Freeze-Dried Cooked Chickpeas: Considering a Suitable Alternative to Prepare Tasty Reconstituted Dishes

Abstract

:1. Introduction

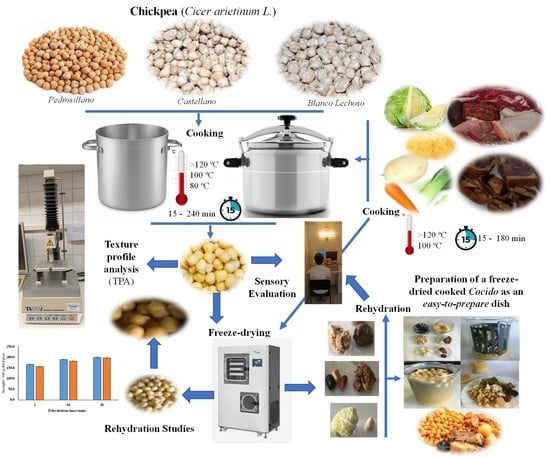

2. Materials and Methods

2.1. Ingredients (Raw Products)

2.2. Cooking Conditions

2.2.1. Chickpea Processing

2.2.2. Processing of Meat and Vegetables as well as Broth Preparation

2.3. Texture Profile Analysis of Chickpeas

2.4. Freeze-Drying and Rehydration Studies

2.5. Sensory Evaluation

2.6. Statistical Analysis

3. Results and Discussion

3.1. Texture Profile and Sensory Analyses of Cooked Chickpeas

3.2. Rehydration Kinetics of Cooked Freeze-Dried Chickpeas

3.3. Analysis of the Cooking and Rehydration Parameters and Sensory Characteristics of the Other Components of the Cocido Dish

3.4. Preparation of a Freeze-Dried Cooked Cocido as an Easy-to-Prepare Dish: Dish Assembly and Packaging Proposal

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Okrent, A.M.; Kumcu, A.U.S. Households’ Demand for Convenience Foods. Economic Research Report Number 211. 2016. Available online: https://www.ers.usda.gov/webdocs/publications/80654/err-211.pdf?v=9803.9 (accessed on 4 June 2023).

- Meenu, M.; Padhan, B.; Zhou, J.; Ramaswamy, H.; Pandey, J.; Patel, R.; Yu, Y.A. Detailed review on quality parameters of functional noodles. Food Rev. Int. 2022, 1–37. [Google Scholar] [CrossRef]

- Rani, S.; Singh, R.; Kaur, B.P.; Upadhyay, A.; Kamble, D.B. Optimization and evaluation of multigrain gluten-enriched instant noodles. Appl. Biol. Chem. 2018, 61, 531–541. [Google Scholar] [CrossRef]

- World Instant Noodle Association (WINA). Available online: https://instantnoodles.org/ (accessed on 4 June 2023).

- Chen, C.; Zhang, M.; Xu, B.; Chen, J. Improvement of the quality of solid ingredients of instant soups: A review. Food Rev. Int. 2023, 39, 1333–1358. [Google Scholar] [CrossRef]

- Pieniazek, F.; Messina, V. Scanning electron microscopy combined with image processing technique: Microstructure and texture analysis of legumes and vegetables for instant meal. Microsc. Res. Technol. 2016, 79, 267–275. [Google Scholar] [CrossRef] [PubMed]

- Barrett, A.H.; Richardson, M.J.; Froio, D.F.; O’Connor, L.F.; Anderson, D.J.; Ndou, T.V. Long-term vitamin stabilization in low moisture products for NASA: Techniques and three-year vitamin retention, sensory, and texture results. J. Food Sci. 2018, 83, 2183–2190. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Hu, L. High efficient freeze-drying technology in food industry. Crit. Rev. Food Sci. Nutr. 2022, 62, 3370–3388. [Google Scholar] [CrossRef]

- Sagar, V.R.; Suresh Kumar, P. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Berk, Z. Freeze drying (lyophilization) and freeze concentration. In Food Process Engineering and Technology, 3rd ed.; Academic Press: San Diego, CA, USA, 2018; pp. 567–581. [Google Scholar] [CrossRef]

- Ma, Y.; Yi, J.; Jin, X.; Li, X.; Feng, S.; Bi, J. Freeze-drying of fruits and vegetables in food industry: Effects on phytochemicals and bioactive properties attributes—A comprehensive review. Food Rev. Int. 2022, 1–19. [Google Scholar] [CrossRef]

- Elma Mathew, S.; Shakappa, D. A review of the nutritional and antinutritional constituents of chickpea (Cicer arietinum) and its health benefits. Crop. Pasture Sci. 2022, 73, 401–414. [Google Scholar] [CrossRef]

- Jukanti, A.K.; Gaur, P.M.; Gowda, C.L.L.; Chibbar, R.N. Nutritional quality and health benefits of chickpea (Cicer arietinum L.): A review. Br. J. Nutr. 2012, 108 (Suppl. S1), S11–S26. [Google Scholar] [CrossRef]

- Polak, R.; Phillips, E.M.; Campbell, A. Legumes: Health benefits and culinary approaches to increase intake. Clin. Diabetes 2015, 33, 198–205. [Google Scholar] [CrossRef]

- Figueira, N.; Curtain, F.; Beck, E.; Grafenauer, S. Consumer understanding and culinary use of legumes in Australia. Nutrients 2019, 11, 1575. [Google Scholar] [CrossRef] [PubMed]

- Iglesias, P.I. Cocidos de España. 2015. Available online: http://www.enciclopediadegastronomia.es/articulos/costumbres-populares/cocidos-de-espana.html (accessed on 4 June 2023).

- Iglesias, P.I. Historia del Cocido. 2015. Available online: http://www.enciclopediadegastronomia.es/articulos/historias-de-los-alimentos/manufacturados/historia-del-cocido.html (accessed on 4 June 2023).

- Oficina Española de Patentes y Marcas (OEPM). Listado de Marcas Registradas, Boletin Oficial de la Propiedad Industrial. 2015. Available online: https://www.imarcas.com/registrodemarcas/patentes-y-marcas-oepm-09-12-2015/ (accessed on 4 June 2023).

- Lescure Beruete, L.F. Diccionario Gastronómico, Términos, Refranes, Citas y Poemas, 1st ed.; Vision Libros: Madrid, Spain, 2007; p. 105. [Google Scholar]

- Barreras, F.L. Preelaboracion y Conservacion de Alimentos; LibrosEnRed: Madrid, Spain, 2007. [Google Scholar]

- Argumosa, G.; Franco, F. Una Receta de Garbanzos; Academia Castellano y Leonesa de Gastronomía y Alimentación: Valladolid, Spain, 2014. [Google Scholar]

- Segura, J.; Escudero, R.; Romero de Ávila, M.D.; Cambero, M.I.; López-Bote, C.J. Effect of fatty acid composition and positional distribution within the triglyceride on selected physical properties of dry-cured ham subcutaneous fat. Meat Sci. 2015, 103, 90–95. [Google Scholar] [CrossRef]

- Cambero, M.I.; Pereira-Lima, C.I.; Ordóñez, J.A.; García de Fernando, G.D. Beef broth flavor: Relation of components with the flavor developed at different cooking temperatures. J. Sci. Food Agric. 2000, 80, 1519–1528. [Google Scholar] [CrossRef]

- Cambero, M.I.; Pereira-Lima, C.I.; Ordóñez, J.A.; García de Fernando, G.D. Beef broth flavor: Study of flavor development. J. Sci. Food Agric. 2000, 80, 1510–1518. [Google Scholar] [CrossRef]

- ISO 6658:2017; Sensory Analysis—Methodology—General Guidance. ISO: Geneva, Switzerland, 2017.

- Christensen, Z.T.; Ogden, L.V.; Dunn, M.L.; Eggett, D.L. Multiple comparison procedures for analysis of ranked data. J. Food Sci. 2006, 71, S132–S143. [Google Scholar] [CrossRef]

- Fabbri, A.D.T.; Crosby, G.A. A review of the impact of preparation and cooking on the nutritional quality of vegetables and legumes. Int. J. Gastron. Food Sci. 2016, 3, 2–11. [Google Scholar] [CrossRef]

- Wood, J.A. Evaluation of cooking time in pulses: A review. Cereal Chem. 2017, 94, 32–48. [Google Scholar] [CrossRef]

- Clemente, A.; Sánchez-Vioque, R.; Vioque, J.; Bautista, J.; Millán, F. Effect of processing on water absorption and softening kinetics in chickpea (Cicer arietinum L.) seeds. J. Sci. Food Agric. 1998, 78, 169–174. [Google Scholar] [CrossRef]

- Tharanathan, R.N.; Mahadevamma, S. Grain legumes—A boon to human nutrition. Trends Food Sci. Technol. 2003, 14, 507–518. [Google Scholar] [CrossRef]

- Sefa-dedeh, S.; Stanley, D.W.; Voisey, P.W. Effects of soaking time and cooking conditions on texture and microstructure of cowpeas (Vigna unguiculata). J. Food Sci. 1978, 43, 1832–1838. [Google Scholar] [CrossRef]

- Hood-Niefer, S.D.; Warkentin, T.D.; Chibbar, R.N.; Vandenberg, A.; Tyler, R.T. Effect of genotype and environment on the concentrations of starch and protein in, and the physicochemical properties of starch from, field pea and fababean. J. Sci. Food Agric. 2012, 92, 141–150. [Google Scholar] [CrossRef]

- Güzel, D.; Sayar, S. Effect of cooking methods on selected physicochemical and nutritional properties of barlotto bean, chickpea, faba bean, and white kidney bean. J. Food Sci. Technol. 2012, 49, 89–95. [Google Scholar] [CrossRef]

- Wani, I.A.; Sogi, D.S.; Wani, A.A.; Gill, B.S. Physical and cooking characteristics of some Indian kidney bean (Phaseolus vulgaris L.) cultivars. J. Saudi Soc. Agric. Sci. 2017, 16, 7–15. [Google Scholar] [CrossRef]

- Acevedo Martínez, K.A.; Yang, M.M.; González de Mejia, E. Technological properties of chickpea (Cicer arietinum): Production of snacks and health benefits related to type-2 diabetes. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3762–3787. [Google Scholar] [CrossRef] [PubMed]

- Xiao, S.; Li, Z.; Zhou, K.; Fu, Y. Chemical composition of Kabuli and Desi chickpea (Cicer arietinum L.) cultivars grown in Xinjiang, China. Food Sci. Nutr. 2023, 11, 236–248. [Google Scholar] [CrossRef]

- Sayar, S.; Turhan, M.; Gunasekaran, S. Analysis of chickpea soaking by simultaneous water transfer and water–starch reaction. J. Food Eng. 2001, 50, 91–98. [Google Scholar] [CrossRef]

- Wang, T.L.; Domoney, C.; Hedley, C.L.; Casey, R.; Grusak, M.A. Can we improve the nutritional quality of legume seeds? Plant Physiol. 2003, 131, 886–891. [Google Scholar] [CrossRef]

- Avola, G.; Patanè, C. Variation among physical, chemical and technological properties in three Sicilian cultivars of Chickpea (Cicer arietinum L.). Int. J. Food Sci. Technol. 2010, 45, 2565–2572. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, N.; Sodhi, N.S. Physicochemical, cooking, textural and roasting characteristics of chickpea (Cicer arietinum L.) cultivars. J. Food Eng. 2005, 69, 511–517. [Google Scholar] [CrossRef]

- Singh, N.; Kaur, S.; Isono, N.; Noda, T. Genotypic diversity in physico-chemical, pasting and gel textural properties of chickpea (Cicer arietinum L.). Food Chem. 2010, 122, 65–73. [Google Scholar] [CrossRef]

- Gómez-Favela, M.A.; García-Armenta, E.; Reyes-Moreno, C.; Garzón-Tiznado, J.A.; Perales-Sánchez, J.X.K.; Caro-Corrales, J.J.; Gutiérrez-Dorado, R. Modelling of water absorption in chickpea (Cicer arietinum L.) seeds grown in Mexico’s northwest. Rev. Mex. Ing. Quim. 2017, 16, 179–191. [Google Scholar] [CrossRef]

- Costa, R.; Fusco, F.; Gândara, J.F.M. Mass transfer dynamics in soaking of chickpea. J. Food Eng. 2018, 227, 42–50. [Google Scholar] [CrossRef]

- Kalefetoğlu Macar, T.; Macar, O.; İnci Mart, D. Variability in some biochemical and nutritional characteristics in Desi and Turkish Kabuli chickpea (Cicer arietinum L.) types. Celal Bayar Üniv. Fen Bilim. Derg. 2017, 13, 677–680. [Google Scholar] [CrossRef]

- Ipekesen, S.; Basdemir, F.; Tunc, M.; Bicer, B.T. Minerals, vitamins, protein and amino acids in wild Cicer species and pure line chickpea genotypes selected from a local population. J. Elem. 2022, 27, 127–140. [Google Scholar] [CrossRef]

- Sahu, V.K.; Tiwari, S.; Gupta, N.; Tripathi, M.K.; Yasin, M. Evaluation of physiological and biochemical contents in Desi and Kabuli chickpea. Legume Res. 2022, 45, 1197–1208. [Google Scholar] [CrossRef]

- Koskosidis, A.; Khah, E.; Mavromatis, A.; Irakli, M.; Vlachostergios, D.N. Effect of genotype and sowing period on chickpea quality, bioactive and antioxidant traits. Legume Res. 2021, 44, 1026–1031. [Google Scholar] [CrossRef]

- Ozaktan, H.; Uzun, S.; Uzun, O.; Yasar Ciftci, C. Change in chemical composition and morphological traits of chickpea (Cicer arietinum L.) genotypes grown under natural conditions. Gesunde Pflanz. 2022, 1–16. [Google Scholar] [CrossRef]

- Klamczynska, B.; Czuchajowska, Z.; Baik, B.-K. Composition, soaking, cooking properties and thermal characteristics of starch of chickpeas, wrinkled peas and smooth peas. Int. J. Food Sci. Technol. 2001, 36, 563–572. [Google Scholar] [CrossRef]

- Cobos, M.J.; Izquierdo, I.; Sanz, M.A.; Tomás, A.; Gil, J.; Flores, F.; Rubio, J. Genotype and environment effects on sensory, nutritional, and physical traits in chickpea (Cicer arietinum L.). Span. J. Agric. Res. 2016, 14, e0709. [Google Scholar] [CrossRef]

- Chigwedere, C.M.; Wanasundara, J.P.D.; Shand, P.J. Sensory descriptors for pulses and pulse-derived ingredients: Toward a standardized lexicon and sensory wheel. Compr. Rev. Food Sci. Food Saf. 2022, 21, 999–1023. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, X.; Deng, Y.; Matinfar, G.; Singh, A.; Mandal, R.; Pratap-Singh, A. Impact of Three Different Dehydration Methods on Nutritional Values and Sensory Quality of Dried Broccoli, Oranges, and Carrots. Foods 2020, 9, 1464. [Google Scholar] [CrossRef]

- Johnny, S.; Razavi, S.M.A.; Khodaei, D. Hydration kinetics and physical properties of split chickpea as affected by soaking temperature and time. J. Food Sci. Technol. 2015, 52, 8377–8382. [Google Scholar] [CrossRef]

- Prasad, K.; Vairagar, P.R.; Bera, M.B. Temperature dependent hydration kinetics of Cicer arietinum splits. Food Res. Int. 2010, 43, 483–488. [Google Scholar] [CrossRef]

- Mannam, V. Role of hydration in grain processing: A review. In Developing Technologies in Food Science: Status, Applications, and Challenges, 1st ed.; Meghwal, M., Goyal, M.R., Eds.; Apple Academic Press: New York, NY, USA, 2017; pp. 33–63. [Google Scholar]

- Frías, J.; Vidal-Valverde, C.; Sotomayor, C.; Díaz-Pollan, C.; Urbano, G. Influence of processing on available carbohydrate content and antinutritional factors of chickpeas. Eur. Food Res. Technol. 2000, 210, 340–345. [Google Scholar] [CrossRef]

- Krokida, M.K.; Marinos-Kouris, D. Rehydration kinetics of dehydrated products. J. Food Eng. 2003, 57, 1–7. [Google Scholar] [CrossRef]

- Monteiro, R.L.; Domschke, N.N.; Tribuzi, G.; Teleken, J.T.; Carciofi, B.A.M.; Laurindo, J.B. Producing crispy chickpea snacks by air, freeze, and microwave multi-flash drying. LWT-Food Sci. Technol. 2021, 140, 110781. [Google Scholar] [CrossRef]

- Uzogara, S.; Morton, I.; Daniel, J. Influence of various salts in the cooking water on pectin losses and cooked texture of cowpeas (Vigna unguiculata). J. Food Biochem. 2007, 14, 283–291. [Google Scholar] [CrossRef]

- Aravindakshan, S.; Nguyen, T.H.A.; Kyomugasho, C.; Buvé, C.; Dewettinck, K.; Van Loey, A.; Hendrickx, M.E. The impact of drying and rehydration on the structural properties and quality attributes of pre-cooked dried beans. Foods 2021, 10, 1665. [Google Scholar] [CrossRef]

- Ulloa, J.A.; Ibarra-Zavala, S.J.; Ramírez-Salas, S.P.; Rosas-Ulloa, P.; Ramírez-Ramírez, J.C.; Ulloa-Rangel, B.E. Chemical, physicochemical, nutritional, microbiological, sensory and rehydration characteristics of instant whole beans (Phaseolus vulgaris). Food Technol. Biotechnol. 2015, 53, 48–56. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, M.; Bhandari, B.; Sun, J.; Chen, J. Novel freeze drying based technologies for production and development of healthy snacks and meal replacement products with special nutrition and function: A review. Dry. Technol. 2022, 40, 1582–1597. [Google Scholar] [CrossRef]

- Gupta, S.; Liu, C.; Sathe, S.K. Quality of a chickpea-based high protein snack. J. Food Sci. 2019, 84, 1621–1630. [Google Scholar] [CrossRef]

- Jayasena, D.D.; Ahn, D.U.; Nam, K.C.; Jo, C. Flavour chemistry of chicken meat: A review. Asian-Australas. J. Anim. Sci. 2013, 26, 732–742. [Google Scholar] [CrossRef]

- Kerth, C.R.; Miller, R.K. Beef flavor: A review from chemistry to consumer. J. Sci. Food Agric. 2015, 95, 2783–2798. [Google Scholar] [CrossRef]

- Juárez, M.; Aldai, N.; López-Campos, Ó.; Dugan, M.; Uttaro, B.; Aalhus, J. Beef texture and juiciness. In Handbook of Meat and Meat Processing, 2nd ed.; Hui, Y.H., Ed.; CCR Press: Boca Ratón, FL, USA, 2012; pp. 177–206. [Google Scholar] [CrossRef]

- Caliskan, G.; Dirim, S.N. Drying characteristics of pumpkin (Cucurbita moschata) slices in convective and freeze dryer. Heat Mass Transf./Waerme-Und Stoffuebertragung 2017, 53, 2129–2141. [Google Scholar] [CrossRef]

- Juknienė, I.; Zaborskienė, G.; Jankauskienė, A.; Kabašinskienė, A.; Zakarienė, G.; Bliznikas, S. Effect of lyophilization process on nutritional value of meat by-products. Appl. Sci. 2022, 12, 12984. [Google Scholar] [CrossRef]

- Etherington, D.J.; Sims, T.J. Detection and estimation of collagen. J. Sci. Food Agric. 1981, 32, 539–546. [Google Scholar] [CrossRef]

- Sims, J.S.; Bailey, J.B. Connective tissue. In Developments in Meat Science, 1st ed.; Lawrie, R.A., Ed.; Applied Science: London, UK, 1981; Volume 2, pp. 29–59. [Google Scholar]

- Álvarez, M.D.; Canet, W.; Tortosa, M.E. Kinetics of thermal softening of potato tissue (cv. Monalisa) by water heating. Eur. Food Res. Technol. 2001, 212, 588–596. [Google Scholar] [CrossRef]

- Bordoloi, A.; Singh, J.; Kaur, L. In vitro digestibility of starch in cooked potatoes as affected by guar gum: Microstructural and rheological characteristics. Food Chem. 2012, 133, 1206–1213. [Google Scholar] [CrossRef]

- Paulus, K.; Saguy, I. Effect of heat treatment on the quality of cooked carrots. J. Food Sci. 1980, 45, 239–241. [Google Scholar] [CrossRef]

- Paciulli, M.; Ganino, T.; Carini, E.; Pellegrini, N.; Pugliese, A.; Chiavaro, E. Effect of different cooking methods on structure and quality of industrially frozen carrots. J. Food Sci. Technol. 2016, 53, 2443–2451. [Google Scholar] [CrossRef] [PubMed]

- Kaur, L.; Singh, N.; Singh Sodhi, N.; Singh Gujral, H. Some properties of potatoes and their starches I. Cooking, textural and rheological properties of potatoes. Food Chem. 2002, 79, 177–181. [Google Scholar] [CrossRef]

- Wang, L.; Qiao, K.; Duan, W.; Zhang, Y.; Xiao, J.; Huang, Y. Comparison of taste components in stewed beef broth under different conditions by means of chemical analyzed. Food Sci. Nutr. 2020, 8, 955–964. [Google Scholar] [CrossRef]

- Pereira-Lima, C.I.; Ordóñez, J.A.; García de Fernando, G.D.; Cambero, M.I. Influence of heat treatment on carnosine, anserine and free amino acid composition of beef broth and its role in flavour development. Eur. Food Res. Technol. 2000, 210, 165–172. [Google Scholar] [CrossRef]

- Pérez-Palacios, T.; Eusebio, J.; Palma, S.F.; Carvalho, M.J.; Mir-Bel, J.; Antequera, T. Taste compounds and consumer acceptance of chicken soups as affected by cooking conditions. Int. J. Food Prop. 2017, 20, S154–S165. [Google Scholar] [CrossRef]

- Zhang, L.; Hao, Z.; Zhao, C.; Zhang, Y.; Li, J.; Sun, B.; Tang, Y.; Yao, M. Taste compounds, affecting factors, and methods used to evaluate chicken soup: A review. Food Sci. Nutr. 2021, 9, 5833–5853. [Google Scholar] [CrossRef]

- Dekker, M.; Hennig, K.; Verkerk, R. Differences in thermal stability of glucosinolates in five brassica vegetables. Czech J. Food Sci. 2009, 27, S85–S88. [Google Scholar] [CrossRef]

- Renz, M.; Dekker, M.; Rohn, S.; Hanschen, F.S. Plant matrix concentration and redox status influence thermal glucosinolate stability and formation of nitriles in selected Brassica vegetable broths. Food Chem. 2023, 404, 134594. [Google Scholar] [CrossRef]

- Toldrá, F.; Reig, M. Sausages. In Handbook of Food Products Manufacturing, 1st ed.; Hui, Y.H., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007; Volume 2, pp. 251–264. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Franco Ruiz, D.; Carballo, J. Fat content of dry-cured sausages and its effect on chemical, physical, textural and sensory properties. In Fermented Meat Products, 1st ed.; Zdolec, N., Ed.; CRC Press: Boca Ratón, FL, USA, 2016; Volume 1, pp. 474–487. [Google Scholar]

- Paris, J.M.G.; Falkenberg, T.; Nöthlings, U.; Heinzel, C.; Borgemeister, C.; Escobar, N. Changing dietary patterns is necessary to improve the sustainability of Western diets from a One Health perspective. Sci. Total Environ. 2022, 811, 151437. [Google Scholar] [CrossRef]

| Cooking System | Temperature (°C) | Time (min) | Hardness (N) | Adhesiveness (N×s, ×101) | Springiness (m, ×102) | Cohesiveness | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BL | CA | PD | BL | CA | PD | BL | CA | PD | BL | CA | PD | |||

| OC | 80 | 30 | 34.8 ± 6.76 a,β | 65.6 ± 9.01 a,α | 29.8 ± 2.92 a,γ | −0.04 ± 0.027 a | −0.03 ± 0.007 a | −0.02 ± 0.021 a | 0.20 ± 0.020 b,α | 0.25 ± 0.050 c,α | 0.11 ± 0.039 c,β | 0.15 ± 0.041 ab | 0.11 ± 0.008 ab | 0.14 ± 0.021 ab |

| 60 | 21.6 ± 2.50 b,β | 42.1 ± 5.57 b,α | 21.9 ± 3.15 b,β | −0.05 ± 0.019 a | −0.03 ± 0.015 a | −0.03 ± 0.023 a | 0.21 ± 0.031 b,β | 0.28 ± 0.011 b,α | 0.13 ± 0.058 c,γ | 0.23 ± 0.039 a | 0.11 ± 0.009 ab | 0.13 ± 0.020 ab | ||

| 90 | 19.8 ± 3.52 b,α | 21.0 ± 9.00 c,α | 13.8 ± 3.48 c,β | −0.09 ± 0.044 a | −0.06 ± 0.018 a | −0.04 ± 0.013 a | 0.22 ± 0.039 b,β | 0.30 ± 0.043 b,α | 0.13 ± 0.039 c,γ | 0.17 ± 0.049 a | 0.17 ± 0.008 a | 0.18 ± 0.011 a | ||

| 120 | 12.8 ± 4.31 b,β | 17.2 ± 6.30 c,α | 13.7 ± 6.43 c,β | −0.04 ± 0.031 a | −0.06 ± 0.017 a | −0.06 ± 0.030 a | 0.27 ± 0.051 ab,α | 0.33 ± 0.066 b,α | 0.21 ± 0.038 b,β | 0.18 ± 0.038 a | 0.19 ± 0.014 a | 0.19 ± 0.031 a | ||

| 150 | 10.5 ± 1.88 b,β | 19.3 ± 7.14 c,α | 8.90 ± 1.79 c,β | −0.03 ± 0.020 a | −0.02 ± 0.011 a | −0.03 ± 0.013 a | 0.30 ± 0.033 a,β | 0.41 ± 0.019 a,α | 0.23 ± 0.078 ab,γ | 0.15 ± 0.048 ab | 0.15 ± 0.041 a | 0.14 ± 0.021 ab | ||

| 180 | 6.72 ± 1.52 c,β | 18.3 ± 4.01 c,α | 11.8 ± 5.33 c,β | −0.09 ± 0.041 a | −0.05 ± 0.019 a | −0.03 ± 0.023 a | 0.33 ± 0.074 a,α | 0.37 ± 0.033 a,α | 0.23 ± 0.030 ab,β | 0.19 ± 0.090 a | 0.16 ± 0.071 a | 0.18 ± 0.009 a | ||

| 210 | 5.24 ± 1.22 c,β | 8.83 ± 4.01 d,β | 15.8 ± 2.98 c,α | −0.04 ± 0.026 a | −0.03 ± 0.016 a | −0.02 ± 0.023 a | 0.30 ± 0.064 a,α | 0.37 ± 0.071 a,α | 0.23 ± 0.041 ab,β | 0.24 ± 0.048 a | 0.17 ± 0.043 a | 0.13 ± 0.041 ab | ||

| 240 | 3.64 ± 1.12 c,β | 12.2 ± 3.00 d,α | 10.2 ± 3.74 c,α | −0.05 ± 0.022 a | −0.03 ± 0.007 a | −0.04 ± 0.011 a | 0.25 ± 0.014 b,α | 0.35 ± 0.099 ab,α | 0.18 ± 0.058 b,β | 0.15 ± 0.014 ab | 0.20 ± 0.032 a | 0.17 ± 0.011 a | ||

| 100 | 30 | 14.1 ± 4.70 b,α | 3.25 ± 0.51 e,β | 9.98 ± 2.92 c,α | −0.16 ± 0.061 b,β | −0.11 ± 0.001 b,γ | −0.60 ± 0.101 b,α | 0.23 ± 0.059 b,α | 0.25 ± 0.010 c,α | 0.17 ± 0.060 ab,γ | 0.16 ± 0.021 ab | 0.12 ± 0.041 ab | 0.17 ± 0.020 a | |

| 60 | 7.45 ± 1.50 c,α | 2.08 ± 0.03 f,β | 6.49 ± 0.15 d,α | −0.19 ± 0.091 b,β | −0.12 ± 0.003 b,γ | −1.07 ± 0.121 c,α | 0.27 ± 0.058 ab,β | 0.32 ± 0.004 b,β | 0.23 ± 0.059 ab,β | 0.15 ± 0.011 ab | 0.14 ± 0.033 ab | 0.17 ± 0.019 a | ||

| 90 | 1.42 ± 0.700 d,α | 1.02 ± 0.011 g,β | 1.14 ± 0.137 e,α | −0.20 ± 0.081 bc,β | −0.18 ± 0.081 c,β | −1.90 ± 0.301 d,α | 0.33 ± 0.060 a,α | 0.35 ± 0.061 ab,α | 0.23 ± 0.049 ab,β | 0.17 ± 0.023 ab | 0.15 ± 0.021 ab | 0.17 ± 0.031 a | ||

| 120 | 0.39 ± 0.018 e | 0.28 ± 0.013 h | 0.27 ± 0.010 f | −0.20 ± 0.071 bc,β | −0.20 ± 0.023 c,β | −1.60 ± 0.173 d,α | 0.35 ± 0.060 a,α | 0.37 ± 0.059 a,α | 0.27 ± 0.058 a,β | 0.15 ± 0.011 ab | 0.17 ± 0.041 ab | 0.16 ± 0.021 a | ||

| 150 | 0.35 ± 0.019 e | 0.26 ± 0.140 h | 0.20 ± 0.014 f | −0.21 ± 0.055 bc,β | −0.21 ± 0.004 c,β | −1.57 ± 0.151 d,α | 0.37 ± 0.059 a,α | 0.40 ± 0.080 a,α | 0.27 ± 0.059 a,β | 0.17 ± 0.022 ab | 0.14 ± 0.023 ab | 0.14 ± 0.019 ab | ||

| 180 | 0.19 ± 0.013 e | 0.20 ± 0.010 h | 0.18 ± 0.010 f | −0.21 ± 0.039 bc,β | −0.19 ± 0.090 c,β | −1.43 ± 0.423 d,α | 0.37 ± 0.039 a,αβ | 0.45 ± 0.030 a,α | 0.33 ± 0.021 a,β | 0.15 ± 0.014 ab | 0.16 ± 0.018 ab | 0.16 ± 0.009 ab | ||

| 210 | 0.19 ± 0.020 e | 0.18 ± 0.011 h | 0.16 ± 0.015 f | −0.29 ± 0.061 c,β | −0.22 ± 0.013 bc,β | −1.60 ± 0.464 d,α | 0.37 ± 0.044 a,β | 0.47 ± 0.029 a,α | 0.30 ± 0.018 a,γ | 0.14 ± 0.013 b | 0.15 ± 0.019 ab | 0.14 ± 0.019 ab | ||

| 240 | 0.15 ± 0.017 e | 0.16 ± 0.015 h | 0.11 ± 0.031 f | −0.25 ± 0.071 c,β | −0.26 ± 0.043 c,β | −1.24 ± 0.321 bc,α | 0.23 ± 0.014 b,β | 0.35 ± 0.027 ab,α | 0.23 ± 0.013 ab,β | 0.11 ± 0.011 b | 0.12 ± 0.009 b | 0.12 ± 0.011 b | ||

| PC | 120 | 15 | 0.19 ± 0.011 | 0.18 ± 0.020 | 0.19 ± 0.019 | −0.17 ± 0.018 a | −0.16 ± 0.013 a | −0.14 ± 0.018 a | 0.33 ± 0.039 b,α | 0.30 ± 0.031 b,α | 0.23 ± 0.022 b,β | 0.16 ± 0.012 a,β | 0.16 ± 0.010 a,β | 0.19 ± 0.020 a,α |

| 20 | 0.18 ± 0.013 | 0.18 ± 0.010 | 0.17 ± 0.010 | −0.22 ± 0.010 b,β | −0.17 ± 0.010 a,α | −0.26 ± 0.013 b,β | 0.37 ± 0.045 ab,α | 0.37 ± 0.060 ab,α | 0.30 ± 0.013 a,β | 0.14 ± 0.020 a,β | 0.14 ± 0.011 a,β | 0.17 ± 0.010 a,α | ||

| 30 | 0.17 ± 0.010 | 0.17 ± 0.011 | 0.16 ± 0.070 | −0.30 ± 0.020 c,β | −0.27 ± 0.017 b,α | −0.44 ± 0.011 c,γ | 0.40 ± 0.011 a,α | 0.39 ± 0.020 a,α | 0.31 ± 0.010 a,β | 0.05 ± 0.010 b | 0.04 ± 0.010 b | 0.05 ± 0.009 b | ||

| Cooking Parameters 1 | Sum of Ranks 2 | ||||||

|---|---|---|---|---|---|---|---|

| Chickpea Variety 3 | |||||||

| System | t (Min) | PD | BL | CA | |||

| OC | 90 | 10 | c | 11 | c | 10 | c |

| 120 | 17 | bc | 17 | bc | 18 | bc | |

| 150 | 35 | ab | 27 | ab | 26 | ab | |

| 180 | 49 | a | 53 | a | 51 | a | |

| 210 | 45 | a | 39 | ab | 43 | ab | |

| 240 | 33 | ab | 42 | ab | 41 | ab | |

| PC | 15 | 27 | ab | 28 | ab | 28 | ab |

| 20 | 36 | a | 35 | a | 34 | a | |

| 30 | 18 | bc | 17 | bc | 19 | bc | |

| 60 | 9 | c | 10 | c | 9 | c | |

| Cooking Parameters 1 | Rehydration Parameters | Sum of Ranks 2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Chickpea Variety 3 | |||||||||

| System | t (Min) | % NaCl | T (°C) | PD | BL | CA | |||

| OC | 180 | 0 | 20–22 | 9 | c | 10 | c | 10 | c |

| 2 | 20–22 | 19 | bc | 19 | bc | 17 | bc | ||

| 0 | 90–100 | 26 | ab | 26 | ab | 28 | ab | ||

| 2 | 90–100 | 36 | a | 35 | a | 35 | a | ||

| PC | 20 | 0 | 20–22 | 11 | c | 10 | c | 12 | c |

| 2 | 20–22 | 16 | bc | 18 | bc | 18 | bc | ||

| 0 | 90–100 | 29 | ab | 26 | ab | 25 | ab | ||

| 2 | 90–100 | 34 | a | 36 | a | 35 | a | ||

| Ingredients Cooked Together for Broth Obtention | Sensory Analysis * | Open Cooker, 100 °C | Pressure Cooker | ||||

|---|---|---|---|---|---|---|---|

| t (min) | t (min) | ||||||

| 60 | 90 | 180 | 30 | 60 | 90 | ||

| Chicken (quarters) | Sum of ranks | 9b | 19ab | 26a | 12b | 19ab | 23a |

| Descriptive after cooking | Tough texture. Poor development of taste and aroma | Cohesive and maintains integrity. Not juicy. Mild taste and aroma but pleasant | Texture: soft and juicy. Chicken broth flavor. Pleasant aroma and appearance | Texture: tough. Mild flavor and aroma to chicken broth. Pleasant appearance | Texture: soft but compact and mildly dry. Pleasant taste and aroma to chicken broth | Texture: soft and disintegrated, lack of cohesion. Pleasant taste and aroma | |

| Descriptive after freeze-drying and rehydration | Texture, flavor and appearance similar to the cooked product | Texture: compact and dry. Taste and aroma similar to the cooked product | Texture: soft and juicy. Flavor, aroma and appearance similar to the cooked product | Texture, flavor and appearance similar to the cooked product | Texture: compact and dry. Taste and aroma: similar to the cooked product | Texture: soft and disintegrated, lack of cohesion. Meat crumbled during mastication. Flavor and appearance similar to the cooked product | |

| Beef: flank and shank cuts | Sum of ranks | 9b | 18ab | 27a | 10b | 17ab | 27a |

| Descriptive after cooking | Excessively tough meat, hard to chew. Poor flavor development, very slightly umami. Pleasant appearance | Tough meat. Pleasant taste, aroma and appearance, slightly meaty, umami | Doneness desired. Soft and juicy meat. Intense sapid and aromatic development, very pleasant, umami and meaty touches | Hard, compact meat. Little but pleasant sapid and aromatic development | Tender meat. Pleasant taste, smell and appearance. Soft sapid and aromatic development | Doneness desired. Very soft meat. Soft sapid and aromatic development | |

| Descriptive after freeze-drying and rehydration | Tough and leathery meat, hard to chew. Nice appearance. Taste and aroma similar to the cooked product | Hard, compact meat. Nice look. Little sapid and aromatic development. Pleasant | Maintains structure. Smooth and juicy meat. Very pleasant tasty and aromatic development, similar to the cooked product | Texture, flavor and appearance similar to the cooked product | Texture, flavor, aroma and appearance similar to the cooked product | Doneness desired. Soft and juicy meat. Disintegrates easily, frayed. Good flavorful and aromatic development | |

| Turnip (Brassica napus), Carrot (Daucus carota sativus), Leek (Allium ampeloprasum var. porrum) and Potato (Solanum tuberosum) | Sum of ranks | 9b | 19ab | 26a | 9b | 18ab | 27a |

| Descriptive after cooking | Texture: tough. Pleasant appearance, flavor and aroma | Smooth, somewhat rough texture. Pleasant taste, smell and appearance | Texture: soft and juicy. Pleasant flavor, aroma and appearance | Hard texture. Little sapid and aromatic development. Pleasing appearance | Slightly rough and fibrous texture. Mild flavor and aroma. Pleasing appearance | Smooth texture. Good flavor and aromatic development. Pleasing appearance | |

| Descriptive after freeze-drying and rehydration | Dry texture and appearance similar to the cooked product | Rubbery texture, but juicy. Flavor and aroma characteristics very similar to those of the cooked product | Maintains structure. Soft and juicy. Maintains flavor and aroma | Texture, flavor and appearance similar to the cooked product | Fibrous, juicy texture. Similar flavor and aroma to the freshly cooked product | Maintains tissue integrity. Soft and juicy texture. Taste and aroma similar to the freshly cooked product | |

| Broth | Sum of ranks | 9b | 18ab | 27a | 9b | 20a | 25a |

| Descriptive after cooking | Little sapid and aromatic development. Light umami and meaty flavor | Pleasant sapid and aromatic development, but mild umami and meaty flavor. Aroma and taste associated with plain beef broth | Very nice sapid development. Meaty, tasty, similar to the traditional product. Dense | Little sapid and aromatic development. Light umami and meaty flavor | Pleasant sapid and aromatic development, but mild umami and meaty flavor. Aroma and taste associated with plain beef broth | Meaty, tasty, similar to the traditional product. Dense. Certain "overheated" aftertaste | |

| Descriptive after freeze-drying and rehydration | N/A | Maintains the sapid and aromatic characteristics of the cooked product | Maintains the sapid and aromatic characteristics of the cooked product | N/A | Maintains the sapid and aromatic flavor and aroma characteristics of the cooked product | Maintains the sapid and aromatic characteristics of the cooked product | |

| Ingredients cooked independently | Open Cooker, 100 °C | Pressure Cooker | |||||

| t (min) | t (min) | ||||||

| 15 | 30 | 60 | 15 | 30 | 60 | ||

| Cabbage (Brassica Oleracea) | Sum of ranks | 10b | 26a | 18ab | 25a | 18ab | 11b |

| Descriptive after cooking | Texture: tough. Flavor and aroma: poorly developed. Pleasant appearance | Smooth texture. Nice taste and appearance | Pleasant flavor and appearance but soft texture | Smooth texture. Maintains integrity. Nice taste and appearance | Texture: disintegrated, extremely soft | Texture: disintegrated, extremely soft | |

| Descriptive after freeze-drying and rehydration | Similar texture and flavor to the cooked product | Maintains integrity. Similar flavor and aroma to the cooked product | Maintains integrity. Similar flavor and aroma to the cooked product | Similar flavor and aroma to the cooked product | N/A | N/A | |

| Spicy pork sausage (Spanish chorizo) | Sum of ranks | 27a | 17ab | 10b | |||

| Descriptive after cooking | Texture: compact, soft and juicy. Appearance, flavor and aroma typic of the product | Texture: compact and juicy. Typic (characteristic) flavor and aroma of the product | Compact but dry texture. Characteristic flavor of the product but with aftertastes with slight touches of rancid. Nice appearance | ||||

| Descriptive after freeze-drying and rehydration | Soft texture but fatty. Characteristic flavor and aroma of the product, with rancid nuances. Nice appearance | Texture: compact and dry. flavor and aroma: similar to the cooked product | Texture: compact and dry. flavor and aroma: similar to the cooked product | ||||

| Pork blood sausage (Spanish morcilla) | Sum of ranks | 27a | 15ab | 12b | |||

| Descriptive after cooking | Texture: compact, soft and juicy. Appearance, flavor and aroma typic of the product | Texture: disintegrated, lack of cohesion. Appearance, flavor and aroma typic of the product | Texture: dry and disintegrated, lack of cohesion. Appearance, flavor and aroma typic of the product but with slight hints of rancidity | ||||

| Descriptive after freeze-drying and rehydration | Texture: soft. Pleasant appearance, flavor and aroma; typic of the product | Texture: compact and dry. flavor and aroma: similar to the cooked product | Texture: compact and dry. flavor and aroma: similar to the cooked product | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cambero, M.I.; García de Fernando, G.D.; Romero de Ávila, M.D.; Remiro, V.; Capelo, L.; Segura, J. Freeze-Dried Cooked Chickpeas: Considering a Suitable Alternative to Prepare Tasty Reconstituted Dishes. Foods 2023, 12, 2339. https://0-doi-org.brum.beds.ac.uk/10.3390/foods12122339

Cambero MI, García de Fernando GD, Romero de Ávila MD, Remiro V, Capelo L, Segura J. Freeze-Dried Cooked Chickpeas: Considering a Suitable Alternative to Prepare Tasty Reconstituted Dishes. Foods. 2023; 12(12):2339. https://0-doi-org.brum.beds.ac.uk/10.3390/foods12122339

Chicago/Turabian StyleCambero, M. Isabel, Gonzalo Doroteo García de Fernando, M. Dolores Romero de Ávila, Víctor Remiro, Luis Capelo, and José Segura. 2023. "Freeze-Dried Cooked Chickpeas: Considering a Suitable Alternative to Prepare Tasty Reconstituted Dishes" Foods 12, no. 12: 2339. https://0-doi-org.brum.beds.ac.uk/10.3390/foods12122339