1. Introduction

The National Health and Nutrition Examination (2005) [

1] reported that Koreans consume an average of 1291.4 g of food per person per day. This consumption includes 76.2 g (5.9%) of seafood products, which is gradually increasing every year.

According to the Korea Rural Economic Institute, the per capita consumption of seafood in Korea increased from 52.8 kg in 2001 to 68.4 kg in 2020. This increase in the consumption of aquatic products is likely attributable to the improvement in national income and the general interest among the population in consuming healthy food. This has increased consumer preference for aquatic products as healthy foods.

Cephalopods are among the most important aquatic resources worldwide due to their excellent taste and high nutritional value. Korea consumes more than 400,000 tons of cephalopods annually. The Korea Fishery Trade Association reports that cephalopod imports in Korea have been steadily increasing since 2017 [

2,

3].

Based on the datasets provided by the National Statistical Office of the Republic of Korea, the proportion of the elderly population was recorded at 7.0% in the year 2000, signifying the onset of a demographic transition towards an aging society. This reached 14.2% in 2017, which indicated a transition into an aged society. By 2025, it is predicted that the elderly population will reach 20.6%; thus, the country will enter into being a super-aged society [

4].

Recently, due to the increase in the number of elderly citizens in Korea, Korean food factories are also producing elderly-friendly foods. Standards for elderly-friendly foods are presented and managed by the Food Code [

5] of the Ministry of Food and Drug Safety and the Korean Industrial Standards (KS standards) [

6] of the Ministry of Trade, Industry and Energy. Specifically, the Ministry of Agriculture, Food, and Rural Affairs and the Ministry of Oceans and Fisheries have recently designated excellent elderly-friendly foods; most of the 79 types of these excellent elderly-friendly foods are mainly agricultural or livestock products, and only eight products are related to aquatic products. These aquatic products use flatfish, hairtail, cod, abalone, seaweed, pollack, mackerel, and bonito flakes. However, no elderly-friendly food using octopuses (small octopus or long-arm octopus), preferred by Koreans, has been released.

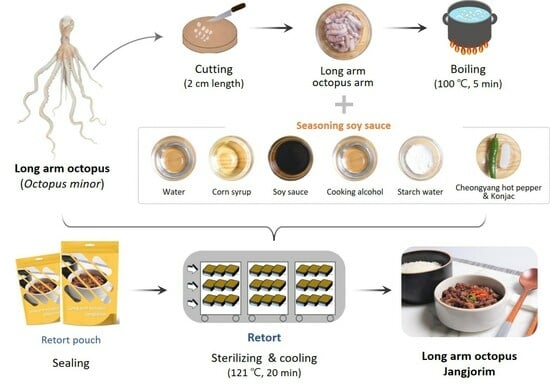

In Korea, long-arm octopuses are mainly consumed in stir-fried, steamed, and

yeonpo-tang (octopus soup) form, and processed foods such as stir-fried and canned foods have been studied [

7,

8]. However, to the best of our knowledge, there is no elder-friendly food that uses a long-arm octopus.

Jangjorim is a Korean food prepared by boiling meat or eggs in soy sauce [

9]. Starting with the 1988 Seoul Olympics, the number of people in the West who became aware of

Jangjorim has increased, and it is known as the most popular Korean dish among foreigners, along with

Galbitang (beef ribs Korean soup),

Samgyetang (chicken and ginseng Korean soup), and

Bibimbap (Korean food composed of steamed rice, minced beef, and other vegetables along with

Gochujang (a red chili paste) and sesame seed oil). In East Asia, many people like

Jangjorim because there are similar dishes in Chinese and Japanese cuisines, and their tastes are quite similar. Raw materials for making soybean paste for

Jangjorim include beef [

10,

11], pork [

12], and chicken meat [

13] for meat dishes, and chicken eggs [

14] and quail eggs [

15] for egg dishes. However, to the best of our knowledge,

Jangjorim has rarely been developed using seafood as raw meat.

Long-arm octopus is known to be a representative seafood product that helps strengthen immunity due to its high taurine content so it is receiving great attention from elderly consumers. However, it is difficult for elderly consumers with chewing disorders to consume it raw or after simple heat treatment.

Therefore, in this study, we identified a method of softening the physical properties of long-arm octopus, which has hard muscle tissue, to make it easier for elderly consumers to consume and investigated the quality characteristics of Jangjorim developed using long-arm octopus.

4. Discussion

Recent studies on marine-product-based home meal replacement (HMR) products in Korea have introduced HMR foods or elderly-friendly foods such as salmon, chub mackerel, hairtail, pollack, flatfish, Pacific anchovy, and abalone [

27,

28,

29,

30,

31,

32]. Among these, Sutikno et al. [

33] studied the development of HMR products using a mollusk, namely, web-foot octopus (

Amphioctopus sp.), Negara et al. [

34] focused on improving quality characteristics of HMR products using common squid (

Todarodes pacificus Steenstrup), Kang et al. [

17] studied texture-modified octopus (

Octopus vulgaris) arms, and Kang et al. [

35] conducted a study on the development of an elderly-friendly HMR product using common squid (

Todarodes pacificus). However, to date, no studies have reported the development of a

Jangjorim prototype using the long-arm octopus (

Octopus minor); therefore, it was developed in this study.

p-values for the lack of fit of the design model’s equation for hardness (

Y1), salinity (

Y2), and sensory taste (

Y3) according to the mixing ratio of the materials of the LOJP were 0.152, 0.114, and 0.154, respectively. These values were all > 0.05, and the coefficients of determination (R

2) for hardness (

Y1), salinity (

Y2), and sensory taste (

Y3) were 0.955, 0.973, and 0.927, respectively, which were all close to 1. The

p-values of the response surface models for hardness (

Y1), salinity (

Y2), and sensory taste (

Y3) were all 0.000, which were all < 0.05 and confirmed the suitability of the three designed models. These results are consistent with those of the research designed using RSM by Zhou and Regenstein [

36] and Bezerra et al. [

37].

Thus, the change in taste according to the ratio of the main ingredients of the LOJP determined through RSM showed an inverse tendency in salinity and sensory taste because of the influence of starch syrup and soy sauce. These findings indicate that, as their addition ratio increased, the preference score decreased. These results are consistent with those of Heo and Lee [

38] and Kremer et al. [

39], who also reported that the addition of ingredients with high salt content, such as soy sauce, reduces preference. Therefore, the results of this study provide evidence that the optimal mixing ratio should be based on consumer preferences.

The optimal sterilization time that can Ie inferred from the F

0 value of the LOJP was determined to be 20 min. Although the hardness results of the LOJP showed no significant difference between the LOJPs sterilized for 15 and 20 min, when consumed by elderly consumers, 20 min was judged to be appropriate considering safety. Kim et al. [

40] conducted a study to establish sterilization conditions for canned goods using skipjack tuna (

Katsuwonus pelamis) and reported that sterilization must be performed, indicating that the F

0 value should be ≥4 min to ensure safety during distribution and storage. These findings are consistent with the results presented in this study.

Presumably, the longer the heating treatment time of the LOJP, the higher the hardness of the LOJP because the sauce and long-arm octopus heated for a long time under high-temperature conditions tended to clump together. Furthermore, it was determined that the pectin, sugars, and organic acids in starch syrup and soy sauce were gelled by heat treatment. These results are similar to those reported by Choi et al. [

41], who studied changes in quality characteristics during refrigerated storage of soy sauce manufactured using superheated steam and ultra-high-pressure processing. Accordingly, in this study, the sterilization time (20 min) was established at a level where the hardness of the LOJP did not interfere with the masticatory function of elderly consumers.

The comparison of the crude protein of the LOJP and the total amino acid content showed that the crude protein content of the LOJP (8.7 g/100 g) increased by 11.5% compared with that of the raw long-arm octopus (9.7 g/100 g) (

p < 0.05). Additionally, the total amino acid content of the LOJP was 8824.7 mg/100 g, which was 6.3% higher than that of the raw long-arm octopus (8299.9 mg/100 g); however, the difference was not significant. The difference between these results was due to the addition of soy sauce as an ingredient in the LOJP. Soy sauce is generally manufactured through the fermentation of soy protein and is a seasoning with <10% protein content [

42]. Wang et al. [

43] reported that the protein contained in soy sauce powder can be used as an ingredient and a nutritional source for various foods.

The fatty acid content in the raw long-arm octopus and the LOJP was confirmed to be made up of 22 (11:0–22:6n-3) and 24 (4:0–22:6n-3) fatty acids, respectively. The main fatty acids in the raw long-arm octopus were 22:6n-3 (EPA, 78.7 mg/100 g), 20:5n-3 (DHA, 79.8 mg/100 g), 16:0 (palmitic acid, 56.5 mg/100 g), and 18:0 (stearic acid, 23.2 mg/100 g). Among the total fatty acid contents of raw long-arm octopus, the percentage of polyunsaturated fatty acid was the highest at 163.7 mg/100 g (48.6%), followed by saturated fatty acid (SFA) at 137.3 mg/100 g (40.8%).

The main fatty acids of the LOJP were C22:6n-3 (EPA, 626.4 mg/100 g), C23:0 (413.1 mg/100 g), C18:0 (stearic acid, 383.5 mg/100 g), C16:0 (palmitic acid, 344.4 mg/100 g), and C20:5n-3 (DHA, 263.2 mg/100 g), which were different when compared to the fatty acid composition of raw long-arm octopus. Regarding the overall fatty acid content of the LOJP, the proportion of SFA was the highest at 1277.5 mg/100 g (49.9%), followed by PUFA at 1114.0 mg/100 g (43.5%), and monounsaturated fatty acid was 170.9 mg/100 g (6.6%), which accounted for the lowest proportion.

The ω-3 fatty acid content in LOJP was 914.0 mg/100 g (35.8%). This was confirmed to be higher by 751 mg/100 g compared to the content of ω-6 fatty acid (163.0 mg/100 g, 6.3%). Panpipat and Yongsawatdigul [

44] and Kang et al. [

17] reported that nutritionally balanced foods contain relatively higher levels of ω-3 fatty acids than ω-6 fatty acids. Foods typically contain various fatty acids, but studies support that a higher ω-6 fatty acid content can cause disease [

44,

45]. The results of the fatty acid content of the LOJP suggest it to be an excellent food that can provide nutrients to elderly consumers through ω-3 fatty acids.

The mineral content of long-arm octopus was compared with the nutritional intake standards for elderly age Korean consumers (65–74 years old), as reported by Korea’s Ministry of Health and Welfare [

26]. It was 2.7% for men and 2.4% for women compared with the recommended daily calcium intake (700 mg/day for men and 800 mg/day for women). It was 4.1% of the standard daily potassium intake (3500 mg/day for both men and women) for both men and women. Compared with the recommended daily iron intake (9 mg/day for men and 8 mg/day for women), it was 42.2% for men and 47.5% for women, and it was 12.2% for men and 15.7% for women when compared with the recommended daily zinc intake (9 mg/day for men and 7 mg/day for women).

In contrast, the calcium content of the LOJP was 23.7 mg/100 g, potassium content was 375.7 mg/100 g, iron content was 4.6 mg/100 g, and zinc content was 2.4 mg/100 g. This was 3.4% for men and 3.0% for women compared with the recommended daily calcium intake according to the nutritional intake standards for elderly age Korean consumers (65–74 years old). This was 10.7% for both men and women compared with the standard daily potassium intake. The recommended daily iron intake was 51.1% for men and 57.5% for women. Compared with the recommended daily zinc intake (9 mg/day for men and 7 mg/day for women), this was 26.7% for men and 34.3% for women. Therefore, the mineral content of the LOJP was higher than that of the raw long-arm octopus, and the LOJP was determined to be a major source of minerals.

The LOJP had a pH of 6.87 and a VBN content of 15.4 mg/100 g, indicating excellent freshness. Additionally, when the LOJP was produced using raw long-arm octopuses, TBC and BGA were not detected in the LOJP, confirming its safety against bacteria. In particular, it met all the standards presented in Korea’s Food Code [

5], indicating that it has hygiene indicators for supplying safe food to elderly consumers. Ramírez-Suárez et al. [

46] reported the indicators of most heat-vulnerable bacteria that are present in food. Thus, the heating conditions (121 °C, 20 min) applied to the LOJP developed in this study were confirmed to be suitable conditions for sterilizing the LOJP. Ates et al. [

47] reported that no bacteria were detected when fish soup was sterilized for 5.5 min, 6.8 min, and 11.5 min in a retort at 62 °C, 65 °C, and 68 °C.

Additionally, the heavy metal content of the LOJP had low concentrations of Pb (0.002 mg/kg) and Cd (0.003 mg/kg) compared to the standards provided by Korea’s Food Code [

5], and it was determined that this amount did not affect the safety of the consumers. Therefore, the microbiological characteristics of the LOJP and the trace heavy metal content results indicate that it is a safe food for elderly consumers.

Yun et al. [

31] reported that among marine products, the microstructures of animal raw materials with muscles have different textures depending on the various muscle materials. Hence, the microstructure of animal seafood products can serve as a basis for consumers to consider texture factors when chewing [

48,

49].

The raw long-arm octopus (sample A) exhibited a very dense tissue structure. This may be possible because the long-arm octopus was not subjected to any heat treatment, and the space between the muscle fibers of the myofibrillar protein was small, resulting in a dense structure. In contrast, the cross-section of the LOJP (sample B) produced using the long-arm octopus that had only been boiled presented with more holes compared with sample A, which were created due to cracking between muscle fibers. The cross-section of the LOJP (sample C) produced using a sterilized long-arm octopus presented more widely spaced muscle fibers. It was determined that the muscle fibers of the long-arm octopus expanded because of the heat treatment, and the muscle tissue became softer. These results were inferred from the texture results reported by Torres-Arreola et al. [

50]. Reportedly, after boiling jumbo squid (

Dosidicus gigas) muscle (hardness: 29.5 N) at 100 °C (for 30 min), the hardness was considerably reduced to 9.1 N, and the muscle became softer. In contrast, in this study, it was confirmed that when raw long-arm octopus (hardness: 2153.6 × 1000 N/m

2) was heated at 121 °C for 20 min, the hardness was considerably reduced to 34.4 × 1000 N/m

2. Therefore, it is difficult to find studies on the heat-treatment-induced softening of the physical properties of muscle tissue of the long-arm octopus. However, as reported in a previous study on jumbo squid [

50], the effect of heating raw squid on muscle tissue softening provided evidence to support the softening mechanism for the physical properties of long-arm octopuses.

The preference evaluation of the LOJP by elderly consumers showed that among appearance, taste, flavor, and texture items, preference for texture was the highest at 8.7 points. This can be attributed to the decrease in hardness (from 2153.6 × 1000 N/m

2 to 34.4 × 1000 N/m

2) under heating conditions (121 °C, 20 min). Torres-Arreola et al. [

50] and Ando et al. [

51] showed that heat treatment of the arrow squid (

Loligo bleekert) mantle and jumbo squid (

Dosidicus gigas) muscles softened the physical properties and increased the flavor components, improving palatability, which is consistent with our research results.