vinyl-guaiacol |  | Smoke, phenolic | 40 |

| Methyl vanillate |  | Vanillin | 3000 | |

| 4-Vinyl-phenol |  | Spicy, pharmaceutical | 180 | |

| Lactones | Sotolon |  | Wood, nut, toast | 19 |

| γ-Decalactone |  | Peach | 88 | |

| Whisky lactone |  | Caramel, nut, toast | 67 | |

| Pyrazines | IBMP 4 |  | Leafy | 0.016 |

| SBMP 5 |  | Green, pepper | 0.002 | |

| IPMP 6 |  | Leafy | 0.002 | |

| Sulphur compounds | 3-Mercaptohexyl acetate |  | Passion fruit, box tree | 0.0042 |

| 4-(Methylthio)-4-methyl-2-pentanone |  | Box tree, tropical fruit | 0.0008 | |

| 3-Mercaptohexanol |  | Passion fruit, grapefruit | 0.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abreu, T.; Perestrelo, R.; Bordiga, M.; Locatelli, M.; Daniel Coïsson, J.; Câmara, J.S. The Flavor Chemistry of Fortified Wines—A Comprehensive Approach. Foods 2021, 10, 1239. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10061239

Abreu T, Perestrelo R, Bordiga M, Locatelli M, Daniel Coïsson J, Câmara JS. The Flavor Chemistry of Fortified Wines—A Comprehensive Approach. Foods. 2021; 10(6):1239. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10061239

Chicago/Turabian StyleAbreu, Teresa, Rosa Perestrelo, Matteo Bordiga, Monica Locatelli, Jean Daniel Coïsson, and José S. Câmara. 2021. "The Flavor Chemistry of Fortified Wines—A Comprehensive Approach" Foods 10, no. 6: 1239. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10061239