Impact of Noodle Formulation, Boiling Methodology and Their Interactions on Stable Hydrogen and Oxygen Isotope Ratios

Abstract

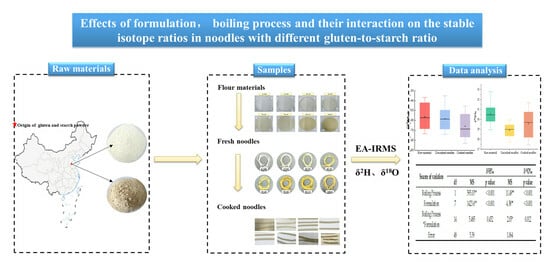

:1. Introduction

2. Materials and Methods

2.1. Raw Materials Used for Noodle Production

2.2. Experimental Procedures

2.2.1. Raw Material Flour Preparation

2.2.2. Manufacturing of Fresh Extruded Noodles

2.2.3. Boiling of Extruded Noodles

2.3. Stable Isotope Determination

2.4. Statistical Analysis

3. Results and Discussion

3.1. The Effects of the Formulation and Boiling Process on the Stable Hydrogen Isotope Ratios in Noodles

3.1.1. Effects of Formulation

3.1.2. Comparison of Raw Materials, Uncooked Noodles and Cooked Noodles

3.2. The Effects of the Formulation and Boiling Process on the Stable Oxygen Isotope Ratios in Noodles

3.2.1. Effects of Formulation

3.2.2. Comparison of Raw Materials, Uncooked Noodles and Cooked Noodles

3.3. Multiway ANOVA

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Gluten–Starch Ratio [w:w] | Cooking Time/Min |

|---|---|

| 0:100 | 4.5 |

| 15:85 | 5 |

| 30:70 | 5.5 |

| 45:55 | 6 |

| 55:45 | 3 |

| 70:30 | 2 |

| 85:15 | 2 |

| 100:0 | 2 |

References

- Cocchi, M.; Durante, C.; Foca, G.; Marchetti, A.; Tassi, L.; Ulrici, A. Durum Wheat Adulteration Detection by NIR Spectroscopy Multivariate Calibration. Talanta 2006, 68, 1505–1511. [Google Scholar] [CrossRef] [PubMed]

- González-Martín, M.I.; Wells Moncada, G.; González-Pérez, C.; Zapata San Martín, N.; López-González, F.; Lobos Ortega, I.; Hernández-Hierro, J.M. Chilean Flour and Wheat Grain: Tracing Their Origin Using near Infrared Spectroscopy and Chemometrics. Food Chem. 2014, 145, 802–806. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.Y.; Wadood, S.A.; Xia, Y.; Liu, Y.; Guo, H.; Guo, B.L.; Gan, R.Y. Wheat Authentication: An Overview on Different Techniques and Chemometric Methods. Crit. Rev. Food Sci. Nutr. 2021, 63, 33–56. [Google Scholar] [CrossRef] [PubMed]

- Zia-Ul-Haq, M.; Ahmad, S.; Qayum, M.; Ercişli, S. Compositional Studies and Antioxidant Potential of Albizia lebbeck (L.) Benth. Pods and Seeds. Turk. J. Biol. 2013, 37, 25–32. [Google Scholar] [CrossRef]

- Kelly, S.; Heaton, K.; Hoogewerff, J. Tracing the Geographical Origin of Food: The Application of Multi-Element and Multi-Isotope Analysis. Trends Food Sci. Technol. 2005, 16, 555–567. [Google Scholar] [CrossRef]

- Luo, D.H.; Dong, H.; Luo, H.Y.; Xian, Y.P.; Wan, J.; Guo, X.D.; Wu, Y.L. The Application of Stable Isotope Ratio Analysis to Determine the Geographical Origin of Wheat. Food Chem. 2015, 174, 197–201. [Google Scholar] [CrossRef]

- Rashmi, D.; Shree, P.; Singh, D.K. Stable Isotope Ratio Analysis in Determining the Geographical Traceability of Indian Wheat. Food Control 2017, 79, 169–176. [Google Scholar] [CrossRef]

- Paolini, M.; Ziller, L.; Laursen, K.H.; Søren, H.; Camin, F. Compound-Specific Δ15N and Δ13C Analyses of Amino Acids for Potential Discrimination between Organically and Conventionally Grown Wheat. J. Agric. Food Chem. 2015, 63, 5841–5850. [Google Scholar] [CrossRef]

- Laursen, K.H.; Mihailova, A.; Kelly, S.D.; Epov, V.N.; Berail, S.; Schjoerring, J.K.; Donard, O.F.X.; Larsen, E.H.; Pedentchouk, N.; Marca-Bell, A.D.; et al. Is It Really Organic? Multi-Isotopic Analysis as a Tool to Discriminate between Organic and Conventional Plants. Food Chem. 2013, 141, 2812–2820. [Google Scholar] [CrossRef]

- Liu, H.Y.; Guo, B.L.; Wei, Y.M.; Wei, S.; Ma, Y.Y.; Zhang, W. Effects of Region, Genotype, Harvest Year and Their Interactions on Δ13C, Δ15N and Δd in Wheat Kernels. Food Chem. 2015, 171, 56–61. [Google Scholar] [CrossRef]

- Suzuki, Y.; Murata, S.; Tanaka, T.; Hirao, E.; Noguchi, K.; Okusu, H.; Satoh, R. Preliminary Study for Tracing the Geographical Origin of Wheat Flour in Breads Using Stable Isotope Analysis of Wheat Proteins. Food Anal. Methods 2021, 14, 186–195. [Google Scholar] [CrossRef]

- Liu, H.Y.; Guo, B.L.; Zhang, B.; Zhang, Y.Q.; Wei, S.; Li, M.; Wadood, S.A.; Wei, Y.M. Characterizations of Stable Carbon and Nitrogen Isotopic Ratios in Wheat Fractions and Their Feasibility for Geographical Traceability: A Preliminary Study. J. Food Compos. Anal. 2018, 69, 149–155. [Google Scholar] [CrossRef]

- Bostic, J.N.; Palafox, S.J.; Rottmueller, M.E.; Jahren, A.H. Effect of Baking and Fermentation on the Stable Carbon and Nitrogen Isotope Ratios of Grain-Based Food. Rapid Commun. Mass Spectrom. 2015, 29, 937–947. [Google Scholar] [CrossRef]

- Bontempo, L.; Camin, F.; Paolini, M.; Micheloni, C.; Laursen, K.H. Multi-Isotopic Signatures of Organic and Conventional Italian Pasta along the Production Chain. J. Mass Spectrom. 2016, 51, 675–683. [Google Scholar] [CrossRef]

- Wadood, S.A.; Guo, B.L.; Wei, Y.M. Geographical Traceability of Wheat and Its Products Using Multielement Light Stable Isotopes Coupled with Chemometrics. J. Mass Spectrom. 2019, 54, 178–188. [Google Scholar] [CrossRef]

- Fernandes, R.; Meadows, J.; Dreves, A.; Nadeau, M.-J.; Grootes, P. Focus Article A Preliminary Study on the in Fl Uence of Cooking on the C and N Isotopic Composition of Multiple Organic Fractions of Fish (Mackerel and Haddock). J. Archaeol. Sci. 2014, 50, 153–159. [Google Scholar] [CrossRef]

- Zhou, J.; Guo, B.; Wei, Y.; Zhang, G.; Wei, S.; Ma, Y. The Effect of Different Cooking Processes on Stable C, N, and H Isotopic Compositions of Beef. Food Chem. 2015, 182, 23–26. [Google Scholar] [CrossRef]

- Royer, A.; Daux, V.; Fourel, F.; Lécuyer, C. Carbon, Nitrogen and Oxygen Isotope Fractionation during Food Cooking: Implications for the Interpretation of the Fossil Human Record. Am. J. Phys. Anthr. 2017, 163, 759–771. [Google Scholar] [CrossRef] [PubMed]

- Bontempo, L.; Camin, F.; Manzocco, L.; Nicolini, G.; Wehrens, R.; Ziller, L.; Larcher, R. Traceability along the Production Chain of Italian Tomato Products on the Basis of Stable Isotopes and Mineral Composition. Rapid Commun. Mass Spectrom. 2011, 25, 899–909. [Google Scholar] [CrossRef]

- AACC. Method 66-50.01; Pasta and Noodle Cooking Quality—Firmness. In Approved Method of Analysis, 11th ed.; Cereal & Grains Association: St. Paul, MN, USA, 1999. [Google Scholar]

- Ye, X.; Sui, Z. Physicochemical Properties and Starch Digestibility of Chinese Noodles in Relation to Optimal Cooking Time. Int. J. Biol. Macromol. 2016, 84, 428–433. [Google Scholar] [CrossRef] [PubMed]

- Wassenaar, L.I.; Hobson, K.A. Comparative Equilibration and Online Technique for Determination of Non-Exchangeable Hydrogen of Keratins for Use in Animal Migration Studies. Isot. Env. Health Stud. 2003, 39, 211–217. [Google Scholar] [CrossRef] [PubMed]

- Shapiro, S.S.; Wilk, M.B. An Analysis of Variance Test for Normality (Complete Samples). Biometrika 1965, 52, 591. [Google Scholar] [CrossRef]

- Duncan, D.B. Multiple Range and Multiple F Tests. Biometrics 1955, 11, 1–42. [Google Scholar] [CrossRef]

- Schmidt, H.L.; Werner, R.A.; Eisenreich, W. Systematics of 2H Patterns in Natural Compounds and Its Importance for the Elucidation of Biosynthetic Pathways. Phytochem. Rev. 2003, 2, 61–85. [Google Scholar] [CrossRef]

- Yakir, D.; DeNiro, M.J. Oxygen and Hydrogen Isotope Fractionation during Cellulose Metabolism in Lemna gibba L. Plant Physiol. 1990, 93, 325–332. [Google Scholar] [CrossRef]

- Vermeer, A.W.P.; Norde, W. The Thermal Stability of Immunoglobulin: Unfolding and Aggregation of a Multi-Domain Protein. Biophys. J. 2000, 78, 394–404. [Google Scholar] [CrossRef]

- Georget, D.M.R.; Belton, P.S. Effects of Temperature and Water Content on the Secondary Structure of Wheat Gluten Studied by FTIR Spectroscopy. Biomacromolecules 2006, 7, 469–475. [Google Scholar] [CrossRef]

- Wang, P.; Zou, M.; Gu, Z.; Yang, R. Heat-Induced Polymerization Behavior Variation of Frozen-Stored Gluten. Food Chem. 2018, 255, 242–251. [Google Scholar] [CrossRef]

- Abrahim, A.; Cannavan, A.; Kelly, S.D. Stable Isotope Analysis of Non-Exchangeable Hydrogen in Carbohydrates Derivatised with N-Methyl-Bis-Trifluoroacetamide by Gas Chromatography–Chromium Silver Reduction/High Temperature Conversion-Isotope Ratio Mass Spectrometry (GC-CrAg/HTC-IRMS). Food Chem. 2020, 318, 126413. [Google Scholar] [CrossRef]

- Yoshida, M.; Tabata, A.; Niino, T.; Chiku, K.; Nakashita, R.; Suzuki, Y. Potential Application of Light Element Stable Isotope Ratio in Crude Fiber for Geographical Origin Verification of Raw and Cooked Kabocha Pumpkin (Cucurbita maxima). Food Chem. 2021, 373, 131462. [Google Scholar] [CrossRef]

- Andrus, C.F.T.; Crowe, D.E. Alteration of Otolith Aragonite: Effects of Prehistoric Cooking Methods on Otolith Chemistry. J. Archaeol. Sci. 2002, 29, 291–299. [Google Scholar] [CrossRef]

- Wang, X.; Choi, S.G.; Kerr, W.L. Water Dynamics in White Bread and Starch Gels as Affected by Water and Gluten Content. LWT-Food Sci. Technol. 2004, 37, 377–384. [Google Scholar] [CrossRef]

- Bernin, D.; Steglich, T.; Röding, M.; Moldin, A.; Topgaard, D.; Langton, M. Multi-Scale Characterization of Pasta during Cooking Using Microscopy and Real-Time Magnetic Resonance Imaging. Food Res. Int. 2014, 66, 132–139. [Google Scholar] [CrossRef]

- Ling, X.; Tang, N.; Zhao, B.; Zhang, Y.; Guo, B.; Wei, Y.M. Study on the Water State, Mobility and Textural Property of Chinese Noodles during Boiling. Int. J. Food Sci. Technol. 2020, 55, 1716–1724. [Google Scholar] [CrossRef]

| Gluten–Starch Ratio [w/w] | Raw Materials | Uncooked Noodles | Cooked Noodles |

|---|---|---|---|

| 0:100 | −39.2 aA ± 0.0 | −39.6 aA ± 0.8 | −46.8 aB ± 1.2 |

| 15:85 | −41.1 aA ± 1.4 | −46.6 bB ± 2.1 | −51.4 bC ± 0.1 |

| 30:70 | −48.3 bA ± 5.0 | −51.4 cA ± 3.2 | −56.6 cA ± 0.1 |

| 45:55 | −54.1 cA ± 0.0 | −56.3 dA ± 0.8 | −64.4 dB ± 1.0 |

| 55:45 | −60.1 dA ± 1.4 | −62.2 eA ± 0.3 | −73.6 eB ± 1.1 |

| 70:30 | −66.0 eA ± 1.0 | −67.8 fgA ± 0.4 | −75.8 efB ± 1.2 |

| 85:15 | −69.6 efA ± 0.3 | −69.8 fA ± 0.2 | −77.6 fgB ± 0.3 |

| 100:0 | −73.0 fA ± 0.1 | −73.3 gA ± 0.5 | −80.1 gB ± 2.3 |

| Gluten–Starch Ratio [w/w] | ∆δ2Huncooked–raw | ∆δ2Hcooked–raw | ∆δ2Hcooked–uncooked |

|---|---|---|---|

| 0:100 | −0.4 | −7.6 | −7.2 |

| 15:85 | −5.5 | −10.3 | −4.8 |

| 30:70 | −3.1 | −8.3 | −5.2 |

| 45:55 | −2.2 | −10.3 | −8.1 |

| 55:45 | −2.1 | −13.4 | −11.3 |

| 70:30 | −1.9 | −9.9 | −8.0 |

| 85:15 | −0.2 | −8.0 | −7.8 |

| 100:0 | −0.3 | −7.1 | −6.9 |

| Gluten–Starch Ratio [w/w] | Raw Materials | Uncooked Noodles | Cooked Noodles |

|---|---|---|---|

| 0:100 | 29.1 cA ± 0.2 | 28.4 aAB ± 0.8 | 27.7 cB ± 0.2 |

| 15:85 | 29.6 bcA ± 0.2 | 28.9 aA ± 0.1 | 29.2 bA ± 0.4 |

| 30:70 | 30.6 abAB ± 0.8 | 29.3 aB ± 0.7 | 30.9 aA ± 0.3 |

| 45:55 | 30.4 aB ± 0.3 | 29.6 aC ± 0.3 | 31.3 aA ± 0.3 |

| 55:45 | 30.3 abcA ± 0.1 | 28.7 aB ± 0.4 | 30.1 abA ± 1.5 |

| 70:30 | 30.6 abcA ± 0.3 | 28.7 aC ± 0.4 | 29.9 abB ± 0.0 |

| 85:15 | 31.2 aA ± 0.2 | 28.8 aB ± 0.5 | 28.9 bcB ± 0.6 |

| 100:0 | 31.5 aA ± 0.3 | 28.9 aB ± 0.6 | 28.6 bcB ± 0.7 |

| Gluten–Starch Ratio [w/w] | ∆ δ18O uncooked–raw | ∆ δ18O cooked–raw | ∆ δ18O cooked–uncooked |

|---|---|---|---|

| 0:100 | −0.7 | −1.4 | −0.7 |

| 15:85 | −0.7 | −0.4 | 0.3 |

| 30:70 | −1.2 | 0.3 | 1.6 |

| 45:55 | −0.9 | 0.9 | 1.7 |

| 55:45 | −1.7 | −0.2 | 1.4 |

| 70:30 | −1.9 | −0.7 | 1.2 |

| 85:15 | −2.4 | −2.3 | 0.1 |

| 100:0 | −2.5 | −2.9 | −0.3 |

| Source of Variation | δ2H‰ | δ18O‰ | |||

|---|---|---|---|---|---|

| df | MS | p Value | MS | p Value | |

| Boiling Process | 1 | 595.03 ** | <0.001 | 11.49 ** | <0.001 |

| Formulation | 7 | 1423.6 ** | <0.001 | 4.38 ** | <0.001 |

| Boiling Process × Formulation | 14 | 5.485 | 0.452 | 2.05 * | 0.012 |

| Error | 48 | 5.39 | 1.064 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Erasmus, S.W.; Sun, Q.; Guo, B.; van Ruth, S.M. Impact of Noodle Formulation, Boiling Methodology and Their Interactions on Stable Hydrogen and Oxygen Isotope Ratios. Foods 2024, 13, 959. https://0-doi-org.brum.beds.ac.uk/10.3390/foods13060959

Yang J, Erasmus SW, Sun Q, Guo B, van Ruth SM. Impact of Noodle Formulation, Boiling Methodology and Their Interactions on Stable Hydrogen and Oxygen Isotope Ratios. Foods. 2024; 13(6):959. https://0-doi-org.brum.beds.ac.uk/10.3390/foods13060959

Chicago/Turabian StyleYang, Jingjie, Sara Wilhelmina Erasmus, Qianqian Sun, Boli Guo, and Saskia Marieke van Ruth. 2024. "Impact of Noodle Formulation, Boiling Methodology and Their Interactions on Stable Hydrogen and Oxygen Isotope Ratios" Foods 13, no. 6: 959. https://0-doi-org.brum.beds.ac.uk/10.3390/foods13060959