The Grade of Dried Jujube (Ziziphus jujuba Mill. cv. Junzao) Affects Its Quality Attributes, Antioxidant Activity, and Volatile Aroma Components

Abstract

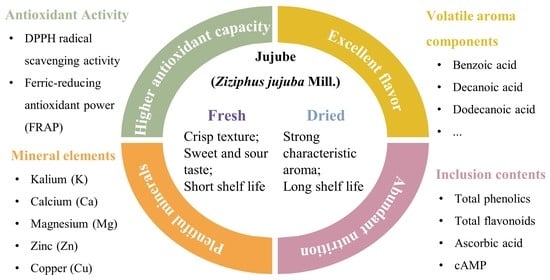

:1. Introduction

2. Materials and Methods

2.1. Materials and Treatments

2.2. Shape Index and Moisture

2.3. Total Soluble Solids (TSS) and Total Acidity (TA)

2.4. Total Phenolics (TP) and Total Flavonoids (TF)

2.5. Ascorbic Acid (AsA)

2.6. Cyclic Adenosine Monophosphate (cAMP)

2.7. Antioxidant Activity

2.8. Mineral Elements

2.9. Volatile Aroma Components Analysis

2.10. Statistical Analysis

3. Results and Discussion

3.1. The Quality Attributes of Dried Jujube

3.2. TP and TF of Dried Jujube

3.3. AsA and cAMP of Dried Jujube

3.4. The Antioxidant Activity of Dried Jujube

3.5. The Mineral Elements of Dried Jujube

3.6. The Correlation Analysis of Dried Jujube

3.7. The Volatile Aroma Components of Dried Jujube

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, Q.-H.; Wu, C.-S.; Wang, M. The Jujube (Ziziphus Jujuba Mill.) Fruit: A Review of Current Knowledge of Fruit Composition and Health Benefits. J. Agric. Food Chem. 2013, 61, 3351–3363. [Google Scholar] [CrossRef] [PubMed]

- Hernández, F.; Noguera-Artiaga, L.; Burló, F.; Wojdyło, A.; Carbonell-Barrachina, Á.A.; Legua, P. Physico-chemical, nutritional, and volatile composition and sensory profile of Spanish jujube (Ziziphus jujuba Mill.) fruits: Bioactive Compounds of Jujube Fruits. J. Sci. Food Agric. 2016, 96, 2682–2691. [Google Scholar] [CrossRef]

- Plastina, P.; Bonofiglio, D.; Vizza, D.; Fazio, A.; Rovito, D.; Giordano, C.; Barone, I.; Catalano, S.; Gabriele, B. Identification of bioactive constituents of Ziziphus jujube fruit extracts exerting antiproliferative and apoptotic effects in human breast cancer cells. J. Ethnopharmacol. 2012, 140, 325–332. [Google Scholar] [CrossRef]

- Zhu, Q.-Y.; Zhang, Q.-Y.; Cao, J.; Cao, W.; Xu, J.-J.; Peng, L.-Q. Cyclodextrin-assisted liquid-solid extraction for determination of the composition of jujube fruit using ultrahigh performance liquid chromatography with electrochemical detection and quadrupole time-of-flight tandem mass spectrometry. Food Chem. 2016, 213, 485–493. [Google Scholar] [CrossRef]

- Kubota, H.; Morii, R.; Kojima-Yuasa, A.; Huang, X.; Yano, Y.; Matsui-Yuasa, I. Effect of Zizyphus jujuba Extract on the Inhibition of Adipogenesis in 3T3-L1 Preadipocytes. Am. J. Chin. Med. 2009, 37, 597–608. [Google Scholar] [CrossRef]

- Zhang, Z.; Gao, W.; Yan, Y.; Huang, L. Study on The Relationship Between Chemical Compositions and Antioxidative Activity of Ziziphus Jujuba Mill. by Chemometric Approach. Int. J. Food Prop. 2015, 18, 277–289. [Google Scholar] [CrossRef]

- Shi, Q.; Li, X.; Zhu, D.; Jiang, J.; Li, X. Comprehensive analysis of antibacterial and anti-hepatoma activity of metabolites from jujube fruit. Food Biosci. 2022, 47, 101511. [Google Scholar] [CrossRef]

- Pan, X.; Zhang, S.; Xu, X.; Lao, F.; Wu, J. Volatile and non-volatile profiles in jujube pulp co-fermented with lactic acid bacteria. LWT 2022, 154, 112772. [Google Scholar] [CrossRef]

- Mayuoni-Kirshinbaum, L.; Porat, R. The flavor of pomegranate fruit: A review. J. Sci. Food Agric. 2013, 94, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Jiang, L.; Ye, S.; Ye, Y.; Ren, F. Systematic evaluation of antioxidant capacities of the ethanolic extract of different tissues of jujube (Ziziphus jujuba Mill.) from China. Food Chem. Toxicol. 2010, 48, 1461–1465. [Google Scholar] [CrossRef] [PubMed]

- Bao, T.; Hao, X.; Shishir, M.; Karim, N.; Chen, W. Cold plasma: An emerging pretreatment technology for the drying of jujube slices. Food Chem. 2020, 337, 127783. [Google Scholar] [CrossRef]

- Zhu, B.M.; Wen, X.S.; Wei, G.D. Effect of Pre-Treatments on Drying Characteristics of Chinese Jujube (Zizyphus Jujuba Miller). Int. J. Agric. Biol. Eng. 2014, 7, 94–102. [Google Scholar] [CrossRef]

- Song, J.; Chen, Q.; Bi, J.; Meng, X.; Wu, X.; Qiao, Y.; Lyu, Y. GC/MS coupled with MOS e-nose and flash GC e-nose for volatile characterization of Chinese jujubes as affected by different drying methods. Food Chem. 2020, 331, 127201. [Google Scholar] [CrossRef]

- Bandeira Reidel, R.V.; Melai, B.; Cioni, P.L.; Pistelli, L. Chemical composition of volatiles emitted by Ziziphus jujuba during different growth stages. Plant Biosyst.—Int. J. Deal. all Asp. Plant Biol. 2018, 152, 825–830. [Google Scholar] [CrossRef]

- Xia, Y.; Liu, Y.; Wang, J.; Shuang, Q. Assessment of key aroma compounds in fresh jujube brandy by GC-O-MS and odor activity value. J. Food Process. Preserv. 2020, 44, e14494. [Google Scholar] [CrossRef]

- Liu, Y.; Liao, Y.; Guo, M.; Zhang, W.; Sang, Y.; Wang, H.; Cheng, S.; Chen, G. Comparative elucidation of bioactive and volatile components in dry mature jujube fruit (Ziziphus jujuba Mill.) subjected to different drying methods. Food Chem. X 2022, 14, 100311. [Google Scholar] [CrossRef]

- Carbonell-Barrachina, A.; Calín-Sánchez, A.; Bagatar, B.; Hernández, F.; Legua, P.; Martínez-Font, R.; Melgarejo, P. Potential of Spanish sour–sweet pomegranates (cultivar C25) for the juice industry. Food Sci. Technol. Int. 2012, 18, 129–138. [Google Scholar] [CrossRef]

- Wang, Z.; Song, M.; Wang, Z.; Chen, S.; Ma, H. Metabolome and transcriptome analysis of flavor components and flavonoid biosynthesis in fig female flower tissues (Ficus carica L.) after bagging. BMC Plant Biol. 2021, 21, 396. [Google Scholar] [CrossRef] [PubMed]

- Ajayi, O.; Obadina, A.; Idowu, M.; Adegunwa, M.; Kajihausa, O.; Sanni, L.; Asagbra, Y.; Ashiru, B.; Tomlins, K. Effect of packaging materials on the chemical composition and microbiological quality of edible mushroom (Pleurotus ostreatus) grown on cassava peels. Food Sci. Nutr. 2015, 3, 284–291. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.-H.; Wu, C.-S.; Yu, J.-G.; Wang, M.; Ma, Y.-J.; Li, C.-L. Textural Characteristic, Antioxidant Activity, Sugar, Organic Acid, and Phenolic Profiles of 10 Promising Jujube (Ziziphus jujuba Mill.) Selections. J. Food Sci. 2012, 77, C1218–C1225. [Google Scholar] [CrossRef]

- Bi, J.; Chen, Q.; Zhou, Y.; Liu, X.; Wu, X.; Chen, R. Optimization of Short- and Medium-Wave Infrared Drying and Quality Evaluation of Jujube Powder. Food Bioprocess Technol. 2014, 7, 2375–2387. [Google Scholar] [CrossRef]

- Chen, K.; Fan, D.; Fu, B.; Zhou, J.; Li, H. Comparison of physical and chemical composition of three chinese jujube (Ziziphus jujuba Mill.) cultivars cultivated in four districts of Xinjiang region in China. Food Sci. Technol. 2019, 39, 912–921. [Google Scholar] [CrossRef] [Green Version]

- Jiménez-Muñoz, R.; Palma, F.; Carvajal, F.; Castro-Cegrí, A.; Pulido, A.; Jamilena, M.; Romero-Puertas, M.; Garrido, D. Pre-storage nitric oxide treatment enhances chilling tolerance of zucchini fruit (Cucurbita pepo L.) by S-nitrosylation of proteins and modulation of the antioxidant response. Postharvest Biol. Technol. 2021, 171, 111345. [Google Scholar] [CrossRef]

- Kou, X.; Chen, Q.; Li, X.; Li, M.; Kan, C.; Chen, B.; Zhang, Y.; Xue, Z. Quantitative assessment of bioactive compounds and the antioxidant activity of 15 jujube cultivars. Food Chem. 2015, 173, 1037–1044. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaj, R.; Pareek, S.; Domínguez-Avila, J.A.; Gonzalez-Aguilar, G.A.; Valero, D.; Serrano, M. An Exogenous Pre-Storage Melatonin Alleviates Chilling Injury in Some Mango Fruit Cultivars, by Acting on the Enzymatic and Non-Enzymatic Antioxidant System. Antioxidants 2022, 11, 384. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Jiang, T.; Liu, N.; Wu, C.; Xu, H.; Lei, H. Biotransformation of phenolic profiles and improvement of antioxidant capacities in jujube juice by select lactic acid bacteria. Food Chem. 2021, 339, 127859. [Google Scholar] [CrossRef]

- Mattila, P.; Könkö, K.; Eurola, M.; Pihlava, J.-M.; Astola, J.; Vahteristo, L.; Hietaniemi, V.; Kumpulainen, J.; Valtonen, M.; Piironen, V. Contents of Vitamins, Mineral Elements, and Some Phenolic Compounds in Cultivated Mushrooms. J. Agric. Food Chem. 2001, 49, 2343–2348. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Fang, W.-C.; Zhu, G.-R.; Cao, K.; Chen, C.-W.; Wang, X.-W.; Wang, L.-R. Accumulated chilling hours during endodormancy impact blooming and fruit shape development in peach (Prunus persica L.). J. Integr. Agric. 2016, 15, 1267–1274. [Google Scholar] [CrossRef] [Green Version]

- Li, J.-W.; Fan, L.-P.; Ding, S.-D.; Ding, X.-L. Nutritional composition of five cultivars of chinese jujube. Food Chem. 2007, 103, 454–460. [Google Scholar] [CrossRef]

- Khalid, S.; Malik, A.U.; Khan, A.S.; Khan, M.N.; Ullah, M.I.; Abbas, T.; Khalid, M.S. Tree age and fruit size in relation to postharvest respiration and quality changes in ‘Kinnow’ mandarin fruit under ambient storage. Sci. Hortic. 2017, 220, 183–192. [Google Scholar] [CrossRef]

- Vanzo, A.; Jenko, M.; Vrhovsek, U.; Stopar, M. Metabolomic Profiling and Sensorial Quality of ‘Golden Delicious’, ‘Liberty’, ‘Santana’, and ‘Topaz’ Apples Grown Using Organic and Integrated Production Systems. J. Agric. Food Chem. 2013, 61, 6580–6587. [Google Scholar] [CrossRef] [PubMed]

- Wojdyło, A.; Carbonell-Barrachina, A.; Legua, P.; Hernández, F. Phenolic composition, ascorbic acid content, and antioxidant capacity of Spanish jujube (Ziziphus jujuba Mill.) fruits. Food Chem. 2016, 201, 307–314. [Google Scholar] [CrossRef]

- Gao, Q.-H.; Wu, P.-T.; Liu, J.-R.; Wu, C.-S.; Parry, J.W.; Wang, M. Physico-chemical properties and antioxidant capacity of different jujube (Ziziphus jujuba Mill.) cultivars grown in loess plateau of China. Sci. Hortic. 2011, 130, 67–72. [Google Scholar] [CrossRef]

- Barbagallo, M.G.; Guidoni, S.; Hunter, J.J. Berry Size and Qualitative Characteristics of Vitis vinifera L. cv. Syrah. S. Afr. Soc. Enol. Vitic. 2011, 32, 129–136. [Google Scholar] [CrossRef] [Green Version]

- Baliga, M.S.; Baliga, B.R.V.; Kandathil, S.M.; Bhat, H.P.; Vayalil, P.K. A review of the chemistry and pharmacology of the date fruits (Phoenix dactylifera L.). Food Res. Int. 2011, 44, 1812–1822. [Google Scholar] [CrossRef]

- Choi, S.-H.; Ahn, J.-B.; Kim, H.-J.; Im, N.-K.; Kozukue, N.; Levin, C.E.; Friedman, M. Changes in Free Amino Acid, Protein, and Flavonoid Content in Jujube (Ziziphus jujube) Fruit during Eight Stages of Growth and Antioxidative and Cancer Cell Inhibitory Effects by Extracts. J. Agric. Food Chem. 2012, 60, 10245–10255. [Google Scholar] [CrossRef]

- Guo, S.; Duan, J.-A.; Tang, Y.; Qian, D.; Zhu, Z.; Qian, Y.; Shang, E.; Su, S. UHPLC-TOFMS coupled with chemometric method as a powerful technique for rapid exploring of differentiating components between two Ziziphus species: Liquid Chromatography. J. Sep. Sci. 2011, 34, 659–666. [Google Scholar] [CrossRef]

- Pawlowska, A.M.; Camangi, F.; Bader, A.; Braca, A. Flavonoids of Zizyphus jujuba L. and Zizyphus spina-christi (L.) Willd (Rhamnaceae) fruits. Food Chem. 2009, 112, 858–862. [Google Scholar] [CrossRef]

- Wu, C.-S.; Gao, Q.-H.; Guo, X.-D.; Yu, J.-G.; Wang, M. Effect of ripening stage on physicochemical properties and antioxidant profiles of a promising table fruit ‘pear-jujube’ (Zizyphus jujuba Mill.). Sci. Hortic. 2012, 148, 177–184. [Google Scholar] [CrossRef]

- Yang, L.; Wang, X.; He, S.; Luo, Y.; Chen, S.; Shan, Y.; Wang, R.; Ding, S. Heat shock treatment maintains the quality attributes of postharvest jujube fruits and delays their senescence process during cold storage. J. Food Biochem. 2021, 45, e13937. [Google Scholar] [CrossRef]

- Guo, S.; Duan, J.-A.; Zhang, Y.; Qian, D.; Tang, Y.; Zhu, Z.; Wang, H. Contents Changes of Triterpenic Acids, Nucleosides, Nucleobases, and Saccharides in Jujube (Ziziphus jujuba) Fruit During the Drying and Steaming Process. Molecules 2015, 20, 22329–22340. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Q.; Song, J.; Bi, J.; Meng, X.; Wu, X. Characterization of volatile profile from ten different varieties of Chinese jujubes by HS-SPME/GC–MS coupled with E-nose. Food Res. Int. 2018, 105, 605–615. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wang, Y.; Wang, W.; Zheng, F.; Chen, F. Comparison of volatile compositions of 15 different varieties of Chinese jujube (Ziziphus jujuba Mill.). J. Food Sci. Technol. 2019, 56, 1631–1640. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhu, J.; Wang, Y.; Wang, X.; Chen, F.; Wang, X. Characterization of aroma-impact compounds in dry jujubes (Ziziphus jujube Mill.) by aroma extract dilution analysis (AEDA) and gas chromatography-mass spectrometer (GC-MS). Int. J. Food Prop. 2018, 21, 1844–1853. [Google Scholar] [CrossRef] [Green Version]

- Spadafora, N.D.; Cocetta, G.; Cavaiuolo, M.; Bulgari, R.; Dhorajiwala, R.; Ferrante, A.; Spinardi, A.; Rogers, H.J.; Mueller, C.T. A complex interaction between pre-harvest and post-harvest factors determines fresh-cut melon quality and aroma. Sci. Rep. 2019, 9, 2745. [Google Scholar] [CrossRef] [PubMed]

| Grade | G1 | G2 | G3 | G4 | G5 |

|---|---|---|---|---|---|

| Transverse diameter (mm) | ≥32 | ≥30, <32 | ≥28, <30 | ≥26, <28 | ≥24, <26 |

| Number of jujube per kilogram | ≤70 | 71–85 | 86–105 | 106–125 | 126–150 |

| Grades | Contents (mg/kg) | ||||

|---|---|---|---|---|---|

| K | Ca | Mg | Zn | Cu | |

| G1 | 13,485.13 ± 393.24 b | 149.89 ± 5.45 d | 206.35 ± 9.22 b | 0.88 ± 0.03 d | 1.97 ± 0.06 b |

| G2 | 10,223.80 ± 648.03 a | 174.40 ± 11.05 c | 222.01 ± 14.06 b | 2.30 ± 0.14 c | 1.80 ± 0.12 bc |

| G3 | 12,308.21 ± 701.14 b | 196.10 ± 11.15 b | 225.97 ± 13.00 b | 4.10 ± 0.23 a | 1.70 ± 0.09 d |

| G4 | 15,442.79 ± 895.98 a | 177.62 ± 10.33 bc | 253.37 ± 14.63 a | 3.63 ± 0.21 b | 2.01 ± 0.12 b |

| G5 | 16,620.82 ± 788.23 a | 308.67 ± 14.64 a | 216.99 ± 10.31 b | 3.75 ± 0.17 b | 3.06 ± 0.15 a |

| Shape Index | Moisture | TSS | TA | AsA | cAMP | TP | TF | DPPH | FRAP | K | Ca | Mg | Zn | Cu | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shape index | 1 | ||||||||||||||

| Moisture | 0.236 | 1 | |||||||||||||

| TSS | 0.526 * | 0.776 ** | 1 | ||||||||||||

| TA | −0.777 ** | −0.284 | −0.491 | 1 | |||||||||||

| AsA | −0.202 | 0.48 | 0.056 | 0.288 | 1 | ||||||||||

| cAMP | −0.335 | 0.344 | −0.068 | 0.537 * | 0.811 ** | 1 | |||||||||

| TP | −0.401 | 0.318 | 0.269 | 0.697 ** | 0.396 | 0.512 | 1 | ||||||||

| TF | −0.808 ** | −0.081 | −0.485 | 0.928 ** | 0.499 | 0.611 * | 0.638 * | 1 | |||||||

| DPPH | −0.720 ** | −0.249 | −0.434 | 0.982 ** | 0.405 | 0.597 * | 0.734 ** | 0.912 ** | 1 | ||||||

| FRAP | −0.374 | 0.674 ** | 0.144 | 0.377 | 0.658 ** | 0.786 ** | 0.502 | 0.575 * | 0.36 | 1 | |||||

| K | −0.640 * | −0.525 * | −0.542 * | 0.899 ** | 0.184 | 0.29 | 0.581 * | 0.773 ** | 0.921 ** | −0.011 | 1 | ||||

| Ca | −0.748 ** | −0.065 | −0.349 | 0.709 ** | 0.159 | 0.106 | 0.528 * | 0.817 ** | 0.647 ** | 0.352 | 0.621 * | 1 | |||

| Mg | −0.219 | 0.337 | 0.16 | 0.535 * | 0.585 * | 0.898 ** | 0.679 ** | 0.468 | 0.593 * | 0.654 ** | 0.31 | −0.013 | 1 | ||

| Zn | −0.569 * | 0.373 | −0.204 | 0.595 * | 0.838 ** | 0.804 ** | 0.501 | 0.822 ** | 0.619 * | 0.845 ** | 0.357 | 0.573 * | 0.546 * | 1 | |

| Cu | −0.710 ** | −0.4 | −0.448 | 0.769 ** | −0.152 | −0.077 | 0.504 | 0.716 ** | 0.697 ** | 0.028 | 0.780 ** | 0.898 ** | −0.059 | 0.258 | 1 |

| Compounds | Relative Content (%) | Evolution | ||||

|---|---|---|---|---|---|---|

| G1 | G2 | G3 | G4 | G5 | ||

| 1-Octadecene | 0.79 ± 0.04 cd | 1.05 ± 0.13 bc | 2.18 ± 0.15 a | 1.29 ± 0.33 b | 0.61 ± 0.1 d |  |

| 1-Pentadecene | 0.35 ± 0.08 a | 0.4 ± 0.01 a | 0.2 ± 0.04 b | 0.37 ± 0.06 a | 0.33 ± 0.03 a |  |

| 2-Octenoic acid | 2.66 ± 0.04 b | 3.31 ± 0.11 a | 2.36 ± 0.32 d | 2.51 ± 0.01 bc | 2.66 ± 0.03 b |  |

| 2-Pentadecanone, 6,10,14-trimethyl- | 0.59 ± 0.04 c | 0.96 ± 0.05 b | 0.95 ± 0.08 b | 1.26 ± 0.2 a | 0.52 ± 0.22 c |  |

| 2-Undecanone, 6,10-dimethyl- | 0.85 ± 0.19 b | 1.16 ± 0.08 a | 0.37 ± 0.13 c | 0.91 ± 0.13 ab | 0.99 ± 0.17 ab |  |

| 9-Hexadecenoic acid, methyl ester, (Z)- | 0.40 ± 0.05 c | 1.30 ± 0.13 a | 0.76 ± 0.08 b | 0.19 ± 0.04 d | 0.20 ± 0.08 d |  |

| Acetic acid | 8.13 ± 1.06 b | 6.38 ± 0.8 c | 5.23 ± 0.68 cd | 4.66 ± 0.87 d | 10.88 ± 0.87 a |  |

| Benzaldehyde | 0.52 ± 0.05 b | 0.39 ± 0.05 c | 0.28 ± 0.07 c | 0.38 ± 0.03 c | 1.37 ± 0.12 a |  |

| Benzoic acid | 17.19 ± 2.47 b | 13.23 ± 0.29 c | 17.07 ± 1.13 b | 22.63 ± 1.49 a | 0 ± 0 d |  |

| Benzoic acid, 2-ethylhexyl ester | 0.55 ± 0.12 a | 0 ± 0 b | 0.66 ± 0.24 a | 0.43 ± 0.14 a | 0.15 ± 0.06 b |  |

| Decanoic acid, ethyl ester | 0.71 ± 0.11 b | 0.92 ± 0.03 b | 1.39 ± 0.3 a | 1.42 ± 0.24 a | 0 ± 0 c |  |

| Dibutyl phthalate | 0.30 ± 0.03 b | 0.34 ± 0.04 b | 1.12 ± 0.34 a | 0.22 ± 0.06 b | 0.12 ± 0.05 b |  |

| Dodecanoic acid | 11.99 ± 1.23 bc | 12.25 ± 1.3 b | 18.85 ± 2.37 a | 8.72 ± 1.69 cd | 7.83 ± 2.15 d |  |

| Dodecanoic acid, methyl ester | 1.82 ± 0.52 b | 2.38 ± 0.11 a | 0.67 ± 0.36 c | 1.39 ± 0.12 b | 1.33 ± 0.09 b |  |

| Ethyl 9-hexadecenoate | 1.33 ± 0.13 b | 2.02 ± 0.18 a | 1.73 ± 0.24 a | 0.27 ± 0.07 c | 0.40 ± 0.15 c |  |

| Heptadecane | 0.57 ± 0.17 a | 0 ± 0c | 0.70 ± 0.13 a | 0.51 ± 0.12 ab | 0.31 ± 0.04 b |  |

| Heptanoic acid | 5.78 ± 0.52 bc | 4.8 ± 0.21 c | 2.55 ± 0.57 d | 7.66 ± 0.52 b | 10.17 ± 2.21 a |  |

| Hexadecane | 0.60 ± 0.15 b | 0.61 ± 0.02 b | 0 ± 0 c | 1.11 ± 0.14 a | 1.36 ± 0.24 a |  |

| Hexadecane, 2,6,10,14-tetramethyl- | 0.54 ± 0.14 ab | 0 ± 0 c | 0.73 ± 0.20 a | 0.50 ± 0.21 ab | 0.26 ± 0.07 bc |  |

| Hexadecanoic acid, methyl ester | 0.26 ± 0.02 ab | 0.30 ± 0.02 a | 0.23 ± 0.04 bc | 0.18 ± 0.03 c | 0.06 ± 0.02 d |  |

| Hexanoic acid | 6.75 ± 0.44 ab | 5.73 ± 0.44 b | 2.88 ± 0.38 c | 5.75 ± 0.55 b | 7.56 ± 1.66 a |  |

| Hydrocinnamic acid | 0.76 ± 0.08 b | 0.76 ± 0.02 b | 2.03 ± 0.4 a | 0.83 ± 0.05 b | 0.50 ± 0.04 b |  |

| Methyl myristoleate | 0.90 ± 0.08 b | 1.47 ± 0.1 a | 0.47 ± 0.08 c | 0.33 ± 0.06 cd | 0.32 ± 0.09 d |  |

| n-Decanoic acid | 14.35 ± 0.69 ab | 16.37 ± 0.71 ab | 16.57 ± 1.69 a | 13.28 ± 0.83 b | 15.10 ± 2.83 ab |  |

| Nonanoic acid | 1.65 ± 0.05 b | 1.47 ± 0.03 c | 0.91 ± 0.07 d | 1.72 ± 0.06 b | 1.87 ± 0.04 a |  |

| Octadecane | 0.47 ± 0.09 b | 0 ± 0 d | 0.68 ± 0.06 a | 0.41 ± 0.1 b | 0.21 ± 0.06 c |  |

| Octanoic acid | 4.55 ± 1.04 b | 5.24 ± 0.52 b | 1.91 ± 0.39 c | 5.52 ± 0.44 b | 17.94 ± 0.28 a |  |

| Pentadecane | 0.61 ± 0.09 a | 0.48 ± 0.02 ab | 0.44 ± 0.13 b | 0.46 ± 0.08 ab | 0.55 ± 0.02 ab |  |

| Pentadecane, 2,6,10,14-tetramethyl- | 0.63 ± 0.21 a | 0 ± 0 b | 0.68 ± 0.28 a | 0.49 ± 0.19 a | 0.33 ± 0.15 ab |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Zhang, S.; Liu, L.; Wang, L.; Ban, Z. The Grade of Dried Jujube (Ziziphus jujuba Mill. cv. Junzao) Affects Its Quality Attributes, Antioxidant Activity, and Volatile Aroma Components. Foods 2023, 12, 989. https://0-doi-org.brum.beds.ac.uk/10.3390/foods12050989

Wu Z, Zhang S, Liu L, Wang L, Ban Z. The Grade of Dried Jujube (Ziziphus jujuba Mill. cv. Junzao) Affects Its Quality Attributes, Antioxidant Activity, and Volatile Aroma Components. Foods. 2023; 12(5):989. https://0-doi-org.brum.beds.ac.uk/10.3390/foods12050989

Chicago/Turabian StyleWu, Zhengbao, Shuang Zhang, Lingling Liu, Luyin Wang, and Zhaojun Ban. 2023. "The Grade of Dried Jujube (Ziziphus jujuba Mill. cv. Junzao) Affects Its Quality Attributes, Antioxidant Activity, and Volatile Aroma Components" Foods 12, no. 5: 989. https://0-doi-org.brum.beds.ac.uk/10.3390/foods12050989